Design and Experiment of Quantitative Seed Feeding Wheel of Air-Assisted High-Speed Precision Seed Metering Device

Abstract

:1. Introduction

2. Materials and Methods

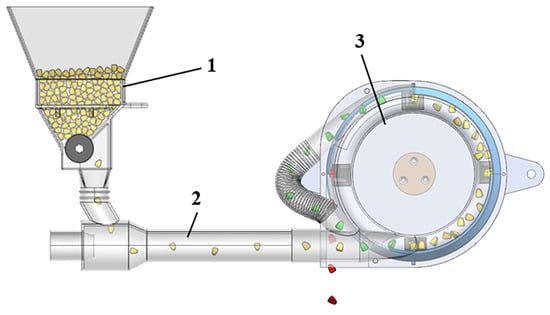

2.1. Structure and Working Principle of the Seed Feeding Device

2.2. Structural Design of Seed Feeding Wheel

2.2.1. Determination of Structural Parameters of Seed Feeding Wheel

2.2.2. Groove Helical Inclination Range

2.3. Simulation Modeling

2.4. Seed Feeding Test

2.5. Performance Test of Seed Metering Device

3. Results and Discussion

3.1. Simulation Test Results and Analysis

3.1.1. Effect of Groove Inclination on Seed Discharge Uniformity

3.1.2. Effect of Groove Length on Seed Discharge Uniformity

3.1.3. Effect of Spiral Groove Structure on Seed Motion

3.2. Seed Feeding Test

3.3. Seed Metering Test

4. Conclusions

- (1)

- In order to ensure a uniform and continuous seed flow with an air-assisted high-speed precision seed metering device, a new staggered and symmetrical spiral fluted seed feeding wheel design was developed, and the comparative analysis showed that this structure has good applicability for the uniform seed discharge of maize.

- (2)

- By analyzing the forces on the seeds in the grooves, the effect of the inclination of the spiral grooves on the variation of the forces on the seeds was determined. With a moderate inclination, the seeds changed from a relatively static state to an active sliding motion and the effect on the axial dispersion of the seeds in the grooves was enhanced.

- (3)

- The discrete element method was used to analyze the seed motion in the staggered symmetrical spiral groove seed feeding wheel, and it was found that the seed velocity of the forced layer varied the most. The information on the force of seeds in the forced layer of the conventional straight groove and staggered symmetric spiral groove structures was extracted separately, and it was concluded that the force of seeds in the staggered symmetric spiral groove was smaller, which could effectively reduce the rate of seed breakage to certain extent and was verified by the bench test method.

- (4)

- A full-factor simulation test assessing the spiral recess inclination angle and spiral recess length was conducted, and it was concluded that the staggered symmetric spiral recess seed feeding wheel led to a greater improvement in terms of the uniformity of seed flow discharge, and the spiral recess length had little effect on the coefficient of variation of seed increase, while the change in the length of the spiral recess wheel affected the uniformity of seed feeding under the seed feeding rate of the adapted high-speed seeding volume, and it was concluded that the length was relatively uniform at 50 mm. The coefficient of variation of seed flow discharge pulsation was relatively small, 3.12%, when the length of spiral groove was 50 mm and the inclination angle of spiral groove was 45°, which was determined through a bench test. This structure can effectively improve the uniformity of seed flow, and the seed discharge performance test verified that this structure can improve the seed discharge performance of air-assisted high-speed precision seed metering devices.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Yost, M.A.; Kitchen, N.R.; Sudduth, K.A.; Massey, R.E.; Sadler, E.J.; Drummond, S.T.; Volkmann, M.R. A long-term precision agriculture system sustains grain profitability. Precis. Agric. 2019, 20, 1177–1198. [Google Scholar] [CrossRef]

- Zhao, Y.S.; Gong, L.; Huang, Y.X.; Liu, C. A review of key techniques of vision-based control for harvesting robot. Comput. Electron. Agr. 2016, 127, 311–323. [Google Scholar] [CrossRef]

- Mikula, K.; Izydorczyk, G.; Skrzypczak, D.; Mironiuk, M.; Chojnacka, K. Controlled release micronutrient fertilizers for precision agriculture—A review. Sci. Total Environ. 2020, 712, 136365. [Google Scholar] [CrossRef]

- Kusumastuti, R.D.; Van Donk, D.P.; Teunter, R. Crop-related harvesting and processing planning: A review. Int. J. Prod. Econ. 2016, 174, 76–92. [Google Scholar] [CrossRef]

- O’Brien, P.; Daigh, A. Tillage practices alter the surface energy balance—A review. Soil Till. Res. 2019, 195, 104354. [Google Scholar] [CrossRef]

- Gao, X.J.; Zhou, Z.Y.; Xu, Y.; Yu, Y.B.; Su, Y.; Cui, T. Numerical simulation of particle motion characteristics in quantitative seed feeding system. Powder Technol. 2020, 367, 643–658. [Google Scholar] [CrossRef]

- Wang, J.W.; Qi, X.; Xu, C.S.; Wang, Z.; Jiang, Y.; Tang, H. Design Evaluation and Performance Analysis of the Inside-Filling Air-Assisted High-Speed Precision Maize Seed-Metering Device. Sustainability 2021, 13, 5483. [Google Scholar] [CrossRef]

- Shi, Y.Y.; Chen, M.; Wang, X.C.; Odhiambo, M.O.; Ding, W. Analysis and experiment of fertilizing performance for precision fertilizer applicator in rice and wheat fields. Trans. Chin. Soc. Agric. Mach. 2017, 48, 97–103. [Google Scholar] [CrossRef]

- Sun, J.F.; Chen, H.M.; Duan, J.L.; Liu, Z.; Zhu, Q.C. Mechanical properties of the grooved-wheel drilling particles under multivariate interaction influenced based on 3D printing and EDEM simulation. Comput. Electron. Agr. 2020, 172, 105329. [Google Scholar] [CrossRef]

- Tian, L.Q.; Wang, J.W.; Tang, H.; Li, S.W.; Zhou, W.Q.; Shen, H.G. Design and performance experiment of helix grooved rice seeding device. Trans. Chin. Soc. Agric. Mach. 2016, 47, 46–52. [Google Scholar] [CrossRef]

- Liu, C.B.; Zang, Y.; Luo, X.W.; Zeng, S.; Wang, Z.M.; Yang, W. Design and experiment of spiral grooved wheel for rice direct seeding machine. J. Shenyang Agric. Univ. 2016, 47, 734–739. [Google Scholar] [CrossRef]

- Jiang, M.; Liu, C.L.; Du, X. Research on continuous granular material flow detection method and sensor. Measurement 2021, 182, 109773. [Google Scholar] [CrossRef]

- Yi, M.G.; Zhang, S.M.; Liu, C.L.; Wen, Q. Design and experimental analysis of new type force feed for alfalfa sowing. J. Agric. Mech. Res. 2014, 36, 161–164. [Google Scholar] [CrossRef]

- Karayel, D.; Wiesehoff, M.; Merzi, A.O.; Müller, J. Laboratory measurement of seed drill seed spacing and velocity of fall of seeds using high-speed camera system. Comput. Electron. Agr. 2006, 50, 89–96. [Google Scholar] [CrossRef]

- Gao, X.J.; Xu, Y.; Yang, L.; Zhang, D.; Cui, T. Simulation and experiment of uniformity of venturi feeding tube based on DEM CFD coupling. Trans. Chin. Soc. Agric. Mach. 2018, 49, 92–100. [Google Scholar] [CrossRef]

- Lei, X.L.; Liao, Y.T.; Li, Z.D.; Cao, X.Y.; Li, S.; Wei, Y.P.; Liao, Q.X. Design and experiment of seed feeding device in air-assisted centralized metering device for rapeseed and wheat. Trans. Chin. Soc. Agric. Eng. 2015, 31, 734–739. [Google Scholar] [CrossRef]

- Correia, T.; Sousa, S.; Silva, P.; Dias, P.P.; Gomes, A. Sowing performance by a metering mechanism of continuous flow in different slope conditions. Eng. Agric. 2016, 36, 839–845. [Google Scholar] [CrossRef] [Green Version]

- Gao, X.J.; Xie, G.F.; Xu, Y.; Yu, Y.B.; Lai, Q.H. Application of a staggered symmetrical spiral groove wheel on a quantitative feeding device and investigation of particle motion characteristics based on DEM. Powder Technol. 2022, 407, 117650. [Google Scholar] [CrossRef]

- Ma, X.; Kuang, J.X.; Qi, L.; Liang, Z.; Tan, Y.; Jiang, L. Design and experiment of precision seeder for rice paddy field seedling. Trans. Chin. Soc. Agric. Mach. 2015, 46, 31–37. [Google Scholar] [CrossRef]

- Gao, X.J.; Cui, T.; Zhou, Z.Y.; Yu, Y.B.; Song, W. DEM study of particle motion in novel high-speed seed metering device. Adv. Powder Technol. 2021, 32, 1438–1449. [Google Scholar] [CrossRef]

- Maleki, M.R.; Jafari, J.; Raufat, M.; Mouazen, A.; Baerdemaeker, J. Evaluation of seed distribution uniformity of a multi-flight auger as a grain drill metering device. Biosyst. Eng. 2006, 94, 535–543. [Google Scholar] [CrossRef]

- Zeng, S.; Tang, H.T.; Luo, X.W.; Ma, G.H.; Wang, Z.M.; Zang, Y.; Zhang, M.H. Design and experiment of precision rice hill-drop drilling machine for dry land with synchronous fertilizing. Trans. Chin. Soc. Agric. Eng. 2012, 28, 12–19. [Google Scholar] [CrossRef]

- Geng, F.; Xu, D.Y.; Yuan, Z.L.; Yan, Y.M.; Luo, D.S.; Wang, H.S.; Li, B. Numerical simulation on fluidization characteristics of tobacco particles in fluidized bed dryers. Chem. Eng. J. 2009, 150, 581–592. [Google Scholar] [CrossRef]

- Altieri, G.; Renzo, G.; Genovese, F. Horizontal centrifuge with screw conveyor (decanter): Optimization of oil/water levels and differential speed during olive oil extraction. J. Food Eng. 2013, 119, 561–572. [Google Scholar] [CrossRef]

- Jin, M.; Zhang, M.; Wang, G.; Liang, S.N.; Wu, C.Y.; He, R.Y. Analysis and simulation of wheel-track high clearance chassis of rape wind rower. Agriculture 2022, 12, 1150. [Google Scholar] [CrossRef]

- Pan, S.Q.; Zhao, Y.X.; Jin, L.; Qu, G.B.; Tian, G. Design and experimental research of external grooved wheel fertilizer apparatus of 2BFJ-6 type variable. J. Chin. Agric. Mech. 2016, 37, 40–42. [Google Scholar] [CrossRef]

- Liu, Q.W.; Cui, T.; Zhang, D.X.; Yang, L.; Wang, Y.X.; He, X.T.; Wang, M.T. Design and experiment of seed precise delivery mechanism for high-speed planter. Int. J. Agric. Biol. Eng. 2017, 11, 81–87. [Google Scholar] [CrossRef]

| Subsets | Parameters | Numerical Value |

|---|---|---|

| Maize grain attribute | Poisson’s ratio | 0.40 |

| Shear modulus (Pa) | 1.37 × 108 | |

| Density (kg/m3) | 1197 | |

| Seed wheel device attribute | Poisson’s ratio | 0.50 |

| Shear modulus (Pa) | 1.77 × 108 | |

| Density (kg/m3) | 1180 | |

| Collision recovery coefficient | Seed–seed | 0.18 |

| Seed–feeding wheel | 0.71 | |

| Static friction coefficient | Seed–seed | 0.03 |

| Seed-feeding wheel | 0.46 | |

| Dynamic friction coefficient | Seed–seed | 0.01 |

| Seed–feeding wheel | 0.09 | |

| Other parameters | Gravity acceleration (m/s2) | 9.81 |

| Factor | Horizontal | ||||

|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | |

| Spiral groove inclination ρ (°) | 30 | 45 | 60 | 75 | 90 |

| Spiral groove length l (mm) | 20 | 35 | 50 | ||

| Serial Number | Spiral Groove Length (mm) | Spiral Groove Inclination ρ (°) | Coefficient of Variation of Seed Increment (%) |

|---|---|---|---|

| 1 | 20 | 30 | 27.33 |

| 2 | 20 | 45 | 20.92 |

| 3 | 20 | 60 | 26.25 |

| 4 | 20 | 75 | 28.89 |

| 5 | 20 | 90 | 37.53 |

| 6 | 35 | 30 | 26.12 |

| 7 | 35 | 45 | 22.05 |

| 8 | 35 | 60 | 25.34 |

| 9 | 35 | 75 | 28.15 |

| 10 | 35 | 90 | 33.58 |

| 11 | 50 | 30 | 24.55 |

| 12 | 50 | 45 | 19.39 |

| 13 | 50 | 60 | 24.25 |

| 14 | 50 | 75 | 26.80 |

| 15 | 50 | 90 | 31.88 |

| Groove Obliquity | Test Number | Coefficient of Variation (%) | Average of Coefficient of Variation (%) | Breakage Rate (%) |

|---|---|---|---|---|

| ρ = 30° | 1 | 5.72 | 6.88 | 1.92 |

| 2 | 5.33 | |||

| 3 | 5.69 | |||

| ρ = 45° | 1 | 2.28 | 3.12 | 0.69 |

| 2 | 2.13 | |||

| 3 | 2.08 | |||

| ρ = 90° | 1 | 14.37 | 16.32 | 3.12 |

| 2 | 13.83 | |||

| 3 | 13.46 |

| Geneva Type | Interval | Qualified Rate (%) | Missed Seeding Rate (%) |

|---|---|---|---|

| Straight slotted seed feeding wheel | 0~200 | 83.0 | 17.0 |

| 200~400 | 89.0 | 6.0 | |

| 400~600 | 91.5 | 3.0 | |

| 600~800 | 91.0 | 2.0 | |

| 800~1000 | 92.0 | 2.0 | |

| Spiral groove type seed feeding wheel | 0~200 | 87.5 | 12.0 |

| 200~400 | 89.5 | 7.0 | |

| 400~600 | 91.0 | 2.5 | |

| 600~800 | 92.0 | 2.0 | |

| 800~1000 | 91.5 | 2.5 | |

| Gridded slot seed feeding wheel | 0~200 | 90.0 | 4.0 |

| 200~400 | 89.5 | 5.5 | |

| 400~600 | 91.5 | 2.0 | |

| 600~800 | 91.0 | 2.0 | |

| 800~1000 | 91.5 | 2.5 | |

| Staggered symmetrical spiral groove type seed feeding wheel | 0~200 | 92.5 | 2.0 |

| 200~400 | 93.0 | 0.5 | |

| 400~600 | 91.5 | 0.0 | |

| 600~800 | 92.5 | 0.0 | |

| 800~1000 | 92.0 | 0.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gao, X.; Zhao, P.; Li, J.; Xu, Y.; Huang, Y.; Wang, L. Design and Experiment of Quantitative Seed Feeding Wheel of Air-Assisted High-Speed Precision Seed Metering Device. Agriculture 2022, 12, 1951. https://doi.org/10.3390/agriculture12111951

Gao X, Zhao P, Li J, Xu Y, Huang Y, Wang L. Design and Experiment of Quantitative Seed Feeding Wheel of Air-Assisted High-Speed Precision Seed Metering Device. Agriculture. 2022; 12(11):1951. https://doi.org/10.3390/agriculture12111951

Chicago/Turabian StyleGao, Xiaojun, Pengfei Zhao, Jiang Li, Yang Xu, Yuxiang Huang, and Long Wang. 2022. "Design and Experiment of Quantitative Seed Feeding Wheel of Air-Assisted High-Speed Precision Seed Metering Device" Agriculture 12, no. 11: 1951. https://doi.org/10.3390/agriculture12111951