Controlling of Combustion Process in Energy and Power Systems

A special issue of Energies (ISSN 1996-1073). This special issue belongs to the section "I2: Energy and Combustion Science".

Deadline for manuscript submissions: closed (30 May 2023) | Viewed by 8842

Special Issue Editors

Interests: low-NOx combustion technology; combustion diagnostics; ammonia combustion

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

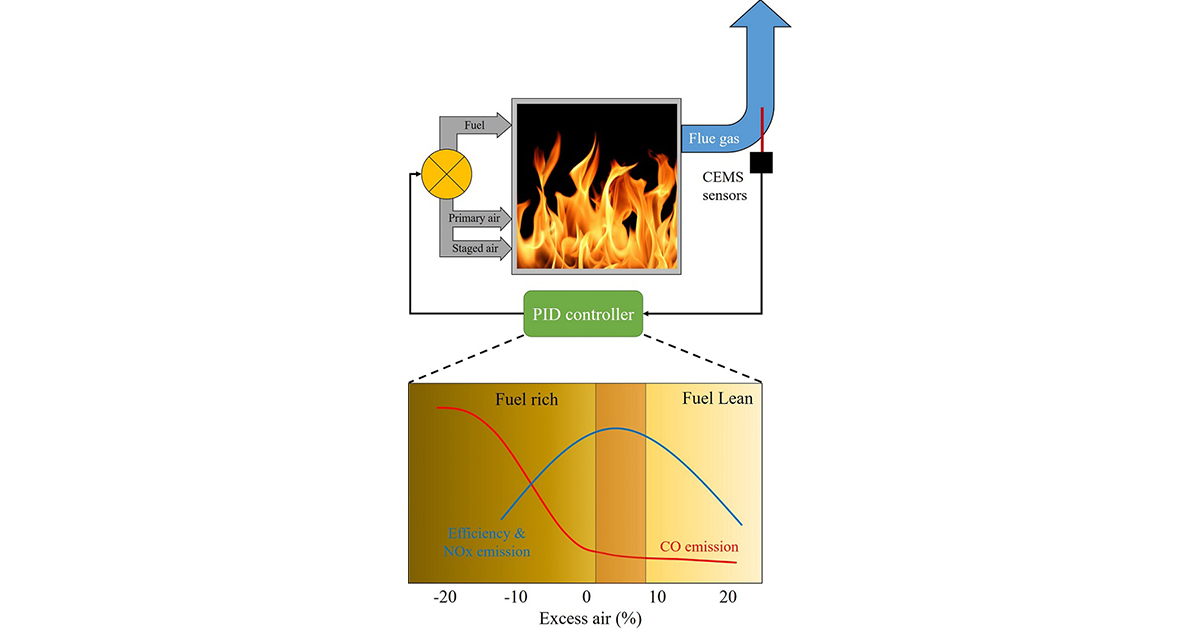

Although the development of renewable energy is currently receiving increasing attention, the global energy supply still heavily relies on combustion process via burning both fossil fuels and traditional biomass in sectors such as boilers, internal combustion engines, gas turbines, and kilns. In order to obtain a higher efficiency while mitigating the environmental impact of these different energy and power systems, it is necessary to effectively control the combustion process in terms of flame temperature, localized oxidizing condition, flue gas residence time, etc. For such aims, manners such as adjusting burner geometries, fuel compositions, injection angles, and air split ratios are usually taken. On the other hand, the control logic is also important and influential to the safe, stable, and economic operation of the combustion system. Therefore, it is of great significance to control combustion process from both hardware and software perspectives.

This Special Issue aims to publish critical reviews and in-depth technical research papers on combustion process control in energy and power systems, with emphasis on combustion efficiency and pollutant emissions.

The topics of interest for this Special Issue include, but are not limited to, the following:

- Advanced combustion control strategies and technologies;

- Combustion pollutant emission control concepts and methods;

- High-efficiency and low-emission combustion theories and technologies;

- Control methods of combustion diagnostics and measurement;

- Combustion control of low-carbon fuels;

- Process modeling and control of combustion systems.

Dr. Yaojie Tu

Dr. Qingguo Peng

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Energies is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- combustion optimization

- combustion system control

- pollutant emission control

- advanced combustion technologies