Production of Energy-Efficient Natural Gas Hydrate

A special issue of Processes (ISSN 2227-9717). This special issue belongs to the section "Energy Systems".

Deadline for manuscript submissions: closed (15 April 2024) | Viewed by 4317

Special Issue Editors

Interests: natural gas hydrate exploitation; CO2 capture and storage; heat and mass transfer in porous media; gas-liquid two-phase flow; multiscale numerical simulation

Interests: natural gas hydrate; CO2 hydrate; thermodynamics; kinetics; numerical modeling; reservoir simulation

Special Issues, Collections and Topics in MDPI journals

Interests: natural gas hydrate production; CCUS; hydrate technology; wastewater treatment

Interests: hydrate-based CO2 capture; hydrogen storage by hydrate method; natural gas hydrate production

Special Issue Information

Dear Colleagues,

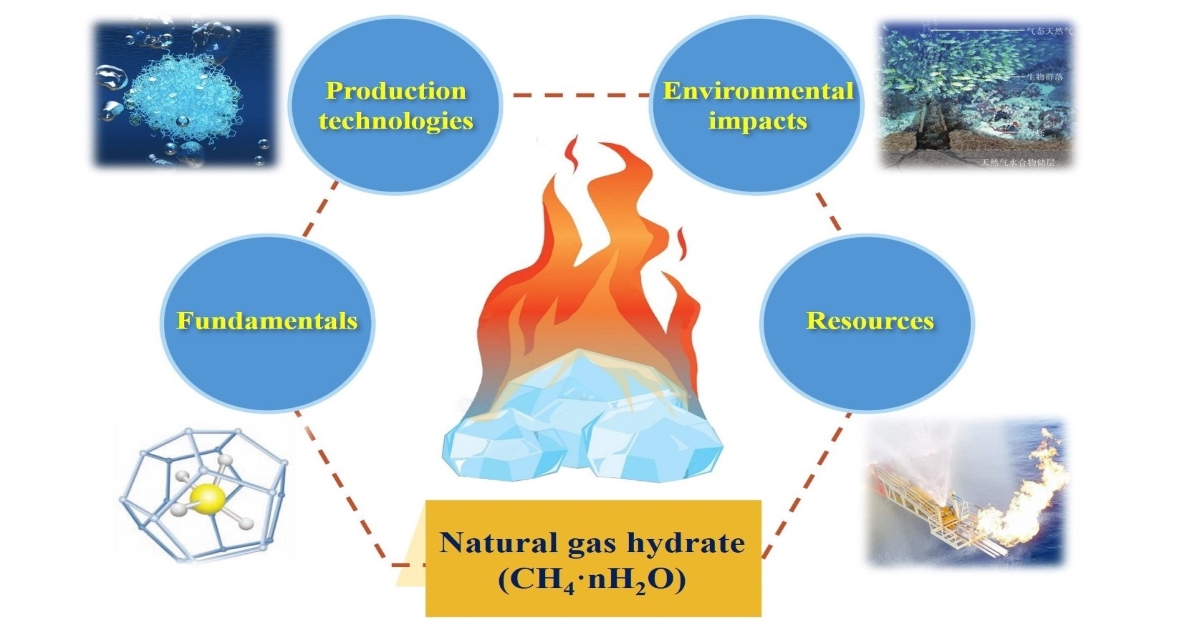

Natural gas hydrate is considered as a promising source of energy for the 21st century, which has attracted widespread attention for the last decades. Although there have been several field production tests from land and marine hydrate reservoirs worldwide, challenges and open questions still remain prior to the commercial exploitation of natural gas hydrates. This requires a fundamental understanding of these resources as well as their application in energy-environment related areas.

The special issue, “Production of Energy-efficient Natural Gas Hydrate”, aims to report on the latest findings on hydrates from researchers around the world, covering experimental, theoretical, and simulation studies. We encourage original research papers on this special issue from a wide range of topics regarding hydrates including, but not limited to:

- Fundamentals of gas hydrate phase transfer

- Natural gas hydrate production technologies

- Environmental impacts of gas hydrate (Climate, Geohazard,etc.)

- Natural gas hydrate resource (Characterization, Exploration, Recovery, etc.)

- Flow assurance

- Hydrate-based CO2 capture and storage

- Numerical simulation (Laboratory scale, Site scale, Prediction etc.)

Dr. Tao Yu

Dr. Zhenyuan Yin

Dr. Bingbing Chen

Dr. Pengfei Wang

Dr. Ying Teng

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Processes is an international peer-reviewed open access monthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2400 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- natural gas hydrate

- production technology

- environmental impact

- energy-efficient

- flow assurance