Advanced Civil Engineering Materials: From Synthesis to Application

Share This Topical Collection

Editor

Prof. Dr. Łukasz Sadowski

Prof. Dr. Łukasz Sadowski

Prof. Dr. Łukasz Sadowski

Prof. Dr. Łukasz Sadowski

E-Mail

Website

Collection Editor

Department of Building Engineering, Wroclaw University of Science and Technology, Wybrzeze Wyspianskiego 27, 50-370 Wrocław, Poland

Interests: cementitious materials; sustainable development; artificial intelligence; nondestructive testing; surface morphology

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

In recent years, much progress has been made in the development of advanced civil engineering materials. This progress has largely concerned the synthesis of new materials, the modification of the material composition of traditional materials, and recycling. This multidisciplinary approach has been used to develop innovative products and materials with new or improved properties. Their application can accelerate economic development and contribute to improving the security and standard of living of a region’s inhabitants. An indispensable element of meeting this challenge is the development of new construction materials that are both of high strength and durability and safe for humans and the environment. This development should be carried out in accordance with principles of sustainable development and economically sensible. Thanks to nanotechnology and biotechnology, it is now possible to design and modify the structure of materials to obtain a construction product with the desired functional properties. With this in mind, this Topical Collection will be devoted to advanced civil engineering materials. Particular emphasis will be placed on their synthesis and application. We welcome experimental articles, review articles, and case studies demonstrating the application potential of advanced civil engineering materials.

Prof. Dr. Łukasz Sadowski

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- innovations

- civil engineering

- functional properties

- materials

- synthesis

- applications

- sustainable development

- recycling

- nanotechnology

- construction products

Published Papers (24 papers)

Open AccessArticle

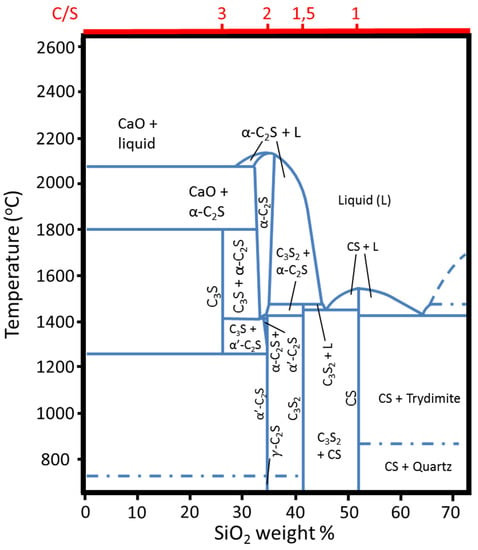

The Use of Solid Sodium Silicate as Activator for an Amorphous Wollastonitic Hydraulic Binder

by

Mónica Antunes, Rodrigo Lino Santos, João Pereira, Ricardo Bayão Horta and Rogério Colaço

Viewed by 516

Abstract

To ensure the acceptable mechanical strength of amorphous wollastonitic hydraulic binders (AWHs), activation with a sodium silicate solution is necessary. However, the use of this type of activator increases the final cost and the complexity of the product’s overall use. In this work,

[...] Read more.

To ensure the acceptable mechanical strength of amorphous wollastonitic hydraulic binders (AWHs), activation with a sodium silicate solution is necessary. However, the use of this type of activator increases the final cost and the complexity of the product’s overall use. In this work, we focus on enhancing the manufacturing of the alkaline activator by producing three Na

2SiO

3 powders using cost-effective raw materials. The procedure consisted of heating a mixture of NaOH pebbles with either sand, glass, or diatomite to a temperature of 330 °C for 2 h. After synthesis, the powders were characterized by Fourier Transform Infrared Spectroscopy (FTIR) and X-ray Diffraction (XRD) techniques. Finally, mortars made with AWHs were activated using the synthesized powders that were added either as a solid or dissolved in an aqueous solution. The compressive strength results in these mortars show that the lab-made activators are competitive with the traditional sodium silicate activators. Furthermore, the synthetized activators can be added in either solid form or pre-dissolved in a solution. This innovative approach represents a more economical, sustainable and easy-to-use approach to enhancing the competitiveness of AWHs.

Full article

►▼

Show Figures

Open AccessArticle

Rutting Performance Evaluation of BMD Surface Mixtures with Conventional and High RAP Contents under Full-Scale Accelerated Testing

by

Bilin Tong, Jhony Habbouche, Gerardo W. Flintsch and Brian K. Diefenderfer

Cited by 1 | Viewed by 773

Abstract

The balanced mix design (BMD) constitutes a significant step forward in the pursuit of better-performing asphalt mixtures. This approach/framework offers increased innovative opportunities for the proper design and production of engineered asphalt mixtures without the need to strictly adhere to traditional volumetric requirements.

[...] Read more.

The balanced mix design (BMD) constitutes a significant step forward in the pursuit of better-performing asphalt mixtures. This approach/framework offers increased innovative opportunities for the proper design and production of engineered asphalt mixtures without the need to strictly adhere to traditional volumetric requirements. The primary objective of this paper is to conduct a comprehensive investigation of the permanent deformation (rutting) behavior of surface mixtures (SMs) with conventional and high reclaimed asphalt pavement (HRAP) contents through full-scale accelerated testing under incremental loading conditions while accounting for the environmental aging effect. HRAP SMs were designed in this study, marking the initial application of Virginia Department of Transportation (VDOT) BMD special provisions, with attempts to incorporate 45% and even 60% RAP. Results showed that all BMD HRAP mixtures exhibited higher rut depths compared to the control mixture, which can be attributed to the inclusion of high binder contents aimed at enhancing cracking resistance. The asphalt pavement analyzer (APA) rut test and the stress sweep rutting tests were performed on mixtures sampled during production. Correlation analysis revealed significant and strong positive correlations between accelerated pavement testing (APT) and the multilevel laboratory rutting performance tests considered in this study. Finally, while acknowledging the limitations and all the assumptions considered in this study, the correlation analysis recommended refining the VDOT BMD APA rut depth threshold by lowering the current limit of 8 mm to 7 mm to ensure good performing mixtures from a rutting point of view.

Full article

►▼

Show Figures

Open AccessReview

Novel Amorphous-Wollastonitic Low-Calcium Hydraulic Binders: A State-of-the-Art Review

by

Mónica Antunes, Rodrigo L. Santos, Ricardo B. Horta and Rogério Colaço

Cited by 1 | Viewed by 651

Abstract

Because of the severe environmental impact of the CO

2 emissions associated with the production of ordinary Portland cement (OPC) and the increasing demand for this commodity material, the development of alternative products has become a global concern. One alternative to OPC, or

[...] Read more.

Because of the severe environmental impact of the CO

2 emissions associated with the production of ordinary Portland cement (OPC) and the increasing demand for this commodity material, the development of alternative products has become a global concern. One alternative to OPC, or alitic-based clinkers, are amorphous-wollastonitic low-calcium hydraulic binders (AWLCs). This new class of hydraulic binders, described in the literature for the first time in 2015, may significantly reduce the CO

2 emissions associated with its production, resulting from its lower calcium content, but also from the fact that its production technology can be fully electrified. In this paper, a state-of-the-art review is presented, providing a comprehensive description of the latest research, summarizing both the physicochemical and mechanical characteristics of this type of hydraulic binder, as well as possible routes for its production at an industrial scale.

Full article

►▼

Show Figures

Open AccessArticle

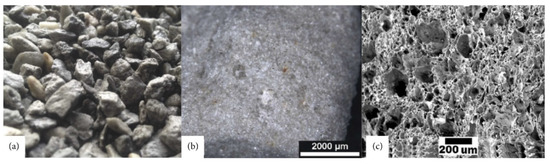

Ceramic Thermal Insulator Based on Diatomite Obtained by Starch Consolidation Casting

by

Cinthya Alvarado, Hernán Alvarado-Quintana and Raúl Siche

Cited by 1 | Viewed by 1476

Abstract

Researchers are continuously seeking to develop new materials to protect against inclement weather and thus optimize energy efficiency in housing. This research aimed to determine the influence of corn starch percentage on the physicomechanical and microstructural properties of a diatomite-based porous ceramic. The

[...] Read more.

Researchers are continuously seeking to develop new materials to protect against inclement weather and thus optimize energy efficiency in housing. This research aimed to determine the influence of corn starch percentage on the physicomechanical and microstructural properties of a diatomite-based porous ceramic. The starch consolidation casting technique was applied to fabricate a diatomite-based thermal insulating ceramic with hierarchical porosity. Diatomite mixtures with 0%, 10%, 20%, 30%, and 40% starch were consolidated. The results show that starch content significantly influences apparent porosity, and this, in turn, influences several parameters, such as thermal conductivity, diametral compressive strength, microstructure, and water absorption of diatomite-based ceramics. The porous ceramic processed by the starch consolidation casting method corresponding to the mixture of diatomite with 30% starch obtained the best properties, with a thermal conductivity of 0.0984 W/m·K, an apparent porosity of 57.88%, a water absorption of 58.45%, and a diametral compressive strength of 35.18 kg/cm

2 (3.45 MPa). Our results reveal that the diatomite-based ceramic thermal insulator obtained by starch consolidation is effective for use on roofs to improve thermal comfort in dwellings located in cold regions.

Full article

►▼

Show Figures

Open AccessArticle

Improving the Thermal Performance and Energy Efficiency of Buildings by Incorporating Biomass Waste into Clay Bricks

by

Sama Ahmed, Mohamed Esmat El Attar, Nasser Zouli, Ahmed Abutaleb, Ibrahim M. Maafa, M. M. Ahmed, Ayman Yousef and Ayman Ragab

Cited by 5 | Viewed by 1729

Abstract

Excessive urban construction is primarily driven by uncontrolled population growth, which has serious consequences for the environment, energy, cost, and human life in general when building materials are massively used. In terms of energy and economic efficiency, buildings that make use of sustainable

[...] Read more.

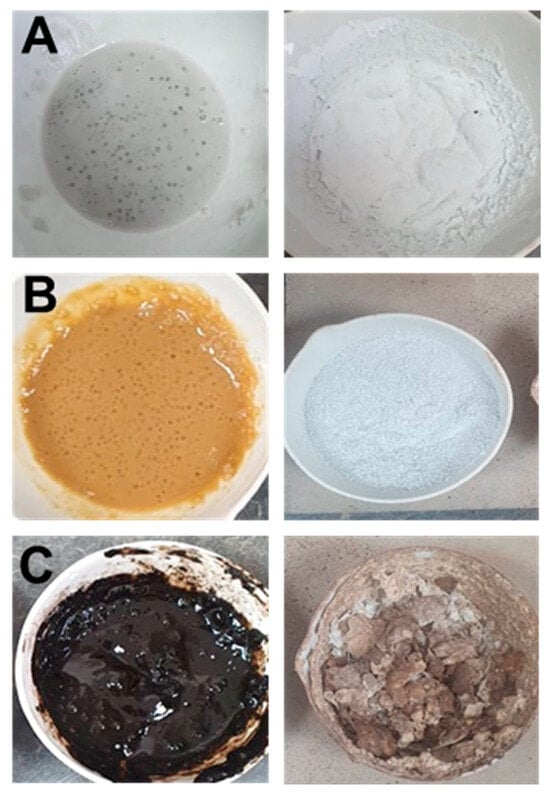

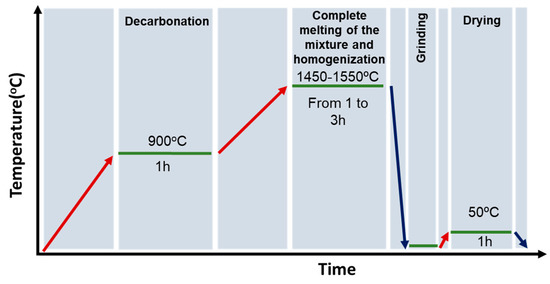

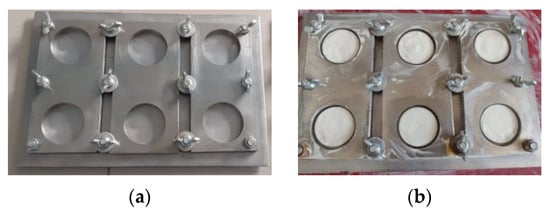

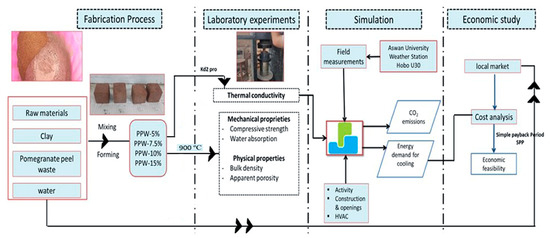

Excessive urban construction is primarily driven by uncontrolled population growth, which has serious consequences for the environment, energy, cost, and human life in general when building materials are massively used. In terms of energy and economic efficiency, buildings that make use of sustainable construction materials and technologies perform better. This is because building in an eco-friendly way results in less waste. Agro-industrial by-products and insulating materials are two examples of sustainable materials that have been put to good use in the climate change mitigation effort and to preserve the environment. Precast components are emphasized as a viable option that is suitable for this purpose and may potentially fulfill the need for housing units. Thus, this study investigated the viability of employing agricultural waste consisting of pomegranate peel waste to produce fired clay bricks. Results demonstrated that the optimum amount of pomegranate peel waste was determined to be 15%, and the optimal firing temperature was determined to be 900 °C. The thermal conductivity of all test samples was lower than that of conventional brick. Furthermore, when compared to conventional wall brick, all the tested samples of manufactured brick reduced energy consumption by 17.55% to 33.13% and carbon dioxide emissions by 7.50% to 24.50%. In addition, the economic feasibility of employing each synthetic sample was evaluated by computing the simple payback time (SPP). It was determined that 1.88–10.74 years were required for the brick samples to provide a return on their initial investment. Due to its ability to decrease heat gain, preserve energy, minimize CO

2 emissions, and shorten the payback time, burned clay bricks manufactured from pomegranate peel waste are regarded as a feasible building material. Hence, manufactured bricks are usually considered an exceptional contribution to environmental sustainability.

Full article

►▼

Show Figures

Open AccessArticle

A Study on the Heating and Deicing Performance of Microwave-Absorbing Asphalt Mixtures

by

Yuyuan Deng, Xuancang Wang, Lv Chen, Mingyan Liu, Maohong Gao and Jing Zhao

Cited by 1 | Viewed by 1131

Abstract

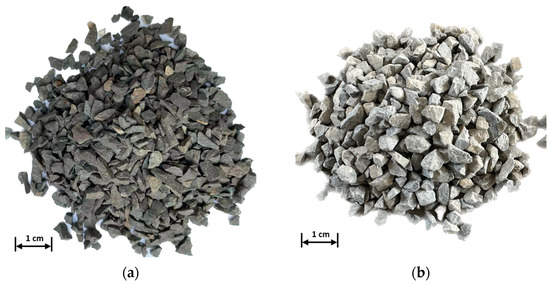

Road icing in winter brings challenges to traffic safety, and microwave heating and deicing technology is an effective method with the advantages of high efficiency and environmental protection. Magnetite has been widely used as a microwave-absorbing material in pavement. In this paper, magnetite

[...] Read more.

Road icing in winter brings challenges to traffic safety, and microwave heating and deicing technology is an effective method with the advantages of high efficiency and environmental protection. Magnetite has been widely used as a microwave-absorbing material in pavement. In this paper, magnetite powder formed by crushing natural magnetite and high-purity Fe

3O

4 powder after purification were mixed to replace mineral powder, and the magnetite aggregate was used to replace the limestone aggregate with the same particle size to enhance the asphalt mixtures’ microwave absorption capacity. The effect of microwave heating time and microwave power on the heating of the asphalt mixtures was studied, and the heating performance of different thicknesses of the asphalt mixtures under microwave radiation was evaluated. The heating performance of the mixtures under different initial temperatures and ice layer thicknesses was also assessed. The results showed that the addition of the magnetite powder–Fe

3O

4 powder and the magnetite aggregate significantly enhanced the heating performance of the asphalt mixtures by microwave heating. The replacement of the magnetite powder–Fe

3O

4 powder, the microwave heating time, and the microwave power had positive effects on the heating efficiency of the asphalt mixtures. Moreover, the thinner asphalt mixtures had a better heating performance. The heating and deicing performance of the mixtures decreased with a decline in initial temperature. As the ice thickness increased, the deicing time of the specimen surface to reach 0 °C also increased.

Full article

►▼

Show Figures

Open AccessArticle

A Study of Strength Parameter Evolution and a Statistical Damage Constitutive Model of Cemented Sand and Gravel

by

Honglei Ren, Xin Cai, Yingli Wu, Peiran Jing and Wanli Guo

Cited by 5 | Viewed by 1130

Abstract

Cemented sand and gravel (CSG) has a wide range of applications in dam construction, and its properties are between rockfill and roller compacted concrete (RCC). A difference in gel content will result in a variance in CSG’s structure and mechanical properties. To investigate

[...] Read more.

Cemented sand and gravel (CSG) has a wide range of applications in dam construction, and its properties are between rockfill and roller compacted concrete (RCC). A difference in gel content will result in a variance in CSG’s structure and mechanical properties. To investigate the intricate structural mechanical properties of CSG, this study conducted a series of laboratory tests and associated discrete element analyses. Accordingly, the evolution law of the strength parameters of CSG is explored and a statistical damage constitutive model suitable for CSG is established. The main contributions of this study are as follows: (1) The failure mechanism of the CSG was described from the microscopic level, and the evolution law of the strength parameter cohesion and friction angle of the CSG was analyzed and summarized. (2) Based on the particle flow model, the energy development law and the spatiotemporal distribution law of acoustic emission (AE) provide illustrations of the strain hardening–softening transition features and the interaction between cohesion and friction of CSG. (3) The evolution function between the strength parameter and the strain softening parameter was built, and the critical strain softening parameter was determined by the microcrack evolution law of the particle flow model. (4) The accuracy of the evolution curve was confirmed by comparing it to experimental results. (5) Based on the relationship between cohesion loss and material damage, a statistical damage constitutive model was developed using the improved Mohr–Coulomb strength criterion as the micro strength function. The constitutive model can accurately describe the stress–strain curves of CSG with different gel content. Furthermore, the model reflects the strain hardening–softening properties of CSG and reveals the relationship between the weakening of cohesion and material damage at the microscopic level. These findings provide valuable guidelines for investigating the damage laws and microcosmic failure features of CSG and other relevant materials.

Full article

►▼

Show Figures

Open AccessArticle

Influence of Scale Effect on Strength and Deformation Characteristics of Rockfill Materials

by

Hongxing Han, Jing Li, Jicun Shi and Cuina Yang

Cited by 1 | Viewed by 1421

Abstract

The hybrid method was adopted to model the original gradation of rockfill materials. According to the specification requirements, three simulated gradations of rockfill materials have been obtained. By the same token, the corresponding maximum particle sizes are 20 mm, 40 mm and 60

[...] Read more.

The hybrid method was adopted to model the original gradation of rockfill materials. According to the specification requirements, three simulated gradations of rockfill materials have been obtained. By the same token, the corresponding maximum particle sizes are 20 mm, 40 mm and 60 mm, respectively. With samples prepared under the same criterion of relative density, the scale effect on strength and deformation characteristics of the rockfill materials were studied by large-scale and consolidated-drained triaxial compression tests. The results show that when the confining pressure is higher, the peak deviator stress decreases with the increase of the maximum particle size. With the increase of the maximum particle size, the cohesion of rockfill materials gradually increases and the internal friction angle gradually decreases. Under the condition of the same maximum particle size, with the increase of confining pressure, the volume strain at the phase transition increases gradually, while the stress ratio at the phase transition decreases. Under the same confining pressure, the larger the particle size is, the smaller the volume strain becomes and the lower the stress ratio at the phase transition is. Therefore, the research results can provide a theoretical basis for establishing the constitutive model of rockfill materials considering the scale effect.

Full article

►▼

Show Figures

Open AccessArticle

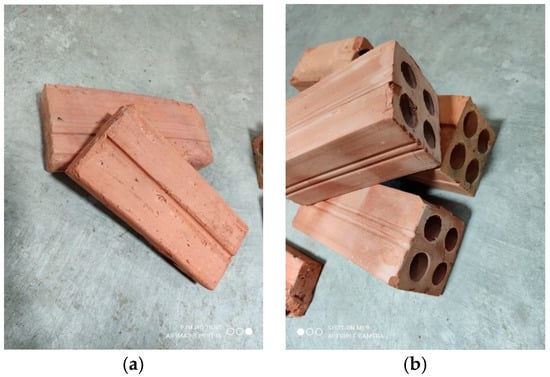

Derivation of Empirical Relationships to Predict Cambodian Masonry Strength

by

Nurmurat Kandymov, Nor Fazilah Mohd Hashim, Syuhaida Ismail and Serdar Durdyev

Cited by 3 | Viewed by 1518

Abstract

Masonry material characteristics, such as compressive strength, and the relationship between brick, mortar, and masonry compressive strengths are required for the analysis and assessment of masonry structures. This paper aimed to investigate the compressive strength relationship of Cambodian masonry. A total number of

[...] Read more.

Masonry material characteristics, such as compressive strength, and the relationship between brick, mortar, and masonry compressive strengths are required for the analysis and assessment of masonry structures. This paper aimed to investigate the compressive strength relationship of Cambodian masonry. A total number of 42 prisms were constructed in the laboratory using six different brick/mortar combinations. Two brick types, solid and hollow, and three—1:3, 1:4, and 1:6—cement–sand mortar combinations were used. The effects of brick and mortar strengths were analysed. Using regression analysis, a simple empirical relationship was derived for masonry compressive strength as a function of brick and mortar strength in the Cambodian context.

Full article

►▼

Show Figures

Open AccessArticle

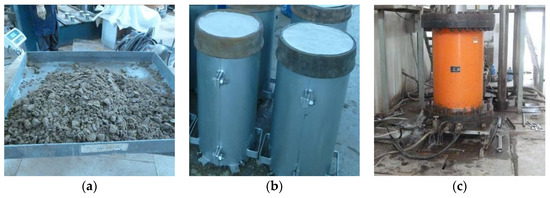

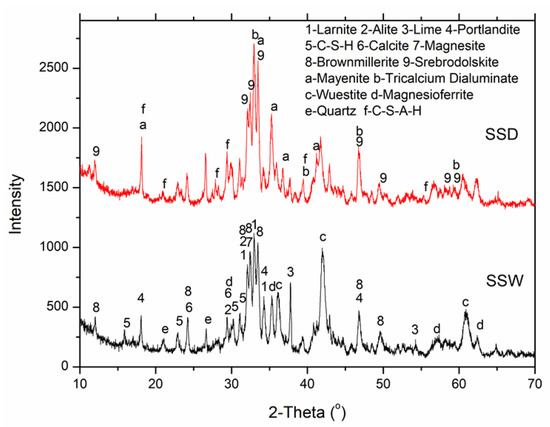

Carbonation Curing on Magnetically Separated Steel Slag for the Preparation of Artificial Reefs

by

Jiajie Li, Shaowei Zhao, Xiaoqian Song, Wen Ni, Shilong Mao, Huihui Du, Sitao Zhu, Fuxing Jiang, Hui Zeng, Xuejie Deng and Michael Hitch

Cited by 12 | Viewed by 2396

Abstract

Magnetic separation is an effective method to recover iron from steel slag. However, the ultra-fine tailings generated from steel slag become a new issue for utilization. The dry separation processes generates steel slag powder, which has hydration activity and can be used as

[...] Read more.

Magnetic separation is an effective method to recover iron from steel slag. However, the ultra-fine tailings generated from steel slag become a new issue for utilization. The dry separation processes generates steel slag powder, which has hydration activity and can be used as cement filler. However, wet separation processes produce steel slag mud, which has lost its hydration activity and is no longer suitable to be used as a cement filler. This study investigates the potential of magnetically separated steel slag for carbonation curing and the potential use of the carbonated products as an artificial reef. Steel slag powder and steel slag mud were moulded, carbonation-cured and seawater-cured. Various testing methods were used to characterize the macro and micro properties of the materials. The results obtained show that carbonation and hydration collaborated during the carbonation curing process of steel slag powder, while only carbonation happened during the carbonation curing process of steel slag mud. The seawater-curing process of carbonated steel slag powder compact had three stages: C-S-H gel formation, C-S-H gel decomposition and equilibrium, which were in correspondence to the compressive strength of compact increasing, decreasing and unchanged. However, the seawater-curing process of carbonated steel slag mud compact suffered three stages: C-S-H gel decomposition, calcite transfer to vaterite and equilibrium, which made the compressive strength of compact decreased, increased and unchanged. Carbonated steel slags tailings after magnetic separation underwent their lowest compressive strength when seawater-cured for 7 days. The amount of CaO in the carbonation active minerals in the steel slag determined the carbonation consolidation ability of steel slag and durability of the carbonated steel slag compacts. This paper provides a reference for preparation of artificial reefs and marine coagulation materials by the carbonation curing of steel slag.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceReview

Alternative Clinker Technologies for Reducing Carbon Emissions in Cement Industry: A Critical Review

by

Mónica Antunes, Rodrigo Lino Santos, João Pereira, Paulo Rocha, Ricardo Bayão Horta and Rogério Colaço

Cited by 33 | Viewed by 5166

Abstract

Currently, the production of one ton of ordinary Portland cement (OPC) releases considerable amounts of CO

2 into the atmosphere. As the need and demand for this material grows exponentially, it has become a challenge to increase its production at a time when

[...] Read more.

Currently, the production of one ton of ordinary Portland cement (OPC) releases considerable amounts of CO

2 into the atmosphere. As the need and demand for this material grows exponentially, it has become a challenge to increase its production at a time when climate-related problems represent a major global concern. The two main CO

2 contributors in this process are fossil fuel combustion to heat the rotary kiln and the chemical reaction associated with the calcination process, in the production of the clinker, the main component of OPC. The current paper presents a critical review of the existent alternative clinker technologies (ACTs) that are under an investigation trial phase or under restricted use for niche applications and that lead to reduced emissions of CO

2. Also, the possibility of transition of clinker production from traditional rotary kilns based on fuel combustion processes to electrification is discussed, since this may lead to the partial or even complete elimination of the CO

2 combustion-related emissions, arising from the heating of the clinker kiln.

Full article

►▼

Show Figures

Open AccessReview

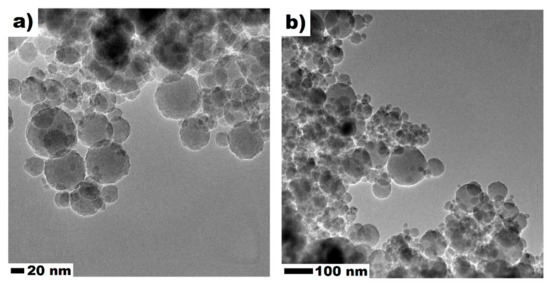

Modification of Lightweight Aggregate Concretes with Silica Nanoparticles—A Review

by

Karol Federowicz, Mateusz Techman, Myroslav Sanytsky and Pawel Sikora

Cited by 16 | Viewed by 2985

Abstract

The use of lightweight concrete (LWC) for structural and non-structural applications has attracted great interest in recent years. The main benefits include reduced deadload of structural elements and generally lower production and transportation costs. However, a decrease in concrete density often leads to

[...] Read more.

The use of lightweight concrete (LWC) for structural and non-structural applications has attracted great interest in recent years. The main benefits include reduced deadload of structural elements and generally lower production and transportation costs. However, a decrease in concrete density often leads to a decrease in strength and durability. Typically, concretes are mostly modified with mineral additives such as silica fume or fly ash. Because of the recent developments in nanotechnology, research attention has turned to the possibility of improving concrete properties with nanomaterials, i.e., nano-SiO

2. However, there are still certain issues with the dosage and efficiency of nanomaterials. Therefore, in order to establish the current state of knowledge in this field, this review gathers most recent results about the performance of LWC modified with nanomaterials. The review is divided into sections about the influence of nanoparticles on the fresh properties of concrete and their influence on the mechanical and durability characteristics. The paper studies in depth the most common approach to nanomaterials in concrete technology and proposes areas for further development.

Full article

►▼

Show Figures

Open AccessArticle

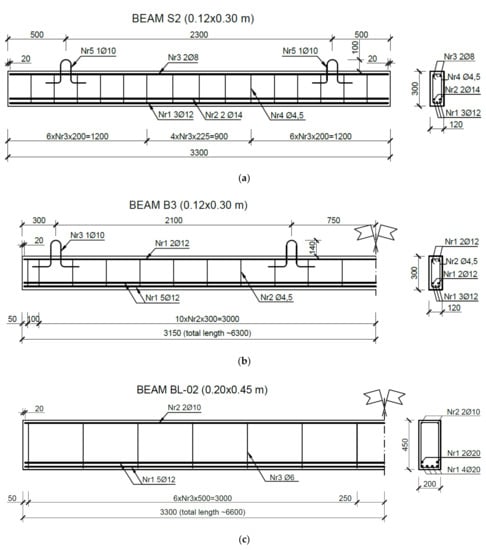

Shear Capacity of Reinforced Concrete Beams under Monotonic and Cyclic Loads: Experiments and Computational Models

by

Kamil Bacharz and Barbara Goszczyńska

Cited by 2 | Viewed by 2444

Abstract

The paper reports the results of a comparative analysis of the experimental shear capacity obtained from the tests of reinforced concrete beams with various static schemes, loading modes and programs, and the shear capacity calculated using selected models. Single-span and two-span reinforced concrete

[...] Read more.

The paper reports the results of a comparative analysis of the experimental shear capacity obtained from the tests of reinforced concrete beams with various static schemes, loading modes and programs, and the shear capacity calculated using selected models. Single-span and two-span reinforced concrete beams under monotonic and cyclic loads were considered in the analysis. The computational models were selected based on their application to engineering practice, i.e., the approaches implemented in the European and US provisions. Due to the changing strength characteristics of concrete, the analysis was also focused on concrete contribution in the shear capacity of reinforced concrete beams in the cracked phase and on the angle of inclination of diagonal struts. During the laboratory tests, a modern ARAMIS digital image correlation (DIC) system was used for tracking the formation and development of diagonal cracks.

Full article

►▼

Show Figures

Open AccessArticle

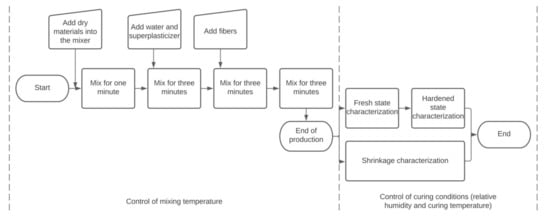

Shrinkage Mitigation of an Ultra-High Performance Concrete Submitted to Various Mixing and Curing Conditions

by

Cédric Androuët and Jean-Philippe Charron

Cited by 12 | Viewed by 2913

Abstract

Ultra-High Performance Concretes (UHPC) are cement-based materials with a very low water-to-binder ratio that present a very-high compressive strength, high tensile strength and ductility as well as excellent durability, making them very interesting for various civil engineering applications. However, one drawback of UHPC

[...] Read more.

Ultra-High Performance Concretes (UHPC) are cement-based materials with a very low water-to-binder ratio that present a very-high compressive strength, high tensile strength and ductility as well as excellent durability, making them very interesting for various civil engineering applications. However, one drawback of UHPC is their pretty high autogenous shrinkage stemming from their very low water-to-binder ratio. There are several options to reduce UHPC shrinkage, such as the use of fibers (steel fibers, polypropylene fibers, wollastonite microfibers), shrinkage-reducing admixtures (SRA), expansive admixtures (EA), saturated lightweight aggregates (SLWA) and superabsorbent polymers (SAP). Other factors related to curing conditions, such as humidity and temperature, also affect the shrinkage of UHPC. The aim of this paper is to investigate the impact of various SRA, different mixing and curing conditions (low to moderate mixing temperatures, moderate to high relative humidity and water immersion) as well as different curing starting times and durations on the shrinkage of UHPC. The major importance of the initial mixing and curing conditions has been clearly demonstrated. It was shown that the shrinkage of the UHPC was reduced by more than 20% at early-age and long-term when the fresh UHPC temperature was closer to 20 °C. In addition, curing by water immersion led to drastic reductions in shrinkage of up to 65% and 30% at early-age and long-term, respectively, in comparison to a 20% reduction for fog curing at early-age. Finally, utilization of a liquid polyol-based SRA allowed for reductions of 69% and 63% of early-age and long-term shrinkages, respectively, while a powder polyol-based SRA provided a decrease of 47% and 35%, respectively.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

The Influence of External Environmental Conditions on Properties of Ceramic Building Materials with Waste Material Additives

by

Maria Wesołowska, Anna Kaczmarek and Jerzy Hoła

Viewed by 1744

Abstract

In this paper, we analyze the state of conservation of ceramic building materials (clay masonry units) containing a large share of waste materials in the form of ash and slag from coal combustion and sawdust from wood processing, operated for several decades in

[...] Read more.

In this paper, we analyze the state of conservation of ceramic building materials (clay masonry units) containing a large share of waste materials in the form of ash and slag from coal combustion and sawdust from wood processing, operated for several decades in facing walls of religious buildings, in external environment conditions. For the purpose of this analysis, comparative tests were carried out on the samples of ceramic materials cut out from facing walls and samples extracted from the same ceramic materials; they were stored in laboratory conditions for the entire time. The following were investigated: initial water absorption, capillary rise, and porosity structure determined with mercury intrusion porosimetry (MIP). The research has shown, among other things, that the ceramic materials exploited in the external environment are characterized by an almost twofold increase in the initial rate of water absorption and by a different size of dominant pores and a pore size distribution in comparison with ceramic materials stored in laboratory conditions. The results, obtained for ceramic building materials (clay masonry units) containing the above-mentioned waste materials in their composition, constitute a novelty. They fill a gap in the literature by establishing how decades-long operation in natural conditions affected the capillary properties and the porosity structure of the ceramics under investigation. Based on the obtained research results, conclusions of cognitive and practical significance have been formulated that relate to the possibility of the exploitation of facing walls made of investigated ceramic materials.

Full article

►▼

Show Figures

Open AccessArticle

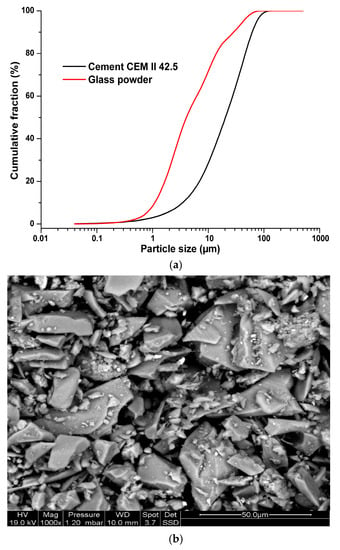

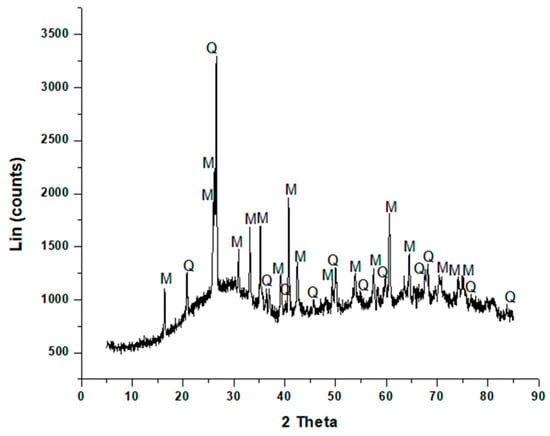

Mechanical and Microstructural Properties of Ordinary Concrete with High Additions of Crushed Glass

by

Cherif Belebchouche, Karim Moussaceb, Salah-Eddine Bensebti, Abdelkarim Aït-Mokhtar, Abdelkader Hammoudi and Slawomir Czarnecki

Cited by 18 | Viewed by 2148

Abstract

This study investigates the use of crushed glass waste as partial cement replacement in ordinary concretes. Six concrete mixes were designed and prepared: a reference without substitution and five substitution percentages of crushed glass waste ranging from 5% to 25%. The made concrete

[...] Read more.

This study investigates the use of crushed glass waste as partial cement replacement in ordinary concretes. Six concrete mixes were designed and prepared: a reference without substitution and five substitution percentages of crushed glass waste ranging from 5% to 25%. The made concrete mix design underwent different tests, namely: slump test, mechanical strength, thermogravimetric analysis (TGA), X-ray diffraction (XRD), Brunauer–Emmett–Teller (BET) determination and finally, water porosimetry, in order to evaluate the influence of the use of crushed glass waste on the properties of fresh and hardened concrete. Mechanical strengths results show that the use of 15% of the crushed glass waste improves the mechanical strength. TGA analysis confirms this result by highlighting a higher hydration degree. The latter contributes to the reduction of the porosity and, consequently, the mechanical strength increases. Also, it can be caused by the increasing amount of chromium which, if added a little, accelerates the hydration of C3S and leads to an increase of the mechanical strength. The BET technique and porosimetry tests showed that the use of crushed glass waste reduces the global porosity of concrete. This is due to the filling effect of the glass powder.

Full article

►▼

Show Figures

Open AccessArticle

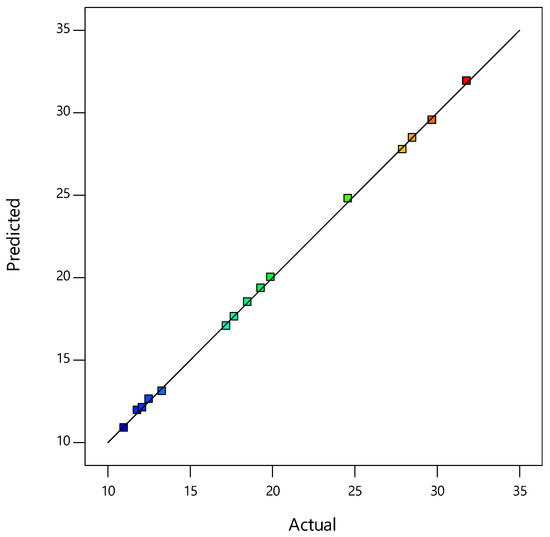

Response Surface Method Analysis of Chemically Stabilized Fiber-Reinforced Soil

by

Abdullah Almajed, Dinesh Srirama and Arif Ali Baig Moghal

Cited by 18 | Viewed by 2424

Abstract

One of the significant issues persisting in the study of soil stabilization is the establishment of the optimum proportions of the quantity of stabilizer to be added to the soil. Determining optimum solutions or the most feasible remedies for the utilization of stabilizing

[...] Read more.

One of the significant issues persisting in the study of soil stabilization is the establishment of the optimum proportions of the quantity of stabilizer to be added to the soil. Determining optimum solutions or the most feasible remedies for the utilization of stabilizing products in terms of their dose rates has become a significant concern in major civil engineering design projects. Using the response surface methodology, this study primarily focused on investigating the optimal levels of reinforcement fiber length (FL), fiber dosage (FD), and curing time (CT) for geotechnical parameters of stabilized soil. To realize this objective, an experimental study was undertaken on the California bearing ratio (CBR) and unconfined compressive strength (UCS). Hydraulic conductivity (HC) tests were also performed, with stabilizer proportions of 6–12 mm for the FL and 0.2–0.6% for the FD calculated for the total dry weight of soil and 6% lime (total weight of dry soil). The curing times used for testing were 0, 7, and 14 days for the CBR tests; 60, 210, and 360 days for the UCS tests; and 7, 17, and 28 days for the HC tests. All practical experiments were conducted with experimental techniques using stabilizer proportions and curing times. The FL, FD, CT, CBR, UCS, and HC response factors were determined using the central composite design. The results point toward a statistically significant model constructed (

p ≤ 0.05) using the analysis of variance. The results from this optimization procedure show that the optimal values for the FL, FD, and CT were 11.1 mm, 0.5%, and 13.2 days, respectively, as these provided the maximum values for the CBR; 11.7 mm for the FL, 0.3% for the FD, and 160 days for the CT corresponded to the maximum values for the UCS; and 10.5 mm for the FL, 0.5% for the FD, and 15 days for the CT led to the minimum value for the HC. In practice, the suggested values may be useful for experiments, especially for preliminary assessments prior to stabilization.

Full article

►▼

Show Figures

Open AccessArticle

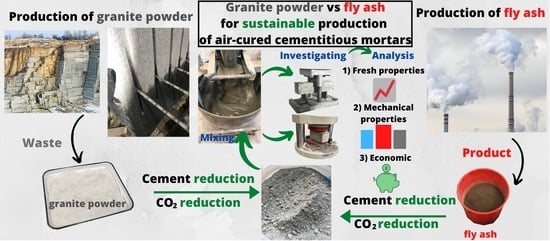

Granite Powder vs. Fly Ash for the Sustainable Production of Air-Cured Cementitious Mortars

by

Adrian Chajec

Cited by 37 | Viewed by 2611

Abstract

The partial replacement of cement in concrete with the addition of granite powder and fly ash can help to reduce the carbon dioxide (CO

2) emissions into the atmosphere associated with cement production. The aim of the article is to compare the

[...] Read more.

The partial replacement of cement in concrete with the addition of granite powder and fly ash can help to reduce the carbon dioxide (CO

2) emissions into the atmosphere associated with cement production. The aim of the article is to compare the performance of granite powder and fly ash for the sustainable production of air-cured cementitious mortars. The morphological, chemical, and granulometric properties of these additives were first compared with the properties of cement. Afterward, a series of mortars modified with the addition of granite powder and fly ash was made. The properties of the fresh mixes and the mechanical properties of the hardened composites were then tested. Finally, based on the obtained results, a cost analysis of the profitability of modifying cementitious composites with granite powder or fly ash was investigated. The obtained results allow similarities and differences between granite powder and fly ash in relation to cement to be shown. To conclude, it should be stated that both of these materials can successfully be used for the sustainable production of air-cured cementitious composites. This conclusion has a significant impact on the possibility of improving the natural environment by reducing the amount of cement production. More sustainable production of cement-based materials could enable CO

2 emissions to be decreased. The use of granite powder for the production of cementitious mortars can significantly reduce the amount of this material deposited in landfills.

Full article

►▼

Show Figures

Open AccessArticle

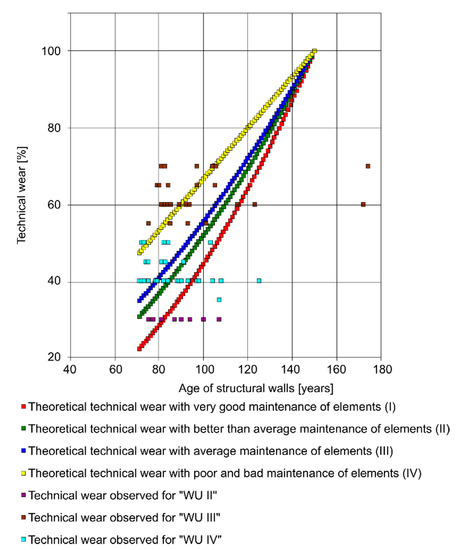

Overdurability and Technical Wear of Materials Used in the Construction of Old Buildings

by

Jarosław Konior

Cited by 2 | Viewed by 1404

Abstract

The technical maintenance of old tenement houses traditionally constructed is an ongoing problem, and will continue to be so in the coming years. The subject of the article includes old residential buildings from the turn of the XIX and XX centuries, which are

[...] Read more.

The technical maintenance of old tenement houses traditionally constructed is an ongoing problem, and will continue to be so in the coming years. The subject of the article includes old residential buildings from the turn of the XIX and XX centuries, which are a part of Wroclaw’s downtown district. They can be understood as an essential link in the process of shaping the cultural and social microenvironment of man. The ability of them to meet the multiple expectations of residents depends on the natural aging of tenement houses’ materials, the methods of their maintenance and use, and the influence of the many factors that cause their accelerated wear. The assumed durability is the main reference parameter of the changing age of the inspected tenement houses. The course of the theoretical and observed degree of the technical wear of these buildings was compared with their durability. For the age of these buildings, the technical wear should reach 100%. It was observed that in the first period of use of tenement houses, the phenomenon of “infradurability” occurs, and after exceeding a certain age—depending on the maintenance conditions of the building—the phenomenon of “overdurability” of the building occurs. It was shown that the durability of important elements of old buildings, as a parameter that was defined “a posteriori”, ranges from 153 to 177 years, and is greater than the corresponding literature values indicated “a priori”. The probability of reaching such an age of an element, in which the observed values of technical wear exceed the theoretical values, is much higher than the probability of an opposite event. A comparative analysis of the distribution functions of these probabilities indicates that the probabilities of theoretical wear values are higher than those observed in the case of the assumed literature durability of elements. There is also an inverse relationship for durability that corresponds to the age of the oldest examined elements of tenement houses.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

The Effects of Temperature Curing on the Strength Development, Transport Properties, and Freeze-Thaw Resistance of Blast Furnace Slag Cement Mortars Modified with Nanosilica

by

Karol Federowicz, Vitoria Alves Figueiredo, Hussein Al-kroom, Hamdy A. Abdel-Gawwad, Mohamed Abd Elrahman and Pawel Sikora

Cited by 9 | Viewed by 2198

Abstract

This investigation studies the effects of hot water and hot air curing on the strength development, transport properties, and freeze-thaw resistance of mortars incorporating low-heat blast furnace slag cement and nanosilica (NS). Mortar samples were prepared and stored in ambient conditions for 24

[...] Read more.

This investigation studies the effects of hot water and hot air curing on the strength development, transport properties, and freeze-thaw resistance of mortars incorporating low-heat blast furnace slag cement and nanosilica (NS). Mortar samples were prepared and stored in ambient conditions for 24 h. After demolding, mortar samples were subjected to two different hot curing methods: Hot water and hot air curing (40 °C and 60 °C) for 24 h. For comparison purposes, mortar reference mixes were prepared and cured in water and air at ambient conditions. Strength development (from 1 to 180 days), capillary water porosity, water sorptivity, and freeze-thaw resistance were tested after 180 days of curing. The experimental results showed that both curing regimes accelerate the strength development of mortars, especially in the first seven days of hydration. The highest early strengths were reported for mortars subjected to a temperature of 60 °C, followed by those cured at 40 °C. The hot water curing regime was found to be more suitable, as a result of more stable strength development. Similar findings were observed in regard to durability-related properties. It is worth noting that thermal curing can more efficiently increase strength in the presence of nanosilica, suggesting that NS is more effective in enhancing strength under thermal curing.

Full article

►▼

Show Figures

Open AccessArticle

Fly Ash-Based Geopolymer Building Materials for Green and Sustainable Development

by

Rosicky Methode Kalombe, Victor Tunde Ojumu, Chuks Paul Eze, Sammy Mwasaha Nyale, John Kevern and Leslie Felicia Petrik

Cited by 36 | Viewed by 3464

Abstract

This study reports on formulations and conditions for producing fly ash-based geopolymers with a view to showing that the compressive strength required for construction applications can be obtained without the addition of aggregates, sand, and/or cement. It was shown in a series of

[...] Read more.

This study reports on formulations and conditions for producing fly ash-based geopolymers with a view to showing that the compressive strength required for construction applications can be obtained without the addition of aggregates, sand, and/or cement. It was shown in a series of experiments constituting at least 73% fly ash that a compressive strength of up to 90 MPa can be obtained depending on the curing conditions. While high alkalinity resulted in stronger materials, the results showed about 40% savings in CO

2 emissions without using sand and cement. Such materials are suited for construction applications with minimal environmental impact.

Full article

►▼

Show Figures

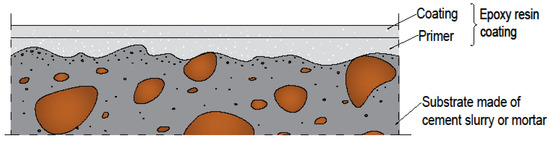

Open AccessArticle

The Effect of the Addition of Polypropylene Fibers to Primer on the Pull-Off Strength of Epoxy Resin Coatings

by

Łukasz Kampa, Agnieszka Chowaniec, Aleksandra Królicka and Łukasz Sadowski

Cited by 9 | Viewed by 2774

Abstract

This article describes the effect of adding polypropylene fibers to primer on the pull-off strength of epoxy resin coatings. Investigated primers were laid on substrates made of cement mortar and cement slurry. The primer was made of epoxy resin modified with the addition

[...] Read more.

This article describes the effect of adding polypropylene fibers to primer on the pull-off strength of epoxy resin coatings. Investigated primers were laid on substrates made of cement mortar and cement slurry. The primer was made of epoxy resin modified with the addition of 0.5%, 1%, 1.5% and 2% of polypropylene fibers. One reference sample was made without the addition of fibers. Then, an epoxy resin coating was applied to each substrate. Four pull-off strength tests were performed for each material configuration. For this purpose, an automatic device for measuring the pull-off strength of the coatings was used. The results were compared with the results obtained for the reference sample. The optimum content of polypropylene fibers was found to be in the range of 0.5–1.0 wt. % of the mass of the resin. One percent of fibers was optimum for the epoxy resin laid on the cement slurry, while 0.5 wt. % of fibers was optimum for the mortar substrate. The addition of a higher amount of polypropylene fibers resulted in a lower pull-off strength of coatings than for the reference sample.

Full article

►▼

Show Figures

Open AccessArticle

Thermal-Insulation Effect and Evaluation Indices of Asphalt Mixture Mixed with Phase-Change Materials

by

Biao Ma, Heting Shi, Jiayun Xu, Kun Wei, Xiaoqing Wang and Yue Xiao

Cited by 3 | Viewed by 1873

Abstract

Under strong winds and at low temperatures, heat loss of hot-mix asphalt mixtures is likely to occur, which leads to temperature segregation. Temperature segregation affects the forming quality and the performance of asphalt pavements. In this study, a phase-change thermal-insulation agent (PCTIA) was

[...] Read more.

Under strong winds and at low temperatures, heat loss of hot-mix asphalt mixtures is likely to occur, which leads to temperature segregation. Temperature segregation affects the forming quality and the performance of asphalt pavements. In this study, a phase-change thermal-insulation agent (PCTIA) was prepared for reducing the temperature dissipation. A cooling simulation experiment was performed to test the temperature-dissipation process for an ordinary asphalt mixture and the asphalt mixture mixed with PCTIA (AM-PCTIA). The thermal-insulation effect was analyzed according to the temperature difference and the thermal-insulation extension time. Moreover, two indices—the thermal-insulation accumulated time difference value (IATDV) and thermal-insulation accumulated time difference index (IATDI)—were proposed for evaluating the thermal-insulation ability and efficiency. The results indicated that the temperature at the center of the AM-PATIA was 4 °C higher than that for the ordinary asphalt mixture. The insulation time was prolonged by 29.8 min at the ambient temperature of 15 °C. As the ambient temperature increased, the thermal-insulation effect of the PCTIA improved.

Full article

►▼

Show Figures

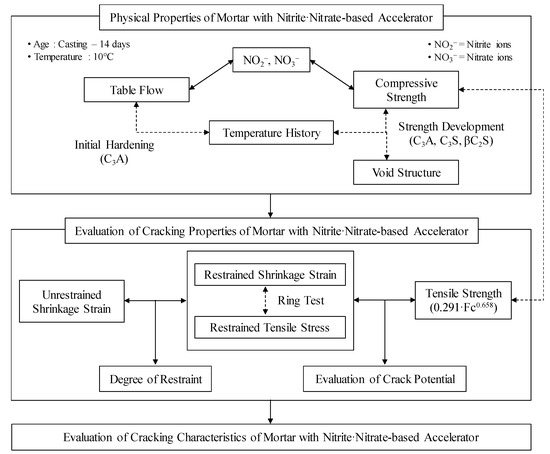

Open AccessArticle

Evaluation of Mechanical and Shrinkage Behavior of Lowered Temperatures Cementitious Mortars Mixed with Nitrite–Nitrate Based Accelerator

by

Yusuke Tomita, Akira Yoneyama, Heesup Choi, Masumi Inoue, Jihoon Kim, Hyeonggil Choi and Yuhji Sudoh

Cited by 7 | Viewed by 1792

Abstract

Recently, calcium nitrite (Ca(NO

2)

2) and calcium nitrate (Ca(NO

3)

2) have been increasingly used as the main components of salt- and alkali-free anti-freezing agents, for promoting concrete hydration in cold-weather concreting. With an increase in the amount

[...] Read more.

Recently, calcium nitrite (Ca(NO

2)

2) and calcium nitrate (Ca(NO

3)

2) have been increasingly used as the main components of salt- and alkali-free anti-freezing agents, for promoting concrete hydration in cold-weather concreting. With an increase in the amount of nitrite-based accelerator, the hydration of C

3A, C

3S, and βC

2S in the cement is accelerated, thereby improving its early strength and effectively preventing the initial frost damage. Meanwhile, with an increase in the amount of nitrite-based accelerator, the expansion and shrinkage of the concrete—and, therefore, the crack occurrence—are expected to increase. In this study, various experiments were conducted on shrinkage, crack initiation, and the development of mortar containing a considerable amount of a nitrite-based accelerator. The result confirmed that, as the amount of nitrite-based accelerator was increased, the shrinkage was increased, and cracking in early age was more likely to occur, compared to the cases without the addition of this accelerator.

Full article

►▼

Show Figures