Topic Menu

► Topic MenuTopic Editors

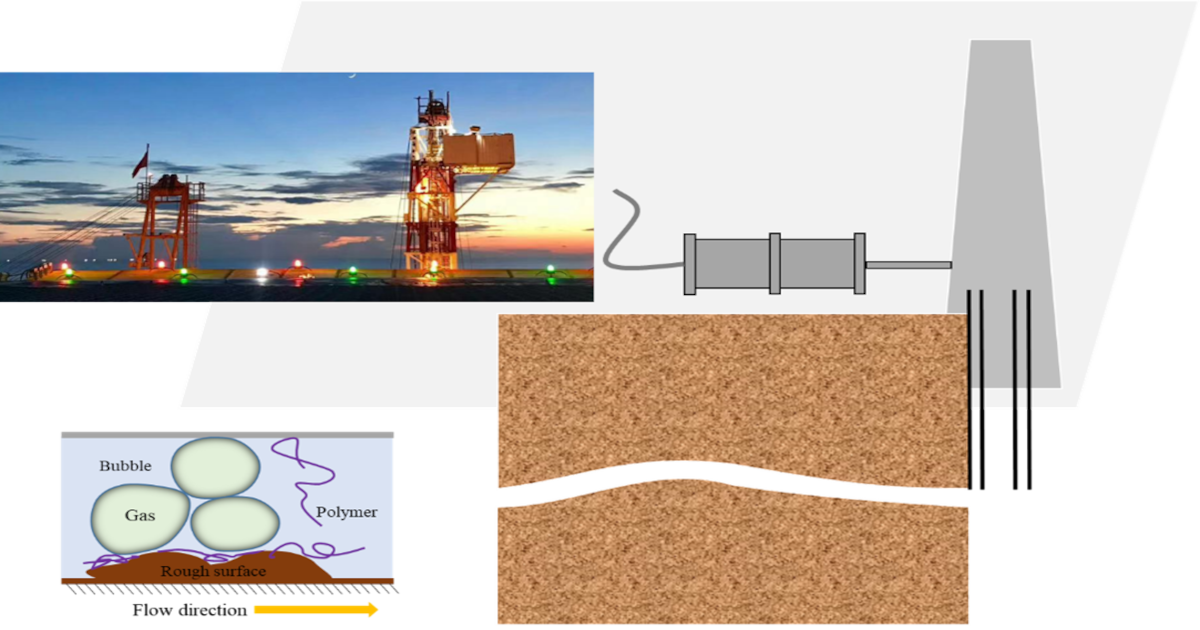

Multi-Phase Flow and Unconventional Oil/Gas Development

Topic Information

Dear Colleagues,

Unconventional oil and gas resources have huge reserves, but the geological structures of reservoirs are generally complex. Therefore, the flowing capability of reservoir fluids often needs to be improved during the oil and gas production process in order to be developed effectively. In recent years, the problems of multi-phase flow during oil and gas production in unconventional reservoirs (heavy oil reservoirs, fractured carbonate reservoirs, low-permeability reservoirs, etc.) have obtained the attention of many scholars. In addition, the effects of oil‒gas and oil‒water interfaces during multi-phase flow in reservoirs and the effects of the addition of surfactants, polymers and nanoparticles on multi-phase flow are also the major focus of this theme. Mathematical modeling and numerical simulation of multi-phase flow in formation‒wellbore‒surface facility processes are also included. In order to strengthen the deep integration of multi-phase flow mechanics theory and engineering and promote the development of emerging interdisciplinary subjects, we have launched this Special Issue call for papers with the support of relevant academic journals. We invite you to submit manuscripts on topics including (but not limited to) the following:

- Multi-phase flow from wellbore to ground facilities;

- Multi-phase flows and EOR mechanisms of oil and gas in reservoirs;

- Application of nanoparticles and chemicals in unconventional reservoirs and the effects on multi-phase flow;

- Mathematical modeling and numerical simulation of multiphase flow in the formation‒wellbore‒surface facility process;

- Application of artificial intelligence in multi-phase flow.

Prof. Dr. Wei Liu

Prof. Dr. Shibao Yuan

Topic Editors

Keywords

- multi-phase flow

- oil and gas development

- unconventional reservoirs

- nanoparticles and chemicals

- phase behavior

- numerical simulation

- artificial intelligence

Participating Journals

| Journal Name | Impact Factor | CiteScore | Launched Year | First Decision (median) | APC |

|---|---|---|---|---|---|

Applied Sciences

|

2.7 | 4.5 | 2011 | 16.9 Days | CHF 2400 |

Energies

|

3.2 | 5.5 | 2008 | 16.1 Days | CHF 2600 |

Gases

|

- | - | 2021 | 15.0 days * | CHF 1000 |

Gels

|

4.6 | 2.9 | 2015 | 11.1 Days | CHF 2600 |

Nanomaterials

|

5.3 | 7.4 | 2010 | 13.6 Days | CHF 2900 |

Processes

|

3.5 | 4.7 | 2013 | 13.7 Days | CHF 2400 |

* Median value for all MDPI journals in the second half of 2023.

MDPI Topics is cooperating with Preprints.org and has built a direct connection between MDPI journals and Preprints.org. Authors are encouraged to enjoy the benefits by posting a preprint at Preprints.org prior to publication:

- Immediately share your ideas ahead of publication and establish your research priority;

- Protect your idea from being stolen with this time-stamped preprint article;

- Enhance the exposure and impact of your research;

- Receive feedback from your peers in advance;

- Have it indexed in Web of Science (Preprint Citation Index), Google Scholar, Crossref, SHARE, PrePubMed, Scilit and Europe PMC.