Mechanics of Polymer Composites (Closed)

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Analysis and Characterization".

Viewed by 14158Editors

Interests: solid mechanics (mathematical-physical modeling, simulation and experimentation); advanced composites; continuum mechanics; fatigue; fracture and damage mechanics; computational solid mechanics; design and analysis of materials and structures

Special Issues, Collections and Topics in MDPI journals

Interests: materials characterization; modeling; optimization; composites; machine design; machine learning

Special Issues, Collections and Topics in MDPI journals

Interests: fracture mechanics; computational solid mechanics; experimental solid mechanics

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Researchers,

Polymer and polymer-based composites have become one of the advanced technological materials with excellent chemical, physical and mechanical properties that are widely used in the manufacturing of structures in aerospace, automotive, marine, oil and gas, and energy industries. These materials continue to play important rules in the growth of new applications in markets such as transportation, infrastructure, construction, sports, etc. Therefore, new developments in the mechanics of polymers and polymer composite materials and structures, including manufacturing, design, and analysis of polymer composites, have been the goal of many research projects in academic societies and industrial sectors.

This topical collection on the mechanics of polymer composites promotes and contributes to the new developments and findings related to engineering, design, and examination of polymers and polymer composites at material and structural levels. It covers new topics in the development of new materials, manufacturing science, characterization, mathematical modelling, physical behavior, computational science, experimental solid mechanics, structural design, etc., at different nano-to-macro and structural scales. The aim and scope of the topical collection includes:

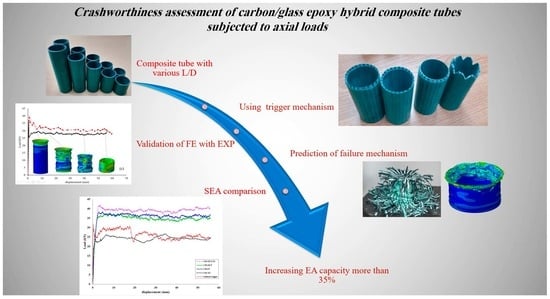

- Development of new materials: thermoplastic, thermoset, FGM, FRP composites, FML, coating, etc.

- Manufacturing science: additive manufacturing, synthesis, molding, forming, etc.

- Characterization: mechanical, thermal, physical, etc.

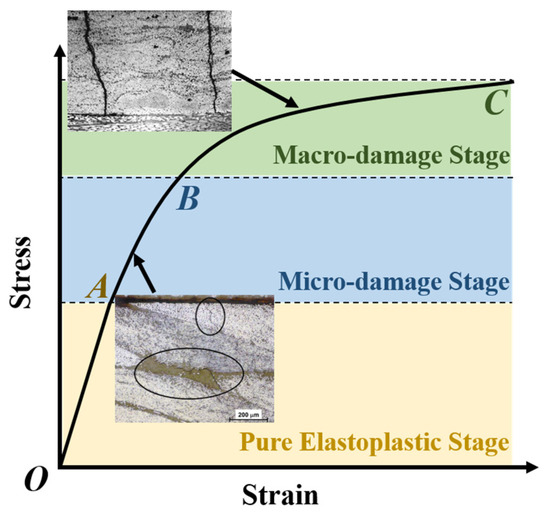

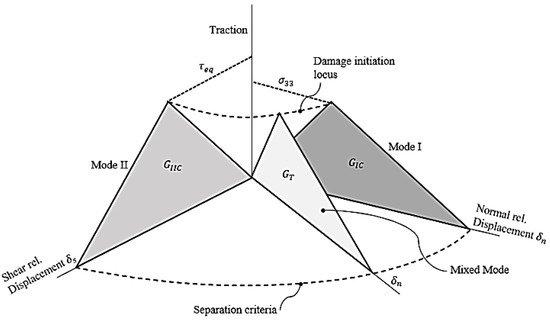

- Mathematical modelling: elastic, hyperelastic, viscoelastic, plastic, damage, failure, fatigue, etc.

- Computational solid mechanics: finite element method, finite difference, peridynamics, real-time simulation, etc.

- Novel testing methods: static, monotonic, dynamic, impact, cyclic, creep, etc.

- Experimental solid mechanics in material characterization, determination of structural response, testing of complex structures, experimental stress analysis, etc.

- Design: micro-systems, material level, structures and assemblies, super-structures, etc.

- Physical behavior: moisture absorption, erosive/corrosive environmental effect, aging and long-term performance, etc.

- New Sciences: nanomechanics, micromechanics, photomechanics, repair mechanics, recycling technology, etc.

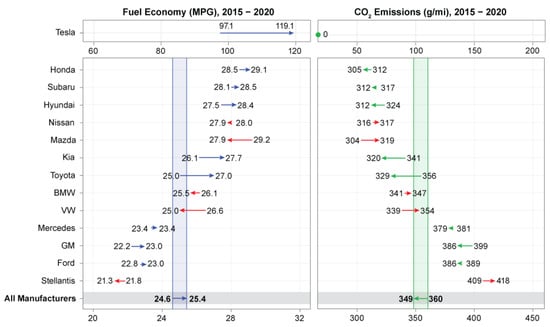

- New applications: aerospace, automotive, robotics, marine, energy, etc.

Authors are welcome to submit their latest research and findings in the form of original research articles or reviews/mini reviews on the above-mentioned topics.

Dr. Seyed Saeid Rahimian Koloor

Dr. Michal Petrů

Prof. Dr. Majid Reza Ayatollahi

Collection Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- polymers

- polymer composites

- new polymer-based materials

- manufacturing science

- characterization

- mathematical modelling

- physical behavior

- computational solid mechanics

- novel experimental methods

- new applications