Assessment of the Ageing and Durability of Polymers

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Applications".

Viewed by 50297Editor

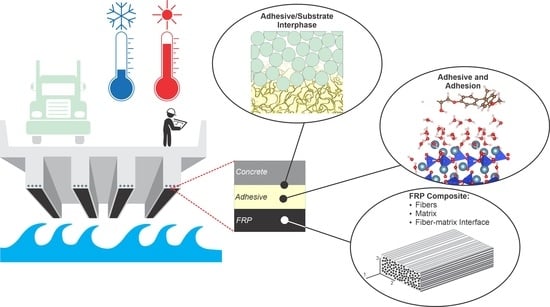

Interests: cold-cured adhesives and matrices for FRP employed in constructions; polymeric nanostructured adhesives and coatings; hydrophobic coatings for stone conservation and wood protection; durability of polymers, adhesives and coatings; eco-efficient materials for construction and cultural heritage

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

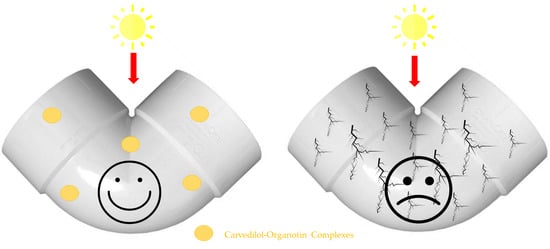

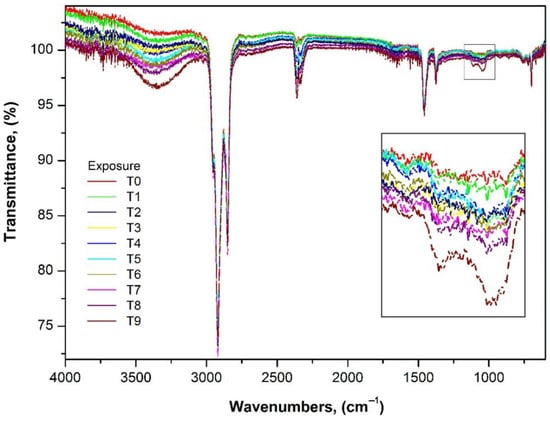

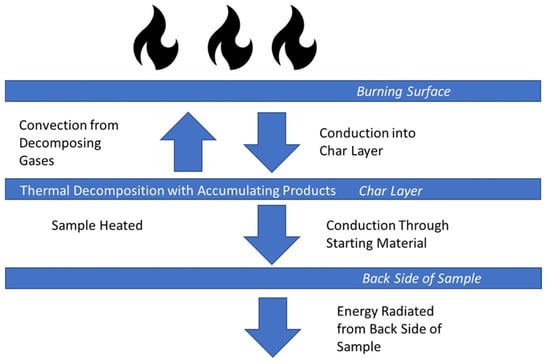

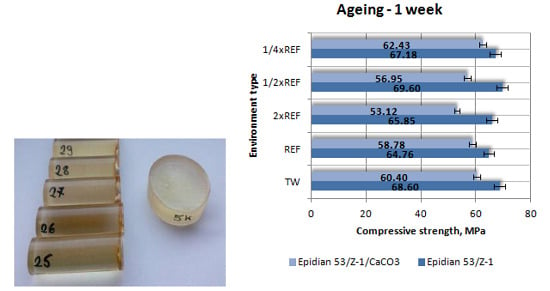

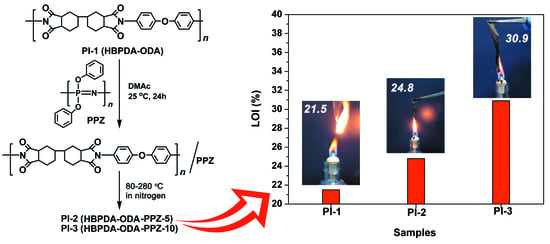

The ageing and degradation of polymeric materials, and their stability against external—possibly harsh—agents, fire and mechanical stresses, represent a fundamental issue for any application involving polymers. Although polymers are believed to be “everlasting materials”, they actually experience degradation during their service life, resulting in an appreciable modification in their properties.

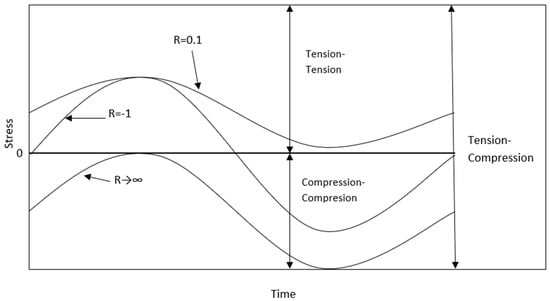

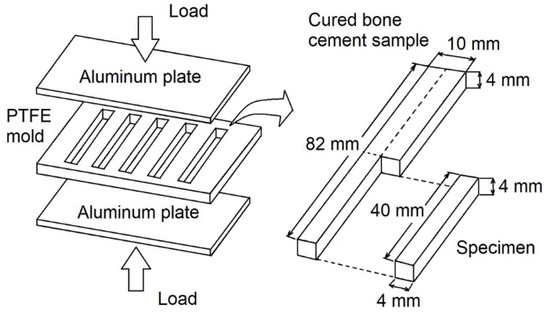

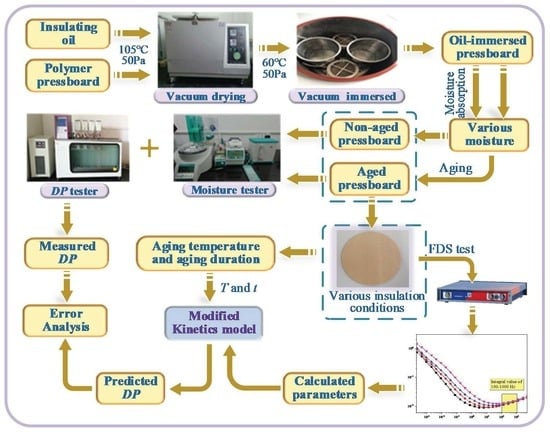

The durability of a polymeric material can be defined as its average lifetime under the in-service conditions. It depends on several parameters—the most important being the type of polymer, the process used to manufacture and apply it, the usage and load regime, and the kind and level of environmental exposure.

Due to the wide selection of polymers (thermoplastic, semi-crystalline and amorphous, cross-linked, thermosetting, elastomers, natural and biodegradable polymers, composites and nano-composites, etc.), to the variety of their applications and utilization, and to the variability of involved stresses and exposure regimes, despite the extensive attention devoted to the durability of polymers, several issues are still open. These include: the most appropriate methods and procedures to foresee their long-term performance, the reliability of standard accelerated ageing tests, and the identification of ageing and degradation mechanisms taking place under complex and coupled mechanical–environmental conditions and/or in the event of fire, stabilization procedures and protection against fire.

This Topical Collection aims at providing a platform for the discussion of open issues, challenges, and achievements when analyzing the chemical ageing, degradation routes, and durability features of different polymers and the possibility of making reliable previsions for their long-term performance.

Prof. Dr. Mariaenrica Frigione

Topical Collection Editor

Journal Editorial Board Member

Keywords

- chemical aging

- degradation mechanisms

- durability

- environmental agents

- mechanical stresses

- natural and accelerated procedures

- service conditions

- weathering

- fire protection

- stabilization

Related Special Issues

- Assessment of the Ageing and Durability of Polymers: Procedures and Reliability in Polymers (19 articles - displayed below)

- Assessment of the Ageing and Durability of Polymers II: Procedures and Reliability in Polymers (21 articles - displayed below)

- Degradation and Stabilization of Polymer-Based Materials in Polymers (21 articles - displayed below)

- Degradation of Wood-Based Materials in Polymers (11 articles - displayed below)

- Durability of Natural Fibers and Plastics in Polymers (4 articles - displayed below)

- Degradation and Stabilization of Polymer Systems: Recent Advances in Polymers (3 articles - displayed below)

- Fire and Polymers in Polymers (79 articles - displayed below)

- Advances in Flame Retardant Polymers in Polymers (7 articles - displayed below)

- Recent Advances in Flame Retardancy of Textile Related Products in Polymers (16 articles - displayed below)

- Flame Retardancy of Polymeric Materials in Polymers (19 articles - displayed below)

- Flame Retarded Polymers and Composites in Polymers (4 articles - displayed below)

- Advances in Flame Retardant Polymeric Materials in Polymers (12 articles - displayed below)

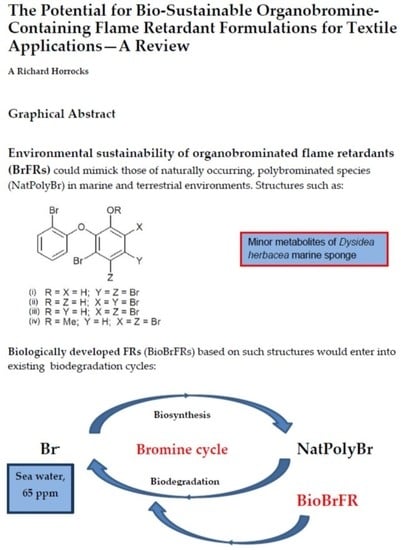

- Flame Retardancy of Polymeric Materials II- Bio-Inspired and Environmentally-Benign Formulations and Methods in Polymers (10 articles - displayed below)

- Flame Retardant Polyolefins in Polymers (1 article - displayed below)

- Polymer Nanocomposites: Processing, Degradation and Applications in Polymers (5 articles - displayed below)

- Assessment of the Ageing and Durability of Polymers III in Polymers (14 articles - displayed below)