Progress in Recycling of (Bio)Polymers and Composites

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Circular and Green Polymer Science".

Viewed by 36625Editor

Interests: structure/processing/properties relationships in polymers; biopolymers; micro- and nano- composites; polymers and biopolymers degradation and stabilization

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

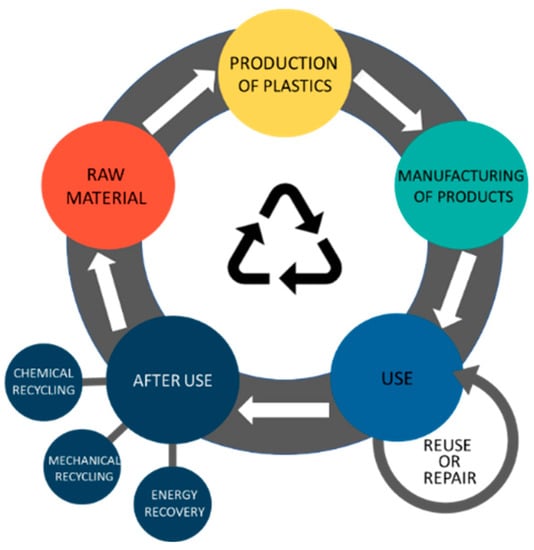

The continuous increase in the production and use of numerous plastic goods requires an adequate design of material end-of-life that considers appropriate polymer recycling. The advance in polymer recycling is related to two main points—first, adequate polymer separation, and second, properties and performance optimization of second-life recyclates. There are also other important issues related to the polymer compatibility and/or incompatibility, the impact of numerous additives on the recycling process and the adding of further additives to second-life recyclates, which aim to improve the properties and performance.

Therefore, to further the implementation and development of an efficient polymer material recovery process, i.e., recycling for polymers, specific attention and inputs from both academic and industrial parties are required; notably, some industries in the EU are already carrying out efficient recycling processes.

Prof. Dr. Nadka Tz. Dintcheva

Collection Editor

Keywords

- polymer recycling

- plastics

- polymer compatibility

- recycling process