Journal Description

Fuels

Fuels

is an international, peer-reviewed, open access journal on fuel science, published quarterly online by MDPI. The Institute of Energy and Fuel Processing Technology (ITPE) is affiliated to Fuels and their members receive a discount on the article processing charges.

- Open Access— free for readers, with article processing charges (APC) paid by authors or their institutions.

- High Visibility: indexed within ESCI (Web of Science), EBSCO, and other databases.

- Rapid Publication: manuscripts are peer-reviewed and a first decision is provided to authors approximately 28.9 days after submission; acceptance to publication is undertaken in 11.8 days (median values for papers published in this journal in the second half of 2023).

- Recognition of Reviewers: APC discount vouchers, optional signed peer review, and reviewer names published annually in the journal.

- Fuels is a companion journal of Energies.

Latest Articles

Grindability of Torrefied Camelina Straw and Microparticle Evaluation by Confocal Laser Scanning Microscopy for Use as Biofuel

Fuels 2024, 5(2), 137-156; https://doi.org/10.3390/fuels5020009 - 11 Apr 2024

Abstract

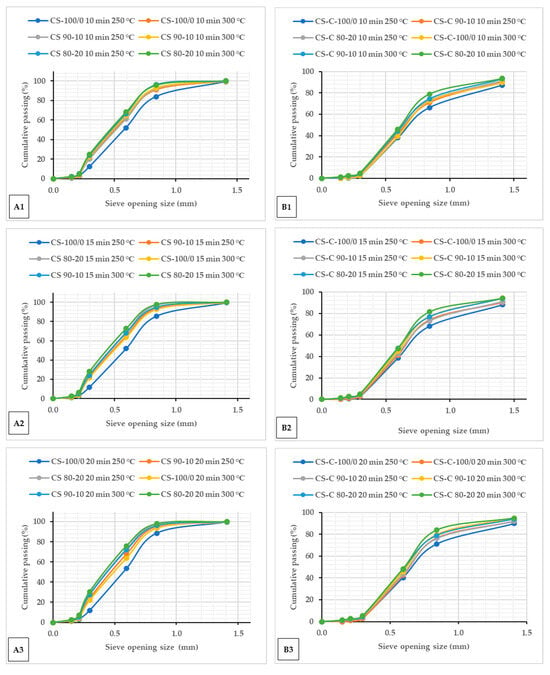

This study examined the combined effect of torrefaction and microwave absorbers on improving biomass thermochemical characteristics and grindability for heat, power, and value-added products. Camelina straw in two grinds, ground (6.4 mm screen size) and chopped with biochar addition (0%, 10% and 20%),

[...] Read more.

This study examined the combined effect of torrefaction and microwave absorbers on improving biomass thermochemical characteristics and grindability for heat, power, and value-added products. Camelina straw in two grinds, ground (6.4 mm screen size) and chopped with biochar addition (0%, 10% and 20%), was torrefied in a bench-scale microwave reactor at torrefaction temperatures of 250 °C and 300 °C with residence times of 10, 15 and 20 min under inert conditions and nitrogen-activated. After torrefaction, the geometric mean particle and size distribution, moisture content, ash content, bulk and particle densities were determined, and the grinding performance values of torrefied ground and chopped with and without biochar were determined and compared with the raw camelina straw. The results showed that the geometric diameter decreased after torrefaction in both grinds. The specific energy required for grinding torrefied biomass decreased significantly with biochar addition, longer residence times, and increased torrefaction temperatures. Torrefied ground camelina straw with biochar after grinding had the lowest grinding energy of 34.30 kJ at 300 °C/20 min. The surface morphology by confocal laser scanning microscopy of torrefied camelina straw particles indicated that biochar addition (>10%) and a torrefaction temperature at 250 °C can create profound surface distortion, and beyond 300 °C, colossal surface damage and carbonized weight fractions were produced.

Full article

(This article belongs to the Special Issue Waste to Fuels and Chemicals: Toward a Clean, Green, and Sustainable World)

►

Show Figures

Open AccessArticle

Carbon Footprint of Oxygenated Gasolines: Case Studies in Latin America, Asia, and Europe

by

John Koupal, Sarah Cashman, Ben Young and Andrew D. Henderson

Fuels 2024, 5(2), 123-136; https://doi.org/10.3390/fuels5020008 - 01 Apr 2024

Abstract

►▼

Show Figures

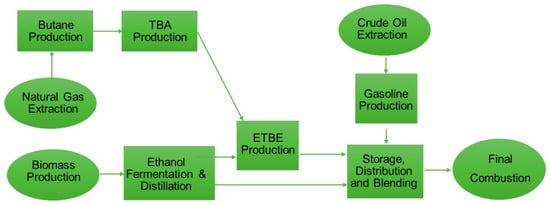

Lifecycle analysis was used to estimate well-to-wheel greenhouse gas (GHG) emissions associated with the production, transport, and use of oxygenated gasoline in Colombia, Japan, and France. The study evaluated fuel blends containing ethanol and/or ethyl tertiary-butyl ether (ETBE) that aligned with oxygen and

[...] Read more.

Lifecycle analysis was used to estimate well-to-wheel greenhouse gas (GHG) emissions associated with the production, transport, and use of oxygenated gasoline in Colombia, Japan, and France. The study evaluated fuel blends containing ethanol and/or ethyl tertiary-butyl ether (ETBE) that aligned with oxygen and octane specifications currently in place or under consideration for each country. For Colombia, fuel blends meeting a 3.7 wt.% oxygen specification were analyzed using ethanol sourced and produced in the U.S. from corn and in Colombia from sugarcane, and ETBE processed in the U.S. Gulf Coast. For Japan, blends with 1.3, 2.7 and 3.7 wt.% oxygen were analyzed using ethanol sourced and produced in the U.S. and Brazil, and ETBE processed in the U.S. Gulf Coast. For France, oxygenated gasoline blends with 3.7 to 8.0 wt.% oxygen content were analyzed with ethanol produced locally from corn, beet, and wood and imported sugarcane ethanol. Data were populated from both publicly available secondary data sources and new primary data developed for ETBE production in the U.S. and Europe. This study also accounted for distinct lifecycle emissions among gasoline components, focused on aromatic-rich reformate used to boost octane in non-oxygenated fuels. Across each country, results indicate that the replacement of reformate in ethanol-free (E0) gasoline with oxygenates up to 3.7 wt.% oxygen reduces lifecycle GHG emissions by 6–9%, with the highest GHG reduction provided when ETBE alone is used for oxygenate. For higher oxygen blends modeled for France, the highest GHG reduction (19%) was for a blend of 51 vol.% ETBE to achieve 8.0 wt.% oxygen, the equivalent of E23 (gasoline with 23 vol.% ethanol). Overall, displacing ethanol with ETBE to achieve a fixed oxygen level increased GHG benefits relative to ethanol-only blends, owing to the greater volume of the carbon-intensive reformate displaced.

Full article

Figure 1

Open AccessArticle

1H NMR and UV-Vis as Analytical Techniques to Evaluate Biodiesel Conversion and Oxidative Stability

by

Emanuelle Braga, Luana Damasceno, Chastryane Barros de Sousa Silva, Lucas Silva, Maria Cavalcante, César Barreto, Silvia Silva, Francisco Murilo Tavares de Luna, Luciana Bertini, Tassio Nascimento and Maria Rios

Fuels 2024, 5(1), 107-122; https://doi.org/10.3390/fuels5010007 - 18 Mar 2024

Abstract

►▼

Show Figures

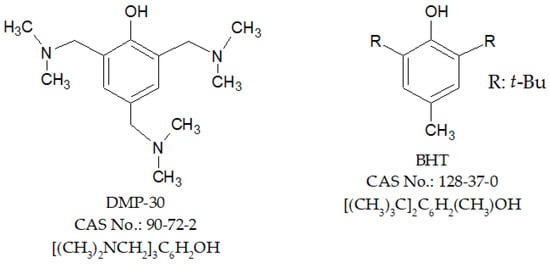

The present study evaluated the applicability of 1H NMR and UV-Vis spectroscopies as analytical techniques for the characterization and determination of biodiesel conversion and for monitoring the oxidative stability of biodiesel samples with antioxidants. For this study, safflower and babassu biodiesels were

[...] Read more.

The present study evaluated the applicability of 1H NMR and UV-Vis spectroscopies as analytical techniques for the characterization and determination of biodiesel conversion and for monitoring the oxidative stability of biodiesel samples with antioxidants. For this study, safflower and babassu biodiesels were obtained through transesterification, and physicochemical properties confirmed the success of both reactions. A bench-top accelerated oxidation system was used as an alternative to the Rancimat® method, with samples of 6.0 g heated at 110 ± 5 °C and collected every 2 h for 12 h. The agreement for biodiesel conversions was good, with divergences between 2% and 0.4% for safflower biodiesel and 1.9% for babassu biodiesel. As for UV-Vis spectroscopy, the technique showed the same trend as the Rancimat® method, showing efficiency in evaluating the oxidative stability of safflower biodiesel and in the performance of antioxidants BHT and DMP-30. The accuracy of NMR signals integration for mixtures of safflower oil and safflower biodiesel and the use of UV-Vis spectroscopy associated with a bench-top accelerated oxidation system to investigate the performance of phenolic and amine antioxidants in safflower and babassu biodiesel were explored for the first time, showing results close to the standard methods. Therefore, 1H NMR and UV-Vis spectroscopies could be applied as alternatives to the GC and Rancimat® methods to determine conversion and monitor the oxidative stability of biodiesel rapidly and practically.

Full article

Figure 1

Open AccessArticle

Numerical Study of Premixed PODE3-4/CH4 Flames at Engine-Relevant Conditions

by

Yupeng Leng, Xiang Ji, Chengcheng Zhang, Nigel Simms, Liming Dai and Chunkan Yu

Fuels 2024, 5(1), 90-106; https://doi.org/10.3390/fuels5010006 - 12 Mar 2024

Abstract

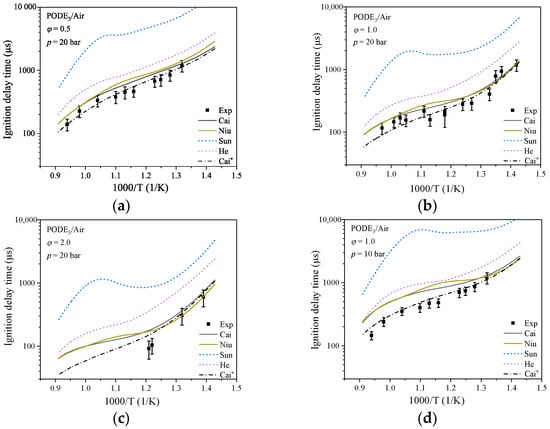

Polyoxymethylene dimethyl ether (PODEn, n ≥ 1) is a promising alternative fuel to diesel with higher reactivity and low soot formation tendency. In this study, PODE3-4 is used as a pilot ignition fuel for methane (CH4) and the

[...] Read more.

Polyoxymethylene dimethyl ether (PODEn, n ≥ 1) is a promising alternative fuel to diesel with higher reactivity and low soot formation tendency. In this study, PODE3-4 is used as a pilot ignition fuel for methane (CH4) and the combustion characteristics of PODE3-4/CH4 mixtures are investigated numerically using an updated PODE3-4 mechanism. The ignition delay time (IDT) and laminar burning velocity (LBV) of PODE3-4/CH4 blends were calculated at high temperature and high pressure relevant to engine conditions. It is discovered that addition of a small amount of PODE3-4 has a dramatic promotive effect on IDT and LBV of CH4, whereas such a promoting effect decays at higher PODE3-4 addition. Kinetic analysis was performed to gain more insight into the reaction process of PODE3-4/CH4 mixtures at different conditions. In general, the promoting effect originates from the high reactivity of PODE3-4 at low temperatures and it is further confirmed in simulations using a perfectly stirred reactor (PSR) model. The addition of PODE3-4 significantly extends the extinction limit of CH4 from a residence time of ~0.5 ms to that of ~0.08 ms, indicating that the flame stability is enhanced as well by PODE3-4 addition. It is also found that NO formation is reduced in lean or rich flames; moreover, NO formation is inhibited by too short a residence time.

Full article

(This article belongs to the Special Issue Chemical Kinetics of Biofuel Combustion)

►▼

Show Figures

Figure 1

Open AccessArticle

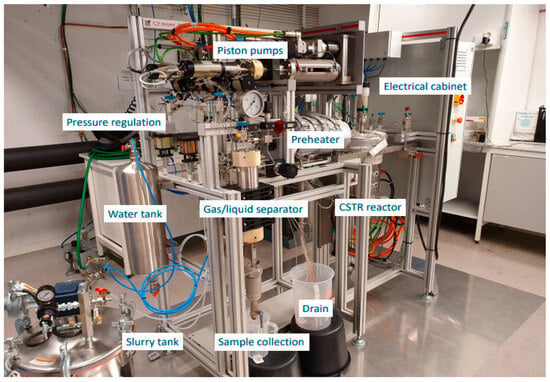

Sub-Supercritical Hydrothermal Liquefaction of Lignocellulose and Protein-Containing Biomass

by

Ayaz Ali Shah, Kamaldeep Sharma, Tahir Hussain Seehar, Saqib Sohail Toor, Judit Sandquist, Inge Saanum and Thomas Helmer Pedersen

Fuels 2024, 5(1), 75-89; https://doi.org/10.3390/fuels5010005 - 26 Feb 2024

Abstract

►▼

Show Figures

Hydrothermal liquefaction (HTL) is an emerging technology for bio-crude production but faces challenges in determining the optimal temperature for feedstocks depending on the process mode. In this study, three feedstocks—wood, microalgae spirulina (Algae Sp.), and hydrolysis lignin were tested for sub-supercritical HTL

[...] Read more.

Hydrothermal liquefaction (HTL) is an emerging technology for bio-crude production but faces challenges in determining the optimal temperature for feedstocks depending on the process mode. In this study, three feedstocks—wood, microalgae spirulina (Algae Sp.), and hydrolysis lignin were tested for sub-supercritical HTL at 350 and 400 °C through six batch-scale experiments. An alkali catalyst (K2CO3) was used with wood and hydrolysis lignin, while e (Algae Sp.) was liquefied without catalyst. Further, two experiments were conducted on wood in a Continuous Stirred Tank Reactor (CSTR) at 350 and 400 °C which provided a batch versus continuous comparison. Results showed Algae Sp. had higher bio-crude yields, followed by wood and lignin. The subcritical temperature of 350 °C yielded more biocrude from all feedstocks than the supercritical range. At 400 °C, a significant change occurred in lignin, with the maximum percentage of solids. Additionally, the supercritical state gave higher values for Higher Heating Values (HHVs) and a greater amount of volatile matter in bio-crude. Gas Chromatography and Mass Spectrometry (GCMS) analysis revealed that phenols dominated the composition of bio-crude derived from wood and hydrolysis lignin, whereas Algae Sp. bio-crude exhibited higher percentages of N-heterocycles and amides. The aqueous phase analysis showed a Total Organic Carbon (TOC) range from 7 to 22 g/L, with Algae Sp. displaying a higher Total Nitrogen (TN) content, ranging from 11 to 13 g/L. The pH levels of all samples were consistently within the alkaline range, except for Wood Cont. 350. In a broader perspective, the subcritical temperature range proved to be advantageous for enhancing bio-crude yield, while the supercritical state improved the quality of the bio-crude.

Full article

Figure 1

Open AccessArticle

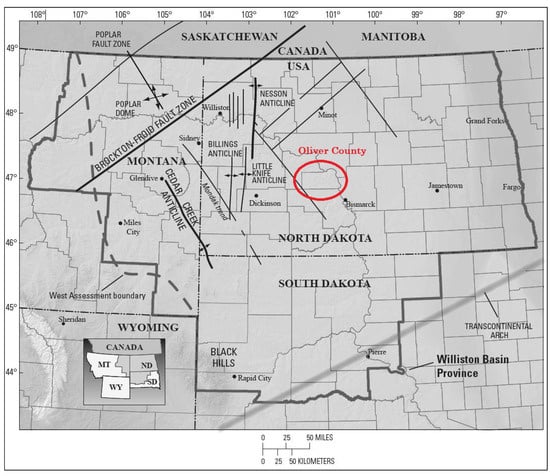

Integrated Petrophysical Evaluation and Rock Physics Modeling of Broom Creek Deep Saline Aquifer for Geological CO2 Storage

by

Prasad Pothana, Ghoulem Ifrene and Kegang Ling

Fuels 2024, 5(1), 53-74; https://doi.org/10.3390/fuels5010004 - 06 Feb 2024

Abstract

►▼

Show Figures

Fossil fuels, such as coal and hydrocarbons, are major drivers of global warming and are primarily responsible for worldwide greenhouse gas emissions, including carbon dioxide CO2. The storage of CO2 in deep saline reservoirs is acknowledged as one of the

[...] Read more.

Fossil fuels, such as coal and hydrocarbons, are major drivers of global warming and are primarily responsible for worldwide greenhouse gas emissions, including carbon dioxide CO2. The storage of CO2 in deep saline reservoirs is acknowledged as one of the top practical and promising methods to reduce CO2 emissions and meet climate goals. The North Dakota Industrial Commission (NDIC) recently approved the fourth Class VI permit for a carbon capture and storage project in the Williston basin of North Dakota for the geological CO2 storage in the Broom Creek formation. The current research aimed to conduct a comprehensive petrophysical characterization and rock physics modeling of the Broom Creek deep saline reservoir to unravel the mineralogical distribution and to understand the variations in petrophysical and elastic properties across the formation. This study utilized geophysical well logs, routine core analysis, and advanced core analysis to evaluate the Broom Creek formation. Multimineral petrophysical analysis calibrated with X-ray diffraction results reveals that this formation primarily comprises highly porous clean sandstone intervals with low-porosity interspersed with dolomite, anhydrite, and silt/clay layers. The formation exhibits varying porosities up to 0.3 and Klinkenberg air permeabilities up to ∼2600 mD. The formation water resistivity using Archie’s equation is approximately 0.055 ohm-m at 150 °F, corresponding to around 63,000 ppm NaCl salinity, which is consistent with prior data. The pore throat distribution in the samples from clean sandstone intervals is primarily situated in the macro-mega scales. However, the presence of anhydrite and dolomite impedes both porosity and pore throat sizes. The accurate prediction of effective elastic properties was achieved by developing a rock physics template. Dry rock moduli were modeled using Hill’s average, while Berryman’s self-consistent scheme was employed for modeling saturated moduli.

Full article

Figure 1

Open AccessArticle

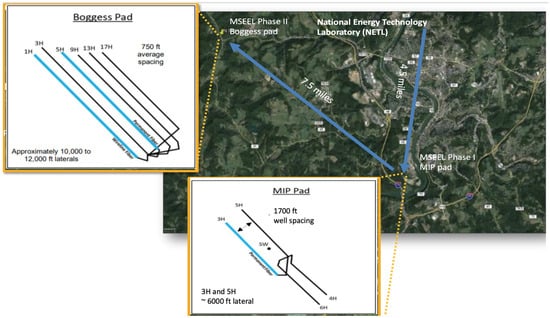

Application of Fiber Optics for Completion Design Optimization: A Methodological Approach and Key Findings

by

Ebrahim Fathi, Fatemeh Belyadi, Mohammad Faiq Adenan and Christian Pacheco

Fuels 2024, 5(1), 33-52; https://doi.org/10.3390/fuels5010003 - 30 Jan 2024

Abstract

►▼

Show Figures

This study investigates the application of fiber optic technology to optimize completion design in a hydraulic fracture stimulation for Marcellus Shale Reservoir. With a focus on improving cluster efficiencies and overcoming interstage communication challenges, the research utilizes real-time data from distributed acoustic (DAS),

[...] Read more.

This study investigates the application of fiber optic technology to optimize completion design in a hydraulic fracture stimulation for Marcellus Shale Reservoir. With a focus on improving cluster efficiencies and overcoming interstage communication challenges, the research utilizes real-time data from distributed acoustic (DAS), temperature (DTS), and strain (DSS) measurements. The methodology comprises a comprehensive analysis of completion and stimulation reports, fiber optics, microseismic data, and well logs. Conducted at the MSEEL well pads, MIP, and Boggess, and equipped with permanent and deployable fiber optic cables, this study emphasizes that engineered/geomechanical completion design leads to sustained cluster efficiency and stage production performance. Inefficient cluster efficiencies are primarily linked to fracture communication. Recommendations include employing a geomechanical completion design, avoiding non-uniform high natural fracture zones during hydraulic fracture stimulations, implementing short stage length, and using more 100 mesh sand. These insights, derived from correlations between fracture counts, distributed strain sensing (DSS), cluster efficiency, production logging, and production data, offer significant implications for optimizing completion design in unconventional reservoirs. The effective application of fiber optic technology, providing real-time DAS, DTS, and slow strain data, proves instrumental in addressing interstage communication challenges, contributing to improved reservoir performances and cost-effective operations in hydraulic fracture stimulations.

Full article

Figure 1

Open AccessArticle

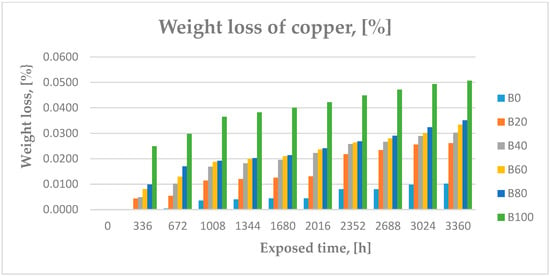

Corrosion Effect of Biodiesel-Diesel Blend on Different Metals/Alloy as Automotive Components Materials

by

Ancaelena Eliza Sterpu, Bianca Georgiana Simedrea, Timur Vasile Chis and Olga Valerica Săpunaru

Fuels 2024, 5(1), 17-32; https://doi.org/10.3390/fuels5010002 - 15 Jan 2024

Cited by 1

Abstract

►▼

Show Figures

Biodiesel has emerged as a progressively widespread and significant alternative to traditional diesel fuel within the transportation sector. Despite its growing popularity, the issue of corrosive tendencies upon interaction with both moving and static components of diesel engines and fuel systems poses a

[...] Read more.

Biodiesel has emerged as a progressively widespread and significant alternative to traditional diesel fuel within the transportation sector. Despite its growing popularity, the issue of corrosive tendencies upon interaction with both moving and static components of diesel engines and fuel systems poses a serious concern. This research endeavors to assess the corrosion characteristics of materials commonly found in automotive fuel systems when exposed to various blends of rapeseed oil biodiesel and diesel. The study involved static immersion tests, lasting 3360 h at room temperature, using B0, B20, B40, B60, B80, and B100 fuels. Copper, brass, aluminum, zinc, and stainless steel plate samples were subjected to these tests. The evaluation at the conclusion of the study included weight loss measurements, corrosion rate calculations, and observation of changes in the exposed metal surfaces. Surface morphology was scrutinized using a Bresser LCD MICRO 5MP digital microscope. Additionally, the total acid number (TAN) was employed to assess alterations in fuel acidity before and after the immersion tests.

Full article

Figure 1

Open AccessArticle

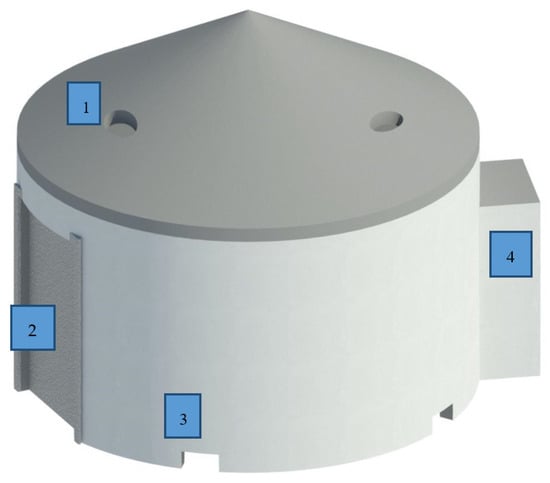

Effect of Firewood Moisture Content on Quality, Yield, and Economic Gain during Charcoal Production in a Modified Half-Orange Kiln

by

Juan García-Quezada, Ricardo Musule-Lagunes, Christian Wehenkel, José Angel Prieto-Ruíz, Víctor Núñez-Retana and Artemio Carrillo-Parra

Fuels 2024, 5(1), 1-16; https://doi.org/10.3390/fuels5010001 - 25 Dec 2023

Cited by 2

Abstract

Tropical firewood species are of foremost importance for charcoal production worldwide. The objective of this study was to evaluate the impact of the moisture content of tropical fuelwood on charcoal production in modified Argentinean half-orange kilns in terms of yield, quality, and economic

[...] Read more.

Tropical firewood species are of foremost importance for charcoal production worldwide. The objective of this study was to evaluate the impact of the moisture content of tropical fuelwood on charcoal production in modified Argentinean half-orange kilns in terms of yield, quality, and economic viability. Ten tropical species from the state of Quintana Roo, Mexico, were selected for charcoal production. The data were analyzed using a completely randomized design. The moisture content of the firewood was 48.99–79.31%. Temperatures close to 500 °C were obtained in the three kilns, as well as production yields of 28% with a consumption of 6.4 m3 of firewood and 38% with a consumption of 4.5–5 m3. Charcoal moisture values of less than 8%, volatile material of 20–30%, ash < 8%, fixed carbon of 60–70%, and higher heating values of 28–30 MJ kg−1 were obtained. Burn I obtained the highest energy yield of 54%, with a production of 20.87 MWh of charcoal recovered. The production cost of the kiln for the producer is USD 0.00825 (MXN 0.16) per MJ.

Full article

(This article belongs to the Special Issue Renewable and Sustainable Biofuel Production: Technical, Economic and Environmental Aspects)

►▼

Show Figures

Figure 1

Open AccessArticle

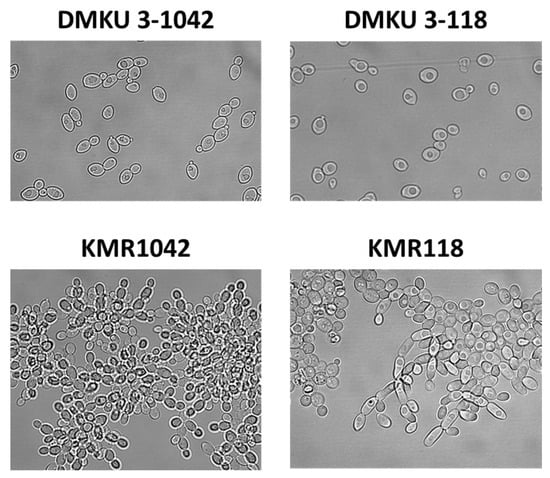

Mutants with Enhanced Multi-Stress Tolerance of Kluyveromyces marxianus and Their Ability for Ethanol Fermentation

by

Noppon Lertwattanasakul, Sornsiri Pattanakittivorakul, Sukanya Nitiyon, Minenosuke Matsutani, Akihiro Oguchi, Katsushi Hirata, Tomoyuki Kosaka, Savitree Limtong and Mamoru Yamada

Fuels 2023, 4(4), 469-483; https://doi.org/10.3390/fuels4040029 - 30 Nov 2023

Cited by 1

Abstract

Kluyveromyces marxianus is an attractive thermotolerant yeast species for ethanol production because of its ability to utilize various carbon sources as a fermentation substrate. The use of thermotolerant microorganisms enables the performance of high-temperature ethanol fermentation, which has several advantages, including the reduction

[...] Read more.

Kluyveromyces marxianus is an attractive thermotolerant yeast species for ethanol production because of its ability to utilize various carbon sources as a fermentation substrate. The use of thermotolerant microorganisms enables the performance of high-temperature ethanol fermentation, which has several advantages, including the reduction of cooling costs and minimization of contamination risks. To improve K. marxianus for ethanol fermentation under stress conditions, two strains, DMKU 3-1042 and DMKU 3-118, were adapted for heat resistance and resistance to toxic substances in pulp wastewater from a paper mill, respectively, resulting in the generation of KMR1042 and KMR118, respectively. Both adapted mutants exhibited clumpy clusters of cells as pseudo-hyphae and altered colony morphology, and their sedimentation speeds were much faster than those of the corresponding parent strains. The two mutants showed stronger tolerance to various stresses and higher performance for ethanol production than those of the corresponding parent strains at high temperatures or in the presence of toxic substances. Genome sequencing analysis revealed that both mutants had disruption of the same gene, SWI5, despite adaptation under different stress conditions, suggesting that the formation of pseudo-hyphae is a common strategy of K. marxianus for coping with stresses.

Full article

(This article belongs to the Special Issue Biomass Conversion to Biofuels)

►▼

Show Figures

Figure 1

Open AccessArticle

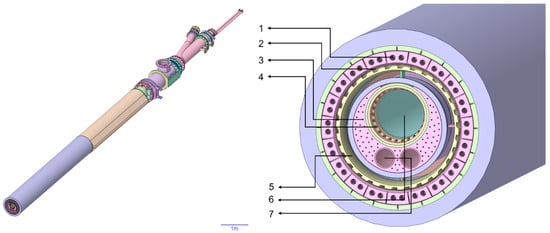

Industrial Rotary Kiln Burner Performance with 3D CFD Modeling

by

Duarte M. Cecílio, Margarida Mateus and Ana Isabel Ferreiro

Fuels 2023, 4(4), 454-468; https://doi.org/10.3390/fuels4040028 - 02 Nov 2023

Cited by 1

Abstract

►▼

Show Figures

As the need to minimize environmental impacts continues to rise, it is essential to incorporate, advance, and adopt renewable energy sources and materials to attain climate neutrality in industrial operations. It is established that economic growth is built upon infrastructure, where the cement

[...] Read more.

As the need to minimize environmental impacts continues to rise, it is essential to incorporate, advance, and adopt renewable energy sources and materials to attain climate neutrality in industrial operations. It is established that economic growth is built upon infrastructure, where the cement industry plays a crucial role. However, it is also known that this industry is actively looking for ways to transition toward low-carbon practices to encourage sustainable and environmentally conscious practices. To this end, the use of refuse-derived fuels to substitute fossil fuels is very appealing, as these have the potential to lower clinker production costs and CO2 emissions. Bearing this in mind, the primary objective of this work is to gain insights into the combustion behavior in an industrial rotary kiln by studying real-life scenarios and to assess the potential of substituting alternative fuels for fossil fuels to reduce CO2 emissions. A 3D CFD turbulent combustion model was formulated in Ansys® considering a Pillard NOVAFLAM® burner, where refuse-derived and petcoke fuels were used, and different secondary air mass flows were considered. From the obtained results, it was possible to conclude that the outcome of the combustion process is greatly influenced by the fuel-to-air ratio. Increasing the secondary air mass flow promotes the occurrence of a complete and efficient combustion process, leading to enhanced fuel conversion and the decreased formation of pollutants such as CO, soot, and unburned hydrocarbons. An increase in combustion efficiency from 93% to 96% was observed, coupled with a slight decrease in the pollutant mass fraction in the flue gas.

Full article

Figure 1

Open AccessArticle

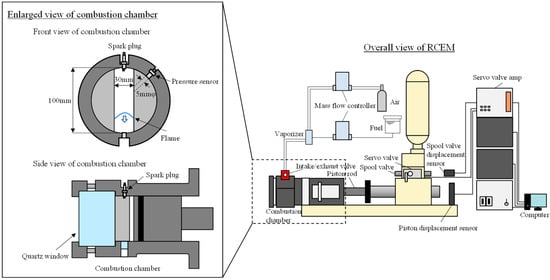

Effect of Blending Dimethyl Carbonate and Ethanol with Gasoline on Combustion Characteristics

by

Shunsuke Suzuki, Eiichi Takahashi, Mitsuharu Oguma and Kazuhiro Akihama

Fuels 2023, 4(4), 441-453; https://doi.org/10.3390/fuels4040027 - 26 Oct 2023

Abstract

We investigated the effects of blending dimethyl carbonate (DMC) and ethanol with commercial gasoline on combustion characteristics. Our experimental approach involved using a rapid compression and expansion machine (RCEM) to achieve elevated temperatures and pressures. The fuels containing different volumes of oxygenated hydrocarbons

[...] Read more.

We investigated the effects of blending dimethyl carbonate (DMC) and ethanol with commercial gasoline on combustion characteristics. Our experimental approach involved using a rapid compression and expansion machine (RCEM) to achieve elevated temperatures and pressures. The fuels containing different volumes of oxygenated hydrocarbons were burned at equivalence ratios of 1.0 or 0.7, an initial temperature of 340 K, and initial pressures of 0.10 or 0.05 MPa. To simulate knocking phenomena, we installed a rectangular channel in the combustion chamber of the RCEM and measured the pressure history inside the chamber. By analyzing the pressure history resulting from the end-gas autoignition, we evaluated the combustion duration and maximum pressure amplitude. Blending both oxygenated fuels with gasoline effectively reduced the maximum-pressure amplitude in the end-gas autoignition, with ethanol exhibiting a more pronounced suppression effect compared to DMC in the same volumetric mixing ratio. At an initial pressure of 0.10 MPa, the combustion durations of DMC/gasoline blends showed non-linear behavior, being shorter than those of pure gasoline and DMC and comparable to those of the ethanol/gasoline blends. However, the blending effect of DMC on combustion durations was greatly mitigated when the initial pressure was reduced to 0.05 MPa. Conversely, the combustion durations for ethanol/gasoline blends showed a nearly monotonic reduction with an increase in the ethanol blending ratio at both initial pressures of 0.10 and 0.05 MPa. Finally, we discussed the differential impact of the blending effect of oxygenated hydrocarbons on combustion characteristics.

Full article

(This article belongs to the Special Issue Advances in Synthetic Fuel)

►▼

Show Figures

Figure 1

Open AccessArticle

Investigating the Impact of Undulation Amplitude of Unconventional Oil Well Laterals on Transient Multiphase Flow Behavior: Experimental and Numerical Study

by

Youcef Khetib, Kegang Ling, Clement Tang, Ala Eddine Aoun, Adesina Samson Fadairo and Habib Ouadi

Fuels 2023, 4(4), 417-440; https://doi.org/10.3390/fuels4040026 - 24 Oct 2023

Cited by 1

Abstract

►▼

Show Figures

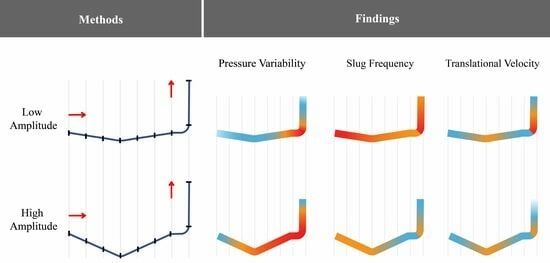

The growing popularity of unconventional wells has led to increased interest in assessing and predicting their production performance. These wells, with their extended-reach structures, are able to generate and access larger reservoir volumes. Therefore, understanding the impact of a well’s lateral trajectory on

[...] Read more.

The growing popularity of unconventional wells has led to increased interest in assessing and predicting their production performance. These wells, with their extended-reach structures, are able to generate and access larger reservoir volumes. Therefore, understanding the impact of a well’s lateral trajectory on its transient production performance is crucial. This study investigates the effect of lateral-trajectory undulation amplitude on flow behavior based on the experimental results obtained at the University of North Dakota using an undulated two-phase (UTP) flow loop. The experiments involved injecting an air-and-water mixture through a section with variable undulation amplitude followed by a vertical section. The results revealed that the increasing undulation amplitude resulted in lower translational velocity, frequency, and length, with consistent slug acceleration along the system profile. Additionally, the frequency of slugs decreased as they traveled through the vertical section. The measured data indicated that higher undulation amplitudes led to increased horizontal pressure losses and variability, suggesting larger instabilities. The numerical simulations predicted lower translational velocity and frequency, longer slug length, and similar vertical pressure losses when compared to the experimental results.

Full article

Graphical abstract

Open AccessArticle

Stress-Dependent Petrophysical Properties of the Bakken Unconventional Petroleum System: Insights from Elastic Wave Velocities and Permeability Measurements

by

Prasad Pothana, Ghoulem Ifrene and Kegang Ling

Fuels 2023, 4(4), 397-416; https://doi.org/10.3390/fuels4040025 - 30 Sep 2023

Abstract

►▼

Show Figures

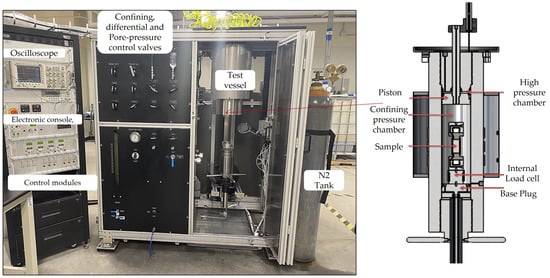

The net-effective stress is a fundamental physical property that undergoes dynamic changes in response to variations in pore pressure during production and injection activities. Petrophysical properties, including porosity, permeability, and wave velocities, play a critical role and exhibit strong dependence on the mechanical

[...] Read more.

The net-effective stress is a fundamental physical property that undergoes dynamic changes in response to variations in pore pressure during production and injection activities. Petrophysical properties, including porosity, permeability, and wave velocities, play a critical role and exhibit strong dependence on the mechanical stress state of the formation. The Williston basin’s Bakken Formation represents a significant reservoir of hydrocarbons within the United States. To investigate this formation, we extracted core plugs from three distinct Bakken members, namely Upper Bakken, Middle Bakken, and Lower Bakken. Subsequently, we conducted a series of measurements of ultrasonic compressional and shear wave velocities, as well as pulse decay permeabilities using nitrogen, under various confining pressures employing the Autolab-1500 apparatus. Our experimental observations revealed that the ultrasonic wave velocities and permeability display a significant sensitivity to stress changes. We investigated existing empirical relationships on velocity-effective stress, compressional-shear wave velocities, and permeability-effective stress, and proposed the best models and associated fitting parameters applicable to the current datasets. In conjunction with the acquired datasets, these models have considerable potential for use in time-lapse seismic monitoring and the study of production decline behavior. The best fitting models can be used to forecast the petrophysical and geomechanical property changes as the reservoir pore pressure is depleted due to the production, which is critical to the production forecast for unconventional reservoirs.

Full article

Figure 1

Open AccessReview

A Comprehensive Review of Fishbone Well Applications in Conventional and Renewable Energy Systems in the Path towards Net Zero

by

Uchenna Frank Ndulue, Olusegun Stanley Tomomewo and Houdaifa Khalifa

Fuels 2023, 4(4), 376-396; https://doi.org/10.3390/fuels4040024 - 25 Sep 2023

Abstract

►▼

Show Figures

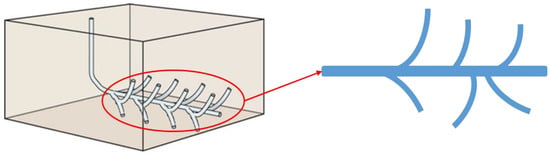

Fishbone drilling (FbD) involves drilling multiple micro-holes branching out in various directions from the primary vertical or deviated wellbore. FbD is similar to multilateral micro-hole drilling and can be employed to boost hydrocarbon production in naturally fractured formations or during refracturing operations by

[...] Read more.

Fishbone drilling (FbD) involves drilling multiple micro-holes branching out in various directions from the primary vertical or deviated wellbore. FbD is similar to multilateral micro-hole drilling and can be employed to boost hydrocarbon production in naturally fractured formations or during refracturing operations by connecting existing natural fractures. Key design elements in fishbones include determining the number, length, and spacing between the branches, and the angle at which the branches deviate from the main borehole. Fishbone wells have emerged as a promising technology for improving well performance and reducing environmental impact. In this paper, we present a comprehensive review of the different applications of fishbone wells in conventional and renewable energy systems. We discuss the potential of fishbone wells for enhanced oil and gas recovery, as well as their application in unconventional resources such as coal bed methane. Moreover, we examine the feasibility of fishbone wells in renewable energy systems, such as geothermal energy and carbon capture, utilization, and storage (CCUS). We highlight the various benefits of fishbone wells, including reduced carbon footprint, enhanced efficiency, and increased sustainability. Finally, we discuss the challenges and limitations associated with fishbone wells in different energy systems. This review provides a comprehensive overview of the potential and challenges of fishbone wells in reducing carbon footprint and improving well performance in a wide range of energy systems.

Full article

Figure 1

Open AccessArticle

CFD Simulation of Hydrogen Sulfide (H2S) Desulfurization Using Ionic Liquids and Graphene Oxide Membrane

by

Alon Davidy

Fuels 2023, 4(3), 363-375; https://doi.org/10.3390/fuels4030023 - 04 Sep 2023

Abstract

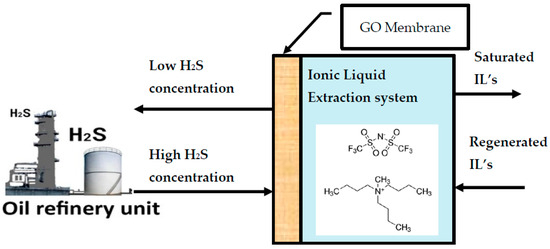

Hydrogen sulfide (H2S) is considered a toxic and corrosive gas, commonly found in natural gas, crude oil, and other fossil fuels. This corrosive gas may lead to stress corrosion cracking (SCC). This phenomenon is caused by the combined influence of tensile

[...] Read more.

Hydrogen sulfide (H2S) is considered a toxic and corrosive gas, commonly found in natural gas, crude oil, and other fossil fuels. This corrosive gas may lead to stress corrosion cracking (SCC). This phenomenon is caused by the combined influence of tensile stress and a corrosive environment. This may lead to the sudden failure of normally ductile metal alloys, especially at an elevated temperature. Desulfurization is the process of removing H2S from these fuels to reduce their harmful environmental and health impacts. Ionic liquids (ILs) have shown great potential for application as liquid absorbents for H2S extraction because of their advantages such as non-volatility, functionality, high carbon solubility and low energy requirements for regeneration. The proposed hydrogen sulfide extraction system consists of a tube, membrane and shell. 1-ethyl-3-methylimidazolium (emim)-based ionic liquids with bis-(trifluoromethyl) sulfonylimide (NTf2) anion has been selected due to its high H2S diffusion coefficient. Functionalized graphene oxide (GO) advanced membranes have been employed in this design. In this research, H2S extraction with ionic liquids has been numerically studied. The COMSOL finite element and multi-physics code has been employed to solve the continuity, turbulent fluid flow (k-ε model), and transient diffusion equations. For small time periods, there is sharp gradient in H2S concentration profile inside the shell section. This is because the diffusion coefficient of H2S in the ionic liquid is very small and the shell section is much thicker than the membrane. It has been determined that H2S is absorbed almost completely by ionic liquids after a time period of 30,000 s.

Full article

(This article belongs to the Special Issue Valorization of Biogenic and Not Biogenic Residuals/Byproducts from Thermochemical Processes: Diagnostic, Product Characterization, and Emissions Control)

►▼

Show Figures

Figure 1

Open AccessArticle

Biofuel Policy-Making Based on Outdated Modelling? The Cost of Road Transport Decarbonisation in EU

by

Zoltán Szabó

Fuels 2023, 4(3), 354-362; https://doi.org/10.3390/fuels4030022 - 31 Aug 2023

Abstract

►▼

Show Figures

The cost of transport decarbonisation matters, yet little information is available. Policies need to reflect the costs to society. The European Union relies on the PRIMES model, a private model with limited transparency. Our research revealed its methodological deficiencies. Based on a revised

[...] Read more.

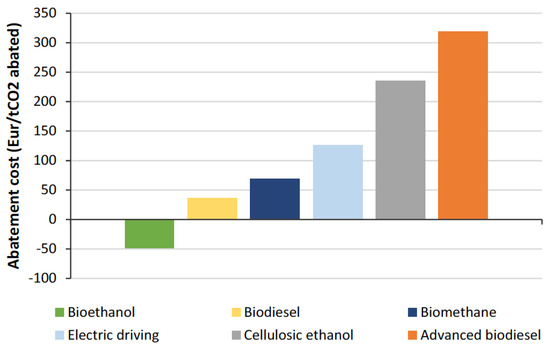

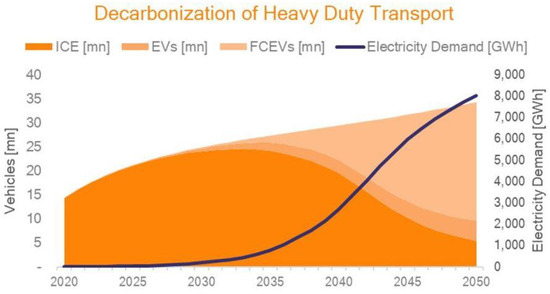

The cost of transport decarbonisation matters, yet little information is available. Policies need to reflect the costs to society. The European Union relies on the PRIMES model, a private model with limited transparency. Our research revealed its methodological deficiencies. Based on a revised PRIMES model, modelling was carried out and compared with an official impact assessment prepared for a key EU policy. Our modelling results indicate that crop-based bioethanol has negative abatement costs, biodiesel and biomethane have costs below 100 EUR/tCO2eq, electromobility falls in the range of 100–150 EUR/tCO2eq, cellulosic ethanol has costs above 200 EUR/tCO2eq, while advanced biodiesel has costs above 300 EUR/tCO2eq. Our results on carbon abatement costs suggest that policy-making has often been based on outdated modelling in the EU. With regard to transport decarbonisation policies, a large number of recent energy and climate proposals by the European Commission seem to have been misguided.

Full article

Figure 1

Open AccessArticle

New Insights into Fracture Porosity Estimations Using Machine Learning and Advanced Logging Tools

by

Ghoulem Ifrene, Doina Irofti, Ruichong Ni, Sven Egenhoff and Prasad Pothana

Fuels 2023, 4(3), 333-353; https://doi.org/10.3390/fuels4030021 - 29 Aug 2023

Abstract

►▼

Show Figures

Fracture porosity is crucial for storage and production efficiency in fractured tight reservoirs. Geophysical image logs using resistivity measurements have traditionally been used for fracture characterization. This study aims to develop a novel, hybrid machine-learning method to predict fracture porosity using conventional well

[...] Read more.

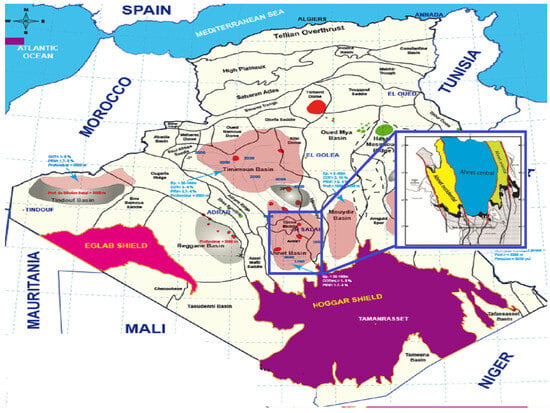

Fracture porosity is crucial for storage and production efficiency in fractured tight reservoirs. Geophysical image logs using resistivity measurements have traditionally been used for fracture characterization. This study aims to develop a novel, hybrid machine-learning method to predict fracture porosity using conventional well logs in the Ahnet field, Algeria. Initially, we explored an Artificial Neural Network (ANN) model for regression analysis. To overcome the limitations of ANN, we proposed a hybrid model combining Support Vector Machine (SVM) classification and ANN regression, resulting in improved fracture porosity predictions. The models were tested against logging data by combining the Machine Learning approach with advanced logging tools recorded in two wells. In this context, we used electrical image logs and the dipole acoustic tool, which allowed us to identify 404 open fractures and 231 closed fractures and, consequently, to assess the fracture porosity. The results were then fed into two machine-learning algorithms. Pure Artificial Neural Networks and hybrid models were used to obtain comprehensive results, which were subsequently tested to check the accuracy of the models. The outputs obtained from the two methods demonstrate that the hybridized model has a lower Root Mean Square Error (RMSE) than pure ANN. The results of our approach strongly suggest that incorporating hybridized machine learning algorithms into fracture porosity estimations can contribute to the development of more trustworthy static reservoir models in simulation programs. Finally, the combination of Machine Learning (ML) and well log analysis made it possible to reliably estimate fracture porosity in the Ahnet field in Algeria, where, in many places, advanced logging data are absent or expensive.

Full article

Figure 1

Open AccessArticle

Green Fleet: A Prototype Biogas and Hydrogen Refueling Management System for Private Fleet Stations

by

Antonio Martín-Márquez, José Francisco Rangel-Serrano, José Manuel Oyola-González, Adrian Talegón-Vázquez, Mario Garrido, Rodrigo García-Velayos, Carla Patricia García-Heras, David Bolonio and Marcelo F. Ortega-Romero

Fuels 2023, 4(3), 314-332; https://doi.org/10.3390/fuels4030020 - 02 Aug 2023

Abstract

Biogas and hydrogen (H2) are breaking through as alternative energy sources in road transport, specifically for heavy-duty vehicles. Until a public network of service stations is deployed for such vehicles, the owners of large fleets will need to build and manage

[...] Read more.

Biogas and hydrogen (H2) are breaking through as alternative energy sources in road transport, specifically for heavy-duty vehicles. Until a public network of service stations is deployed for such vehicles, the owners of large fleets will need to build and manage their own refueling facilities. Fleet refueling management and remote monitoring at these sites will become key business needs. This article describes the construction of a prototype system capable of solving those needs. During the design and development process of the prototype, the standard industry protocols involved in these installations have been considered, and the latest expertise in information technology systems has been applied. This prototype has been essential to determine the Strengths, Challenges, Opportunities and Risks (SCOR) of such a system, which is the first step of a more ambitious project. A second stage will involve setting up a pilot study and developing a commercial system that can be widely installed to provide a real solution for the industry.

Full article

(This article belongs to the Special Issue Renewable and Sustainable Biofuel Production: Technical, Economic and Environmental Aspects)

►▼

Show Figures

Figure 1

Open AccessArticle

Performance Analysis of Hydrogen Production for a Solid Oxide Fuel Cell System Using a Biogas Dry Reforming Membrane Reactor with Ni and Ni/Cr Catalysts

by

Akira Nishimura, Yuki Hayashi, Syogo Ito and Mohan Lal Kolhe

Fuels 2023, 4(3), 295-313; https://doi.org/10.3390/fuels4030019 - 24 Jul 2023

Abstract

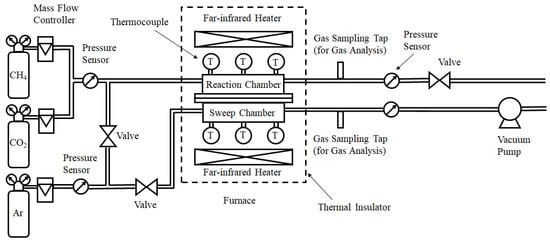

The present study aims to analyze the performance characteristics of the biogas dry reforming process conducted in a membrane reactor using Ni/Cr catalysts and to compare these characteristics with those obtained using pure Ni catalysts. The effect of the pre-set reaction temperature, the

[...] Read more.

The present study aims to analyze the performance characteristics of the biogas dry reforming process conducted in a membrane reactor using Ni/Cr catalysts and to compare these characteristics with those obtained using pure Ni catalysts. The effect of the pre-set reaction temperature, the molar ratio of CH4:CO2 and the pressure difference between the reaction chamber and the sweep chamber on the characteristics of biogas dry reforming is analyzed. In the present work, the molar ratio of the supplied CH4:CO2 is varied to 1.5:1, 1:1 and 1:1.5. In this case, CH4:CO2 = 1.5:1 simulates a biogas. The pressure difference between the reaction chamber and the sweep chamber is varied to 0 MPa, 0.010 MPa and 0.020 MPa. The reaction temperature is changed to 400 °C, 500 °C and 600 °C. It is revealed that the highest concentration of H2 is achieved using a Ni/Cr catalyst when the molar ratio of CH4:CO2 is 1.5:1 at the differential pressure of 0.010 MPa and the reaction temperature of 600 °C. Under this condition, the H2 yield, H2 selectivity and thermal efficiency are 12.8%, 17.5% and 174%, respectively. The concentration of the H2 produced using a Ni/Cr catalyst is larger than that produced using a Ni catalyst regardless of the pre-set reaction temperature, the molar ratio of CH4:CO2 and the differential pressure.

Full article

(This article belongs to the Special Issue Clean and Renewable Hydrogen Fuel)

►▼

Show Figures

Figure 1

Highly Accessed Articles

Latest Books

E-Mail Alert

News

Topics

Topic in

Energies, Sustainability, Machines, Processes, Fuels

Evolution of Land-Based Gas Turbines

Topic Editors: Silvia Ravelli, Pietro BartocciDeadline: 31 August 2024

Conferences

Special Issues

Special Issue in

Fuels

Advances in Synthetic Fuel

Guest Editors: Nicolaus Dahmen, Olaf ToedterDeadline: 15 May 2024

Special Issue in

Fuels

Advances in Propulsion and Energy Systems Utilising Alternative Fuels: Fuel Injection and Combustion Systems

Guest Editors: Steven Begg, Nwabueze EmekwuruDeadline: 31 May 2024

Special Issue in

Fuels

Valorization of Biogenic and Not Biogenic Residuals/Byproducts from Thermochemical Processes: Diagnostic, Product Characterization, and Emissions Control

Guest Editors: Barbara Apicella, Giovanna RuoppoloDeadline: 30 June 2024

Special Issue in

Fuels

Sustainability Assessment of Renewable Fuels Production

Guest Editors: Stella Bezergianni, Loukia P. ChrysikouDeadline: 31 October 2024