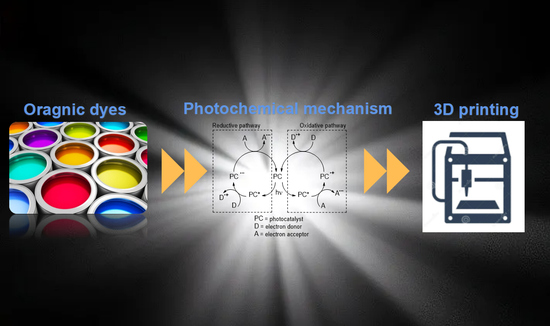

3D Printing/Vat Photopolymerization of Photopolymers Activated by Novel Organic Dyes as Photoinitiators

Abstract

:1. Introduction

2. State-of-the-Art Techniques

- (1)

- There are Type I photoinitiators, which induce the photopolymerization by the following mechanisms [36]:PI → PI* (hν)→R● + R●′

- (2)

- There are Type II photoinitiators, which induce the photopolymerization by the following mechanisms [36]:PI → PI* (hν) + DH→RH● + D●

2.1. Type I Photoinitiators

2.1.1. N-hydroxynaphthalimide Esters

2.1.2. Bis-chalcones Based Oxime Ester Derivatives

| No. | OXEs | Absorption Properties | Conversion |

|---|---|---|---|

| 1 |  NPIE-1 | λmax~397 nm εmax~16,000 M−1 cm−1 ε405nm~15,000 M−1 cm−1 | ~69% in TMPTA @405 nm |

| 2 |  NPIE-2 | λmax~398 nm εmax~15,200 M−1 cm−1 ε405nm~14,400 M−1 cm−1 | ~57% in TMPTA @405 nm |

| 3 |  NPIE-3 | λmax~398 nm εmax~15,600 M−1 cm−1 ε405nm~14,900 M−1 cm−1 | ~61% in TMPTA @405 nm |

| 4 |  NPIE-4 | λmax~397 nm εmax~14,100 M−1 cm−1 ε405nm~13,100 M−1 cm−1 | ~15% in TMPTA @405 nm |

| 5 |  NPIE-5 | λmax ~ 397 nm εmax ~ 15,300 M−1 cm−1 ε405nm~ 14,500 M−1 cm−1 | ~64% in TMPTA @405 nm |

| 6 |  NPIE-6 | λmax~397 nm εmax~14,700 M−1 cm−1 ε405nm~13,800 M−1 cm−1 | ~54% in TMPTA @405 nm |

| 7 |  NPIE-7 | λmax~397 nm εmax~13,500 M−1 cm−1 ε405nm~12,800 M−1 cm−1 | ~67% in TMPTA @405 nm |

| 8 |  NPIE-8 | λmax~397 nm εmax~12,900 M−1 cm−1 ε405nm~12,000 M−1 cm−1 | ~58% in TMPTA @405 nm |

| 9 |  NPIE-9 | λmax~397 nm εmax~14,900 M−1 cm−1 ε405nm~14,000 M−1 cm−1 | ~68% in TMPTA @405 nm |

| 10 |  NPIEMO | λmax~394 nm εmax~11,600 M−1 cm−1 ε405nm~10,200 M−1 cm−1 | ~62% in TMPTA @405 nm |

| 11 |  TA1 | λmax~437 nm εmax~33,750 M−1 cm−1 ε455nm~30,450 M−1 cm−1 | ~78% in HDDA @455 nm |

| 12 |  TA2 | λmax~465 nm εmax~39,530 M−1 cm−1 ε455nm~37,830 M−1 cm−1 | ~66% in HDDA @405 nm ~75% in HDDA @455 nm ~79% in HDDA @470 nm ~72% in HDDA @490 nm |

| 13 |  TA3 | λmax~436 nm εmax~29,380 M−1 cm−1 ε455nm~25,830 M−1 cm−1 | ~56% in HDDA @455 nm |

2.1.3. Nitrocarbazole-Based Oxime Esters

2.2. Type II Photoinitiators

2.2.1. Benzophenone Derivatives

2.2.2. Newly Developed Push–Pull Dyes

Indane-1,3-dione, 1H-cyclopenta[b]naphthalene-1,3(2H)-dione Derivatives

4-dimethoxyphenyl-1-allylidene Derivatives

2.3. Mechanisms of Newly Developed Photo-Reversible Deactivation Radical Polymerization (Photo-RDRP Polymerization) and Their Applications in 3D Printing

2.3.1. Photoinitiator-Reversible Addition–Fragmentation Chain Transfer Polymerization (Photoinitiator-RAFT Polmyerization)

2.3.2. Oxygen-Tolerant Reversible Addition–Fragmentation Chain Transfer Polymerization (Oxygen Tolerant RAFT Polymerization)

2.3.3. Light-Induced Aqueous Reversible Addition–Fragmentation Chain Transfer Polymerization (Aqueous Photo-RAFT Polymerization)

3. Perspective: Semiconducting Nanomaterials Used as Photoinitiators/Photocatalysts during Photopolymerization

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Shin, K.; Hong, J.; Jang, J. Micropatterning of graphene sheets by inkjet printing and its wideband dipole-antenna application. Adv. Mater. 2011, 23, 2113–2118. [Google Scholar] [CrossRef]

- Balkus, K.; Scott, A. Zeolite coatings on three-dimensional objects via laser ablation. Chem. Mater. 1999, 11, 189–191. [Google Scholar] [CrossRef]

- Tumbleston, J.; Shirvanyants, D.; Ermoshkin, N.; Janusziewicz, R.; Johnson, A.R.; Kelly, D.; Chen, K.; Pinschmidt, R.; Rolland, J.; Ermoshkin, A.; et al. Continuous liquid interface production of 3D objects. Science 2015, 347, 1349–1352. [Google Scholar] [CrossRef] [PubMed]

- Xu, Y.; Jambou, C.; Sun, K.; Lalevée, J.; Simon-Masseron, A.; Xiao, P. Effect of zeolite fillers on the photopolymerization kinetics for photocomposites and lithography. ACS Appl. Polym. Mater. 2019, 1, 2854–2861. [Google Scholar] [CrossRef]

- Al Mousawi, A.; Kermagoret, A.; Versace, D.; Toufaily, J.; Hamieh, T.; Graff, B.; Dumur, F.; Gigmes, D.; Fouassier, J.; Lalevée, J. Copper photoredox catalysts for polymerization upon near UV or visible light: Structure/reactivity/efficiency relationships and use in LED projector 3D printing resins. Polym. Chem. 2017, 8, 568–580. [Google Scholar] [CrossRef]

- Al Mousawi, A.; Garra, P.; Dumur, F.; Bui, T.; Goubard, F.; Toufaily, J.; Hamieh, T.; Graff, B.; Gigmes, D.; Fouassier, J.; et al. Novel carbazole skeleton-based photoinitiators for led polymerization and LED projector 3D printing. Molecules 2017, 22, 2143. [Google Scholar] [CrossRef] [Green Version]

- Zips, S.; Wenzel, O.J.; Rinklin, P.; Grob, L.; Terkan, K.; Adly, N.Y.; Weiß, L.; Wolfrum, B. Direct stereolithographic 3D printing of microfluidic structures on polymer substrates for printed electronics. Adv. Mater. Technol. 2019, 4, 1800455. [Google Scholar] [CrossRef]

- Zarek, M.; Layani, M.; Cooperstein, I.; Sachyani, E.; Cohn, D.; Magdassi, S. 3D printing of shape memory polymers for flexible electronic devices. Adv. Mater. 2016, 28, 4449–4454. [Google Scholar] [CrossRef]

- Espera, A.H.; Dizon, J.R.C.; Chen, Q.; Advincula, R.C. 3D-printing and advanced manufacturing for electronics. Prog. Addit. Manuf. 2019, 4, 245–267. [Google Scholar] [CrossRef]

- Price, R.B.; Rizkalla, A.S.; Hall, G.C. Effect of stepped light exposure on the volumetric polymerization shrinkage and bulk modulus of dental composites and an unfilled resin. Am. J. Dent. 2000, 13, 176–180. [Google Scholar]

- Topa, M.; Ortyl, J. Moving Towards a Finer Way of Light-Cured Resin-Based Restorative Dental Materials: Recent Advances in Photoinitiating Systems Based on Iodonium Salts. Materials 2020, 13, 4093. [Google Scholar] [CrossRef]

- Baroli, B. Photopolymerization of biomaterials: Issues and potentialities in drug delivery, tissue engineering, and cell encapsulation applications. J. Chem. Technol. Biotechnol. Int. Res. Process Environ. Clean Technol. 2006, 81, 491–499. [Google Scholar] [CrossRef]

- Choong, Y.Y.C.; Maleksaeedi, S.; Eng, H.; Wei, J.; Su, P.C. 4D printing of high performance shape memory polymer using stereolithography. Mater. Des. 2017, 126, 219–225. [Google Scholar] [CrossRef]

- Zhao, T.; Yu, R.; Li, X.; Cheng, B.; Zhang, Y.; Yang, X.; Zhao, X.; Zhao, Y.; Huang, W. 4D printing of shape memory polyurethane via stereolithography. Eur. Polym. J. 2018, 101, 120–126. [Google Scholar] [CrossRef]

- Sun, K.; Xu, Y.; Dumur, F.; Morlet-Savary, F.; Chen, H.; Dietlin, C.; Graff, B.; Lalevée, J.; Xiao, P. In silico rational design by molecular modeling of new ketones as photoinitiators in three-component photoinitiating systems: Application in 3D printing. Polym. Chem. 2020, 11, 2230–2242. [Google Scholar] [CrossRef]

- Fouassier, J.P.; Lalevée, J. Photoinitiators for Polymer Synthesis–Scope, Reactivity, and Efficiency; John Wiley & Sons: Hoboken, NJ, USA, 2012. [Google Scholar]

- Fouassier, J.P.; Allonas, X.; Burget, D. Photopolymerization reactions under visible lights: Principle, mechanisms and examples of applications. Prog. Org. Coat. 2003, 47, 16–36. [Google Scholar] [CrossRef]

- Sun, K.; Liu, S.; Pigot, C.; Brunel, D.; Graff, B.; Nechab, M.; Gigmes, D.; Morlet-Savary, F.; Zhang, Y.; Xiao, P.; et al. Novel Push–Pull Dyes Derived from 1H-cyclopenta [b] naphthalene-1, 3 (2H)-dione as Versatile Photoinitiators for Photopolymerization and Their Related Applications: 3D Printing and Fabrication of Photocomposites. Catalysts 2020, 10, 1196. [Google Scholar] [CrossRef]

- Sun, K.; Liu, S.; Chen, H.; Morlet-Savary, F.; Graff, B.; Pigot, C.; Nechab, M.; Xiao, P.; Dumur, F.; Lalevée, J. N-ethyl Carbazole-1-Allylidene-Based Push-Pull Dyes as Efficient Light Harvesting Photoinitiators for Sunlight Induced Polymerization. Eur. Polym. J. 2021, 147, 110331. [Google Scholar] [CrossRef]

- Sun, K.; Chen, H.; Zhang, Y.; Morlet-Savary, F.; Graff, B.; Xiao, P.; Dumur, F.; Lalevée, J. High-performance Sunlight Induced Polymerization Using Novel Push-Pull Dyes with High Light Absorption Properties. Eur. Polym. J. 2021, 151, 110410. [Google Scholar] [CrossRef]

- Sun, K. Photoinitiating Systems for Visible Light: Towards Sunlight Induced Polymerization. Doctoral Dissertation, Université de Haute Alsace-Mulhouse, Mulhouse, France, 2021. [Google Scholar]

- Balta, D.; Arsu, N. Thioxanthone-ethyl anthracene. J. Photochem. Photobiol. A Chem. 2013, 257, 54–59. [Google Scholar] [CrossRef]

- Corakci, B.; Hacioglu, S.; Toppare, L.; Bulut, U. Long wavelength photosensitizers in photoinitiated cationic polymerization: The effect of quinoxaline derivatives on photopolymerization. Polymer 2013, 54, 3182–3187. [Google Scholar] [CrossRef]

- Doğruyol, S.; Doğruyol, Z.; Arsu, N. Thioxanthone based 9-[2-(methyl-phenyl-amino)-acetyl]-thia-naphthacene-12-one as a visible photoinitiator. J. Lumin. 2013, 138, 98–104. [Google Scholar] [CrossRef]

- Podsiadły, R.; Strzelczyk, R. N-substituted quinoxalinobenzothiazine/ iodonium salt systems as visible photoinitiators for hybrid polymerization. Dye. Pigment. 2013, 97, 462–468. [Google Scholar] [CrossRef]

- Yang, J.; Tang, R.; Shi, S.; Nie, J. Synthesis and characterization of polymerizable one-component photoinitiator based on sesamol. Photochem. Photobiol. Sci. 2013, 12, 923–929. [Google Scholar] [CrossRef]

- Chen, M.; Zhong, M.; Johnson, J.A. Light-Controlled Radical Polymerization: Mechanisms, Methods, and Applications. Chem. Rev. 2016, 116, 10167–10211. [Google Scholar] [CrossRef] [Green Version]

- You, J.; Cao, D.; Hu, T.; Ye, Y.; Jia, X.; Li, H.; Hu, X.; Dong, Y.; Ma, Y.; Wang, T. Novel Norrish Type I flavonoid photoinitiator for safe LED light with high activity and low toxicity by inhibiting the ESIPT process. Dye. Pigment. 2021, 184, 108865. [Google Scholar] [CrossRef]

- Lee, Z.; Hammoud, F.; Hijazi, A.; Graff, B.; Lalevee, J.; Chen, Y. Synthesis and free radical photopolymerization of triphenylamine-based oxime ester photoinitiators. Polym. Chem. 2021, 12, 1286–1297. [Google Scholar]

- Fouassier, J.P. Photoinitiator, Photopolymerization and Photocuring: Fundamentals and Applications; HanserPublishers: New York, NY, USA, 1995. [Google Scholar]

- Xiao, P.; Lalevée, J.; Allonas, X.; Fouassier, J.P.; Ley, C.; El Roz, M.; Shi, S.Q.; Nie, J. Photoinitiation mechanism of free radical photopolymerizationin the presence of cyclic acetals and related compounds. J. Polym. Sci. Part A Polym. Chem. 2010, 48, 5758–5766. [Google Scholar] [CrossRef]

- Xu, Y.Y.; Ding, Z.F.; Liu, F.Y.; Sun, K.; Dietlin, C.; Lalevee, J.; Xiao, P. 3D Printing of polydiacetylene photocomposite materials: Two wavelengths for two orthogonal chemistries. ACS Appl. Mater. Interfaces 2019, 12, 1658–1664. [Google Scholar] [CrossRef]

- Sun, K.; Pigot, C.; Chen, H.; Nechab, M.; Gigmes, D.; Morlet-Savary, F.; Graff, B.; Liu, S.; Xiao, P.; Dumur, F.; et al. Free radical photopolymerization and 3D printing using newly developed dyes: Indane-1, 3-dione and 1H-cyclopentanaphthalene-1, 3-dione derivatives as photoinitiators in three-component systems. Catalysts 2020, 10, 463. [Google Scholar] [CrossRef] [Green Version]

- Chen, H.; Noirbent, G.; Zhang, Y.; Brunel, D.; Gigmes, D.; Morlet-Savary, F.; Graff, B.; Xiao, P.; Dumur, F.; Lalevée, J. Novel D–π-A and A–π-D–π-A three-component photoinitiating systems based on carbazole/triphenylamino based chalcones and application in 3D and 4D printing. Polym. Chem. 2020, 11, 6512–6528. [Google Scholar] [CrossRef]

- Borjigin, T.; Noirbent, G.; Gigmes, D.; Xiao, P.; Dumur, F.; Lalevée, J. The new LED-Sensitive photoinitiators of Polymerization: Copper complexes in free radical and cationic photoinitiating systems and application in 3D printing. Eur. Polym. J. 2022, 162, 110885. [Google Scholar] [CrossRef]

- Xiao, P.; Zhang, J.; Dumur, F.; Tehfe, M.A.; Morlet-Savary, F.; Graff, B.; Gigmes, D.; Fouassier, J.P.; Lalevee, J. Visible light sensitive photoinitiating systems: Recent progress in cationic and radical photopolymerization reactions under soft conditions. Prog. Polym. Sci. 2015, 41, 32–66. [Google Scholar] [CrossRef]

- Sun, K.; Xiao, P.; Dumur, F.; Lalevée, J. Organic dye-based photoinitiating systems for visible-light-induced photopolymerization. J. Polym. Sci. 2021, 59, 1338–1389. [Google Scholar] [CrossRef]

- Kabatc, J.; Ortyl, J.; Kostrzewska, K. New kinetic and mechanistic aspects of photosensitization of iodonium salts in photopolymerization of acrylates. RSC Adv. 2017, 7, 41619–41629. [Google Scholar] [CrossRef] [Green Version]

- Brömme, T.; Oprych, D.; Horst, J.; Pinto, P.S.; Strehmel, B. New iodonium salts in NIR sensitized radical photopolymerization of multifunctional monomers. RSC Adv. 2015, 5, 69915–69924. [Google Scholar] [CrossRef]

- Jiang, X.; Luo, X.; Yin, J. Polymeric photoinitiators containing in-chain benzophenone and coinitiators amine: Effect of the structure of coinitiator amine on photopolymerization. J. Photochem. Photobiol. A Chem. 2015, 174, 165–170. [Google Scholar] [CrossRef]

- Wang, H.; Wei, J.; Jiang, X.; Yin, J. Highly efficient sulfur-containing polymeric photoinitiators bearing side-chain benzophenone and coinitiator amine for photopolymerization. J. Photochem. Photobiol. A Chem. 2007, 186, 106–114. [Google Scholar] [CrossRef]

- Bagheri, A.; Jin, J. Photopolymerization in 3D Printing. ACS Appl. Polym. Mater. 2019, 1, 593–611. [Google Scholar] [CrossRef] [Green Version]

- Tasdelen, M.A.; Lalevée, J.; Yagci, Y. Photoinduced free radical promoted cationic polymerization 40 years after its discovery. Polym. Chem. 2020, 11, 1111–1121. [Google Scholar] [CrossRef]

- Mitterbauer, M.; Knaack, P.; Naumov, S.; Markovic, M.; Ovsianikov, A.; Moszner, N.; Liska, R. Acylstannanes: Cleavable and Highly Reactive Photoinitiators for Radical Photopolymerization at Wavelengths above 500 nm with Excellent Photobleaching Behavior. Angew. Chem. Int. Ed. 2018, 57, 12146–12150. [Google Scholar] [CrossRef] [PubMed]

- Noirbent, G.; Dumur, F. Recent advances on naphthalic anhydrides and 1,8-naphthalimide-based photoinitiators of polymerization. Eur. Polym. J. 2020, 132, 109702. [Google Scholar] [CrossRef]

- Yang, J.; Xu, C.; Xiong, Y.; Wang, X.; Xie, Y.; Li, Z.; Tang, H. A Green and Highly Efficient Naphthalimide Visible Photoinitiator with an Ability Initiating Free Radical Polymerization under Air. Macromol. Chem. Phys. 2018, 219, 1800256. [Google Scholar] [CrossRef]

- Xiao, P.; Dumur, F.; Frigoli, M.; Tehfe, M.-A.; Graff, B.; Fouassier, J.P.; Gigmes, D.; Lalevée, J. Naphthalimide based methacrylated photoinitiators in radical and cationic photopolymerization under visible light. Polym. Chem. 2013, 4, 5440–5448. [Google Scholar] [CrossRef]

- Liu, S.; Giacoletto, N.; Graff, B.; Morlet-Savary, F.; Nechab, M.; Xiao, P.; Dumur, F.; Lalevée, J. N-naphthalimide ester derivatives as Type I photoinitiators for LED photopolymerization. Mater. Today Chem. 2022, 26, 101137. [Google Scholar] [CrossRef]

- Hammoud, F.; Giacoletto, N.; Noirbent, G.; Graff, B.; Hijazi, A.; Nechab, M.; Gigmes, D.; Dumur, F.; Lalevée, J. Substituent effects on the photoinitiation ability of coumarin-based oxime-ester photoinitiators for free radical photopolymerization. Mater. Chem. Front. 2021, 5, 8361–8370. [Google Scholar] [CrossRef]

- Zhou, R.; Sun, X.; Mhanna, R.; Malval, J.-P.; Jin, M.; Pan, H.; Wan, D.; Morlet-Savary, F.; Chaumeil, H.; Joyeux, C. Wavelength-Dependent, Large-Amplitude Photoinitiating Reactivity within a Carbazole-Coumarin Fused Oxime Esters Series. ACS Appl. Polym. 2020, 2, 2077–2085. [Google Scholar] [CrossRef]

- Chen, S.; Jin, M.; Malval, J.-P.; Fu, J.; Morlet-Savary, F.; Pan, H.; Wan, D. Substituted stilbene-based oxime esters used as highly reactive wavelength-dependent photoinitiators for LED photopolymerization. Polym. Chem. 2019, 10, 6609–6621. [Google Scholar] [CrossRef]

- Wu, X.; Gong, S.; Chen, Z.; Hou, J.; Liao, Q.; Xiong, Y.; Li, Z.; Tang, H. Photobleachable bis-chalcones-based oxime ester dyes for radical visible photopolymerization. Dye. Pigment. 2022, 205, 110556. [Google Scholar] [CrossRef]

- Liu, S.; Graff, B.; Xiao, P.; Dumur, F.; Lalevée, J. Nitro-Carbazole Based Oxime Esters as Dual Photo/Thermal Initiators for 3D Printing and Composite Preparation. Macromol. Rapid Commun. 2021, 42, 2100207. [Google Scholar] [CrossRef]

- Liu, S.; Giacoletto, N.; Schmitt, M.; Nechab, M.; Graff, B.; Morlet-Savary, F.; Xiao, P.; Dumur, F.; Lalevée, J. Effect of Decarboxylation on the Photoinitiation Behavior of Nitrocarbazole-Based Oxime Esters. Macromolecules 2022, 55, 2475–2485. [Google Scholar] [CrossRef]

- Liu, S.; Brunel, D.; Sun, K.; Zhang, Y.; Chen, H.; Xiao, P.; Dumur, F.; Lalevée, J. Novel photoinitiators based on benzophenone-triphenylamine hybrid structure for LED photopolymerization. Macromolar Rapid Commun. 2020, 41, 2000460. [Google Scholar] [CrossRef]

- Liu, S.; Chen, H.; Zhang, Y.; Sun, K.; Xu, Y.; Morlet-Savary, F.; Graff, B.; Noirbent, G.; Pigot, C.; Brunel, D.; et al. Monocomponent photoinitiators based on benzophenone-carbazole structure for LED photoinitiating systems and application on 3D printing. Polymers 2020, 12, 1394. [Google Scholar] [CrossRef]

- Qin, X.; Ding, G.; Gong, Y.; Jing, C.; Peng, G.; Liu, S.; Niu, L.; Zhang, S.; Luo, Z.; Li, H.; et al. Stilbene-benzophenone dyads for free radical initiating polymerization of methyl methacrylate under visible light irradiation. Dye. Pigment. 2016, 132, 27–40. [Google Scholar] [CrossRef]

- Zhang, J.; Zivic, N.; Dumur, F.; Xiao, P.; Graff, B.; Gigmes, D.; Fouassier, J.; Lalevee, J. A benzophenone-naphthalimide derivative as versatile photoinitiator of polymerization under near UV and visible lights. J. Polym. Sci. Polym. Chem. 2015, 53, 445–451. [Google Scholar] [CrossRef]

- Kumbaraci, V.; Aydogan, B.; Talinli, N.; Yagci, Y. Naphthodioxinone-1,3- benzodioxole as photochemically masked one-component Type II photoinitiator for free radical polymerization. J. Polym. Sci. Polym. Chem. 2012, 50, 2612–2618. [Google Scholar] [CrossRef]

- Huang, T.; Chen, Y. Synthesis and free radical photopolymerization of one-component Type II photoinitiator based on benzophenone segment. J. Photochem. Photobiol. A Chem. 2022, 429, 113900. [Google Scholar] [CrossRef]

- Liu, S.; Brunel, D.; Noirbent, G.; Mau, A.; Chen, H.; Morlet-Savary, F.; Graff, B.; Gigmes, D.; Xiao, P.; Dumur, F.; et al. New multifunctional benzophenone-based photoinitiators with high migration stability and their applications in 3D printing. Mater. Chem. Front. 2021, 5, 1982–1994. [Google Scholar] [CrossRef]

- Sun, K.; Pigot, C.; Zhang, Y.; Borjigin, T.; Morlet-Savary, F.; Graff, B.; Nechab, M.; Xiao, P.; Dumur, F.; Lalevée, J. Sunlight Induced Polymerization Photoinitiated by Novel Push–Pull Dyes: Indane-1, 3-Dione, 1H-Cyclopenta [b] Naphthalene-1, 3 (2H)-Dione and 4-Dimethoxyphenyl-1-Allylidene Derivatives. Macromol. Chem. Phys. 2022, 223, 2100439. [Google Scholar] [CrossRef]

- Bagheri, A.; Fellows, C.; Boyer, C. Reversible deactivation radical polymerization: From polymer network synthesis to 3D printing. Adv. Sci. 2021, 8, 2003701. [Google Scholar] [CrossRef] [PubMed]

- Phommalysack-Lovan, J.; Chu, Y.; Boyer, C.; Xu, J. PET-RAFT polymerisation: Towards green and precision polymer manufacturing. Chem. Commun. 2018, 54, 6591–6606. [Google Scholar] [CrossRef]

- Corrigan, N.; Shanmugam, S.; Xu, J.; Boyer, C. Photocatalysis in organic and polymer synthesis. Chem. Soc. Rev. 2016, 45, 6165–6212. [Google Scholar] [CrossRef] [PubMed]

- Dadashi-Silab, S.; Doran, S.; Yagci, Y. Photoinduced electron transfer reactions for macromolecular syntheses. Chem. Rev. 2016, 116, 10212–10275. [Google Scholar] [CrossRef]

- Pan, X.; Tasdelen, M.A.; Laun, J.; Junkers, T.; Yagci, Y.; Matyjaszewski, K. Photomediated controlled radical polymerization. Prog. Polym. Sci. 2016, 62, 73–125. [Google Scholar] [CrossRef] [Green Version]

- Xu, J.; Shanmugam, S.; Fu, C.; Aguey-Zinsou, K.F.; Boyer, C. Selective photoactivation: From a single unit monomer insertion reaction to controlled polymer architectures. J. Am. Chem. Soc. 2016, 138, 3094–3106. [Google Scholar] [CrossRef] [Green Version]

- Lee, K.; Corrigan, N.; Boyer, C. Rapid High-Resolution 3D Printing and Surface Functionalization via Type I Photoinitiated RAFT Polymerization. Angew. Chem. Int. Ed. 2021, 60, 8839–8850. [Google Scholar] [CrossRef]

- Min, K.; Jakubowski, W.; Matyjaszewski, K. AGET ATRP in the presence of air in miniemulsion and in bulk. Macromol. Rapid Commun. 2006, 27, 594–598. [Google Scholar] [CrossRef]

- Dong, H.; Matyjaszewski, K. ARGET ATRP of 2-(dimethylamino) ethyl methacrylate as an intrinsic reducing agent. Macromolecules 2008, 41, 6868–6870. [Google Scholar] [CrossRef]

- Xue, H.; Peng, L.; Dong, Y.; Zheng, Y.; Luan, Y.; Hu, X.; Chen, G.; Chen, H. Synthesis of star-glycopolymers by Cu (0)-mediated radical polymerisation in the absence and presence of oxygen. RSC Adv. 2017, 7, 8484–8490. [Google Scholar] [CrossRef] [Green Version]

- Nguyen, N.; Leng, X.; Sun, H.; Percec, V. Single-electron transfer-living radical polymerization of oligo (ethylene oxide) methyl ether methacrylate in the absence and presence of air. J. Polym. Sci. Part A Polym. Chem. 2013, 51, 3110–3122. [Google Scholar] [CrossRef]

- Enciso, A.; Fu, L.; Russell, A.; Matyjaszewski, K. A breathing atom-transfer radical polymerization: Fully oxygen-tolerant polymerization inspired by aerobic respiration of cells. Angew. Chem. Int. Ed. 2018, 57, 933–936. [Google Scholar] [CrossRef]

- Huang, Y.; Sun, Y.; Weng, Y.; Zhang, W. A Simple and Green Oxygen-Tolerant RAFT Polymerization without Additional Catalyst and Initiator. ChemistrySelect 2022, 7, e202201583. [Google Scholar] [CrossRef]

- Shi, Y.; Liu, G.; Gao, H.; Lu, L.; Cai, Y. Effect of mild visible light on rapid aqueous RAFT polymerization of water-soluble acrylic monomers at ambient temperature: Initiation and activation. Macromolecules 2009, 42, 3917–3926. [Google Scholar] [CrossRef]

- Tan, J.; Bai, Y.; Zhang, X.; Huang, C.; Liu, D.; Zhang, L. Low-Temperature Synthesis of Thermoresponsive Diblock Copolymer Nano-Objects via Aqueous Photoinitiated Polymerization-Induced Self-Assembly (Photo-PISA) using Thermoresponsive Macro-RAFT Agents. Macromol. Rapid Commun. 2016, 37, 1434–1440. [Google Scholar] [CrossRef]

- Otsu, T. Iniferter concept and living radical polymerization. J. Polym. Sci. Part A Polym. Chem. 2000, 38, 2121–2136. [Google Scholar] [CrossRef]

- Xu, J.; Jung, K.; Atme, A.; Shanmugam, S.; Boyer, C. A Robust and Versatile Photoinduced Living Polymerization of Conjugated and Unconjugated Monomers and Its Oxygen Tolerance. J. Am. Chem. Soc. 2014, 136, 5508–5519. [Google Scholar] [CrossRef]

- McClelland, K.; Clemons, T.; Stupp, S.; Weiss, E. Semiconductor quantum dots are efficient and recyclable photocatalysts for aqueous PET-RAFT polymerization. ACS Macro Lett. 2019, 9, 7–13. [Google Scholar] [CrossRef]

- Fortenberry, A.; Jankoski, P.; Stacy, E.; McCormick, C.; Smith, A.; Clemons, T. A Perspective on the History and Current Opportunities of Aqueous RAFT Polymerization. Macromol. Rapid Commun. 2022, 2200414. [Google Scholar] [CrossRef]

- Smith, A.; Nie, S. Semiconductor Nanocrystals: Structure, Properties, and Band Gap Engineering. Acc. Chem. Res. 2010, 43, 190–200. [Google Scholar] [CrossRef] [Green Version]

- Zhu, Y.; Liu, Y.; Miller, K.A.; Zhu, H.; Egap, E. Lead Halide Perovskite Nanocrystals as Photocatalysts for PET-RAFT Polymerization under Visible and Near-Infrared Irradiation. ACS Macro Lett. 2020, 9, 725–730. [Google Scholar] [CrossRef]

- Zhu, Y.; Egap, E. Light-Mediated Polymerization Induced by Semiconducting Nanomaterials: State-of-the-Art and Future Perspectives. ACS Polym. Au 2021, 1, 76–99. [Google Scholar] [CrossRef]

| No. | OXEs | Absorption Properties | Conversion@405 nm LED (TMPTA) |

|---|---|---|---|

| 1 |  OXE-M | λmax~369 nm εmax~13,000 M−1 cm−1 ε405nm~4100 M−1 cm−1 | ~69% |

| 2 |  OXE-V | λmax~369 nm εmax~12,400 M−1 cm−1 ε405nm~3900 M−1 cm−1 | ~57% |

| 3 |  OXE-P | λmax~368 nm εmax~13,800 M−1 cm−1 ε405nm~4100 M−1 cm−1 | ~61% |

| 4 |  OXE-H | λmax~376 nm εmax~11,500 M−1 cm−1 ε405nm~5800 M−1 cm−1 | ~15% |

| 5 |  OXE-B1 | λmax~371 nm εmax~12,500 M−1 cm−1 ε405nm~4800 M−1 cm−1 | ~64% |

| 6 |  OXE-B2 | λmax~371 nm εmax~12,700 M−1 cm−1 ε405nm~4700 M−1 cm−1 | ~54% |

| 7 |  OXE-C1 | λmax~370 nm εmax~11,900 M−1 cm−1 ε405nm~4500 M−1 cm−1 | ~67% |

| 8 |  OXE-C2 | λmax~370 nm εmax~12,900 M−1 cm−1 ε405nm~4600 M−1 cm−1 | ~58% |

| 9 |  OXE-D1 | λmax~372 nm εmax~13,000 M−1 cm−1 ε405nm~5200 M−1 cm−1 | ~68% |

| 10 |  OXE-D2 | λmax~372 nm εmax~14,000 M−1 cm−1 ε405nm~5400 M−1 cm−1 | ~62% |

| 11 |  OXE-E1 | λmax~370 nm εmax~12,700 M−1 cm−1 ε405nm~5000 M−1 cm−1 | ~64% |

| 12 |  OXE-E2 | λmax~370 nm εmax~13,300 M−1 cm−1 ε405nm~5100 M−1 cm−1 | ~53% |

| 13 |  OXE-F1 | λmax~370 nm εmax~13,000 M−1 cm−1 ε405nm~4300 M−1 cm−1 | ~68% |

| 14 |  OXE-F2 | λmax~370 nm εmax~13,500 M−1 cm−1 ε405nm~4200 M−1 cm−1 | ~56% |

| Organic Dyes | Absorption Properties | Conversion (Monomer) @405 LED | |

|---|---|---|---|

| 1 |  BPN-D | λmax~367 nm εmax~9200 M−1 cm−1 ε405nm~9200 M−1 cm−1 | ~17% in TMPTMA@UV lamp ~13% in TMPTMA@405nm LED |

| 2 |  BPN-Ph | λmax~357 nm εmax~3240 M−1 cm−1 ε405nm~3240 M−1 cm−1 | ~30% in TMPTMA@UV lamp ~16% in TMPTMA@405nm LED |

| 3 |  BPN-N | λmax~358 nm εmax~2160 M−1 cm−1 ε405nm~2160 M−1 cm−1 | ~14% in TMPTMA@UV lamp ~14% in TMPTMA@405nm LED |

| 4 |  BPN-An | λmax~366 nm εmax~5580 M−1 cm−1 ε405nm~5580 M−1 cm−1 | ~21% in TMPTMA@UV lamp ~22% in TMPTMA@405nm LED |

| 5 |  BPN-Py | λmax~356 nm εmax~4250 M−1 cm−1 ε405nm~4250 M−1 cm−1 | ~18% in TMPTMA@UV lamp ~14% in TMPTMA@405nm LED |

| 6 |  BT-1 | λmax~359 nm εmax~21,000 M−1 cm−1 ε405nm~1800 M−1 cm−1 | ~68% in TMPTA ~43% in EPOX |

| 7 |  BT-2 | λmax~373 nm εmax~27,200 M−1 cm−1 ε405nm~5000 M−1 cm−1 | ~72% in TMPTA ~41% in EPOX |

| 8 |  BT-3 | λmax~370 nm εmax~41,680 M−1 cm−1 ε405nm~6100 M−1 cm−1 | ~77% in TMPTA ~47% in EPOX |

| 9 |  BT-4 | λmax~377 nm εmax~21,700 M−1 cm−1 ε405nm~6700 M−1 cm−1 | ~70% in TMPTA ~45% in EPOX |

| 10 |  BC-1 | λmax~338 nm εmax~19,700 M−1 cm−1 ε405nm~20 M−1 cm−1 | ~51% in TMPTA ~26% in EPOX |

| 11 |  BC-2 | λmax~369 nm εmax~24,100 M−1 cm−1 ε405nm~160 M−1 cm−1 | ~58% in TMPTA ~27% in EPOX |

| 12 |  BC-3 | λmax~409 nm εmax~26,700 M−1 cm−1 ε405nm~26,500 M−1 cm−1 | ~70% in TMPTA ~38% in EPOX |

| Push–Pull Dyes | Absorption Properties | Final Acrylate Function Conversion (TMPTA) | |

|---|---|---|---|

| 1 |  | λmax~555 nm εmax~33,360 M−1 cm−1 ε405nm~2030M−1 cm−1 | ~70% @405 nm LED |

| 2 |  | λmax~575 nm εmax~67,380 M−1 cm−1 ε405nm~2280 M−1 cm−1 | ~98% @405 nm LED |

| 3 |  | λmax~507 nm εmax~30,290 M−1 cm−1 ε405nm~5850 M−1 cm−1 | ~94% @405 nm LED |

| 4 |  | λmax~510 nm εmax~29,010 M−1 cm−1 ε405nm~5570 M−1 cm−1 | ~80% @405 nm LED |

| 5 |  | λmax~626 nm εmax~42,550 M−1 cm−1 ε405nm~2550 M−1 cm−1 | ~98% @405 nm LED |

| 6 |  | λmax~656 nm εmax~100,870 M−1 cm−1 ε405nm~3880 M−1 cm−1 | ~62% @405 nm LED |

| 7 |  | λmax~689 nm εmax~113,870 M−1 cm−1 ε405nm~13,640 M−1 cm−1 | ~97% @405 nm LED ~93% @sunlight |

| 8 |  | λmax~598 nm εmax~27,290 M−1 cm−1 ε405nm~8310 M−1 cm−1 | ~61% @405 nnm LED |

| 9 |  | λmax~627 nm εmax~51,700 M−1 cm−1 ε405nm~4610 M−1 cm−1 | ~98% @405 nm LED ~91% @sunlight |

| 10 |  | λmax~650 nm εmax~8570 M−1 cm−1 ε405nm~8950 M−1 cm−1 | ~85% @405 nm LED |

| 11 |  | λmax~671 nm εmax~47,770 M−1 cm−1 ε405nm~6560 M−1 cm−1 | ~99% @405 nm LED ~92% @sunlight |

| 12 |  | λmax~379 nm εmax~27,320 M−1 cm−1 ε405nm~5120 M−1 cm−1 | ~98% @405 nm LED |

| 13 |  | λmax~384 nm εmax~44,320 M−1 cm−1 ε405nm~15,420 M−1 cm−1 | ~93% @405 nm LED |

| No. | Push–Pull Dyes | Absorption Properties | Final Acrylate Function Conversion (TA) |

|---|---|---|---|

| 14 |  | λmax~445 nm εmax~37,375 M−1 cm−1 ε405nm~22,578 M−1 cm−1 | ~94% @405 nm LED ~79% @sunlight |

| 15 |  | λmax~512 nm εmax~30,900 M−1 cm−1 ε405nm~12,680 M−1 cm−1 | ~96% @405 nm LED ~88% @sunlight |

| 16 |  | λmax~523 nm εmax~16,070 M−1 cm−1 ε405nm~6890 M−1 cm−1 | ~95% @405 nm LED |

| 17 |  | λmax~537 nm εmax~24,960 M−1 cm−1 ε405nm~18,640 M−1 cm−1 | ~93% @405 nm LED |

| 18 |  | λmax~432 nm εmax~25,930 M−1 cm−1 ε405nm~19,782 M−1 cm−1 | ~94% @405 nm LED |

| 19 |  | λmax~466 nm εmax~73,550 M−1 cm−1 ε405nm~25,010 M−1 cm−1 | ~97% @405 nm LED |

| 20 |  | λmax~500 nm εmax~40,630 M−1 cm−1 ε405nm~8640 M−1 cm−1 | ~99% @405 nm LED ~87% @sunlight |

| 21 |  | λmax~424 nm εmax~29,680 M−1 cm−1 ε405nm~25,940 M−1 cm−1 | ~90% @405 nm LED |

| 22 |  | λmax~471 nm εmax~54,580 M−1 cm−1 ε405nm~15,830 M−1 cm−1 | ~82% @405 nm LED |

| 23 |  | λmax~531 nm εmax~16,810 M−1 cm−1 ε405nm~16,130 M−1 cm−1 | ~90% @405 nm LED |

| 24 |  | λmax~437 nm εmax~39,190 M−1 cm−1 ε405nm~25,770 M−1 cm−1 | ~92% @405 nm LED |

| 25 |  | λmax~438 nm εmax~43,910 M−1 cm−1 ε405nm~28,060 M−1 cm−1 | ~89% @405 nm LED |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Peng, X.; Gan, Z.; Chen, W.; Li, X.; Gong, T.; Xiao, P. 3D Printing/Vat Photopolymerization of Photopolymers Activated by Novel Organic Dyes as Photoinitiators. Catalysts 2022, 12, 1272. https://doi.org/10.3390/catal12101272

Sun K, Peng X, Gan Z, Chen W, Li X, Gong T, Xiao P. 3D Printing/Vat Photopolymerization of Photopolymers Activated by Novel Organic Dyes as Photoinitiators. Catalysts. 2022; 12(10):1272. https://doi.org/10.3390/catal12101272

Chicago/Turabian StyleSun, Ke, Xiaotong Peng, Zengkang Gan, Wei Chen, Xiaolin Li, Tao Gong, and Pu Xiao. 2022. "3D Printing/Vat Photopolymerization of Photopolymers Activated by Novel Organic Dyes as Photoinitiators" Catalysts 12, no. 10: 1272. https://doi.org/10.3390/catal12101272