1. Introduction

The European Green Deal [

1] and the Circular Economy Initiative [

2] as put forward by the European Commission have impacted the life of polymer products, changing it from a linear model (production–use–disposal) to a more circular model (production—use–recycling) [

3]. One aspect that needs further evaluation is alternative feedstocks like biobased plastics and their role in the transformation to a circular economy [

4,

5].

Biopolymers are defined as polymer materials that are biobased, biodegradable or both [

6]. Currently, the capacity for biopolymer manufacturing on a global scale is 2.42 million tonnes in 2021, rising to 7.59 million tonnes in 2026. This means that biobased plastics are here to stay and that exploring end-of-life (EoL) options is imperative [

7].

Polyhydroxyalkanoates (PHAs) are biobased and biodegradable polymers that are produced as intracellular storage granules by various microorganisms under diverse conditions. PHAs are thermoplastic, biocompatible and non-toxic with good barrier properties [

8]. Depending on the number of carbon atoms in the backbone, they are divided into short, medium and long side chains [

9,

10,

11]. Until now, 160 monomers have been identified, and the number is still growing [

12,

13].

The potential to reduce environmental pollution caused by conventional plastics due to the biodegradability of PHA-based plastics is one of the reasons why they are gaining increased attention. They are also biobased, which means the feedstocks used to produce them are plant-derived sugars or waste streams, making them a promising alternative to fossil-based plastics [

14,

15,

16].

The most studied member of the PHA family is polyhydroxybutyrate (PHB). It has a highly crystalline linear isotactic structure. Additionally, PHB is water-insoluble and relatively resistant to hydrolytic degradation. It has been reported to have a tensile strength of 30–40 MPa and an elongation at break of 2–10%. The melting point of PHB is high at around 177 °C [

6,

17,

18,

19].

Recycling becomes a desirable EoL option for the circular economy [

3] as the amount of plastic increases [

20]. The two main types are mechanical and chemical recycling. Mechanical recycling is the most environmentally attractive and cost-efficient compared to chemical recycling, which needs a lot of new equipment and energy input [

21,

22]. The different segments of the entire mechanical recycling process consist of collecting, sorting, shredding, washing and final processing to make the recyclates [

23].

EoL options for biobased plastics are the same as those for conventional plastics but with some additional options available such as composting. The biobased plastics (bio-polyethylene (bio-PE), bio-polypropylene (bio-PP), bio-polyethylene terephthalate (bio-PET)) are already mechanically recycled along with their petroleum-based counterparts, but for the biobased and biodegradable plastics, the same cannot be said. Technically, biodegradable and biobased plastics can be sorted out by near-infrared spectroscopy, but this is not done yet as the waste streams are very small and the high investment costs are hence not economically feasible. In sorting out plastics, blends of polymers and multilayered plastics are an issue (biobased or conventional plastics). Similar densities of conventional and biobased plastics, e.g., PET and polylactic acid (PLA), introduce additional difficulties to sorting via floatation methods. Having a separate waste stream for these plastics would solve these issues, but currently, no industrial recycling stream for biodegradable and biobased polymers exists [

24,

25,

26]. One of the reasons behind this is the lack of data on the influence of recycling on the molecular and material properties of bio-based polymers.

There have been a few works concentrating on the recyclability of PHAs. The studies range from recycling of the pure polymers PHB, poly(3-hydroxybutyrate-co-3-hydroxyvalerate) PHBV and P(3HB-co-4HB) [

27,

28,

29,

30] to recycling via blend design of PLA/PHB, PHBV/PLA, PHBV/poly (butylene adipate-co-terephthalate) PBAT and PP/PHB and the composite synthesis of PHBV/Sisal [

31,

32,

33,

34,

35,

36,

37,

38]. Since PHBs are expensive and circulate only in small quantities, there are few studies on their mechanical recycling and chemical recycling potential. Even still, the optimal EoL route would be reuse, followed by mechanical recycling and then either pyrolysis or biodegradation. Lamberti et al. [

39] state the different EoL options for selected biobased plastics (PLA, PHA, polyglycolic acid (PGA), bio-PET and bio-PE), highlighting once again the importance of recycling method selection based on the analysis of the waste stream. Rivas et al. [

27] studied the mechanical recyclability of PHB powder. After three cycles of extrusion and compression molding, a decrease in tensile strength (>50%) was noticed. DSC showed an increase in crystallinity with the number of extrusion cycles which could be due to a decrease in molecular weight. FTIR analysis did not display the formation of any new groups, nor was the thermal stability affected much.

Dedieu et al. [

40] reviewed the thermo-mechanical recyclability of biodegradable and biobased plastics with a focus on the degradation mechanisms. With respect to PHAs, the two main pathways of thermal degradation are random β-elimination [

41] and/or E1cB elimination reaction proceeding via α-deprotonation [

42], both leading to the formation of crotonic acids and oligomers. The degradation mechanism consists initially of a non-auto-catalytic random degradation followed by an auto-accelerated catalytic transesterification process. The self-proliferation of the carboxylic compounds in bulk is needed for the auto-accelerated degradation to begin, and this is caused by unzipping reactions at the ends of the molecules (presumably a zeroth-order kinetic chain scission) [

40,

43].

In terms of average molar mass, crystallinity, melting point and tensile strength, PHB is similar to polypropylene (PP). Some material properties, e.g., oxygen, fat and odor barrier properties, are superior for PHB than for conventional polymers like PP and poly(ethylene terephthalate) (PET), which broadens the potential for the application of PHB as a sustainable packaging material [

18,

44,

45]. As PHB aims at the substitution of PP for packaging applications, its recycling should be also explored and compared to that of PP.

The degradation mechanism of PP is more dominated by ß-chain scission due to the presence of the methyl group on the backbone which makes it more prone to shearing as occurs during the extrusion process with H-abstraction. This leads to a reduction in molecular weight on repeated extrusion and also increases the degree of crystallinity and hence the Young’s modulus and reduces the elongation at break [

46]. Another way for the degradation is due to the attack of oxygen which leads to a reaction with oxygen-based radicals but which is not of import with regard to the extrusion process as the oxygen is consumed in the early stages of processing [

46,

47]. Canevarolo et al. [

48] state that the molecular weight distribution curve shifts away from the original position according to the type and extent of degradation. Upon chain scission, the curve shifts towards the lower molecular weight side. Factors that affect the degradation of PP are the presence of peroxides, screw configuration and processing conditions.

As a lot of work has been conducted on the reprocessing of PP already and only four papers from Alotaibi et al. [

49], Hermanova et al. [

50] and Tochacek et al. [

51,

52] dealt with the recycling and characterization of impact copolymer polypropylene (ICPP), we decided to compare PHB with ICPP. Tochacek et al. [

47] studied the degradation of ICPP over multiple extrusion cycles and concluded that the degradation behavior is similar to PP as it constitutes around 90% of the mass of the polymer with the effect of the rubbery fraction more pronounced with regard to fracture behavior.

Alotaibi et al. [

49] discussed the differences in reprocessing ICPP with a quad screw extruder (QSE) vs. a twin screw extruder (TSE) at three different screw speeds. As the number of cycles progressed and the screw speeds increased, melt temperature had two trends. With the increase in cycles, the melt temperature as well as melt viscosity decreased due to polymer degradation, and less shear heating was produced consequently. With an increase in the speeds, the melt temperature increased due to the high shear generated. As the cycles and speeds increased, the melt mass flow rate (MFR) increased, and the rheological measurements indicated a narrowing of the molecular weight distribution (MWD) and a decrease in weight average molecular weight (Mw). The head pressure, on the other hand, decreased with both increasing speed and number of cycles due to the decrease in melt viscosity for both TSE and QSE. The QSE showed higher melt temperature and greater reductions in molecular weight in comparison to TSE as the three intermeshing zones led to higher shears being generated and showed lower head pressure due to greater free volume present in the QSE. The complex viscosity of reprocessed PP at 500 rpm was similar to that of virgin PP for both screws, but at 1500 rpm, a significant decrease in reprocessed PP was observed for QSE, due to the high shear stresses. Izod impact strength showed a decrease with both increasing speed and number of reprocessing cycles. This behavior was similar in both TSE and QSE.

In this work, we studied the reprocessing of PHB pellets via extrusion and injection molding in comparison to PP as an industrial standard material. We performed five consecutive extrusion cycles for PHB and PP and compared the molecular and material properties; to our knowledge, this is the first time such a comparison has been carried out. We observed no significant influence on the material properties due to reprocessing for PHB, which makes it an attractive option for mechanical recycling.

2. Materials and Methods

2.1. Materials

PHB (P263 injection molding grade) pellets with a density of 1.3 g/cm

3 were obtained from Biomer (Schwalbach, Germany). The renewable content is around 86.5%, and the rest is biodegradable or inert material. The material is approved for food contact according to EU regulation 1935/2004. Further property details from the manufacturer (Biomer, Germany) can be found in

Appendix A Table A11.

ICPP (C7069-100NA) pellets with a density of 0.9 g/cm

3 were obtained from Braskem Europe (Braskem, Germany). The MFR value is 100 g/10 min. The material is approved for food contact according to EU regulation 1935/2004. Further property details from the manufacturer (Braskem, Germany) can be found in

Appendix A Table A12. For convenience, the abbreviation PP has been used in the following sections to refer to ICPP.

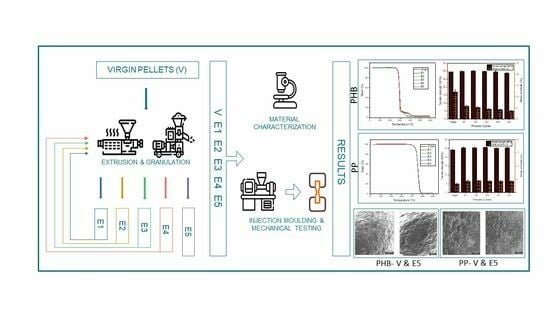

2.2. Processing and Mechanical Recycling

The moisture content of the received PHB was 0.18%, as tested in an FMX HydroTracer (aboni GmbH für Mess-und Automatisierungstechnik, Schwielosee, Germany). The material was predried at 60 °C for 2 h in a DP615 dryer (Piovan S.p.A, Venice, Italy) prior to processing in a co-rotating twin screw extruder ZSE18HPe-48D (Leistritz Extrusionstechnik GmbH, Nürnberg, Germany) with a screw diameter of 17.8 mm and an L/D ratio of 48 and equipped with a double-strand die.

To simulate mechanical recycling, five times repeated extrusions of the virgin material were carried out. No additives were added at any time to the two systems. The temperature profiles used for the PHB and PP systems are detailed in

Table 1 (only the most important parameters are shown, and the remaining data are attached in

Appendix A,

Table A7 and

Table A8). On extrusion, the polymer strands were air-cooled on a conveyor belt and granulated.

Thereafter, multipurpose test specimens (ISO 3167 [

53]) were fabricated on the injection molding machine ALLROUNDER 320 C (Arburg GmbH + Co. KG, Lossburg, Germany) with the processing parameters specified in

Table 2 (more detailed process settings are summarized in

Appendix A,

Table A9 and

Table A10). The variation of the injection rate and nozzle temperature for different recycling steps was necessary to obtain good parts. A schematic of the experimental design is shown in

Figure 1.

2.3. Testing Methods

Gel permeation chromatography (GPC): Molar mass distributions (MMDs), average molar masses (Mn, Mm) and dispersities (Đ) for PHB samples were analyzed via GPC on a PL-GPC-50 setup equipped with an automatic autosampler, isocratic pump, two Agilent ResiPore 3 µm columns, refractive index, viscosimetry and multi-angle (15 and 90°) light scattering detectors. Tetrahydrofuran (THF) was used as an eluent at the flow rate of 1 mL min−1. The columns were kept at 30 °C. The calibration was performed with polystyrene standards (mass average molar mass Mm range from 6 × 106 g mol−1 to 1.62 × 102 g mol−1). Before the analysis, 10 mg of the sample was dissolved in 1 mL of THF and shaken at room temperature for 1 h to ensure complete dissolution. For the analysis of PP samples, an Agilent high-temperature GPC 1260 Infinity II system equipped with an autosampler, three Olexis 3µm columns, refractive index, viscosimetry and multi-angle (15 and 90°) light scattering detectors was used. The analysis was performed in trichlorobenzene at 160 °C. The columns were calibrated with polystyrene standards (mass average molar mass Mm range from 6 × 106 g mol−1 to 1.62 × 102 g mol−1). Before the analysis, ca. 8 mg of the sample was dissolved in 4 mL of the solvent, heated and stirred for 1 h and then filtered through a 20 μm pore filter.

Fourier transform infrared spectroscopy (FTIR): The measurements were carried out on a Bruker 2009 spectrometer (Bruker Corporation, Billerica, MA, USA) with the OPUS 6.5 software. The measurements were carried out in attenuated total reflectance (ATR) and absorbance mode. The spectral resolution was 4 cm−1. For each measurement, 32 scans were averaged in the region of 4000–600 cm−1.

Scanning electron microscopy (SEM): A Phenom Pro Desktop scanning electron microscope (Thermo Fisher Scientific Inc., Waltham, MA, USA) was used to obtain images of the surface morphology of representative impact specimens. The edge was cut out and placed under the microscope, and images were taken at around 500× magnification. The mode used was 5 kV BSD-full. The samples were sputtered with a thin Au coating prior to scanning.

Melt mass flow rate (MFR): The melt mass flow rate was measured using the melt flow tester MP1200 (Tinius Olsen, Salfords, UK). The temperature was set to 180 °C for PHB and 230 °C for PP. The load used was 2.16 kg. The measurements were replicated three times each.

Differential scanning calorimetry (DSC): The machine used was a Mettler Toledo (Greifensee, Switzerland) DSC 1 with a GC 200 gas controller and STARe evaluation software Version 16.00. The sample testing was conducted under a nitrogen atmosphere, and the pans used were 40 µL aluminum crucibles. The heating rate was 10 K/min, and the cooling rate was 20 K/min. The PHB samples were heated from 20 °C to 220 °C. The PP sample was heated from 20 °C to 260 °C. The temperature to which the PHB samples were heated was intentionally kept lower than that for PP as they are heat-sensitive. The non-isothermal runs consisted of two heating ramps and one cooling ramp. The sample mass ranged from 9 to 12 mg with three replicates of each.

The degree of crystallinity

was calculated via [

54]

where

is the melting enthalpy of a 100% crystalline material, which is 146 J/g for PHB according to [

55] and 207 J/g for PP according to [

54].

Thermogravimetric analysis (TGA): A TGA/DSC 1 (Mettler Toledo, Greifensee, Switzerland) with a GC 200 gas controller was used. The measurements were conducted from 25 °C to 600 °C under a nitrogen atmosphere at 10 K/min to observe the degradation temperature. The measurement was replicated two times as the results were always identical. The mass of the sample was from 10 to 20 mg, and the pan was 70 µL aluminum oxide.

Rheology: The machine used for the PHB system was the modular compact rheometer MCR 501 (with the electrical temperature device ETD 400 Anton Paar GmbH., Graz, Austria), and for the PP system, an MCR 702 MultiDrive with a CTD 600 convection temperature device (Anton Paar GmbH., Graz, Austria) was used. The samples were compression molded into discs of 25 mm in diameter and 2 mm in height with the Collin P200PV press (Dr. Collin GmbH, Ebensberg, Germany). Initially, an amplitude sweep was conducted to determine the limits of the linear viscoelastic region (LVE) by shear deformation in the range of 0.1–100% and at the frequency of 1 rad/s. The LVE region of PHB was determined as 3% shear deformation, and that of PP was determined as 10% shear deformation. The frequency sweep measurements were performed at strains in the linear viscoelastic range in the frequency range from 0.1 rad/s to 500 rad/s with a plate–plate geometry of 25 mm diameter at a 1 mm gap in accordance with ISO 6721 [

56]. The PHB samples were tested at 190 °C, and the PP at 180 °C (these temperatures were chosen based on their melting point observed by DSC measurements). The measurement was replicated three times. To avoid thermal degradation, the measurement for the frequency sweep was conducted starting from 0.1 rad/s as at low frequencies, the measurement will require more time, and this would help avoid thermal degradation in the measurement.

Tensile tests: Tensile measurements were conducted on a Zwick Z010 universal testing machine (Zwick/Roell GmbH & Co. KG, Ulm, Germany) equipped with a 10 kN load cell. The measurements were conducted according to ISO 527 [

57] and replicated five times. The modulus was tested at 1 mm/min; after that, the speed of testing was 5 mm/min until break. The gauge length was 115 mm. The strain was measured by displacement transducers with a displacement of 50 mm. The tests were performed at standardized conditions (23 °C air temperature, 50% relative humidity) with ISO 527-1A specimens. For each sample, five replicate measurements were performed. The evaluation of the Young’s modulus, the strain at break and the tensile strength was performed with the software testXpert II Version 3.61 (Zwick/Roell GmbH & Co. KG, Ulm, Germany).

Impact tests: Charpy impact tests were conducted on a CEAST Resil 25 (CEAST Spa, Pianezza, Italy) impact tester equipped with a 0.5 J impact pendulum. The tests were performed according to EN ISO 179-1 [

58] at standardized conditions. The specimens were notched prior to testing with a Type A notch (ISO 179-1eA). The Charpy notched impact strength was evaluated as impact energy divided by the net cross-section area. The mean and standard deviation values were determined for six to seven samples.