Journal Description

Textiles

Textiles

is an international, peer-reviewed, open access journal on textile science and engineering published quarterly online by MDPI.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within Scopus, EBSCO and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 20.6 days after submission; acceptance to publication is undertaken in 4.8 days (median values for papers published in this journal in the second half of 2023).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

Latest Articles

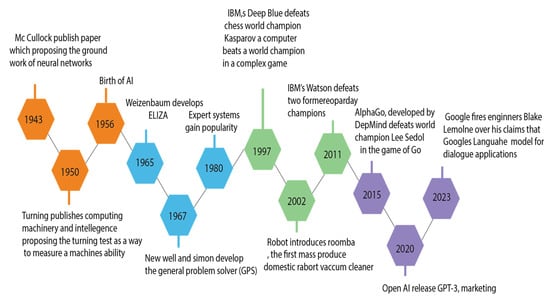

Artificial-Neural-Network-Based Predicted Model for Seam Strength of Five-Pocket Denim Jeans: A Review

Textiles 2024, 4(2), 183-217; https://doi.org/10.3390/textiles4020012 - 22 Apr 2024

Abstract

►

Show Figures

This study explores previous research efforts concerning prediction models related to the textile and polymer industry, especially garment seam strength, emphasizing critical parameters such as stitch density, fabric GSM, thread type, thread count, stitch classes, and seam types. These parameters play a pivotal

[...] Read more.

This study explores previous research efforts concerning prediction models related to the textile and polymer industry, especially garment seam strength, emphasizing critical parameters such as stitch density, fabric GSM, thread type, thread count, stitch classes, and seam types. These parameters play a pivotal role in determining the durability and overall quality of denim jeans based on cellulosic polymer. A significant focus is dedicated to the mathematical computational models employed for predicting seam strength in five-pocket denim jeans. Herein, the discussion poses the application of AI for manufacturing industries, especially for textile and clothing sectors, and highlights the importance of using a machine learning prediction model for sewing thread consumption, seam strength analysis, and seam performance analysis. Therefore, the authors suggest the significant importance of the machine learning prediction model, as future trends anticipate advancements in AI-driven methodologies, potentially leading to high-profile predictions and superior manufacturing processes. The authors also describe the limitation of AI and address a comprehensive model of risk outlines of AI in the manufacturing-based industries, especially the garments industry. Put simply, this review serves as a bridge between the realms of AI, mathematics, and textile engineering, providing a clear understanding of how artificial-neural-network-based models will be shaping the future of seam strength prediction in the denim manufacturing landscape. This type of evolution, based on ANN, will support and enhance the accuracy and efficiency of seam strength predictions by allowing models to discern intricate patterns and relationships within vast and diverse datasets.

Full article

Open AccessReview

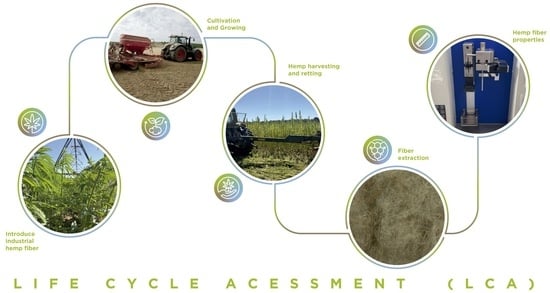

Hemp: From Field to Fiber—A Review

by

João Mariz, Catarina Guise, Teresa Luísa Silva, Lúcia Rodrigues and Carla Joana Silva

Textiles 2024, 4(2), 165-182; https://doi.org/10.3390/textiles4020011 - 12 Apr 2024

Abstract

►▼

Show Figures

Hemp fibers derived from Cannabis sativa L. have experienced a resurgence in popularity over the past few decades, establishing themselves as one of the most sought-after fibers. This article delves into the intricacies of the hemp production chain, offering a comprehensive understanding from

[...] Read more.

Hemp fibers derived from Cannabis sativa L. have experienced a resurgence in popularity over the past few decades, establishing themselves as one of the most sought-after fibers. This article delves into the intricacies of the hemp production chain, offering a comprehensive understanding from field to fiber. Key aspects covered include the botany of hemp, cultivation requirements, the impact of various factors on plant growth, the harvesting process, different methods of fiber extraction, fibers properties, and suitable spinning processes. Recent studies of hemp’s Life Cycle Assessment are explored, shedding light on how it compares to other sustainable crops and providing insights into the true sustainability of hemp, substantiated by numerical data. The article also addresses challenges encountered throughout the hemp production chain and speculates on future directions that may unfold in the coming years. The overall goal of this study is to provide a knowledge base encompassing every facet of hemp fiber production. It elucidates how different technological approaches and the technical properties of fibers play pivotal roles in determining their ultimate applications. By offering a comprehensive overview, this article contributes to the broader understanding of hemp as a valuable and sustainable resource in the textile industry.

Full article

Graphical abstract

Open AccessArticle

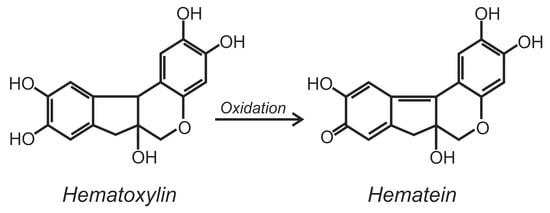

Wood Extracts for Dyeing of Cotton Fabrics—Special View on Mordanting Procedures

by

Thanh Hoa Mai, Thomas Grethe and Boris Mahltig

Textiles 2024, 4(2), 138-164; https://doi.org/10.3390/textiles4020010 - 12 Apr 2024

Abstract

►▼

Show Figures

Natural dyes offer a bio-based opportunity to support the attractive coloration of textile fabrics made from natural fibers like cotton, wool, hemp, and many other textile materials. They can be part of a strategy to realize fully bio-based textiles and clothing materials. In

[...] Read more.

Natural dyes offer a bio-based opportunity to support the attractive coloration of textile fabrics made from natural fibers like cotton, wool, hemp, and many other textile materials. They can be part of a strategy to realize fully bio-based textiles and clothing materials. In line with this statement, the following study investigates the use of wood extracts for dyeing cotton fabrics. Specifically, extract powders of logwood (Haematoxylon campechianum L.), brazilwood (Caesalpinia spp.), and quebracho wood (Schinopsis lorentzii) are used. The aim of the study is to evaluate which colorations can be obtained by the application of those wood extracts and what fastness properties are reached. For this, different modified process parameters and mordants are evaluated. The dyeing process is modified using different mordants based on iron and aluminum salts. These mordants are applied in pre-, meta-, or post-mordant procedures. The color and fastness properties of prepared textile samples are determined by spectroscopic measurements, color measurements, washing procedures, and a Xenotest for measuring the light fastness. Ultimately, it is shown that a broad range of colorations can be realized through different combinations of wood extracts and mordanting procedures. Notably, stronger color depths are reached with pre- and meta-mordanting compared to post-mordanting. Good wash fastness is obtained for some color shades. However, with post-mordanting, better wash fastness can be achieved. The light fastness of the realized samples is only moderate to low. In conclusion, it can be stated that dyes from wood extracts are excellent materials to dye natural fibers if they are combined with the right mordanting agent in pre- or meta-mordanting procedures. The present study is therefore a good proof-of-concept for the realization of fully bio-based colored textile materials.

Full article

Figure 1

Open AccessArticle

Cotton Fiber Strength Measurement and Its Relation to Structural Properties from Fourier Transform Infrared Spectroscopic Characterization

by

Yongliang Liu

Textiles 2024, 4(1), 126-137; https://doi.org/10.3390/textiles4010009 - 19 Mar 2024

Abstract

►▼

Show Figures

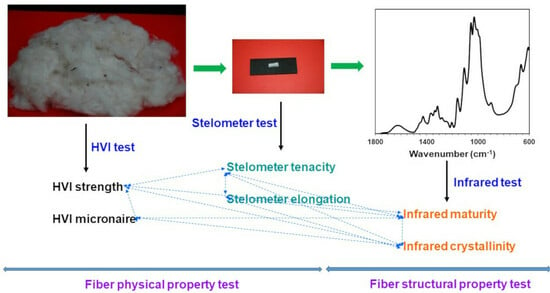

There has been an interest in understanding the relationship between textile cotton fiber strength (or tenacity) and structure for better fiber quality measurement and enhancement. This study utilized coupled Stelometer and high volume instrument (HVI) measurements with attenuated total reflection Fourier transform infrared

[...] Read more.

There has been an interest in understanding the relationship between textile cotton fiber strength (or tenacity) and structure for better fiber quality measurement and enhancement. This study utilized coupled Stelometer and high volume instrument (HVI) measurements with attenuated total reflection Fourier transform infrared spectroscopy methods to relate fiber strength and associated properties (Stelometer elongation and HVI micronaire) with structure properties on six Upland (as A, B, C, D, E, and F) and one Pima cultivar. Although Stelometer tenacity agreed with HVI strength in general, the Upland D cultivar (immature) was observed to show the lowest HVI strength value, while the Upland F cultivar (larger infrared crystallinity index) was found to possess the smallest Stelometer tenacity value. A few strong and significant correlations were noted, for example, between infrared crystallinity and Stelometer elongation for the Upland A fibers, between infrared maturity and Stelometer tenacity for the Upland C fibers, and between infrared maturity and HVI strength for the Upland D fibers. Furthermore, there were apparent distinctions in regressions and statistics of examined correlations between each Upland cultivar and their combined fiber set, addressing the challenge of understanding the unique response between fiber physical and structure properties from different measurements even within one cotton cultivar.

Full article

Graphical abstract

Open AccessArticle

Biosynthesis of Gold- and Silver-Incorporated Carbon-Based Zinc Oxide Nanocomposites for the Photodegradation of Textile Dyes and Various Pharmaceuticals

by

Dineo A. Bopape, David E. Motaung and Nomso C. Hintsho-Mbita

Textiles 2024, 4(1), 104-125; https://doi.org/10.3390/textiles4010008 - 05 Mar 2024

Abstract

►▼

Show Figures

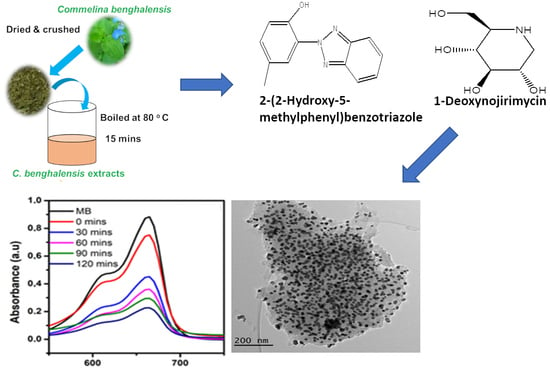

Wastewater contaminated with dyes from the textile industry has been at the forefront in the last few decades, thus, it is imperative to find treatment methods that are safe and efficient. In this study, C. benghalensis plant extracts were used to synthesise by

[...] Read more.

Wastewater contaminated with dyes from the textile industry has been at the forefront in the last few decades, thus, it is imperative to find treatment methods that are safe and efficient. In this study, C. benghalensis plant extracts were used to synthesise by mass 20 mg/80 mg zinc oxide–carbon spheres (20/80 ZnO–CSs) nanocomposites, and the incorporation of the nanocomposites with 1% silver (1% Ag–ZnO–CSs) and 1% gold (1% Au–ZnO–CSs) was conducted. The impact of Ag and Au dopants on the morphological, optical, and photocatalytic properties of these nanocomposites in comparison to 20/80 ZnO–CSs was investigated. TEM, XRD, UV-vis, FTIR, TGA, and BET revealed various properties for these nanocomposites. TEM analysis revealed spherical particles with size distributions of 40–80 nm, 50–200 nm, and 50–250 nm for 1% Ag–ZnO–CSs, 1% Au–ZnO–CSs, and 20/80 ZnO–CSs, respectively. XRD data showed peaks corresponding to Ag, Au, ZnO, and CSs in all nanocomposites. TGA analysis reported a highly thermally stable material in ZnO-CS. The photocatalytic testing showed the 1% Au–ZnO–CSs to be the most efficient catalyst with a 98% degradation for MB textile dye. Moreover, 1% Au–ZnO–CSs also exhibited high degradation percentages for various pharmaceuticals. The material could not be reused and the trapping studies demonstrated that both OH• radicals and the e− play a crucial role in the degradation of the MB. The photocatalyst in this study demonstrated effectiveness and high flexibility in degrading diverse contaminants.

Full article

Graphical abstract

Open AccessArticle

OLEDs on Down-Converting Fabric by Using a High Scalable Planarization Process and a Transparent Polymeric Electrode

by

Carmela Tania Prontera, Marco Pugliese, Fabrizio Mariano, Daniela Taurino, Roberto Giannuzzi, Vitantonio Primiceri, Marco Esposito, Antonio Andretta, Giuseppe Gigli and Vincenzo Maiorano

Textiles 2024, 4(1), 91-103; https://doi.org/10.3390/textiles4010007 - 15 Feb 2024

Abstract

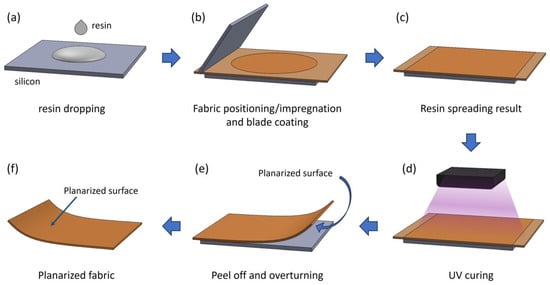

Textile-based electronics represents a key technology for the development of wearable devices. Light-emitting textiles based on OLED architecture are particularly promising due to their intrinsic flexibility and possibility to be fabricated on large areas using scalable processes. Fabric planarization is one of the

[...] Read more.

Textile-based electronics represents a key technology for the development of wearable devices. Light-emitting textiles based on OLED architecture are particularly promising due to their intrinsic flexibility and possibility to be fabricated on large areas using scalable processes. Fabric planarization is one of the most critical issues in their fabrication. Here we report a fast, simple, and industrially scalable planarization method based on the transfer of surface morphological properties from silicon to fabric. A liquid resin is used as a planarization layer, and by exploiting the low roughness of a ‘guide substrate’ it is possible to replicate the smooth and uniform surface from the silicon to the planarization layer. The result is a fabric with a flat and homogeneous polymer layer on its surface, suitable for OLED fabrication. In particular, the effect of resin viscosity on the surface morphology was evaluated to obtain the best planarization layer. The best device shows high luminance and current efficiency values, even after 1000 bending cycles. We also explored the possibility of tuning the color emitted by the device by using a fluorescent fabric as a down-converting layer. Thanks to this approach, it is in principle possible to achieve white emission from a very simple device architecture.

Full article

(This article belongs to the Special Issue Advances in Smart Textiles)

►▼

Show Figures

Figure 1

Open AccessArticle

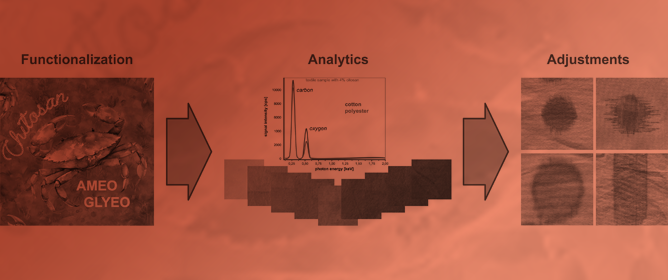

Functionalization of Technical Textiles with Chitosan

by

Kristina Klinkhammer, Hanna Hohenbild, Mohammad Toufiqul Hoque, Laura Elze, Helen Teshay and Boris Mahltig

Textiles 2024, 4(1), 70-90; https://doi.org/10.3390/textiles4010006 - 15 Feb 2024

Abstract

►▼

Show Figures

Textiles are used for many different applications and require a variety of properties. Wet functionalization improve textiles’ properties, such as hydrophilicity or antimicrobial activity. Chitosan is a bio-based polymer widely investigated in the textile industry for this purpose. A weaving comprising a cotton/polyester

[...] Read more.

Textiles are used for many different applications and require a variety of properties. Wet functionalization improve textiles’ properties, such as hydrophilicity or antimicrobial activity. Chitosan is a bio-based polymer widely investigated in the textile industry for this purpose. A weaving comprising a cotton/polyester mix and a pure-polyester weaving was functionalized with different concentrations of chitosan to determine the most robust method for chitosan detection in both cotton- and polyester-containing materials. Additionally, mixtures of chitosan with 3-glycidyloxypropyltriethoxy silane (GLYEO) or 3-aminopropyltriethoxy silane (AMEO) were applied in a one-step or two-step procedure on the same fabrics. Scanning electron microscopy (SEM) combined with energy-dispersive X-ray spectroscopy (EDS) and dyeing with Remazol Brilliant Red F3B demonstrated the presence of chitosan and silanes on the textiles’ surfaces. While non-functionalized textiles were not stained, the dependency of the dyeing depths on the chitosan concentrations enabled us to infer the efficacy of the very short processing time and a mild dyeing temperature. The one-step application of AMEO and chitosan resulted in the highest presence of silicon on the textile and the greatest color intensity. The functionalization with GLYEO reduced the water sink-in time of polyester, while chitosan-containing solutions increased the hydrophobicity of the material. Washing experiments demonstrated the increasing hydrophilicity of the cotton/polyester samples, independent of the type of functionalization. These experiments show that chitosan-containing recipes can be used as part of a useful method, and the type of functionalization can be used to adjust the hydrophilic properties of polyester and cotton/polyester textiles. Via this first step, in the future, new combinations of bio-based polymers with inorganic binder systems can be developed, ultimately leading to sustainable antimicrobial materials with modified hydrophilic properties.

Full article

Graphical abstract

Open AccessArticle

Comparative Analysis of Electrokinetic Properties of Periodate- and TEMPO-Oxidized Regenerated Cellulose Fabric Functionalized with Chitosan

by

Ana Kramar, Matea Korica and Mirjana Kostić

Textiles 2024, 4(1), 57-69; https://doi.org/10.3390/textiles4010005 - 08 Feb 2024

Abstract

►▼

Show Figures

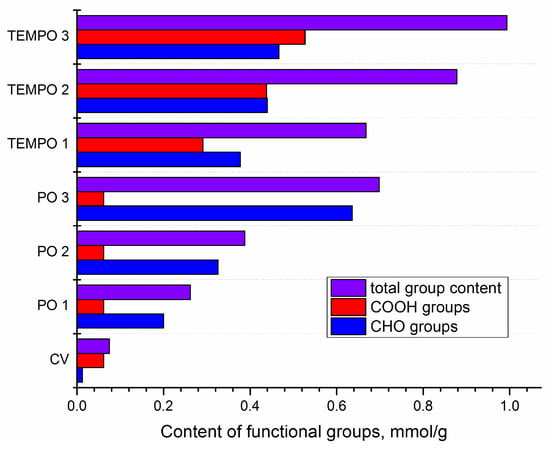

The electrokinetic properties of materials give useful insight into the behavior of surfaces in contact with liquids and other compounds and their quantification is a powerful tool to predict their behavior during further processing and application, especially in textile materials. In this work,

[...] Read more.

The electrokinetic properties of materials give useful insight into the behavior of surfaces in contact with liquids and other compounds and their quantification is a powerful tool to predict their behavior during further processing and application, especially in textile materials. In this work, we perform a comparative analysis of influence of the two most common selective oxidative protocols for viscose (regenerated cellulose) fabrics on subsequent functionalization with chitosan, and cellulose fabrics’ electrokinetic properties, zeta potential in a pH range of approx. 3–10, and isoelectric point (IEP). For oxidation before deposition of chitosan, sodium periodate and 2,2,6,6-tetramethylpiperidine-1-oxy radical (TEMPO) were used. The content of functional groups in oxidized cellulose fabric (carboxyl and carbonyl groups) was determined by titration methods, while amino functional groups’ availability in samples with chitosan was determined using the CI acid orange 7 dye absorption method. This study reveals that the periodate oxidation (PO) of cellulose is more effective for binding chitosan onto material, which gave rise to higher availability of amino groups onto cellulose/chitosan material, which also influenced the shift in zeta potential curve towards positive values at a pH below 5. Analysis of a relationship between zeta potential increase at pH 4.4 and amino groups’ amount measured using absorption of CI acid orange 7 dye at pH 4.4 revealed dependency that can be fitted linearly or exponentially, with the latter providing the better fit (R2 = 0.75).

Full article

Figure 1

Open AccessArticle

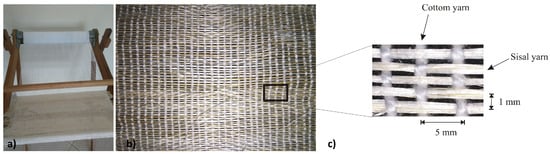

Effect of Number of Layers on Tensile and Flexural Behavior of Cementitious Composites Reinforced with a New Sisal Fabric

by

Adilson Brito de Arruda Filho, Paulo Roberto Lopes Lima, Ricardo Fernandes Carvalho, Otavio da Fonseca Martins Gomes and Romildo Dias Toledo Filho

Textiles 2024, 4(1), 40-56; https://doi.org/10.3390/textiles4010004 - 01 Feb 2024

Abstract

►▼

Show Figures

The use of fabric in reinforcing cement-based materials expands their applications for various types of construction elements. Additionally, employing renewable sources of plant-based fabrics contributes to reducing the environmental impact of the construction industry. However, the variability in the properties of plant fibers

[...] Read more.

The use of fabric in reinforcing cement-based materials expands their applications for various types of construction elements. Additionally, employing renewable sources of plant-based fabrics contributes to reducing the environmental impact of the construction industry. However, the variability in the properties of plant fibers and fabrics necessitates prior studies to confirm their effectiveness as reinforcement materials. In this study, a new sisal fabric was produced and utilized as reinforcement in cement-based matrix composites. The sisal fibers, yarns, and fabrics produced were tested under direct tension. Five composites were manufactured by manual lamination, with reinforcement ranging from one to five layers, and were subjected to direct tension and flexural testing. The results indicate that, while the fiber shows brittle failure, the yarn and fabric exhibit a gradual loss of strength after reaching the maximum tension. All composites display strain-hardening and deflection-hardening behavior, with multiple cracking and an increase in tension and deformation before rupture. The mechanical properties exhibited improvement with an increase in the number of layers, and composites with four and five layers displayed distinct behavior, demonstrating increased stiffness after the occurrence of multiple cracking and a better mechanical performance, qualifying them for use as a construction element.

Full article

Figure 1

Open AccessArticle

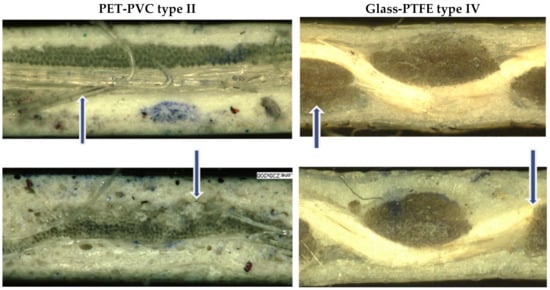

Mechanical Property Characterization of Architectural Coated Woven Fabrics Subjected to Freeze–Thaw Cycles

by

Hastia Asadi, Joerg Uhlemann, Natalie Stranghoener and Mathias Ulbricht

Textiles 2024, 4(1), 26-39; https://doi.org/10.3390/textiles4010003 - 11 Jan 2024

Abstract

►▼

Show Figures

This paper presents experimental investigations into the freeze–thaw response of two common architectural coated woven fabrics. Strip specimens for the tensile tests were exposed to −20 °C for three hours followed by three hours of thaw at ambient temperatures. This was repeated for

[...] Read more.

This paper presents experimental investigations into the freeze–thaw response of two common architectural coated woven fabrics. Strip specimens for the tensile tests were exposed to −20 °C for three hours followed by three hours of thaw at ambient temperatures. This was repeated for a maximum of 100 cycles. Afterwards, the residual tensile strength was measured and compared to results achieved for test specimens without prior freeze–thaw cycles. Maximum mean tensile strength reductions of approximately 21% (warp direction) and 19% (weft direction) for probed polytetrafluoroethylene (PTFE)-coated woven glass fiber fabrics were identified, while no remarkable tensile strength deterioration rate was observed for the investigated polyvinyl chloride-coated woven polyethylene terephthalate materials. Overall, the results indicate that freeze–thaw cycles can have a significant deteriorating impact on the mechanical properties of glass-PTFE fabrics.

Full article

Figure 1

Open AccessReview

Sensory Considerations for Emerging Textile Applications

by

Emma Kay, Jessica Levick, Tawanda Machingura and Stephen Bird

Textiles 2024, 4(1), 17-25; https://doi.org/10.3390/textiles4010002 - 04 Jan 2024

Abstract

Textiles are increasingly playing a role as a therapeutic medium in the disability field as well as in everyday life. This paper aims to review the literature on the relationship between textiles and sensory integration or sensory preferences in the general population. A

[...] Read more.

Textiles are increasingly playing a role as a therapeutic medium in the disability field as well as in everyday life. This paper aims to review the literature on the relationship between textiles and sensory integration or sensory preferences in the general population. A brief literature review was conducted using PubMed (MEDLINE), SCOPUS, and Google Scholar. The review of the current literature highlights some key themes in the literature, including the indication that adaptive and sensory clothing design requires consideration of the textiles and fabrics being used, the functionality and appearance of garments, and affordability and access. The evidence suggests that clothing design should utilize soft fabrics which are seamless, have limited external tags, support social participation and functional engagement in daily activities, and are accessible.

Full article

Open AccessArticle

Antimicrobial Properties of Polyester/Copper Nanocomposites by Melt-Spinning and Melt-Blowing Techniques

by

Alain González-Sánchez, Ricardo Rosas-Macías, José E. Hernández-Bautista, Janett A. Valdez-Garza, Nayeli Rodríguez-Fuentes, Florentino Soriano-Corral, Antonio S. Ledezma-Pérez, Carlos A. Ávila-Orta and Víctor J. Cruz-Delgado

Textiles 2024, 4(1), 1-16; https://doi.org/10.3390/textiles4010001 - 25 Dec 2023

Abstract

In this study, textile fiber prototypes based on polyester and different Cu nanoparticles (CuNP) content were produced using melt-spinning to obtain bi-component multifilament fibers and melt-blowing to obtain non-woven fabrics. The prototypes were tested against pathogenic microorganisms such as S. aureus, E.

[...] Read more.

In this study, textile fiber prototypes based on polyester and different Cu nanoparticles (CuNP) content were produced using melt-spinning to obtain bi-component multifilament fibers and melt-blowing to obtain non-woven fabrics. The prototypes were tested against pathogenic microorganisms such as S. aureus, E. coli, and C. albicans. It was shown that bi-component fibers offer excellent protection against pathogens, with up to 99% growth inhibition with 0.5% w/w for S. aureus and E. coli; meanwhile, non-woven fabric only shows activity against E. coli from 0.1% w/w of CuNP. Using different analytical techniques, it was possible to identify that the CuNP were confined exclusively in the outer cover of the bi-component fibers which may be associated with increased antimicrobial activity compared to the fibers in the non-woven fabric. The use of polymeric nanocomposites based on polyester/copper offers an alternative of great interest due to the versatility of the raw material and the high efficiency of copper nanoparticles as an antimicrobial additive.

Full article

(This article belongs to the Special Issue Advances of Medical Textiles)

►▼

Show Figures

Graphical abstract

Open AccessReview

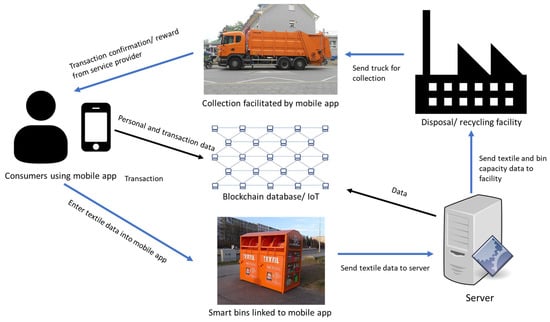

State of the Art in Textile Waste Management: A Review

by

Kuok Ho Daniel Tang

Textiles 2023, 3(4), 454-467; https://doi.org/10.3390/textiles3040027 - 18 Dec 2023

Cited by 2

Abstract

►▼

Show Figures

Textile waste constitutes a significant fraction of municipal solid waste sent to landfill or incinerated. Its innovative management is important to enhance sustainability and circularity. This review aims to present the latest policies and the state-of-the-art technologies in the collection, sorting and recycling

[...] Read more.

Textile waste constitutes a significant fraction of municipal solid waste sent to landfill or incinerated. Its innovative management is important to enhance sustainability and circularity. This review aims to present the latest policies and the state-of-the-art technologies in the collection, sorting and recycling of textile waste. Policies at global and regional levels are increasingly made to address the sustainability of the textile industry and integrate the concept of circular economy. They are crucial to driving changes and innovations in current textile waste management. The Internet of Things, big data, blockchain and smart contracts have been proposed to improve transparency, traceability and accountability in the textile waste collection process. They optimize collection routes, and transactions and agreements among stakeholders. The sorting of textile waste using near-infrared spectroscopy, optical sorting and artificial intelligence enables its separation based on composition, color and quality. The mechanical recycling of textiles regenerates fibers with the same or different applications from those of the original fabrics. Fibers have been used for making building and slope protection materials. Chemical recycling depolymerizes waste textiles using chemicals to produce monomers for new textiles or other materials, while biological recycling uses enzymes and microorganisms for this purpose instead of chemicals. Thermal recycling recovers energy and fuels from textile waste through pyrolysis, gasification and hydrothermal liquefaction. These innovations may have the drawbacks of high cost and scalability. This review contributes to decision making by synthesizing the strengths and weaknesses of the innovations in textile waste management.

Full article

Figure 1

Open AccessArticle

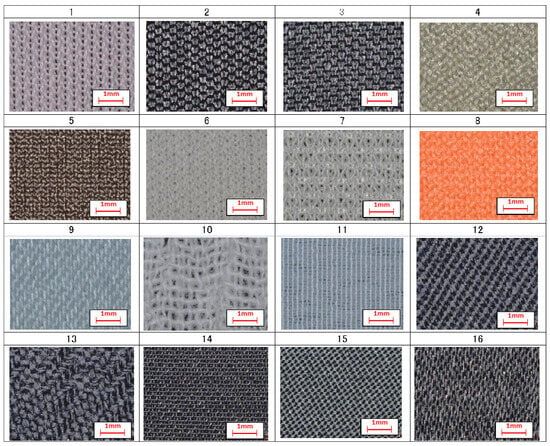

Investigation of Japanese Onomatopoeia Tsuru-Tsuru as a Suitable Sensory Attribute for Perception of Surface Properties of Textiles by Non-Trained Individuals

by

Raphael Romao Santos, Nozomi Katayama and Sachiko Sukigara

Textiles 2023, 3(4), 438-453; https://doi.org/10.3390/textiles3040026 - 28 Nov 2023

Abstract

►▼

Show Figures

In recent years, using non-trained individuals in sensory science for analytical tasks has gained traction. Identifying attributes enabling non-experts to express perceptions is crucial for accurate fabric assessments and effective communication of product properties to consumers. This study explored the potential utility of

[...] Read more.

In recent years, using non-trained individuals in sensory science for analytical tasks has gained traction. Identifying attributes enabling non-experts to express perceptions is crucial for accurate fabric assessments and effective communication of product properties to consumers. This study explored the potential utility of the Japanese onomatopoeia tsuru-tsuru as a sensory attribute for evaluating fabric surface properties. Two experiments were conducted. The first ranked 16 samples to identify those eliciting the tsuru-tsuru sensation, exploring its relationship with attributes like smoothness and coolness. The second involved a detailed descriptive sensory evaluation of selected samples, examining the relationship between tsuru-tsuru, coolness, slipperiness, and hardness. Fabric preferences assessment and cluster analysis were also employed to understand individual differences in perception. Sensory assessments revealed tsuru-tsuru’s comparable performance with attributes like smoothness and slipperiness, facilitating effective sample distinction. Participants showed high agreement, indicating shared perceptions. Preferences favored fabrics with tsuru-tsuru qualities. The clustering analysis revealed participants had slightly different interpretations of tsuru-tsuru. Overall, results indicated the positive potential value of tsuru-tsuru in describing textile surfaces for non-trained individuals.

Full article

Figure 1

Open AccessReview

Current and Future Trends in Textiles for Concrete Construction Applications

by

Martin Scheurer, Danny Friese, Paul Penzel, Gözdem Dittel, Shantanu Bhat, Vanessa Overhage, Lars Hahn, Kira Heins, Chokri Cherif and Thomas Gries

Textiles 2023, 3(4), 408-437; https://doi.org/10.3390/textiles3040025 - 17 Oct 2023

Cited by 1

Abstract

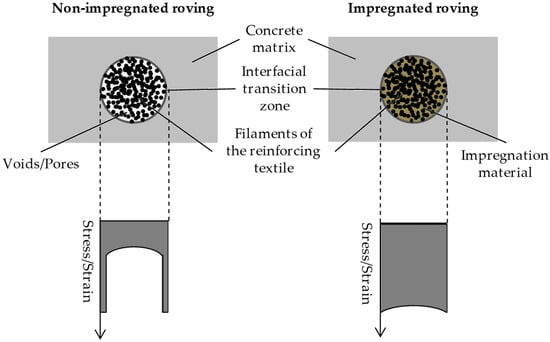

Textile-reinforced concrete (TRC) is a composite material consisting of a concrete matrix with a high-performance reinforcement made of technical textiles. TRC offers unique mechanical properties for the construction industry, enabling the construction of lightweight, material-minimized structures with high load-bearing potential. In addition, compared

[...] Read more.

Textile-reinforced concrete (TRC) is a composite material consisting of a concrete matrix with a high-performance reinforcement made of technical textiles. TRC offers unique mechanical properties for the construction industry, enabling the construction of lightweight, material-minimized structures with high load-bearing potential. In addition, compared with traditional concrete design, TRC offers unique possibilities to realize free-form, double-curved structures. After more than 20 years of research, TRC is increasingly entering the market, with several demonstrator elements and buildings completed and initial commercialization successfully finished. Nevertheless, research into this highly topical area is still ongoing. In this paper, the authors give an overview of the current and future trends in the research and application of textiles in concrete construction applications. These trends include topics such as maximizing the textile utilization rate by improving the mechanical load-bearing performance (e.g., by adapting bond behavior), increasing design freedom by utilizing novel manufacturing methods (e.g., based on robotics), adding further value to textile reinforcements by the integration of additional functions in smart textile solutions (e.g., in textile sensors), and research into increasing the sustainability of TRC (e.g., using recycled fibers).

Full article

(This article belongs to the Special Issue Advances in Technical Textiles)

►▼

Show Figures

Figure 1

Open AccessReview

Clothing Thermophysiological Comfort: A Textile Science Perspective

by

Md Rashedul Islam, Kevin Golovin and Patricia I. Dolez

Textiles 2023, 3(4), 353-407; https://doi.org/10.3390/textiles3040024 - 30 Sep 2023

Cited by 2

Abstract

►▼

Show Figures

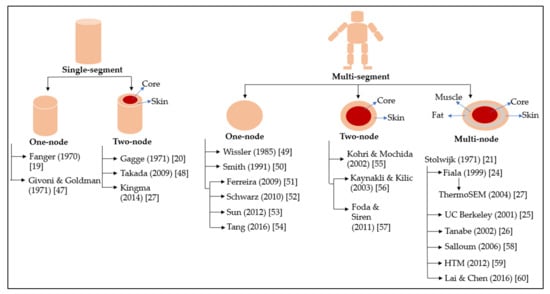

Thermophysiological comfort is a crucial aspect of human life, contributing to health and work performance. The current paper aims to enhance the understanding of current research, progress, and remaining challenges regarding clothing thermophysiological comfort from a textile science perspective. It provides a comprehensive

[...] Read more.

Thermophysiological comfort is a crucial aspect of human life, contributing to health and work performance. The current paper aims to enhance the understanding of current research, progress, and remaining challenges regarding clothing thermophysiological comfort from a textile science perspective. It provides a comprehensive review of several facets of clothing thermophysiological comfort, focusing on the history of thermophysiological comfort prediction models, heat and moisture transfer mechanisms in the skin–clothing–environment system, controlling factors of thermophysiological comfort, textile materials for superior thermophysiological comfort, and thermal comfort assessment techniques. The paper shows that previously developed thermophysiological comfort models were mainly based on the human thermoregulation process. However, the effect of the air gap size between the human skin and the cloth layer, i.e., the microclimate, on the heat and moisture transfer in the skin–clothing–environment system has been largely overlooked. In addition, thermophysiological comfort models of skin–clothing–environment systems generally only considered dry thermal resistance and evaporative resistance, yet many other fabric properties have effects on human thermophysiological comfort. Potential future directions are identified to fill some of the current gaps. A conceptual model of clothing comfort to contribute to a better understanding of thermophysiological comfort is also proposed.

Full article

Figure 1

Open AccessArticle

Effect of Post-Drawing Thermal Treatment on the Mechanical Behavior of Solid-State Drawn Poly(lactic acid) (PLA) Filaments

by

Martín Butto, María Lluisa Maspoch and Celina Bernal

Textiles 2023, 3(3), 339-352; https://doi.org/10.3390/textiles3030023 - 18 Sep 2023

Cited by 1

Abstract

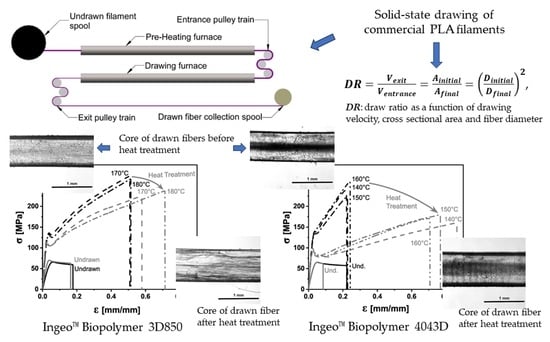

In this work, two commercial extruded filaments for 3D printing obtained from different NatureWorks PLA resins (Ingeo™ Biopolymer 3D850 and Ingeo™ Biopolymer 4043D) were solid-state drawn at varying temperatures and subsequently heat treated by annealing. The aim was to analyze the effect of

[...] Read more.

In this work, two commercial extruded filaments for 3D printing obtained from different NatureWorks PLA resins (Ingeo™ Biopolymer 3D850 and Ingeo™ Biopolymer 4043D) were solid-state drawn at varying temperatures and subsequently heat treated by annealing. The aim was to analyze the effect of post-processing of industrial fibers (solid-state drawing and annealing treatment) with varied composition (PLA grades with different contents of D-isomer) on the mechanical performance and thermal stability of the obtained PLA fibers. Morphological, thermal, and mechanical characterizations were performed for the undrawn filaments and drawn fibers, both before and after heat treatment. Drawn fibers presented a fibrillar core–shell structure, and their mechanical properties were greatly improved with respect to undrawn filaments in accordance with their higher crystallinity. The resin with the higher content of D-isomer (4043D) resulted in lower crystallinities with a subsequent decrease in mechanical properties. After heat treatment, drawn fibers exhibited completely different behaviors depending on the PLA resin, with 3D850 fibers being much more stable than 4043D fibers, which underwent molecular orientation upon drawing rather than crystallization. The solid-state drawn fibers obtained herein are comparable to commercial fibers in terms of mechanical properties.

Full article

(This article belongs to the Special Issue Textile Materials: Structure–Property Relationship)

►▼

Show Figures

Graphical abstract

Open AccessReview

Factors Affecting the Sweat-Drying Performance of Active Sportswear—A Review

by

Surya Nasrin, Sumit Mandal, MD. Momtaz Islam, Adriana Petrova, Robert J. Agnew and Lynn M. Boorady

Textiles 2023, 3(3), 319-338; https://doi.org/10.3390/textiles3030022 - 14 Aug 2023

Abstract

Quick drying is one of the most crucial factors in the comfort and performance of active sportswear clothing. It helps to keep the wearer dry and comfortable by effectively wicking away sweat and moisture from the body. In the light of this, a

[...] Read more.

Quick drying is one of the most crucial factors in the comfort and performance of active sportswear clothing. It helps to keep the wearer dry and comfortable by effectively wicking away sweat and moisture from the body. In the light of this, a substantial number of previous researchers have identified fabric properties and types that have a significant impact on fabric drying performance. Studies have also been conducted to examine the impact of fabric drying on human physiology during sports-related activities. However, there are still some technical knowledge gaps in the existing literature related to the drying performance of active sportswear fabrics. This review article provides a critical analysis of the literature on the impact of various fabric attributes as well as the physiological and environmental factors on moisture management and drying performance. The key issues in this field are determined so that future research can be directed and this scientific field can advance in order to improve the overall performance of active sportswear fabrics.

Full article

Open AccessArticle

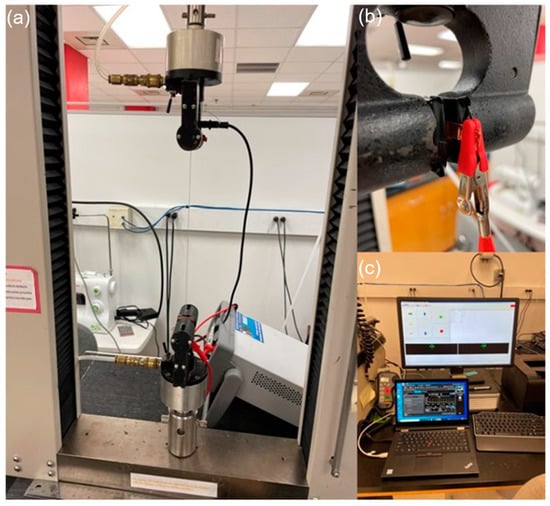

Characterization of the Viscoelastic Properties of Yarn Materials: Dynamic Mechanical Analysis in Longitudinal Direction

by

Karl Kopelmann, Mathis Bruns, Andreas Nocke, Michael Beitelschmidt and Chokri Cherif

Textiles 2023, 3(3), 307-318; https://doi.org/10.3390/textiles3030021 - 11 Aug 2023

Abstract

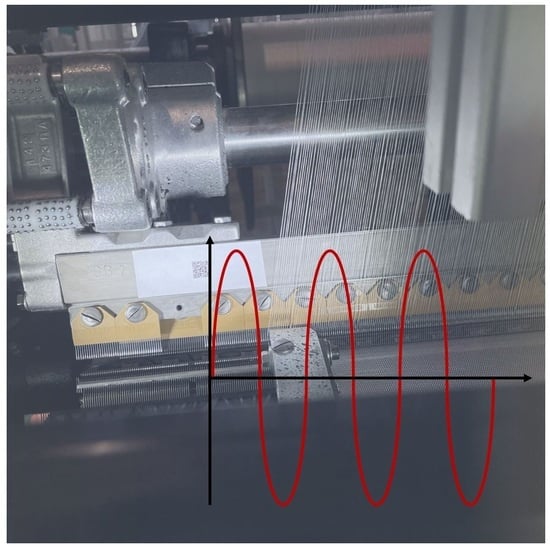

Warp knitting is a highly productive textile manufacturing process and method of choice for many products. With the current generation of machines running up to 4400 min−1, dynamics become a limit for the production. Resonance effects of yarn-guiding elements and oscillations

[...] Read more.

Warp knitting is a highly productive textile manufacturing process and method of choice for many products. With the current generation of machines running up to 4400 min−1, dynamics become a limit for the production. Resonance effects of yarn-guiding elements and oscillations of the yarn lead to load peaks, resulting in breakage or mismatches. This limits material choice to highly elastic materials for high speeds, which compensate for these effects through their intrinsic properties. To allow the processing of high-performance fibers, a better understanding of the viscoelastic yarn behavior is necessary. The present paper shows a method to achieve this in longitudinal yarn direction using a dynamic mechanical analysis approach. Samples of high tenacity polyester and aramid are investigated. The test setup resembles the warp knitting process in terms of similar geometrical conditions, pre-loads, and occurring frequencies. By recording the mechanical load resulting from an applied strain, it is possible to calculate the phase shift and the dissipation factor, which is a key indicator for the damping behavior. It shows that the dissipation factor rises with rising frequency. The results allow for a simulation of the warp knitting process, including a detailed yarn model and representation of stitch-formation process.

Full article

(This article belongs to the Special Issue Advances in Technical Textiles)

►▼

Show Figures

Graphical abstract

Open AccessArticle

Electromechanical Characterization of Commercial Conductive Yarns for E-Textiles

by

Yu Chen, Jacob Hart, Minyoung Suh, Kavita Mathur and Rong Yin

Textiles 2023, 3(3), 294-306; https://doi.org/10.3390/textiles3030020 - 09 Aug 2023

Cited by 1

Abstract

With the development of smart and multi-functional textiles, conductive yarns are widely used in textiles. Conductive yarns can be incorporated into fabrics with traditional textile techniques, such as weaving, knitting and sewing. The electromechanical properties of conductive yarns are very different from conventional

[...] Read more.

With the development of smart and multi-functional textiles, conductive yarns are widely used in textiles. Conductive yarns can be incorporated into fabrics with traditional textile techniques, such as weaving, knitting and sewing. The electromechanical properties of conductive yarns are very different from conventional yarns, and they also affect the processability during end-product manufacturing processes. However, systematic evaluation of the electromechanical properties of commercial conductive yarns is still elusive. Different conductive materials and production methods for making conductive yarns lead to diverse electromechanical properties. In this work, three types of conductive yarn with different conductive materials and yarn structures were selected for electromechanical characterization. A total of 15 different yarns were analyzed. In addition, the change of resistance with strain was tested to simulate and predict the possible changes in electrical properties of the yarn during weaving, knitting, sewing and other end uses. It was found that Metal-based yarns have good electrical properties but poor mechanical properties. The mechanical properties of Metal-coated yarns are similar to conventional yarns, but their electrical properties are relatively poor. The data shown in this research is instructive for the subsequent processing (weaving, knitting, sewing, etc.) of yarns.

Full article

(This article belongs to the Special Issue Fibrous Materials (Textiles) for Functional Applications II)

►▼

Show Figures

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Conferences

Special Issues

Special Issue in

Textiles

Advances in Technical Textiles

Guest Editors: Larisa A. Tsarkova, Thomas Bahners, Xiaomin ZhuDeadline: 30 April 2024

Special Issue in

Textiles

Fibrous Materials (Textiles) for Functional Applications II

Guest Editors: Rajesh Mishra, Tao Yang, Veerakumar ArumugamDeadline: 31 October 2024

Special Issue in

Textiles

Nanofunctionalization of Textiles

Guest Editor: Andrea ZilleDeadline: 31 December 2024