Journal Description

Journal of Composites Science

Journal of Composites Science

is an international, peer-reviewed, open access journal on the science and technology of composites published monthly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, ESCI (Web of Science), Inspec, CAPlus / SciFinder, and other databases.

- Journal Rank: CiteScore - Q2 (Engineering (miscellaneous))

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 14.7 days after submission; acceptance to publication is undertaken in 2.9 days (median values for papers published in this journal in the second half of 2023).

- Recognition of Reviewers: reviewers who provide timely, thorough peer-review reports receive vouchers entitling them to a discount on the APC of their next publication in any MDPI journal, in appreciation of the work done.

Impact Factor:

3.3 (2022);

5-Year Impact Factor:

3.5 (2022)

Latest Articles

Effect of Chitin Nanocrystal Deacetylation on a Nature-Mimicking Interface in Carbon Fiber Composites

J. Compos. Sci. 2024, 8(5), 163; https://doi.org/10.3390/jcs8050163 (registering DOI) - 26 Apr 2024

Abstract

The formation of a rigid, tough interface based on a nacre-like structure in carbon fiber (CF) composites is a promising way to eliminate low delamination resistance. An effective method of coating CFs is electrophoretic deposition (EPD), which, in the case of dissimilar components

[...] Read more.

The formation of a rigid, tough interface based on a nacre-like structure in carbon fiber (CF) composites is a promising way to eliminate low delamination resistance. An effective method of coating CFs is electrophoretic deposition (EPD), which, in the case of dissimilar components like graphene oxide (GO) and polymeric glue, usually requires chemical bonding/strong interactions. In this work, we focus on chitin nanocrystals (ChNCs), leading to an excellent mechanical performance of artificial nacre, where favorable interactions and bonding with GO are controlled by degrees of deacetylation (5, 15, and 30%). We prepared coatings based on GO/ChNC adducts with 95/5, 90/10, 50/50, and 25/75 ratios using optimized EPD conditions (pH, concentration, voltage, and time). The prepared materials were characterized using FTIR, TEM, XPS, SEM, DLS, and XRD. SEM evaluation indicates the formation of a homogeneous interlayer, which has a fair potential for chemical bonding with the epoxy matrix. Short-beam testing of epoxy matrix composites indicates that the coating does not decrease stiffness and has a relatively low dependence on composition. Therefore, all coatings are promising for a detailed study of delamination resistance using laminate samples. Moreover, facile EPD from the water solution/suspension has a fair potential for industrial applications.

Full article

(This article belongs to the Special Issue Carbon Fiber Composites, Volume III)

►

Show Figures

Open AccessCommunication

Microfluidic Synthesis and Properties of Thermoresponsive Hydrogel Core–Shell Particles

by

Klaus-Peter Kronfeld, Johann Michael Köhler and Thomas Ellinger

J. Compos. Sci. 2024, 8(5), 162; https://doi.org/10.3390/jcs8050162 - 26 Apr 2024

Abstract

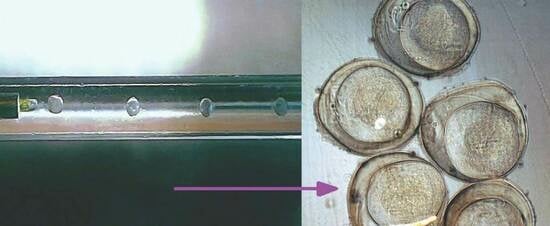

An approach is demonstrated for the generation of swellable core–shell particles in the sub-millimeter range using a one-step microfluidic method. Particles are made of an agarose gel core and a shell consisting of hydrogel based on crosslinked poly-(N-isopropylacrylamide) (PNIPAM). Solidification of the core

[...] Read more.

An approach is demonstrated for the generation of swellable core–shell particles in the sub-millimeter range using a one-step microfluidic method. Particles are made of an agarose gel core and a shell consisting of hydrogel based on crosslinked poly-(N-isopropylacrylamide) (PNIPAM). Solidification of the core was achieved by cooling below the sol–gel temperature, while the shell was cured by photoinitiated co-polymerization. The shell of the particles is reversibly thermoresponsive; it contracts upon heating, releasing water, and becomes hydrophobic. The transition temperature as well as the stability of the particles are mainly affected by the shell monomer composition, while they are less affected by the type of the core material. Such composite particles remain swellable after drying.

Full article

(This article belongs to the Special Issue Multiscale Composite Materials Characterization—Manufacturing, Testing and Structural Integrity Analysis, Volume II)

►▼

Show Figures

Graphical abstract

Open AccessReview

A Review of Biomass Wood Ash in Alkali-Activated Materials: Treatment, Application, and Outlook

by

Yiying Du, Ina Pundienė, Jolanta Pranckevičienė, Modestas Kligys, Giedrius Girskas and Aleksandrs Korjakins

J. Compos. Sci. 2024, 8(5), 161; https://doi.org/10.3390/jcs8050161 - 25 Apr 2024

Abstract

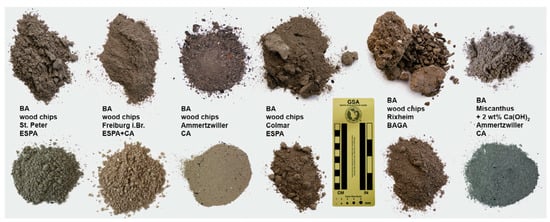

The utilisation of Portland cement has aroused tremendous concerns owing to its production exerting a lot of pressure on the environment. Alternative eco-binders have been developed to replace it, among which alkali-activated materials (AAMs) have drawn great attention, especially due to the possibility

[...] Read more.

The utilisation of Portland cement has aroused tremendous concerns owing to its production exerting a lot of pressure on the environment. Alternative eco-binders have been developed to replace it, among which alkali-activated materials (AAMs) have drawn great attention, especially due to the possibility of encompassing industrial and agricultural waste, which significantly improves the sustainability and cost-efficiency of the material. Biomass wood ash (BWA) is a by-product generated from power plants and, along with the advocation for biomass fuel as a renewable energy resource, there have been increasing applications of BWA in building and construction materials. This review examines the use of BWA as a precursor source in AAMs. Due to its low chemical and hydraulic reactivity, more active binary precursors are usually introduced to guarantee mechanical properties. Whereas the increment of BWA content can have a negative influence on material strength development, it is still a promising and feasible material, and new approaches should be developed to improve the effectiveness of its utilisation. Currently, study of BWA-based AAMs is still in the beginning stages and more research is needed to investigate the effects of BWA characteristics on the property evolution of AAMs, focusing on the durability and analysis of eco-efficiency. Overall, this review provides a comprehensive overview of the characterisation of BWA and its potential applications in AAMs, and meanwhile, based on the analysis of present research trends, proposes some prospective directions for future research.

Full article

(This article belongs to the Special Issue Sustainable Biocomposites, Volume II)

►▼

Show Figures

Figure 1

Open AccessReview

Hot-Dip Galvanizing Process and the Influence of Metallic Elements on Composite Coatings

by

Qi Liu, Yuqing Cao, Shuai Chen, Xinye Xu, Mutian Yao, Jie Fang, Kuan Lei and Guiqun Liu

J. Compos. Sci. 2024, 8(5), 160; https://doi.org/10.3390/jcs8050160 - 25 Apr 2024

Abstract

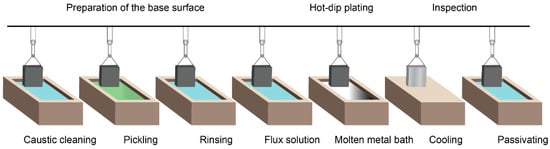

The corrosion of steel materials has become a global issue, causing significant socio-economic losses and safety concerns. Hot-dip galvanizing is currently one of the most widely used steel anti-corrosion processes. With the rapid advancement of science and technology and emerging industries, the performance

[...] Read more.

The corrosion of steel materials has become a global issue, causing significant socio-economic losses and safety concerns. Hot-dip galvanizing is currently one of the most widely used steel anti-corrosion processes. With the rapid advancement of science and technology and emerging industries, the performance of pure galvanized products struggles to meet the demands of practical applications in various environments. Consequently, researchers have begun introducing various metals into the zinc solution to form high-performance alloy coatings. This article primarily explains the process flow of hot-dip galvanizing and the impact of metal elements such as Al, Mg, Sn, and Bi on the coating, as well as outlining the major issues currently faced by the hot-dip galvanizing process. The objective is to offer a more comprehensive introduction to those new to the field of hot-dip galvanizing and to provide theoretical insights for addressing production issues.

Full article

(This article belongs to the Special Issue Metal Composites, Volume II)

►▼

Show Figures

Figure 1

Open AccessArticle

Simulation of the Dynamic Responses of Layered Polymer Composites under Plate Impact Using the DSGZ Model

by

Huadian Zhang, Arunachalam M. Rajendran, Manoj K. Shukla, Sasan Nouranian, Ahmed Al-Ostaz, Steven Larson and Shan Jiang

J. Compos. Sci. 2024, 8(5), 159; https://doi.org/10.3390/jcs8050159 - 23 Apr 2024

Abstract

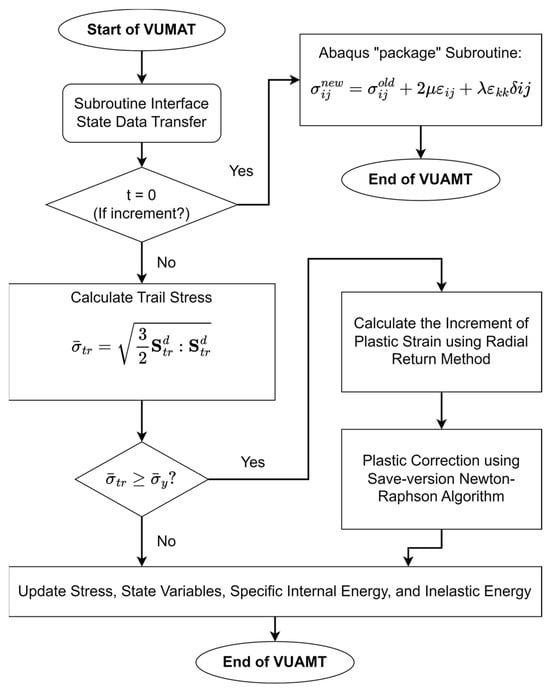

This paper presents a numerical study on the dynamic response and impact mitigation capabilities of layered ceramic–polymer–metal (CPM) composites under plate impact loading, focusing on the layer sequence effect. The layered structure, comprising a ceramic for hardness and thermal resistance, a polymer for

[...] Read more.

This paper presents a numerical study on the dynamic response and impact mitigation capabilities of layered ceramic–polymer–metal (CPM) composites under plate impact loading, focusing on the layer sequence effect. The layered structure, comprising a ceramic for hardness and thermal resistance, a polymer for energy absorption, and a metal for strength and ductility, is analyzed to evaluate its effectiveness in mitigating the impact loading. The simulations employed the VUMAT subroutine of DSGZ material models within Abaqus/Explicit to accurately represent the mechanical behavior of the polymeric materials in the composites. The VUMAT implementation incorporates the explicit time integration scheme and the implicit radial return mapping algorithm. A safe-version Newton–Raphson method is applied for numerically solving the differential equations of the

(This article belongs to the Special Issue Theoretical and Computational Investigation on Composite Materials)

►▼

Show Figures

Figure 1

Open AccessArticle

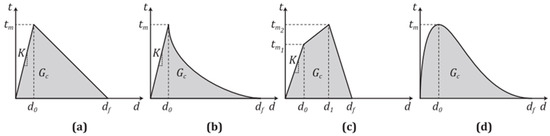

Numerical Simulation of Transverse Crack on Composite Structure Using Cohesive Element

by

Heri Heriana, Rebecca Mae Merida Catalya Marbun, Bambang Kismono Hadi, Djarot Widagdo and Muhammad Kusni

J. Compos. Sci. 2024, 8(4), 158; https://doi.org/10.3390/jcs8040158 - 22 Apr 2024

Abstract

Due to their anisotropic behavior, composite structures are weak in transverse direction loading. produces transverse cracks, which for a laminated composite, may lead to delamination and total failure. The transition from transverse crack to delamination failure is important and the subject of recent

[...] Read more.

Due to their anisotropic behavior, composite structures are weak in transverse direction loading. produces transverse cracks, which for a laminated composite, may lead to delamination and total failure. The transition from transverse crack to delamination failure is important and the subject of recent studies. In this paper, a simulation of transverse crack and its transition to delamination on cross-ply laminate was studied extensively using a cohesive element Finite Element Method (FEM). A pre-cracked [0/90] composite laminate made of bamboo was modeled using ABAQUS/CAE. The specimen was in a three-point bending configuration. Cohesive elements were inserted in the middle of the 90° layer and in the interface between the 0° and 90° layer to simulate transverse crack propagation and its transition to delamination. A load–displacement graph was extracted from the simulation and analyzed. As the loading was given to the specimen, stress occurred in the laminates, concentrating near the pre-cracked region. When the stress reached the tensile transverse strength of the bamboo, transverse crack propagation initiated, indicated by the failure of transverse cohesive elements. The crack then propagated towards the interface of the [0/90] laminates. Soon after the crack reached the interface, delamination propagated along the interface, represented by the failure of the longitudinal cohesive elements. The result of the numerical study in the form of load–displacement graph shows a consistent pattern compared with the data found in the literature. The graph showed a linear path as the load increased and the crack propagated until a point where there was a load-drop in the graph, which showed that the crack was unstable and propagated quickly before it turned into delamination between the 0o and 90° plies.

Full article

(This article belongs to the Section Composites Modelling and Characterization)

►▼

Show Figures

Figure 1

Open AccessArticle

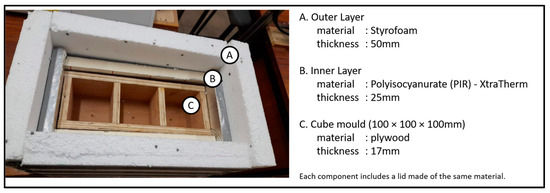

Enhancing Sustainability in Construction: Investigating the Thermal Advantages of Fly Ash-Coated Expanded Polystyrene Lightweight Concrete

by

Andi Prasetiyo Wibowo, Messaoud Saidani and Morteza Khorami

J. Compos. Sci. 2024, 8(4), 157; https://doi.org/10.3390/jcs8040157 - 21 Apr 2024

Abstract

This study investigates a sustainable coating method for modified expanded polystyrene (MEPS) beads to improve the thermal insulation of lightweight concrete intended for wall application. The method employed in this study is based on a novel coating technique that represents a significant advancement

[...] Read more.

This study investigates a sustainable coating method for modified expanded polystyrene (MEPS) beads to improve the thermal insulation of lightweight concrete intended for wall application. The method employed in this study is based on a novel coating technique that represents a significant advancement in modifying Expanded Polystyrene (EPS) beads for enhanced lightweight concrete. This study experimentally assessed the energy-saving capabilities of MEPS concrete in comparison to control groups of uncoated EPS beads and normal concrete by analysing early-stage temperature, thermal conductivity, specific heat capacity, heat flux, and thermal diffusivity. The thermal conductivity of MEPS concrete is approximately 40% lower than that of normal concrete, demonstrating its usefulness in enhancing insulation. The heat flux calculated for MEPS concrete is significantly reduced (approximately 35%), and it has a 20% lower specific heat capacity than ordinary concrete, indicating a reduction in energy transfer through the material and, thus, potential energy-efficiency benefits. Furthermore, the study discovered that all test objects have very low thermal diffusivity values (less than 0.5 × 10−6 m2/s), indicating a slower heat transport through the material. The sustainable coating method utilized fly ash-enhanced thermal efficiency and employed recycled materials, hence decreasing the environmental impact. MEPS concrete provides a practical option for creating sustainable and comfortable buildings through the promotion of energy-efficient wall construction. Concrete incorporating coated EPS can be a viable option for constructing walls where there is a need to balance structural integrity and adequate insulation.

Full article

(This article belongs to the Special Issue Lightweight Composites Materials: Sustainability and Applications, Volume II)

►▼

Show Figures

Figure 1

Open AccessArticle

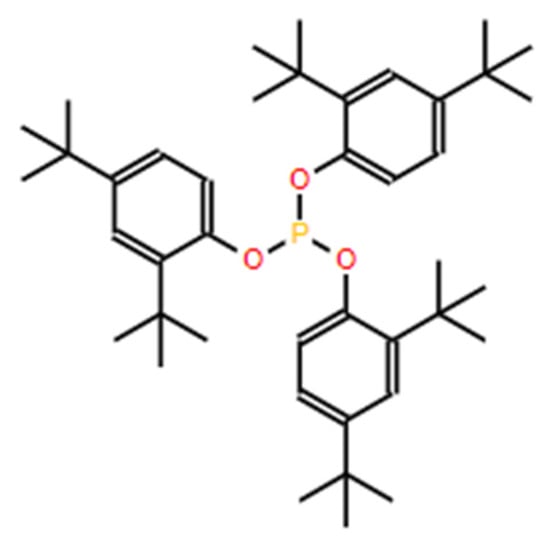

Quantification of Irgafos P-168 and Degradative Profile in Samples of a Polypropylene/Polyethylene Composite Using Microwave, Ultrasound and Soxhlet Extraction Techniques

by

Joaquín Hernández-Fernández, Jaime Pérez-Mendoza and Rodrigo Ortega-Toro

J. Compos. Sci. 2024, 8(4), 156; https://doi.org/10.3390/jcs8040156 - 21 Apr 2024

Abstract

In polypropylene/polyethylene composite (C-PP/PE) production, stabilizing additives such as Irgafos P-168 are essential as antioxidant agents. In this study, an investigation was carried out that covers different solid–liquid extraction methods (Soxhlet, ultrasound, and microwaves); various variables were evaluated, such as temperature, extraction time,

[...] Read more.

In polypropylene/polyethylene composite (C-PP/PE) production, stabilizing additives such as Irgafos P-168 are essential as antioxidant agents. In this study, an investigation was carried out that covers different solid–liquid extraction methods (Soxhlet, ultrasound, and microwaves); various variables were evaluated, such as temperature, extraction time, the choice of solvents, and the type of C-PP/PE used, and the gas chromatography coupled to mass spectrometry (GC-MS) technique was used to quantify the presence of Irgafos P-168 in the C-PP/PE samples. The results revealed that microwave extraction was the most effective in recovering Irgafos P-168. A recovery of 96.7% was achieved when using dichloromethane as a solvent, and 92.83% was achieved when using limonene as a solvent. The ultrasound technique recovered 91.74% using dichloromethane and 89.71% using limonene. The Soxhlet extraction method showed the lowest recovery percentages of 57.39% using dichloromethane as a solvent and 55.76% with limonene, especially when the C-PP/PE was in the form of pellets. The degradation products that obtained the highest degradation percentages were Bis (di-test-butyl phenyl) phosphate and Mono (di-test-butyl phenyl) phosphate using the microwave method with dichloromethane as a solvent and PP in film. Finally, the possible mechanisms for forming the degradation compounds of Irgafos P-168 were postulated.

Full article

(This article belongs to the Special Issue Progress in Polymer Composites, Volume III)

►▼

Show Figures

Figure 1

Open AccessReview

A Review on the Recent Trends in Forming Composite Joints Using Spot Welding Variants

by

Aravinthan Arumugam and Alokesh Pramanik

J. Compos. Sci. 2024, 8(4), 155; https://doi.org/10.3390/jcs8040155 - 19 Apr 2024

Abstract

Traditional resistance spot welding (RSW) has been unsuccessful in forming quality composite joints between steel– or aluminum–polymer-based composites. This has led to the development of spot welding variants such as friction stir spot welding (FFSW), ultrasonic spot welding (USW), and laser spot welding

[...] Read more.

Traditional resistance spot welding (RSW) has been unsuccessful in forming quality composite joints between steel– or aluminum–polymer-based composites. This has led to the development of spot welding variants such as friction stir spot welding (FFSW), ultrasonic spot welding (USW), and laser spot welding (LSW). The paper reviewed the differences in the bonding mechanisms, spot weld characteristics, and challenges involved in using these spot welding variants. Variants of RSW use series electrode arrangement, co-axial electrodes, metallic inserts, interlayers, or external energy to produce composite joints. FFSW and USW use nanoparticles, interlayers, or energy directors to create composite spot welds. Mechanical interlocking is the common composite joint mechanism for all variants. Each spot welding variant has different sets of weld parameters and distinct spot weld morphologies. FFSW is the most expensive variant but is commonly used for composite spot weld joints. USW has a shorter welding cycle compared to RSW and FFSW but can only be used for small components. LSW is faster than the other variants, but limited work was found on its use in composite spot weld joining. The use of interlayers in FFSW and USW to form composite joints is a potential research area recommended in this review.

Full article

(This article belongs to the Special Issue Metal Composites, Volume II)

►▼

Show Figures

Figure 1

Open AccessReview

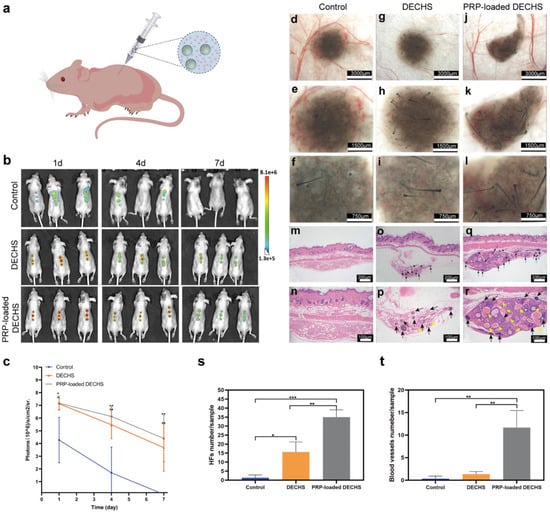

Hydrogel Composites for Multifunctional Biomedical Applications

by

Hossein Omidian, Arnavaz Akhzarmehr and Sumana Dey Chowdhury

J. Compos. Sci. 2024, 8(4), 154; https://doi.org/10.3390/jcs8040154 - 19 Apr 2024

Abstract

Hydrogel composites are pivotal in biomedical research, showing promise across various applications. This review aims to thoroughly examine their significance and versatile roles in regenerative medicine, tissue engineering, and drug delivery systems. Key areas of investigation include integrating growth factor delivery systems, overcoming

[...] Read more.

Hydrogel composites are pivotal in biomedical research, showing promise across various applications. This review aims to thoroughly examine their significance and versatile roles in regenerative medicine, tissue engineering, and drug delivery systems. Key areas of investigation include integrating growth factor delivery systems, overcoming structural limitations in tissue engineering, exploring innovations in clinical applications, and addressing challenges in achieving bioactivity and biomechanical compatibility. Furthermore, the review will discuss controlled release mechanisms for drug delivery, advancements in biocompatibility and mechanical stability, recent progress in tissue regeneration and wound healing, and future prospects such as smart hydrogels, personalized treatments, and integration with wearable technology. Ultimately, the goal is to provide a comprehensive understanding of how hydrogel composites impact biomedical research and clinical practice.

Full article

(This article belongs to the Special Issue Hydrogel and Biomaterials)

►▼

Show Figures

Figure 1

Open AccessCommunication

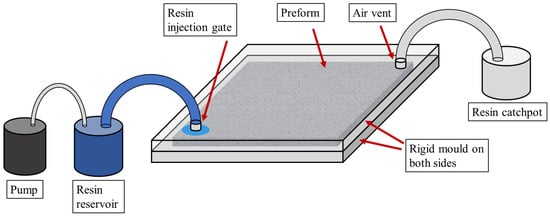

Comprehensive Composite Mould Filling Pattern Dataset for Process Modelling and Prediction

by

Boon Xian Chai, Jinze Wang, Thanh Kim Mai Dang, Mostafa Nikzad, Boris Eisenbart and Bronwyn Fox

J. Compos. Sci. 2024, 8(4), 153; https://doi.org/10.3390/jcs8040153 - 18 Apr 2024

Abstract

The Resin Transfer Moulding process receives great attention from both academia and industry, owing to its superior manufacturing rate and product quality. Particularly, the progression of its mould filling stage is crucial to ensure a complete reinforcement saturation. Contemporary process simulation methods focus

[...] Read more.

The Resin Transfer Moulding process receives great attention from both academia and industry, owing to its superior manufacturing rate and product quality. Particularly, the progression of its mould filling stage is crucial to ensure a complete reinforcement saturation. Contemporary process simulation methods focus primarily on physics-based approaches to model the complex resin permeation phenomenon, which are computationally expensive to solve. Thus, the application of machine learning and data-driven modelling approaches is of great interest to minimise the cost of process simulation. In this study, a comprehensive dataset consisting of mould filling patterns of the Resin Transfer Moulding process at different injection locations for a composite dashboard panel case study is presented. The problem description and significance of the dataset are outlined. The distribution of this comprehensive dataset aims to lower the barriers to entry for researching machine learning approaches in composite moulding applications, while concurrently providing a standardised baseline for evaluating newly developed algorithms and models in future research works.

Full article

(This article belongs to the Special Issue Characterization and Modelling of Composites, Volume III)

►▼

Show Figures

Figure 1

Open AccessArticle

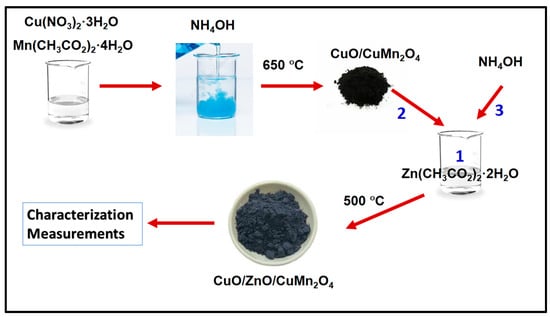

Preparation of New Sm-Doped CuO/ZnO/CuMn2O4 Tri-Composite for Photoremoval of Dissolved Organic Waste and Dielectric-Energy Storage

by

Hanan A. Althikrallah, Ghayah M. Alsulaim, Shada A. Alsharif and Kholoud M. Alnahdi

J. Compos. Sci. 2024, 8(4), 152; https://doi.org/10.3390/jcs8040152 - 18 Apr 2024

Abstract

Photocatalysis is considered as simple, green, and the best strategy for elimination of hazardous organic contaminants from wastewater. Herein, new broad spectrum photocatalysts based on pure and Sm-doped CuO/ZnO/CuMn2O4 ternary composites were simply prepared by co-precipitation approach. The X-ray diffraction

[...] Read more.

Photocatalysis is considered as simple, green, and the best strategy for elimination of hazardous organic contaminants from wastewater. Herein, new broad spectrum photocatalysts based on pure and Sm-doped CuO/ZnO/CuMn2O4 ternary composites were simply prepared by co-precipitation approach. The X-ray diffraction results proved the formation of a composite structure. The transmission electron microscope (TEM) images displayed that most particles have a spherical shape with average mean sizes within 26–29 nm. The optical properties of both samples signified that the addition of Sm ions significantly improves the harvesting of the visible light spectrum of CuO/ZnO/CuMn2O4 ternary composites. The photocatalytic study confirmed that 97% of norfloxacin and 96% of methyl green pollutants were photo-degraded in the presence of the Sm-doped CuO/ZnO/CuMn2O4 catalyst after 50 and 40 min, respectively. The total organic carbon analysis revealed the high mineralization efficiency of the Sm-doped CuO/ZnO/CuMn2O4 catalyst to convert the norfloxacin and methyl green to carbon dioxide and water molecules. During three cycles, this catalyst presented a high removal efficiency for norfloxacin and methyl green contaminants. As a dielectric energy storage material, the Sm-doped CuO/ZnO/CuMn2O4 ternary composite has large dielectric constant values, mainly at low frequencies, with low dielectric loss compared to a pure CuO/ZnO/CuMn2O4 composite.

Full article

(This article belongs to the Section Composites Applications)

►▼

Show Figures

Figure 1

Open AccessArticle

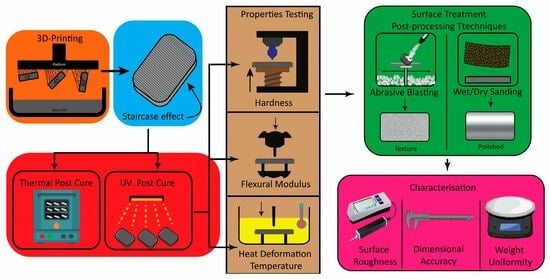

Post-Process Considerations for Photopolymer 3D-Printed Injection Moulded Insert Tooling Applications

by

Gavin Keane, Andrew V. Healy and Declan M. Devine

J. Compos. Sci. 2024, 8(4), 151; https://doi.org/10.3390/jcs8040151 - 17 Apr 2024

Abstract

Injection moulding (IM) is a manufacturing technique used to produce intricately detailed plastic components with various surface finishes, enabling the production of high-tolerance functional parts at scale. Conversely, stereolithography (SLA) three-dimensional (3D) printing offers an alternative method for fabricating moulds with shorter lead

[...] Read more.

Injection moulding (IM) is a manufacturing technique used to produce intricately detailed plastic components with various surface finishes, enabling the production of high-tolerance functional parts at scale. Conversely, stereolithography (SLA) three-dimensional (3D) printing offers an alternative method for fabricating moulds with shorter lead times and reduced costs compared to conventional manufacturing. However, fabrication in a layer-by-layer fashion results in anisotropic properties and noticeable layer lines, known as the stair-step effect. This study investigates post-processing techniques for plaques with contrasting stair-step effects fabricated from commercially available SLA high-temperature resin, aiming to assess their suitability for IM applications. The results reveal that annealing significantly enhances part hardness and heat deflection temperature (HDT), albeit with a trade-off involving reduced flexural strength. Experimental findings indicate that the optimal stage for abrasive surface treatment is after UV curing and before annealing. Plaques exhibiting contrasting stair-step effects are characterized and evaluated for weight loss, dimensional accuracy, and surface roughness. The results demonstrate that abrasive blasting effectively removes the stair-step effect without compromising geometry while achieving polished surface finishes with roughness average (RA) values of 0.1 μm through sanding. Overall, a combination of abrasive blasting and sanding proves capable of precisely defining surface roughness without significant geometry loss, offering a viable approach to achieving traditional IM finishes suitable for both functional and aesthetic purposes.

Full article

(This article belongs to the Special Issue 3D Printing Composites)

►▼

Show Figures

Graphical abstract

Open AccessArticle

Effect of the Energy Director Material on the Structure and Properties of Ultrasonic Welded Lap Joints of PEI Plates with CF Fabric/PEI Prepreg

by

Defang Tian, Vladislav O. Alexenko, Sergey V. Panin, Alexey A. Bogdanov and Dmitry G. Buslovich

J. Compos. Sci. 2024, 8(4), 150; https://doi.org/10.3390/jcs8040150 - 16 Apr 2024

Abstract

To estimate the possibility of using both low-melting TecaPEI and neat PEI films as energy directors (EDs) for ultrasonic welding (USW) of carbon fiber (CF) fabric–polyetherimide (PEI) laminates, some patterns of structure formation and mechanical properties of their lap joints were investigated by

[...] Read more.

To estimate the possibility of using both low-melting TecaPEI and neat PEI films as energy directors (EDs) for ultrasonic welding (USW) of carbon fiber (CF) fabric–polyetherimide (PEI) laminates, some patterns of structure formation and mechanical properties of their lap joints were investigated by varying the process parameters. The experiment was planned by the Taguchi method with the L9 orthogonal matrix. Based on the obtained results, USW parameters were optimized accounting for maintaining the structural integrity of the joined components and improving their functional characteristics. The use of the low-melting EDTecaPEI film enabled US-welding the laminates with minimal damage to the fusion zone, and the achieved lap shear strength (LSS) values of ~7.6 MPa were low. The use of EDSolverPEI excluded thermal degradation of the components as well as damage to the fusion zone, and improved LSS values to 21 MPa. With the use of digital image correlation (DIC) and computed tomography (CT) techniques, the structural factors affecting the deformation behavior of the USW lap joints were justified. A scheme was proposed that established the relationship between structural factors and the deformation response of the USW lap joints under static tension. The TecaPEI film can be used in USW procedures when very high interlayer adhesion properties are not on demand.

Full article

(This article belongs to the Special Issue Manufacturing of Fibrous Composites for Engineering Applications, Volume II)

►▼

Show Figures

Figure 1

Open AccessReview

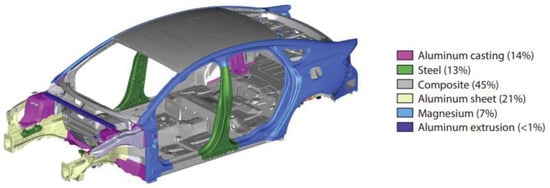

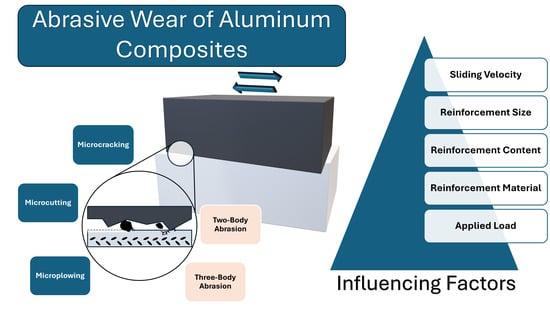

A Review on Abrasive Wear of Aluminum Composites: Mechanisms and Influencing Factors

by

Nima Valizade and Zoheir Farhat

J. Compos. Sci. 2024, 8(4), 149; https://doi.org/10.3390/jcs8040149 - 15 Apr 2024

Abstract

Aluminum matrix composites (AMCs) find extensive use across diverse industries such as automotive, aerospace, marine, and electronics, owing to their remarkable strength-to-weight ratio, corrosion resistance, and mechanical properties. However, their limited wear resistance poses a challenge for applications requiring high tribological performance. Abrasive

[...] Read more.

Aluminum matrix composites (AMCs) find extensive use across diverse industries such as automotive, aerospace, marine, and electronics, owing to their remarkable strength-to-weight ratio, corrosion resistance, and mechanical properties. However, their limited wear resistance poses a challenge for applications requiring high tribological performance. Abrasive wear emerges as the predominant form of wear encountered by AMCs in various industrial settings, prompting significant research efforts aimed at enhancing their wear resistance. Over the past decades, extensive research has investigated the influence of various reinforcements on the abrasive wear behavior of AMCs. This paper presents a comprehensive review of the impact of different variables on the wear and tribological response of aluminum composites. This review explores possible wear mechanisms across various tribosystems, providing examples drawn from the analysis of existing literature. Through detailed discussions on the effects of each variable, conclusions are drawn to offer insights into optimizing the wear performance of AMCs.

Full article

(This article belongs to the Special Issue Particulate Aluminum Matrix Composites: From Fundamentals to Applications, Volume II)

►▼

Show Figures

Graphical abstract

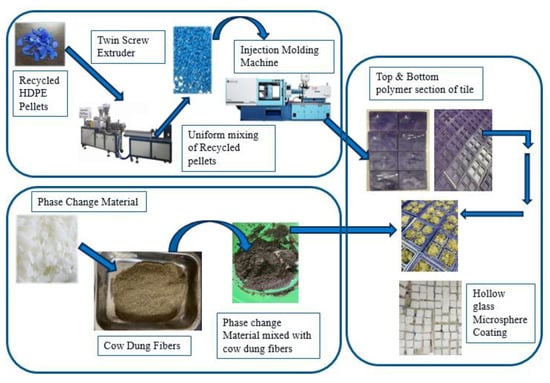

Open AccessArticle

The Morphological and Thermal Characteristics of Hollow-Glass-Microsphere-Coated Phase Change Material–Cow Pie Embedded Recycled Plastic Tiles for Cool Roofs

by

S. Krishna Satya and P. S. Rama Sreekanth

J. Compos. Sci. 2024, 8(4), 148; https://doi.org/10.3390/jcs8040148 - 13 Apr 2024

Abstract

This study addresses the global plastic waste crisis and the urban heat island effect by developing an innovative solution: recycled plastic roof tiles embedded with phase change material (PCM) and coated with hollow-glass-microsphere-based white paint. The samples were fabricated with cow pie fibers,

[...] Read more.

This study addresses the global plastic waste crisis and the urban heat island effect by developing an innovative solution: recycled plastic roof tiles embedded with phase change material (PCM) and coated with hollow-glass-microsphere-based white paint. The samples were fabricated with cow pie fibers, OM37 and OM42 PCM materials with different wt./vol. values, i.e., 15/50, 20/50, 25/50, 30/50 ratios. The fabricated tiles were coated with hollow glass microspheres to provide a reflective layer. The tiles’ effectiveness was evaluated through morphological examination and thermal analysis. The SEM analysis revealed an excellent bonding ability for the PCM blend, i.e., OM37 and OM42 at a 20/50 ratio (wt./vol.) with cow pie fibers. Adding cow pie fibers to the PCM shifted the melting points of OM37 and OM42, indicating an increased heat storage capacity in both blends. The thermal conductivity results revealed decreased thermal conductivity with an increased cow pie fiber percentage. The recycled plastic roof tile of the PCM composite at a 20/50 (wt./vol.) ratio showed good thermal properties. Upon testing in real-time conditions in a physical setup, the roof tiles showed a temperature reduction of 8 °C from outdoors to indoors during the peak of summer. In winter, cozy temperatures were maintained indoors due to the heat regulation from the roof.

Full article

(This article belongs to the Special Issue Characterization and Modelling of Composites, Volume III)

►▼

Show Figures

Figure 1

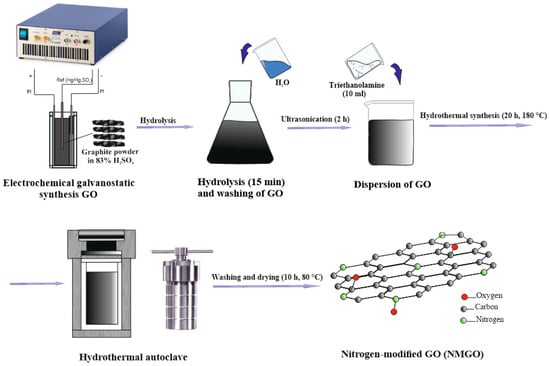

Open AccessArticle

Electrochemical Deposition and Properties of Ni Coatings with Nitrogen-Modified Graphene Oxide

by

Vitaly Tseluikin, Asel Dzhumieva, Alena Tribis, Sergey Brudnik, Denis Tikhonov, Andrey Yakovlev, Anton Mostovoy and Marina Lopukhova

J. Compos. Sci. 2024, 8(4), 147; https://doi.org/10.3390/jcs8040147 - 13 Apr 2024

Abstract

In this study, a method for producing nitrogen-modified graphene oxide (NMGO) using hydrothermal synthesis in the presence of triethanolamine is presented. The composition and structure of NMGO are characterized using X-ray phase analysis (XPA), scanning electron microscopy (SEM), Fourier transform infrared spectroscopy, and

[...] Read more.

In this study, a method for producing nitrogen-modified graphene oxide (NMGO) using hydrothermal synthesis in the presence of triethanolamine is presented. The composition and structure of NMGO are characterized using X-ray phase analysis (XPA), scanning electron microscopy (SEM), Fourier transform infrared spectroscopy, and Raman spectroscopy. Ni-based metal matrix coatings (MMCs) modified with NMGO were obtained from a sulfate-chloride electrolyte in the galvanostatic mode. The process of electrochemical deposition of these coatings was studied using chronovoltammetry. The microstructure of Ni–NMGO MMCs was studied using the XPA and SEM methods. It has been established that the addition of NMGO particles into the Ni matrix results in an increase in the microhardness of the resulting coatings by an average of 1.30 times. This effect is a consequence of the refinement of crystallites and high mechanical properties of NMGO phase. The corrosion-electrochemical behavior of studied electrochemical deposits in 0.5 M sulfuric acid was analyzed. It has been shown that the corrosion rate of Ni–NMGO MMCs in a 3.5% sodium chloride environment decreases by approximately 1.50–1.70 times as compared to unmodified Ni coatings. This is due to NMGO particles that act as a barrier preventing the propagation of the corrosion and form corrosive galvanic microelements with Ni, promoting anodic polarization.

Full article

(This article belongs to the Special Issue Hybrid Metal Matrix Composites)

►▼

Show Figures

Figure 1

Open AccessReview

The Three-Dimensional Printing of Composites: A Review of the Finite Element/Finite Volume Modelling of the Process

by

Theodor Florian Zach and Mircea Cristian Dudescu

J. Compos. Sci. 2024, 8(4), 146; https://doi.org/10.3390/jcs8040146 - 12 Apr 2024

Abstract

Composite materials represent the evolution of material science and technology, maximizing the properties for high-end industry applications. The fields concerned include aerospace and defense, automotive, or naval industries. Additive manufacturing (AM) technologies are increasingly growing in market shares due to the elimination of

[...] Read more.

Composite materials represent the evolution of material science and technology, maximizing the properties for high-end industry applications. The fields concerned include aerospace and defense, automotive, or naval industries. Additive manufacturing (AM) technologies are increasingly growing in market shares due to the elimination of shape barriers, a plethora of available materials, and the reduced costs. The AM technologies of composite materials combine the two growing trends in manufacturing, combining the advantages of both, with a specific enhancement being the elimination of the need for mold manufacturing for composites, or even post-curing treatments. The challenge of AM composites is to compete with their conventional counterparts. The aim of the current paper is to present the additive manufacturing process across different spectrums of finite element analyses (FEA). The first outcomes are building definition (support definition) and the optimization of deposition trajectories. In addition, the multi-physics of melting/solidification using computational fluid dynamics (CFD) are performed to predict the fiber orientation and extrusion profiles. The process modelling continues with the displacement/temperature distribution, which influences porosity, warping, and residual stresses that influence characteristics of the component. This leads to the tuning of the technological parameters, thus improving the manufacturing process.

Full article

(This article belongs to the Special Issue Additive Manufacturing of Advanced Composites)

►▼

Show Figures

Figure 1

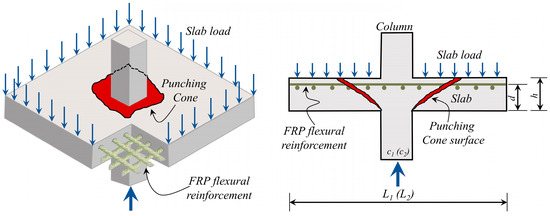

Open AccessArticle

Punching Shear of FRP-RC Slab–Column Connections: A Comprehensive Database

by

Yazan Almomani, Roaa Alawadi, Ahmad Tarawneh, Abdullah Alghossoon and Ahmad Aldiabat

J. Compos. Sci. 2024, 8(4), 145; https://doi.org/10.3390/jcs8040145 - 12 Apr 2024

Abstract

Several design standards have been developed in the last two decades to estimate the punching capacity of two-way reinforced concrete (RC) slabs reinforced with fiber-reinforced polymer (FRP) reinforcement. FRP-RC design standards include the recently published ACI 440.11-22, CSA/S806-12, and JSCE-2007. These models are

[...] Read more.

Several design standards have been developed in the last two decades to estimate the punching capacity of two-way reinforced concrete (RC) slabs reinforced with fiber-reinforced polymer (FRP) reinforcement. FRP-RC design standards include the recently published ACI 440.11-22, CSA/S806-12, and JSCE-2007. These models are either based on empirical data or semi-empirical methods and calibrated using different databases. Additionally, these standards do not have provisions for connections with shear reinforcement. Therefore, a reliable worldwide database for developing and assessing the applicability of such provisions with test results is vital. This study presents a worldwide and up-to-date database for punching shear of FRP-RC slabs. The database includes 197 tested connections, comprising interior and edge connections, with and without shear reinforcement, and a wide range of materials and cross-sectional properties. The database was used to evaluate the accuracy of the mentioned standards in predicting the punching shear capacity. For connections without shear reinforcement, it was determined that the three design standards yielded similar performance with different conservatism levels. ACI 440.11-22 yielded the most conservative results, with average Vexp/Vpred ratios of 2.04 compared to 1.28 and 1.3 for other models. For connection with shear reinforcement, specimens with Evf> 100 GPa resulted in Vexp/Vpred ratios less than 1.0 for ACI and CSA standards.

Full article

(This article belongs to the Special Issue Polymer Composites and Fibers, Volume II)

►▼

Show Figures

Figure 1

Open AccessArticle

Characteristics of Lightweight Concrete Fabricated with Different Types of Strengthened Lightweight Aggregates

by

Laith Mohammed Ridha Mahmmod, Anmar Dulaimi, Luís Filipe Almeida Bernardo and Jorge Miguel de Almeida Andrade

J. Compos. Sci. 2024, 8(4), 144; https://doi.org/10.3390/jcs8040144 - 12 Apr 2024

Abstract

The vast majority of different waste building units have negative environmental impacts around the world. Crushed building units can be recycled and utilized in the concrete industry to solve these problems and maintain natural resources. This study investigated the feasibility of employing crushed

[...] Read more.

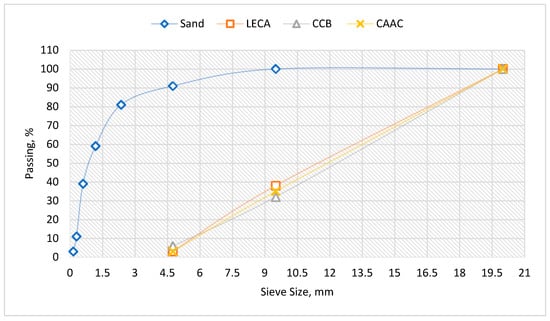

The vast majority of different waste building units have negative environmental impacts around the world. Crushed building units can be recycled and utilized in the concrete industry to solve these problems and maintain natural resources. This study investigated the feasibility of employing crushed autoclaved aerated concrete (CAAC) and crushed clay brick (CCB) as a lightweight aggregate (LWA) to fabricate environmentally friendly recycled lightweight concrete (LWC). In addition, a lightweight expanded clay aggregate (LECA) was also used as an LWA, namely to study how the high porosity of an LWA can adversely affect the properties of LWC. Through the experimental program, all types of LWAs were pre-treated and strengthened with two cementitious grouts, and then the performance of the produced LWC was assessed by determining the slump of fresh concrete, the dry density, the unconfined compressive strength, and the splitting tensile strength at ages of 3, 7, 28, and 56 days. The laboratory results revealed that both CCB and CAAC can be reused as full substitutions for normal-weight coarse aggregate to manufacture LWC with appropriate properties. The obtained data show that the properties of an LECA, CCB, and CAAC were improved, and the porous structure can be strengthened by pre-treatment and coating with grouts. In the same way, the mechanical performance of produced LWC is also enhanced.

Full article

(This article belongs to the Special Issue Lightweight Composites Materials: Sustainability and Applications, Volume II)

►▼

Show Figures

Figure 1

Journal Menu

► ▼ Journal Menu-

- J. Compos. Sci. Home

- Aims & Scope

- Editorial Board

- Reviewer Board

- Topical Advisory Panel

- Instructions for Authors

- Special Issues

- Topics

- Sections

- Article Processing Charge

- Indexing & Archiving

- Editor’s Choice Articles

- Most Cited & Viewed

- Journal Statistics

- Journal History

- Journal Awards

- Conferences

- Editorial Office

Journal Browser

► ▼ Journal BrowserHighly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Energies, J. Compos. Sci., Materials, Metals

Energy-Saving and Emission Reduction in Metallurgy

Topic Editors: Farshid Pahlevani, Smitirupa BiswalDeadline: 31 May 2024

Topic in

Applied Sciences, Crystals, J. Compos. Sci., Materials, Metals

Modern Material Technologies Intended for Industrial Applications

Topic Editors: Tomasz Tański, Andrzej N. Wieczorek, Marcin StaszukDeadline: 30 June 2024

Topic in

Energies, J. Compos. Sci., Materials, Nanomaterials, Polymers

Advanced Polymeric Composites: Processing, Characterization and Mechanical Behavior

Topic Editors: Jude O. Iroh, Derrick Dean, Kirill Levine, Ramakrishnan RajagopalanDeadline: 31 August 2024

Topic in

Fibers, J. Compos. Sci., JMMP, Materials, Polymers

Advanced Composites Manufacturing and Plastics Processing

Topic Editors: Patricia Krawczak, Ludwig CardonDeadline: 31 December 2024

Conferences

Special Issues

Special Issue in

J. Compos. Sci.

Polymer Composites and Fibers, Volume II

Guest Editors: Xiangfa Wu, Oksana ZholobkoDeadline: 30 April 2024

Special Issue in

J. Compos. Sci.

Functional Composites: Fabrication and Application

Guest Editors: Jiunn Jer Hwang, Li-Huei LinDeadline: 20 May 2024

Special Issue in

J. Compos. Sci.

Probabilistic Entropy in Analysis of Composite Materials, Volume II

Guest Editor: Marcin KamińskiDeadline: 31 May 2024

Special Issue in

J. Compos. Sci.

Advances in Graphene-Based Composites: From Synthesis to Applications

Guest Editors: Niranjan Patra, Sayan GangulyDeadline: 11 June 2024