Intermetallics: From Design to Structural and Properties

A special issue of Materials (ISSN 1996-1944). This special issue belongs to the section "Metals and Alloys".

Deadline for manuscript submissions: 20 May 2024 | Viewed by 297

Special Issue Editors

Interests: intermetallic alloys; powder metallurgy; titanium alloys; aluminum alloys; mechanical alloying; spark plasma sintering

Special Issues, Collections and Topics in MDPI journals

Interests: intermetallic alloys; powder metallurgy; titanium alloys; aluminum alloys; mechanical alloying; spark plasma sintering; high-entropy alloys

Special Issues, Collections and Topics in MDPI journals

Special Issue Information

Dear Colleagues,

Intermetallics are a special group of metallic materials whose properties allow use under conditions in which conventional metallic materials fail; these conditions include high temperatures, aggressive corrosive environments, and extreme abrasive and adhesive stresses.

Many intermetallic compounds display excellent physical and mechanical properties, specifically very good thermal stability, high melting point, good corrosion resistance, and low density, making them suitable candidates for high-temperature applications. However, these materials show limited ductility and high brittleness, especially at low temperatures, which impedes their wider use.

The use of materials based on intermediate compounds is very diverse, but it is always necessary to consider the choice of a particular material in terms of its physical or mechanical properties. They are used, for example, as construction materials, shape memory materials (NiTi), heating elements of electric resistance furnaces (MoSi2), magnetic alloys (Ni3Fe), hydrogen storage materials (Mg2Ni, LaNi5) or high-temperature materials (TiAl, NiAl), or for strongly oxidizing environments (FeAl).

It is my great pleasure to invite all researchers from the community of researchers investigating intermetallics to submit a manuscript in the field for this Special Issue. Full papers, communications, and reviews are all welcome.

Dr. Anna Knaislová

Dr. Pavel Novak

Guest Editors

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the special issue website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Materials is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- intermetallic alloys

- powder metallurgy

- titanium alloys

- aluminum alloys

- steels

- mechanical alloying

- spark plasma sintering

- mechanical properties

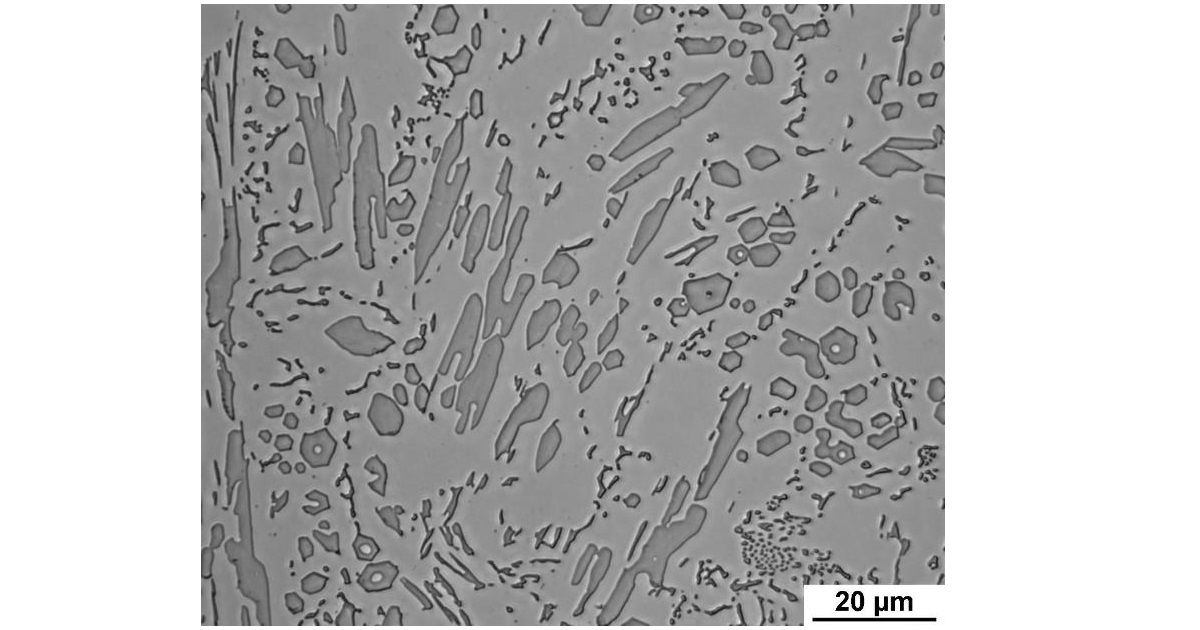

- microstructure

- melting