Feature Papers in Fibers

A topical collection in Fibers (ISSN 2079-6439).

Viewed by 45044

Share This Topical Collection

Editors

Dr. Ionela Andreea Neacsu

Dr. Ionela Andreea Neacsu

Dr. Ionela Andreea Neacsu

Dr. Ionela Andreea Neacsu

E-Mail

Website

Collection Editor

Department of Science and Engineering of Oxide Materials and Nanomaterials, Faculty of Applied Chemistry and Materials Science, University Politehnica of Bucharest, 060042 Bucharest, Romania

Interests: nanomaterials; biomaterials for tissue regeneration; wound-dressings; antimicrobial activity; biomimetic materials; biogenic calcium sources; composite scaffolds

Special Issues, Collections and Topics in MDPI journals

Dr. Alexandru Mihai Grumezescu

Dr. Alexandru Mihai Grumezescu

Dr. Alexandru Mihai Grumezescu

Dr. Alexandru Mihai Grumezescu

E-Mail

Website

Collection Editor

Department of Science and Engineering of Oxide Materials and Nanomaterials, University Politehnica of Bucharest, 011061 Bucharest, Romania

Interests: nanbiomaterials; nanofibers; biofibers; drug delivery and targeting; 3D-printed materials

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

As Guest Editors, we are pleased to announce this Special Issue, entitled “Feature Papers in Fibers”. This Special Issue is dedicated to chemical engineers, materials scientists, biochemists, chemical manufacturers, and other research specialists with specific interests in fiber applications in textile, civil engineering, composites, medical treatment, construction, biology, environment, communications, sensors, transport, sport, etc.

This collection aims to highlight recent advances or new cutting-edge developments in the field of fibers by publishing high-quality reviews and original papers from editorial board members, guest editors, leading researchers, and outstanding scholars invited by the Editorial Board and the Editorial Office.

The potential topics include but are not limited to evaluation of the physical, chemical, and engineering properties of fibrous materials and their applications, natural (plant, animal, mineral) or synthetic fibers, and fiber-reinforced composite materials.

Dr. Ionela Andreea Neacsu

Dr. Alexandru Mihai Grumezescu

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Fibers is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2000 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- natural fibers (plant, animal, mineral)

- synthetic fibers

- fiber preparation and processing

- fiber properties

- fiber characterization

- industrial applications

- biomedical applications

- sustainable fibers

- electrospinning

Published Papers (19 papers)

Open AccessArticle

Strengthening of Laminated Veneer Lumber Slabs with Fiber-Reinforced Polymer Sheets—Preliminary Study

by

Michał Marcin Bakalarz and Paweł Grzegorz Kossakowski

Viewed by 953

Abstract

Analyzing the feasibility of reinforcing new and existing wooden structures is a valid problem, being the subject of numerous scientific papers. The paper presents the preliminary results of a study on reinforcing Laminated Veneer Lumber (LVL) panels with composite materials bonded to exterior

[...] Read more.

Analyzing the feasibility of reinforcing new and existing wooden structures is a valid problem, being the subject of numerous scientific papers. The paper presents the preliminary results of a study on reinforcing Laminated Veneer Lumber (LVL) panels with composite materials bonded to exterior surfaces using epoxy resin. Glass-Fiber-Reinforced Polymer (GFRP) sheets, Carbon-Fiber-Reinforced Polymer (CFRP) sheets, and Ultra-High-Modulus (UHM) CFRP sheets were used as reinforcement. The variables in the analysis were the type of reinforcement and the number of reinforcement layers. The tests were carried out on small samples (45 × 45 × 900 mm) subjected to the so-called four-point bending test. Reinforcement positively affected the mechanical properties of composite section. The highest increases in load bearing were 37 and 48% for two layers of GFRP and CFRP, respectively. The bending stiffness increased up to 53 and 62% for two layers of CFRP and UHM CFRP, respectively. There was a change in failure mode from cracking in the tension zone for unreinforced beams to veneer shear in the support zone (for CFRP and GFRP sheets) and sheet rupture (UHM CFRP). Good agreement was obtained for estimating bending stiffness with the presented numerical and mathematical model; the relative error was up to 6% for CFRP and GFRP and up to 20% for UHM CFRP. This preliminary study proved the effectiveness of combining LVL with FRP sheets and indicated their weak spots, which should be further analyzed to improve their competitiveness against the traditional structures. The key limitation was the shear strength of LVL.

Full article

►▼

Show Figures

Open AccessArticle

Electrospinning Poly(acrylonitrile) Containing Magnetite Nanoparticles: Influence of Magnetite Contents

by

Ana Karen Graciano Alvarez, Marius Dotter, Khorolsuren Tuvshinbayar, Laila Bondzio, Inga Ennen, Andreas Hütten, Tomasz Blachowicz and Andrea Ehrmann

Viewed by 1026

Abstract

Magnetic nanofibers were prepared by electrospinning polymer/metal solutions of poly(acrylonitrile) (PAN) with magnetite (Fe

3O

4) nanoparticles. At a mass ratio of PAN:magnetite of 2:1, the total solid content in the dimethyl sulfoxide (DMSO) solution was varied between 15 wt.% and

[...] Read more.

Magnetic nanofibers were prepared by electrospinning polymer/metal solutions of poly(acrylonitrile) (PAN) with magnetite (Fe

3O

4) nanoparticles. At a mass ratio of PAN:magnetite of 2:1, the total solid content in the dimethyl sulfoxide (DMSO) solution was varied between 15 wt.% and 25 wt.%, which represents the limits of the spinnable range. The results show that the most homogeneous nanofiber mats were 21 wt.% solid contents. At 15 wt.% solid contents, a nano-membrane with some fibrous regions was produced. Nanofibers at 25 wt.% had a much larger and more inhomogeneous diameter. Nevertheless, the magnetic properties of all samples were very similar, indicating that the distribution of magnetite nanoparticles in the fibers is comparable in all samples. The results also suggested that the samples spun from solutions with near-ideal solid contents (19–21 wt.%) contain agglomerations of the nanoparticles inside the nanofibers.

Full article

►▼

Show Figures

Open AccessArticle

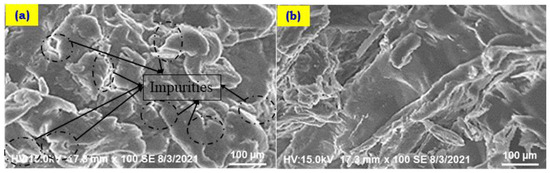

Effect of Elevated Temperature on the Behavior of Amorphous Metallic Fibre-Reinforced Cement and Geopolymer Composites

by

Faiz Uddin Ahmed Shaikh, Narwinder Singh Kahlon and Attiq Ur Rahman Dogar

Cited by 5 | Viewed by 1493

Abstract

To improve the tensile, flexural, and ductility properties of geopolymer composites, amorphous metallic fibres (AMF) are used to reinforce these composites, and the behavior of these composites at elevated temperatures has been assessed in this study. Four types of composites, i.e., cement, reinforced

[...] Read more.

To improve the tensile, flexural, and ductility properties of geopolymer composites, amorphous metallic fibres (AMF) are used to reinforce these composites, and the behavior of these composites at elevated temperatures has been assessed in this study. Four types of composites, i.e., cement, reinforced cement, geopolymer, and reinforced geopolymer composites have been prepared. The composites have been reinforced using AMF with a fibre volume fraction of 0.75%. The composites have been assessed for change in mass loss, cracking, compressive strength, and flexural strength at four elevated temperatures of 200 °C, 400 °C, 600 °C, and 800 °C, and conclusions have been drawn concerning these composites. The results have shown that an increase in temperature has an adverse effect on these composites, and geopolymer composites exhibit higher performance than their counterpart cement composites at elevated temperatures. The mass loss and surface cracking were significantly lower in geopolymer composites, and the fibre reinforcement had a negligible effect on mass loss. Also, the residual compressive and flexural strength of reinforced geopolymer composites was significantly higher than that of the reinforced cement composites. In addition, scanning electron microscopic images also showed that even at higher temperatures, the geopolymer matrix is present on the AMF fibre, which results in higher residual strength than the cement composites in which a negligible amount of matrix is present on the fibres.

Full article

►▼

Show Figures

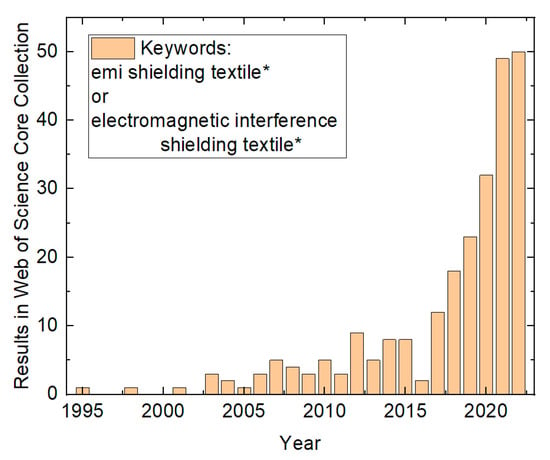

Open AccessReview

Textile Fabrics as Electromagnetic Shielding Materials—A Review of Preparation and Performance

by

Tomasz Blachowicz, Dariusz Wójcik, Maciej Surma, Mirosław Magnuski, Guido Ehrmann and Andrea Ehrmann

Cited by 9 | Viewed by 4580

Abstract

Shielding of instruments and humans from electromagnetic interference (EMI) has become increasingly important during the last decades due to more and more machines and devices radiating electromagnetic waves. While several applications can use rigid shields, more flexibility is enabled by developing bendable, drapable,

[...] Read more.

Shielding of instruments and humans from electromagnetic interference (EMI) has become increasingly important during the last decades due to more and more machines and devices radiating electromagnetic waves. While several applications can use rigid shields, more flexibility is enabled by developing bendable, drapable, ideally even stretchable EMI shielding. Textile fabrics can have these properties, combined with potentially good mechanical properties, depending on the textile structure and the chosen material. On the other hand, the necessary physical properties, especially conductivity and magnetic properties, cannot be taken for granted in normal textile fabrics. These properties have to be added by conductive yarn or layer coatings, integration of conductive or magnetic fibers, producing intrinsically conductive or magnetic fibers, etc. The article gives a critical comparison of the properties of materials typically used for this purpose, such as intrinsically conductive polymers, metal-coated fabrics and metal wires, MXene coatings, MXene fibers, carbon coatings, and fibers. The review concentrates on thematically suitable papers found in the Web of Science and Google Scholar from the last five years and shows that especially MXenes are highly investigated recently due to their high conductivity and EMI shielding effectiveness, while other conductive and magnetic coatings and fibers are nevertheless still interesting for the preparation of EMI shielding textile fabrics.

Full article

►▼

Show Figures

Open AccessArticle

Comparative Study of Atmosphere Effect on Wood Torrefaction

by

Rafael Lopes Quirino, Larissa Richa, Anelie Petrissans, Priscila Rios Teixeira, George Durrell, Allen Hulette, Baptiste Colin and Mathieu Petrissans

Cited by 2 | Viewed by 1749

Abstract

Climate change, biomass utilization, and bioenergy recovery are among the biggest current global concerns. Wood is considered an environmentally benign material. Nevertheless, it must be processed for desired applications. Upon thermal treatment ranging from 180 °C to 280 °C, under low oxygen concentrations,

[...] Read more.

Climate change, biomass utilization, and bioenergy recovery are among the biggest current global concerns. Wood is considered an environmentally benign material. Nevertheless, it must be processed for desired applications. Upon thermal treatment ranging from 180 °C to 280 °C, under low oxygen concentrations, wood becomes a material with improved dimensional stability, resistance to fungal attacks, grindability, hydrophobicity, and storage stability. Several strategies for wood treatment have been investigated over the course of the past decades, including the use of steam, nitrogen, smoke, vacuum, water, and hot oil. The goal of this work is to investigate the influence of pressure and atmosphere on the torrefaction of poplar. Through a systematic analysis of poplar wood samples treated under reduced pressures and different atmospheres, while keeping the same heating profile, it was possible to establish that changes observed for mass loss, color change, wood composition (via TGA/DTG analysis), functional groups (via FTIR), elemental analysis, and X-ray diffractograms relate directly to known reaction pathways occurring during torrefaction. Changes observed under reduced pressures have been associated with the relative concentration of oxygen in the reaction atmosphere and to the reduced diffusion times experienced by reactive by-products during the treatment. Conversely, extended diffusion times resulted in more significant changes for reactions carried out under N

2, water vapor, and air.

Full article

►▼

Show Figures

Open AccessArticle

Performance of Steel Bar Lap Splices at the Base of Seismic Resistant Reinforced Concrete Columns Retrofitted with FRPs—3D Finite Element Analysis

by

Evgenia Anagnostou and Theodoros Rousakis

Cited by 8 | Viewed by 2237

Abstract

This paper examines analytically the design criteria for the composite retrofit of reinforced concrete (RC) columns with a short lap splice length of steel rebars inside the critical region. The advanced potential of pseudo-dynamic three-dimensional (3D) finite element (FE) modelling is utilized to

[...] Read more.

This paper examines analytically the design criteria for the composite retrofit of reinforced concrete (RC) columns with a short lap splice length of steel rebars inside the critical region. The advanced potential of pseudo-dynamic three-dimensional (3D) finite element (FE) modelling is utilized to investigate critical design parameters for the required carbon fiber-reinforced polymer (FRP) jacketing of RC columns with a rectangular cross-section based on the experimental lateral force-to-drift envelope behavior of characteristic cases from the international literature. The satisfactory analytical reproduction of the experimental results allows for the systematic numerical investigation of the developed stress along the lap splice length. The maximum lateral force and the horizontal displacement ductility of the column, as well as the maximum developed tensile axial force on the longitudinal bars, their variation along the lap, the bar yielding, and the plastic hinge length variation, are considered to determine the seismic behavior of the columns. For the first time, cases of smooth bar slip together with delayed bar yielding or without bar yielding are identified that may be recorded through a “ductile” P-d seismic response. Such pseudo-ductile response cases are revisited through suitably revised redesign criteria for adequate FRP jacketing.

Full article

►▼

Show Figures

Open AccessArticle

Angular Momentum of Leaky Modes in Hollow-Core Fibers

by

Grigory Alagashev, Sergey Stafeev, Victor Kotlyar and Andrey Pryamikov

Cited by 2 | Viewed by 1395

Abstract

It is known that angular momentum (AM) is an important characteristic of light, which can be separated into the spin (SAM) and orbital parts (OAM). The dynamical properties of the spin and orbital angular momentums are determined by the polarization and spatial degrees

[...] Read more.

It is known that angular momentum (AM) is an important characteristic of light, which can be separated into the spin (SAM) and orbital parts (OAM). The dynamical properties of the spin and orbital angular momentums are determined by the polarization and spatial degrees of freedom of light. In addition to optical vortex beams possessing spatial polarization and phase singularities, optical fibers can be used to generate and propagate optical modes with the orbital and spin parts of the angular momentum. In this paper, using the example of hollow-core fibers, we demonstrate the fact that their leaky air core modes also have an orbital part of AM in the case of circular polarization arising from the spin–orbit interaction of the air core modes. The reason for the appearance of AM is the leakage of the air core mode energy.

Full article

►▼

Show Figures

Open AccessArticle

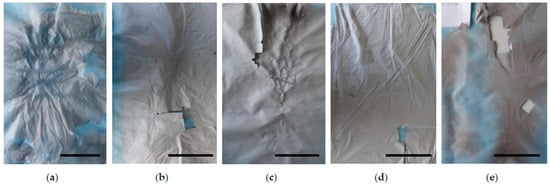

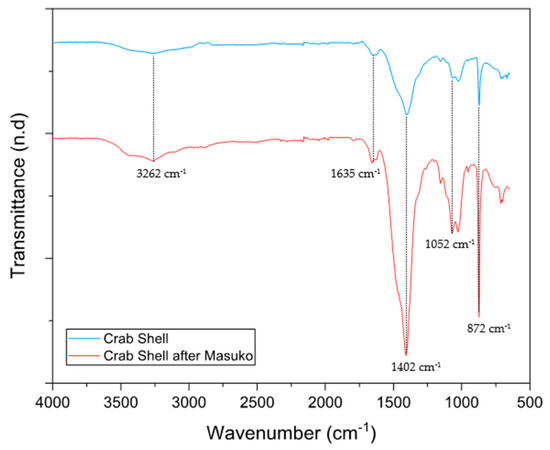

A Unique Crustacean-Based Chitin Platform to Reduce Self-Aggregation of Polysaccharide Nanofibers

by

Carolina Londoño-Zuluaga, Hasan Jameel, Ronalds Gonzalez, Kimberly Nellenbach, Ashley Brown, Guihua Yang and Lucian Lucia

Cited by 2 | Viewed by 1423

Abstract

Every year, over 8 million tons of crustacean shells are discarded. However, there exists an opportunity for valorizing the chitin and calcium carbonate part of the composition of the shells. Our study revealed crustacean chitin reduces self-aggregation effects. It was shown that crustacean-based

[...] Read more.

Every year, over 8 million tons of crustacean shells are discarded. However, there exists an opportunity for valorizing the chitin and calcium carbonate part of the composition of the shells. Our study revealed crustacean chitin reduces self-aggregation effects. It was shown that crustacean-based nanofibers alone or added to cellulose offer unprecedented reductions in viscosity even after drying to produce foams impossible for cellulose. Polysaccharide nanofibers suffer from increased viscosity from strong hydrogen bonding addressed by the incorporation of crustacean-based nanofibers. The ability of the nanocomposite to overcome self-aggregation and collapse was attributed to organized chitin nanofiber morphology in the crustacean matrix. As a result of enhanced surface area from reduced fiber aggregation, the chitin/crustacean-cellulose blend was tested for a biomedical application requiring a high surface area: coagulation. Preliminary experiments showed the crustacean matrices, especially those containing calcium carbonate, induced blood clotting when 35 s. A materials platform is proposed for bio-based nanofiber production overcoming intractable and difficult-to-address self-aggregation effects associated with polysaccharides.

Full article

►▼

Show Figures

Open AccessArticle

Numerical Study of Mid-IR Ultrashort Pulse Reconstruction Based on Processing of Spectra Converted in Chalcogenide Fibers with High Kerr Nonlinearity

by

Arseny A. Sorokin, Alexey V. Andrianov and Elena A. Anashkina

Cited by 1 | Viewed by 1297

Abstract

Ultrashort optical pulses play an important role in fundamental research and applications. It is important to have reliable information about pulse parameters such as duration, intensity profile, and phase. Numerous methods for characterizing pulses in the near-IR range have been well developed by

[...] Read more.

Ultrashort optical pulses play an important role in fundamental research and applications. It is important to have reliable information about pulse parameters such as duration, intensity profile, and phase. Numerous methods for characterizing pulses in the near-IR range have been well developed by now. However, there is a challenge with pulse measurement in the mid-IR, which is largely related to the underdeveloped component base in this spectral range. We investigate by means of numerical simulations a simple method of pulse reconstruction applicable in the mid-IR. The method is based on measuring and processing only the initial pulse spectrum and two converted spectra in elements with Kerr nonlinearity for different

B-integrals characterizing nonlinear phase accumulation. The hardware implementation of the proposed method is very simple. This method requires only a one-dimensional data set, has no moving parts in the optical scheme, and allows for working with high-energy as well as low-energy pulses. We propose a novel simple, efficient, noise-tolerant algorithm for data processing that assumes spectral phase approximation by a polynomial function. We demonstrate numerically the reconstruction of mid-IR ultrashort pulses, namely 3 μm wavelength pulses, using commercial chalcogenide As

2S

3-based glass fibers as nonlinear elements.

Full article

►▼

Show Figures

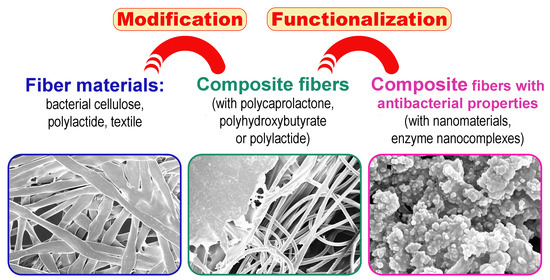

Open AccessFeature PaperArticle

Assessment of Composite with Fibers as a Support for Antibacterial Nanomaterials: A Case Study of Bacterial Cellulose, Polylactide and Usual Textile

by

Ilya Lyagin, Olga Maslova, Nikolay Stepanov, Denis Presnov and Elena Efremenko

Cited by 7 | Viewed by 1876

Abstract

To obtain composite fiber materials with antibacterial properties, the samples of bacterial cellulose (BC), polylactide (PLA) and usual fibers (FM) were modified by poly-ε-caprolactone or polyhydroxybutyrate and then functionalized by the enzyme-polyelectrolyte complex of quorum-quenching enzymes, such as hexahistidine-tagged organophosphorus hydrolase with poly(glutamic

[...] Read more.

To obtain composite fiber materials with antibacterial properties, the samples of bacterial cellulose (BC), polylactide (PLA) and usual fibers (FM) were modified by poly-ε-caprolactone or polyhydroxybutyrate and then functionalized by the enzyme-polyelectrolyte complex of quorum-quenching enzymes, such as hexahistidine-tagged organophosphorus hydrolase with poly(glutamic acid) or by suspension of tantalum nanoparticles (Ta NPs) in ethanol. The structures of the composite fibers were analyzed using scanning electron microscopy. It was shown that the introduction of additional natural polymers into the matrix of BC, PLA and FM resulted in decreasing of the structural porosity. Comparative studies of the antibacterial activity of the composite materials were carried out using

Escherichia coli and

Bacillus subtilis cells. The decrease of adenosine triphosphate concentration in cell samples loaded onto fiber materials was applied as a measurable characteristic of antibacterial effect typical for the new fiber materials. The profound improvement of antibacterial activity was determined in composite materials with polyhydroxybutyrate and Ta NPs.

Full article

►▼

Show Figures

Open AccessArticle

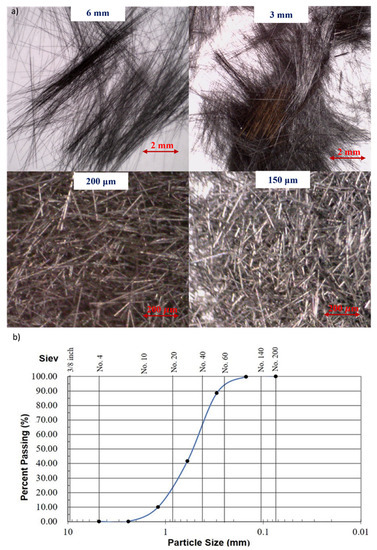

The Significance of Multi-Size Carbon Fibers on the Mechanical and Fracture Characteristics of Fiber Reinforced Cement Composites

by

Mohammed Abdellatef, Daniel Heras Murcia, Joshua Hogancamp, Edward Matteo, John Stormont and Mahmoud M. Reda Taha

Cited by 5 | Viewed by 1943

Abstract

One of the main challenges of using a high fiber volume content in a cement composite is the narrow margin of fiber volume content beyond which fibers can cause an adverse effect on the mechanical properties. In this paper, the significance of fiber

[...] Read more.

One of the main challenges of using a high fiber volume content in a cement composite is the narrow margin of fiber volume content beyond which fibers can cause an adverse effect on the mechanical properties. In this paper, the significance of fiber size distribution and fiber volume content of different proportions of chopped and milled carbon microfibers are investigated. The mixes’ flowability showed improvement with altering the fiber size distribution despite having a high fiber content. Uniaxial compression cylinders and unnotched and notched beams were cast and then tested at 7 and 28 days of age. It was found that the compressive strength is significantly affected by fiber size distribution more than fiber volume content. On the other hand, the modulus of rupture and fracture toughness are proportional to the fiber volume content with little effect of fiber size distribution. Finally, neither high fiber volume content nor altered fiber size distribution significantly affected the elastic modulus of the fiber cement composites.

Full article

►▼

Show Figures

Open AccessArticle

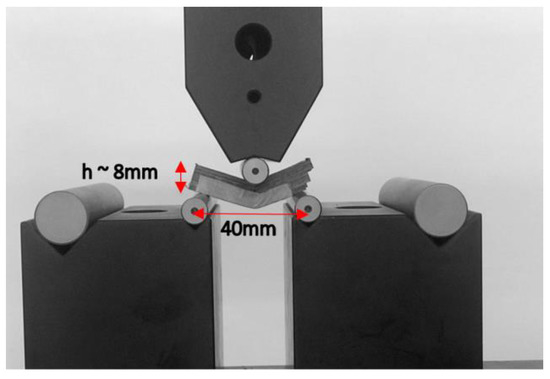

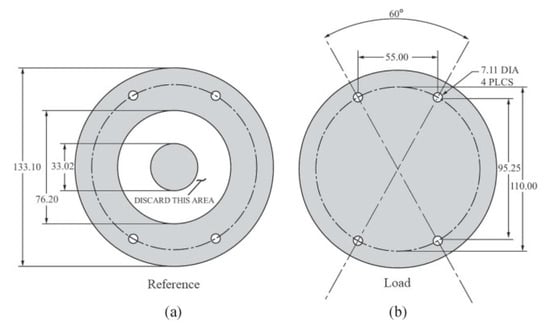

Interlaminar Shear Properties of Bamboo Composite for Structural Applications

by

Ali Rajabipour, Alireza Javadian, Milad Bazli and Mark Masia

Cited by 3 | Viewed by 1812

Abstract

Interlaminar shear strength in bamboo composite (BC) is mainly provided by epoxy resin as the matrix in BC. This may greatly change due to humidity. This study aims at evaluating the shear strength of BC by testing and developing probabilistic relationships. The interlaminar

[...] Read more.

Interlaminar shear strength in bamboo composite (BC) is mainly provided by epoxy resin as the matrix in BC. This may greatly change due to humidity. This study aims at evaluating the shear strength of BC by testing and developing probabilistic relationships. The interlaminar shear strength of bamboo composite (BC) in different moisture conditions was tested according to ASTM D2344. The results show that the maximum shear stress does not generally occur at the centroid of samples, which could be associated with imperfections in BC layers. An extreme value theory-based model is suggested to evaluate the probability of shear failure in BC samples. The shear capacity decreased from 20.4 MPa to 14 MPa as the humidity increased from 60% to 90%. A summary of findings is as follows: It was found that under transient moisture conditions, local failure is likely to happen before the first significant crack occurs. Local failure is suggested to be considered in the design for serviceability. Stress drop caused by the local failure could exceed 10% of total shear strength and, therefore, should be regarded as a serviceability design. The probabilistic model developed in this study could be used for developing structural design safety factors.

Full article

►▼

Show Figures

Open AccessArticle

Experimental Investigation of Effect of Fiber Length on Mechanical, Wear, and Morphological Behavior of Silane-Treated Pineapple Leaf Fiber Reinforced Polymer Composites

by

Praveena Bindiganavile Anand, Avinash Lakshmikanthan, Manjunath Patel Gowdru Chandrashekarappa, Chithirai Pon Selvan, Danil Yurievich Pimenov and Khaled Giasin

Cited by 30 | Viewed by 4310

Abstract

The development of the best properties in polyester composite from pineapple leaf fiber (PALF) as a reinforcing material is a subject of interest. The properties of PALF are reliant upon fiber length, wherein technical difficulties in production of long fibers and processing for

[...] Read more.

The development of the best properties in polyester composite from pineapple leaf fiber (PALF) as a reinforcing material is a subject of interest. The properties of PALF are reliant upon fiber length, wherein technical difficulties in production of long fibers and processing for better characteristics in polyester composites possess inherent challenges. The PALFs are subjected to silane treatment for altering fiber properties. This research attempts to analyze the impact of silane-treated PALF with varying fiber lengths (5, 10, 15, 20, and 25 mm) on the performance of natural fiber composites (NFC) properties. Open mold and hand lay-up techniques were employed to develop the polyester composites. The prepared PALF-based polyester composites were examined for different properties (impact, flexural, tensile strength, and wear rate). Coefficient of friction and wear studies are performed on the prepared composites subjected to different loads (10, 20, and 30 N) via a pin on disc test rig. Polymer composite fracture surfaces were analyzed to observe the interfacial bonding between fibers and matrix via scanning electron microscopy (SEM). SEM results showed that the application of silane treatment resulted in better surface topography (fiber length of 5–10 mm showed smooth surface resulted in crack proliferation possessing low fracture toughness of 15–32 MPa; whereas a 15–20 mm fiber length resulted in better fiber–matrix bonding, improving the fracture toughness from 42–55 MPa) as a result of change in chemical structure in PALF. The 20 mm length of PALF resulted in better properties (flexural, tensile, impact, and wear resistance) which are attributed to fiber–matrix interfacial bonding. These properties ensure the developed polymer composites can be applied to walls, building insulation, and artificial ceilings.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

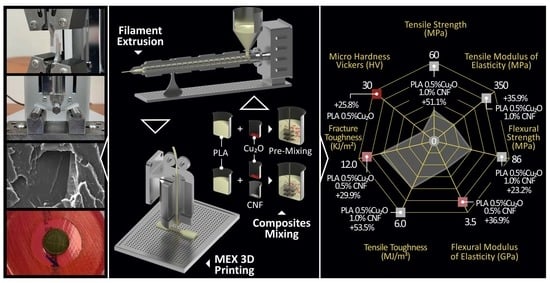

Multifunctional Material Extrusion 3D-Printed Antibacterial Polylactic Acid (PLA) with Binary Inclusions: The Effect of Cuprous Oxide and Cellulose Nanofibers

by

Markos Petousis, Nectarios Vidakis, Nikolaos Mountakis, Vassilis Papadakis, Sotiria Kanellopoulou, Aikaterini Gaganatsiou, Nikolaos Stefanoudakis and John Kechagias

Cited by 34 | Viewed by 3081

Abstract

In this work, we present an effective process easily adapted in industrial environments for the development of multifunctional nanocomposites for material extrusion (MEX) 3D printing (3DP). The literature is still very limited in this field, although the interest in such materials is constantly

[...] Read more.

In this work, we present an effective process easily adapted in industrial environments for the development of multifunctional nanocomposites for material extrusion (MEX) 3D printing (3DP). The literature is still very limited in this field, although the interest in such materials is constantly increasing. Nanocomposites with binary inclusions were prepared and investigated in this study. Polylactic acid (PLA) was used as the matrix material, and cuprous oxide (Cu

2O) and cellulose nanofibers (CNF) were used as nanoadditives introduced in the matrix material to enhance the mechanical properties and induce antibacterial performance. Specimens were built according to international standards with a thermomechanical process. Tensile, flexural, impact, and microhardness tests were conducted. The effect on the thermal properties of the matrix material was investigated through thermogravimetric analysis, and Raman spectroscopic analysis was conducted. The morphological characteristics were evaluated with atomic force microscopy (AFM), scanning electron microscopy (SEM), and energy-dispersive X-ray (EDS) analyses. The antibacterial performance of the prepared nanomaterials was studied against Staphylococcus aureus (

S. aureus) and Escherichia coli (

E. coli) bacteria, with a screening agar well diffusion method. All nanocomposites prepared exhibited biocidal properties against the bacteria tested. The tested PLA/1.0 CNF/0.5 Cu

2O material had 51.1% higher tensile strength and 35.9% higher flexural strength than the pure PLA material.

Full article

►▼

Show Figures

Open AccessArticle

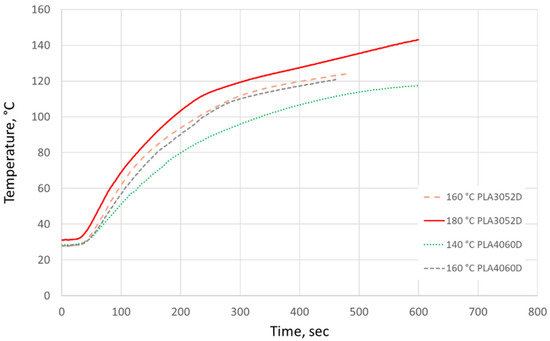

Understanding the PLA–Wood Adhesion Interface for the Development of PLA-Bonded Softwood Laminates

by

Warren J. Grigsby, Marc Gaugler and Desiree Torayno

Cited by 1 | Viewed by 1595

Abstract

With polylactic acid (PLA) usage projected to increase in wood-based composite materials, a study comparing composite processing parameters with resulting PLA−wood adhesion and panel performance is warranted. In this study, PLA-softwood veneer laminates have been prepared and spatial chemical imaging via FTIR analysis

[...] Read more.

With polylactic acid (PLA) usage projected to increase in wood-based composite materials, a study comparing composite processing parameters with resulting PLA−wood adhesion and panel performance is warranted. In this study, PLA-softwood veneer laminates have been prepared and spatial chemical imaging via FTIR analysis was applied to identify PLA bondlines characterizing bondline thickness and the extent of PLA migration into the wood matrix. These PLA–wood adhesion interface characteristics have been compared with the performance of panels varying in pressing temperature, pressing time and PLA grades. For amorphous PLA, bondline thicknesses (60–120 μm) were similar, pressing at 140 °C or 160 °C, whereas with semi-crystalline PLA, the bondline thickness (340 μm) significantly reduced (155–240 μm) only when internal panel temperatures exceeded 140 °C during pressing. Internal temperatures also impacted PLA penetration, with greater PLA migration from bondlines evident with higher pressing temperatures and times with distinctions between PLA grades and bondline position. Performance testing revealed thinner PLA bondlines were associated with greater dry strength for both PLA grades. Cold-water soaking revealed laminated panels exhibit a range of wet-strength performance related to panel-pressing regimes with the semi-crystalline PLA pressed at 180 °C having similar tensile strength in dry and wet states. Moreover, an excellent correlation between wet-strength performance and bondline thickness and penetration values was evident for this PLA grade. Overall, study findings demonstrate PLA wood composite performance can be tuned through a combination of the PLA grade and the pressing regime employed.

Full article

►▼

Show Figures

Open AccessReview

Electromagnetic Interference Shielding with Electrospun Nanofiber Mats—A Review of Production, Physical Properties and Performance

by

Tomasz Blachowicz, Andreas Hütten and Andrea Ehrmann

Cited by 14 | Viewed by 3413

Abstract

With a steadily increasing number of machines and devices producing electromagnetic radiation, especially, sensitive instruments as well as humans need to be shielded from electromagnetic interference (EMI). Since ideal shielding materials should be lightweight, flexible, drapable, thin and inexpensive, textile fabrics belong to

[...] Read more.

With a steadily increasing number of machines and devices producing electromagnetic radiation, especially, sensitive instruments as well as humans need to be shielded from electromagnetic interference (EMI). Since ideal shielding materials should be lightweight, flexible, drapable, thin and inexpensive, textile fabrics belong to the often-investigated candidates to meet these expectations. Especially, electrospun nanofiber mats are of significant interest since they can not only be produced relatively easily and cost efficiently, but they also enable the embedding of functional nanoparticles in addition to thermal or chemical post-treatments to reach the desired physical properties. This paper gives an overview of recent advances in nanofiber mats for EMI shielding, discussing their production, physical properties and typical characterization techniques.

Full article

►▼

Show Figures

Open AccessArticle

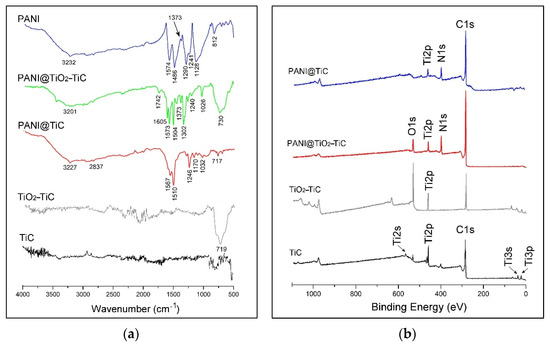

Effects of Incorporating Titanium Dioxide with Titanium Carbide on Hybrid Materials Reinforced with Polyaniline: Synthesis, Characterization, Electrochemical and Supercapacitive Properties

by

Hafida Belhadj, Imane Moulefera, Lilia Sabantina and Abdelghani Benyoucef

Cited by 15 | Viewed by 2599

Abstract

We report on the synthesis of titanium dioxide by titanium carbide for the preparation of hybrid material reinforced with polyaniline (PANI@TiO

2–TiC) using the in situ polymerization technique. The effectiveness of the samples on the thermal, optical and electrochemical properties was investigated.

[...] Read more.

We report on the synthesis of titanium dioxide by titanium carbide for the preparation of hybrid material reinforced with polyaniline (PANI@TiO

2–TiC) using the in situ polymerization technique. The effectiveness of the samples on the thermal, optical and electrochemical properties was investigated. The XRD, XPS, FTIR, SEM and TEM results confirm the successful synthesis of the PANI, PANI@TiC and PANI@TiO

2–TiC samples. Through this, a good connection, an excellent relationship between the structures and the properties of the synthesized hybrid materials were obtained. Moreover, the electrical conductivity and optical bandgap were also tested. Remarkably good electrochemical characteristics were identified by cyclic voltammetry. Moreover, the galvanostatic charge–discharge (GCD) of the supercapacitor was remarkably high. Cyclic stability showed good retention after 1500 cycles at 1.5 A·g

−1.

Full article

►▼

Show Figures

Open AccessArticle

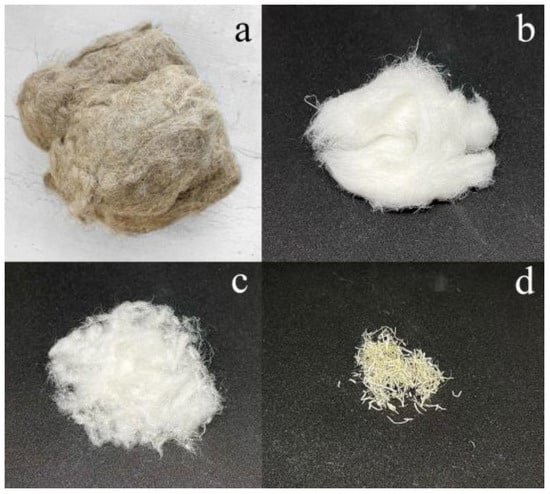

Flax Noils as a Source of Cellulose for the Production of Lyocell Fibers

by

Igor S. Makarov, Lyudmila K. Golova, Alexander G. Smyslov, Markel I. Vinogradov, Ekaterina E. Palchikova and Sergei A. Legkov

Cited by 12 | Viewed by 3454

Abstract

The production of long flax fiber for the subsequent production of textile yarn is accompanied by the formation of a significant amount of waste—noils, which is a mechanical mixture of long and short flax fibers and shives. Comparative studies of the structure and

[...] Read more.

The production of long flax fiber for the subsequent production of textile yarn is accompanied by the formation of a significant amount of waste—noils, which is a mechanical mixture of long and short flax fibers and shives. Comparative studies of the structure and chemical composition of the fibrous fraction of noils and shives were carried out using IR spectroscopy. The solubility of shives and flax noils in N-methylmorpholine-N-oxide (NMMO) was studied, a comparative analysis of the rheological behavior of solutions of flax and wood cellulose was carried out and the optimal temperature–concentration conditions for obtaining flax fibers from noils were determined. It was shown for the first time that using the method of solid-phase activation of the cellulose-solvent system makes it possible to obtain fibers in a short period of time (no more than 10 min). The structure of both the raw material and the resulting fibers was studied by X-ray diffraction analysis. The thermal properties of a new type of cellulose fibers was evaluated. The complex of the conducted studies allows us to consider flax fibers from noils along with flax fibers from long-staple flax, as a real alternative to fibers from wood pulp.

Full article

►▼

Show Figures

Open AccessArticle

Wear Properties and Post-Moisture Absorption Mechanical Behavior of Kenaf/Banana-Fiber-Reinforced Epoxy Composites

by

Sivasubramanian Palanisamy, Mayandi Kalimuthu, Alavudeen Azeez, Murugesan Palaniappan, Shanmugam Dharmalingam, Rajini Nagarajan and Carlo Santulli

Cited by 7 | Viewed by 2866

Abstract

The contribution of natural lignocellulosic fibers to the reduction in wear damage in polymer resins is of interest, especially when two of these fibers can combine their respective effects. Wear properties of hybrid kenaf/banana epoxy composites have been investigated using three different total

[...] Read more.

The contribution of natural lignocellulosic fibers to the reduction in wear damage in polymer resins is of interest, especially when two of these fibers can combine their respective effects. Wear properties of hybrid kenaf/banana epoxy composites have been investigated using three different total amount of fibers, 20, 30 and 40 wt.%, at loading forces up to 30 N and to sliding distances of up to 75 m. This demonstrated that the introduction of the highest level of fibers proved the most suitable for consistency of results and containment of wear with increasing load, as was also found from the morphological evaluation of wear degradation using scanning electron microscopy (SEM). Subsequently, tensile, flexural and impact properties of as-received and post-water-saturation hybrid composites were examined. The tests revealed a limited reduction in tensile and flexural strength, not exceeding 10% of the initial values, which were very high compared to similar materials, almost reaching 140 MPa for tensile strength and exceeding 170 MPa for flexural strength. In contrast, a higher standard deviation of values was found for impact strength, although the decrease in average values was only slightly above 10%. The results suggest the availability of these hybrids for wear-resisting applications in high-moisture environments, and the even more limited water absorption conferred by banana fibers added to kenaf ones.

Full article

►▼

Show Figures

Planned Papers

The below list represents only planned manuscripts. Some of these

manuscripts have not been received by the Editorial Office yet. Papers

submitted to MDPI journals are subject to peer-review.

Title: Lightweight sandwich fiberboards with a shaped core layer

Authors: Piotr Borysiuk, Izabela Burawska, Radosław Auriga, Karol Szymanowski

Affiliation: Institute of Wood Sciences and Furniture, Warsaw University of Life Sciences

Abstract: n.a.

Title: he effect of carbon nanotubes and carbon micro fibers on the piezoresistive and mechanical properties of mortar

Authors: Ioannis A. Kartsonakis, Irene Kanellopoulou, Evangelia K. Karaxi, Athanasia I. Chrysanthopoulou and Costas A. Charitidis

Affiliation: National Technical University of Athens

Abstract: In this study, the mechanical and piezoresistive properties of mortars reinforced with

carbon nanotubes (CNTs) and carbon micro fibers (CMFs) are determined. Silica fume as well as

a polymer with polyalkylene glycol graft chains were used as dispersant agents for the CNTs and

CMFs incorporation into the cement paste . The mechanical properties of the mortar composites

were investigated in respect to their flexural and compressive strength. A four-probe method

was used for the estimation of their piezoresistive response. The test outcomes revealed that the

combination of the dispersant agents along with a low content of CNTs and CMFs by weight of

cement (bwoc) result in the production of a stronger mortar with enhanced mechanical performance

and durability. Moreover, it was observed that the piezoresistive properties of the reinforced

cementitious materials were attributed to the variation of electrical conductivity due to tunneling

transport of electrons. . Current and future opportunities to accelerate progress in the field

through the development of materials with structural sensing and electrical actuation are also

discussed.