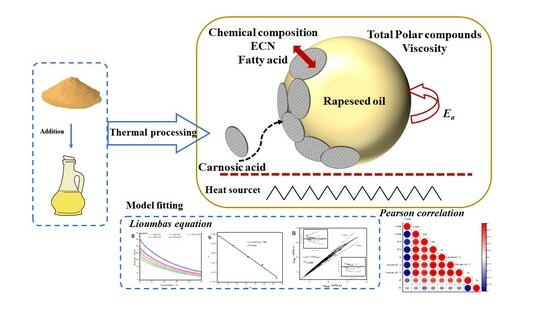

A Novel Model for Evaluating the Natural Antioxidant Carnosic Acid to Improve the Stability of Rapeseed Oil in the Thermal Degradation

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Thermal Degradation Procedure

2.3. Viscosity Properties of Rapeseed Oil

2.4. Fatty Acid Composition of Rapeseed Oil

2.5. Total Polar Compounds (TPC) of Rapeseed Oil

2.6. Statistical Analysis

3. Results and Discussion

3.1. The Newtonian Behavior of Rapeseed Oil

3.2. The Dependency of Viscosity on Temperature

3.3. The Chemical Composition of Rapeseed Oil

3.4. The Total Polar Compounds (TPC) of Rapeseed Oil

3.5. The Model Regression of Rapeseed Oil

3.6. Pearson Correlation of Rapeseed Oil

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| RSO | rapeseed oil |

| ECN | effective carbon numbers |

| TPC | total polar compounds |

| tP | processing time (h) |

| C | control samples |

| CA | carnosic acid |

| TBHQ | tert-Butylhydroquinone |

| FA | fatty acid |

| b | constant data in the Lioumbas model |

| a | constant data in the Lioumbas model |

| μ0 | constant data in the Arrhenius model |

| Ea | activation energy in the Arrhenius model |

| R | universal gas constant, in the Arrhenius model |

| Tm | measured temperature |

| TAG | triacylglycerol |

| UFAs | unsaturated fatty acids |

| MUFAs | monounsaturated fatty acids |

| PUFAs | polyunsaturated fatty acids |

References

- Tang, L.; Cao, M.; Liao, C.; Xu, Y.; Karrar, E.; Liu, R.; Chang, M. Prolonging oxidation stability of peony (Paeonia suffruticosa Andr.) seed oil by endogenous lipid concomitants: Phospholipids enhance antioxidant capacity by improving the function of tocopherol. Ind. Crops Prod. 2023, 197, 116552. [Google Scholar] [CrossRef]

- Rękas, A.; Wroniak, M.; Rusinek, R. Influence of roasting pretreatment on high-oleic rapeseed oil quality evaluated by analytical and sensory approaches. Int. J. Food Sci. Technol. 2015, 50, 2208–2214. [Google Scholar] [CrossRef]

- Asokapandian, S.; Swamy, G.J.; Hajjul, H. Deep fat frying of foods: A critical review on process and product parameters. Crit. Rev. Food Sci. Nutr. 2020, 60, 3400–3413. [Google Scholar] [CrossRef] [PubMed]

- Gupta, M.K. Frying Oils, Bailey’s Industrial Oil and Fat Products; John Wiley & Sons Inc.: Hoboken, NJ, USA, 2005; Volume 6, pp. 1–31. [Google Scholar]

- Randhawa, S.; Mukherjee, T. Effect of containers on the thermal degradation of vegetable oils. Food Control 2023, 144, 109344. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Cai, W.; Liu, Y. Comparison of different polar compounds-induced cytotoxicity in human hepatocellular carcinoma HepG2 cells. Lipids Health Dis. 2016, 15, 30. [Google Scholar] [CrossRef]

- Xu, L.; Wu, G.; Zhang, Y.; Wang, Q.; Zhao, C.; Zhang, H.; Jin, Q.; Wang, X. Evaluation of glycerol core aldehydes formation in edible oils under restaurant deep frying. Food Res. Int. 2020, 137, 109696. [Google Scholar] [CrossRef]

- Wu, G.; Han, S.; Li, X.; Karrar, E.; Xu, L.; Jin, Q.; Zhang, H.; Wang, X. Effect of the phenolic extract of Camellia oleifera seed cake on the oxidation process of soybean oil by 1H nuclear magnetic resonance during frying. LWT 2021, 150, 111900. [Google Scholar] [CrossRef]

- Mestdagh, F.; Castelein, P.; Van Peteghem, C.; De Meulenaer, B. Importance of oil degradation components in the formation of acrylamide in fried foodstuffs. J. Agric. Food Chem. 2008, 56, 6141–6144. [Google Scholar] [CrossRef]

- Wagoner, T.B.; Çakır-Fuller, E.; Shingleton, R.; Drake, M.; Foegeding, E.A. Viscosity drives texture perception of protein beverages more than hydrocolloid type. J. Texture Stud. 2020, 51, 78–91. [Google Scholar] [CrossRef]

- Zhao, B.; Fu, S.; Li, H.; Chen, Z. Chemical characterization of Chinese perilla seed oil. J. Oleo Sci. 2021, 70, 1575–1583. [Google Scholar] [CrossRef]

- Chen, J.; Zhang, L.; Geng, Q.; Jing, B.; Yu, X. Determination of total polar compounds in frying oils by PE-film-based FTIR and ATR-FTIR spectroscopy. Eur. J. Lipid Sci. Technol. 2018, 120, 1800250. [Google Scholar] [CrossRef]

- Cao, X.; Li, X.; Shu, N.; Tan, C.P.; Xu, Y.-J.; Liu, Y. The Characteristics and Analysis of Polar Compounds in Deep-Frying Oil: A Mini Review. Food Anal. Methods 2022, 15, 2767–2776. [Google Scholar] [CrossRef]

- Fasina, O.; Colley, Z. Viscosity and specific heat of vegetable oils as a function of temperature: 35 °C to 180 °C. Int. J. Food Prop. 2008, 11, 738–746. [Google Scholar] [CrossRef]

- Kim, J.; Kim, D.N.; Lee, S.H.; Yoo, S.-H.; Lee, S. Correlation of fatty acid composition of vegetable oils with rheological behaviour and oil uptake. Food Chem. 2010, 118, 398–402. [Google Scholar] [CrossRef]

- Lioumbas, J.S.; Ampatzidis, C.; Karapantsios, T.D. Effect of potato deep-fat frying conditions on temperature dependence of olive oil and palm oil viscosity. J. Food Eng. 2012, 113, 217–225. [Google Scholar] [CrossRef]

- Meenu, M.; Decker, E.A.; Xu, B. Application of vibrational spectroscopic techniques for determination of thermal degradation of frying oils and fats: A review. Crit. Rev. Food Sci. Nutr. 2022, 62, 5744–5765. [Google Scholar] [CrossRef] [PubMed]

- Mira-Sánchez, M.D.; Castillo-Sánchez, J.; Morillas-Ruiz, J.M. Comparative study of rosemary extracts and several synthetic and natural food antioxidants. Relevance of carnosic acid/carnosol ratio. Food Chem. 2020, 309, 125688. [Google Scholar] [CrossRef]

- Velasco, J.; Gil, M.-J.; Wen, Y.-Q.; García-González, A.; Ruiz-Méndez, M.-V. New Insights into the Loss of Antioxidant Effectiveness of Phenolic Compounds in Vegetable Oils in the Presence of Phosphatidylcholine. Antioxidants 2023, 12, 1993. [Google Scholar] [CrossRef]

- Moczkowska, M.; Karp, S.; Horbanczuk, O.K.; Hanula, M.; Wyrwisz, J.; Kurek, M.A. Effect of rosemary extract addition on oxidative stability and quality of hemp seed oil. Food Bioprod. Process. 2020, 124, 33–47. [Google Scholar] [CrossRef]

- Yeddes, W.; Chalghoum, A.; Aidi-Wannes, W.; Ksouri, R.; Saidani Tounsi, M. Effect of bioclimatic area and season on phenolics and antioxidant activities of rosemary (Rosmarinus officinalis L.) leaves. J. Essent. Oil Res. 2019, 31, 432–443. [Google Scholar] [CrossRef]

- Guo, Q.; Gao, S.; Sun, Y.; Gao, Y.; Wang, X.; Zhang, Z. Antioxidant efficacy of rosemary ethanol extract in palm oil during frying and accelerated storage. Ind. Crops Prod. 2016, 94, 82–88. [Google Scholar] [CrossRef]

- Yang, Y.; Song, X.; Sui, X.; Qi, B.; Wang, Z.; Li, Y.; Jiang, L. Rosemary extract can be used as a synthetic antioxidant to improve vegetable oil oxidative stability. Ind. Crops Prod. 2016, 80, 141–147. [Google Scholar] [CrossRef]

- Li, P.; Yang, X.; Lee, W.J.; Huang, F.; Wang, Y.; Li, Y. Comparison between synthetic and rosemary-based antioxidants for the deep frying of French fries in refined soybean oils evaluated by chemical and non-destructive rapid methods. Food Chem. 2021, 335, 127638. [Google Scholar] [CrossRef] [PubMed]

- He, X.; Li, B.; Yu, X.; Zhuang, Y.; Li, C.; Dong, L.; Zhang, Y.; Wang, S. Inhibiting Effects of Ginger and Rosemary on the Formation of Heterocyclic Amines, Polycyclic Aromatic Hydrocarbons, and Trans Fatty Acids in Fried Pork Balls. Foods 2022, 11, 3767. [Google Scholar] [CrossRef] [PubMed]

- Ma, L.; Liu, G.; Liu, X. Amounts of malondialdehyde do not accurately represent the real oxidative level of all vegetable oils: A kinetic study of malondialdehyde formation. Int. J. Food Sci. Technol. 2019, 54, 412–423. [Google Scholar] [CrossRef]

- Li, X.; Wu, X.; Liu, R.; Jin, Q.; Wang, X. Effect of frying conditions on fatty acid profile and total polar materials via viscosity. J. Food Eng. 2015, 166, 349–355. [Google Scholar] [CrossRef]

- Li, P.; Wu, G.; Yang, D.; Zhang, H.; Qi, X.; Jin, Q.; Wang, X. Effect of multistage process on the quality, water and oil distribution and microstructure of French fries. Food Res. Int. 2020, 137, 109229. [Google Scholar] [CrossRef]

- Sharoba, A.M.; Ramadan, M.F. Impact of frying on fatty acid profile and rheological behaviour of some vegetable oils. J. Food Process Technol. 2012, 3, 2. [Google Scholar] [CrossRef]

- Chen, Y.; Wang, Y.; Zheng, X.; Jin, J.; Jin, Q.; Akoh, C.C.; Wang, X. Novel disaturated triacylglycerol-rich fat from Garcinia mangostana: Lipid compositions, fatty acid distributions, triacylglycerol species and thermal characteristics. Ind. Crops Prod. 2023, 197, 116506. [Google Scholar] [CrossRef]

- Li, X.; Wu, G.; Wu, Y.; Karrar, E.; Huang, J.; Jin, Q.; Zhang, H.; Wang, X. Effectiveness of the rapid test of polar compounds in frying oils as a function of environmental and compositional variables under restaurant conditions. Food Chem. 2020, 312, 126041. [Google Scholar] [CrossRef]

- Tarmizi, A.H.A.; Niranjan, K.; Gordon, M. Physico-chemical changes occurring in oil when atmospheric frying is combined with post-frying vacuum application. Food Chem. 2013, 136, 902–908. [Google Scholar] [CrossRef] [PubMed]

- Bou, R.; Navas, J.; Tres, A.; Codony, R.; Guardiola, F. Quality assessment of frying fats and fried snacks during continuous deep-fat frying at different large-scale producers. Food Control 2012, 27, 254–267. [Google Scholar] [CrossRef]

- Liberty, J.T.; Dehghannya, J.; Ngadi, M.O. Effective strategies for reduction of oil content in deep-fat fried foods: A review. Trends Food Sci. Technol. 2019, 92, 172–183. [Google Scholar] [CrossRef]

- Dehghannya, J.; Ngadi, M. Recent advances in microstructure characterization of fried foods: Different frying techniques and process modeling. Trends Food Sci. Technol. 2021, 116, 786–801. [Google Scholar] [CrossRef]

- Zhao, Z.; Huang, J.; Jin, Q.; Wang, X. Influence of oryzanol and tocopherols on thermal oxidation of rice bran oil during the heating process at Chinese cooking temperatures. LWT 2021, 142, 111022. [Google Scholar] [CrossRef]

- Santos, J.; Santos, I.; Souza, A. Effect of heating and cooling on rheological parameters of edible vegetable oils. J. Food Eng. 2005, 67, 401–405. [Google Scholar] [CrossRef]

- Yang, D.; Wu, G.; Lu, Y.; Li, P.; Qi, X.; Zhang, H.; Wang, X.; Jin, Q. Comparative analysis of the effects of novel electric field frying and conventional frying on the quality of frying oil and oil absorption of fried shrimps. Food Control 2021, 128, 108195. [Google Scholar] [CrossRef]

- Senanayake, S.N. Rosemary and green tea extracts as natural antioxidants: Chemistry, technology, and applications. In Lipid Oxidation; Elsevier: Amsterdam, The Netherlands, 2013; pp. 417–438. [Google Scholar]

- Porter, N.A.; Caldwell, S.E.; Mills, K.A. Mechanisms of free radical oxidation of unsaturated lipids. Lipids 1995, 30, 277–290. [Google Scholar] [CrossRef]

- Geller, D.P.; Goodrum, J.W. Rheology of vegetable oil analogs and triglycerides. J. Am. Oil Chem. Soc. 2000, 77, 111–114. [Google Scholar] [CrossRef]

- Erickson, M.D.; Yevtushenko, D.P.; Lu, Z.-X. Oxidation and thermal degradation of oil during frying: A review of natural antioxidant use. Food Rev. Int. 2023, 39, 4665–4696. [Google Scholar] [CrossRef]

- Zhao, Y.; Wu, H.; Qu, M.; Liu, Y.; Wang, D.; Yang, H.; Wang, Y.; Wang, X.; Blasi, F. Enhancement of Oxidative Stability of Deep-Fried Sunflower Oil by Addition of Essential Oil of Amomum villosum Lour. Antioxidants 2023, 12, 1429. [Google Scholar] [CrossRef]

- Jurid, L.S.; Zubairi, S.I.; Kasim, Z.M.; Ab Kadir, I.A. The effect of repetitive frying on physicochemical properties of refined, bleached and deodorized Malaysian tenera palm olein during deep-fat frying. Arab. J. Chem. 2020, 13, 6149–6160. [Google Scholar] [CrossRef]

| C | CA-2 | CA-4 | CA-7 | TB-2 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Lioumbas model | Conditions/h | a | b | R2 | a | b | R2 | A | b | R2 | a | b | R2 | a | b | R2 |

| 0 | 6.32 ± 0.01 e | −0.19 ± 0.01 d | 0.999 | 6.23 ± 0.01 e | −0.20 ± 0.01 c | 0.999 | 6.32 ± 0.02 e | −0.19 ± 0.01 b | 0.999 | 6.23 ± 0.01 e | −0.19 ± 0.01 d | 0.999 | 6.23 ± 0.01 e | −0.20 ± 0.01 b | 0.999 | |

| 8 | 6.48 ± 0.01 d | −0.20 ± 0.01 c | 1.000 | 6.50 ± 0.01 d | −0.20 ± 0.01 c | 0.999 | 6.42 ± 0.02 d | −0.20 ± 0.02 b | 1.000 | 6.43 ± 0.02 d | −0.20 ± 0.01 c | 1.000 | 6.43 ± 0.01 d | −0.20 ± 0.01 b | 1.000 | |

| 16 | 6.79 ± 0.02 c | −0.21 ± 0.01 b | 0.998 | 6.70 ± 0.02 c | −0.21 ± 0.01 b | 0.999 | 6.72 ± 0.01 c | −0.21 ± 0.01 b | 0.999 | 6.70 ± 0.02 c | −0.21 ± 0.02 b | 0.999 | 6.71 ± 0.01 c | −0.21 ± 0.02 a | 1.000 | |

| 24 | 6.88 ± 0.01 b | −0.21 ± 0.01 b | 1.000 | 6.87 ± 0.01 b | −0.21 ± 0.02 b | 0.999 | 6.82 ± 0.01 b | −0.21 ± 0.01 b | 1.000 | 6.87 ± 0.02 b | −0.21 ± 0.01 b | 1.000 | 6.92 ± 0.01 b | −0.21 ± 0.01 a | 0.999 | |

| 32 | 7.10 ± 0.01 a | −0.22 ± 0.01 a | 1.000 | 7.19 ± 0.01 a | −0.22 ± 0.02 a | 1.000 | 7.06 ± 0.01 a | −0.22 ± 0.01 a | 1.000 | 7.19 ± 0.02 a | −0.22 ± 0.02 a | 0.999 | 7.09 ± 0.02 a | −0.22 ± 0.01 a | 1.000 | |

| Arrhenius model | Conditions/h | μ0 | Ea | R2 | μ0 | Ea | R2 | μ0 | Ea | R2 | μ0 | Ea | R2 | μ0 | Ea | R2 |

| 0 | 0.04 ± 0.01 c | 16,684.93 ± 2.22 c | 0.935 | 0.04 ± 0.01 b | 16,684.93 ± 2.96 c | 0.935 | 0.04 ± 0.01 b | 16,684.93 ± 7.21 d | 0.935 | 0.04 ± 0.01 c | 16,684.93 ± 3.97 c | 0.935 | 0.04 ± 0.01 d | 16,684.93 ± 7.33 b | 0.935 | |

| 8 | 0.04 ± 0.01 c | 17,161.38 ± 3.76 b | 0.935 | 0.05 ± 0.02 a | 16,595.06 ± 6.22 c | 0.925 | 0.03 ± 0.01 c | 17,916.81 ± 5.66 b | 0.953 | 0.06 ± 0.01 b | 15,756.17 ± 4.73 d | 0.912 | 0.05 ± 0.01 c | 16,425.37 ± 11.36 c | 0.925 | |

| 16 | 0.04 ± 0.01 c | 17,679.87 ± 3.55 a | 0.933 | 0.04 ± 0.02 b | 17,343.72 ± 3.43 b | 0.930 | 0.04 ± 0.01 b | 17,556.30 ± 6.86 c | 0.936 | 0.04 ± 0.01 bc | 17,343.72 ± 6.61 b | 0.930 | 0.03 ± 0.02 d | 18,052.69 ± 10.51 a | 0.949 | |

| 24 | 0.11 ± 0.01 b | 14,825.43 ± 4.76 d | 0.858 | 0.05 ± 0.03 a | 16,752.26 ± 5.51 c | 0.910 | 0.03 ± 0.01 c | 18,168.82 ± 10.21 a | 0.948 | 0.04 ± 0.01 bc | 17,587.39 ± 7.72 a | 0.936 | 0.07 ± 0.01 b | 15,994.97 ± 6.90 d | 0.886 | |

| 32 | 0.18 ± 0.01 a | 13,704.19 ± 4.11 e | 0.812 | 0.03 ± 0.03 c | 18,683.22 ± 4.44 a | 0.939 | 0.12 ± 0.01 a | 14,762.37 ± 5.92 e | 0.839 | 0.09 ± 0.02 a | 15,588.09 ± 5.59 d | 0.860 | 0.12 ± 0.01 a | 14,842.00 ± 5.11 e | 0.845 | |

| FA | C16:0 Palmitic Acid | C16:1 Palmitoleic Acid | C18:0 Stearic Acid | C18:1 Oleic Acid | C18:2 Linoleic Acid | C20:0 Arachidic Acid | C18:3n3 α-Linolenic Acid | C22:0 Behenic Acid | UFAs | MUFAs | PUFAs |

|---|---|---|---|---|---|---|---|---|---|---|---|

| C-0 | 4.51 ± 0.02 | 0.15 ± 0.01 | 1.49 ± 0.02 | 62.43 ± 0.33 | 20.36 ± 0.27 | 0.45 ± 0.01 | 7.46 ± 0.15 | 0.24 ± 0.01 | 90.40 ± 0.76 | 62.58 ± 0.34 | 27.82 ± 0.42 |

| C-16 | 4.83 ± 0.10 | 0.17 ± 0.01 | 1.62 ± 0.02 | 64.30 ± 0.22 | 19.03 ± 0.14 | 0.49 ± 0.01 | 6.28 ± 0.36 | 0.30 ± 0.01 | 89.78 ± 0.73 | 64.47 ± 0.23 | 25.31 ± 0.50 |

| C-32 | 5.13 ± 0.34 | 0.21 ± 0.01 | 1.80 ± 0.05 | 66.11 ± 0.38 | 17.88 ± 0.02 | 0.53 ± 0.01 | 4.91 ± 0.10 | 0.32 ± 0.01 | 89.11 ± 0.51 | 66.32 ± 0.39 | 22.79 ± 0.12 |

| CA-2-0 | 4.51 ± 0.02 | 0.15 ± 0.01 | 1.49 ± 0.02 | 62.43 ± 0.33 | 20.36 ± 0.27 | 0.45 ± 0.01 | 7.46 ± 0.15 | 0.24 ± 0.01 | 90.40 ± 0.76 | 62.58 ± 0.34 | 27.82 ± 0.42 |

| CA-2-16 | 4.79 ± 0.02 | 0.16 ± 0.01 | 1.61 ± 0.02 | 63.49 ± 0.20 | 19.62 ± 0.10 | 0.49 ± 0.01 | 6.54 ± 0.30 | 0.28 ± 0.01 | 89.81 ± 0.61 | 63.65 ± 0.21 | 26.16 ± 0.40 |

| CA-2-32 | 5.37 ± 0.36 | 0.18 ± 0.01 | 1.77 ± 0.10 | 66.31 ± 0.58 | 17.77 ± 0.24 | 0.56 ± 0.01 | 4.78 ± 0.23 | 0.32 ± 0.01 | 89.04 ± 1.06 | 66.49 ± 0.59 | 22.55 ± 0.47 |

| CA-4-0 | 4.51 ± 0.02 | 0.15 ± 0.01 | 1.49 ± 0.02 | 62.43 ± 0.33 | 20.36 ± 0.27 | 0.45 ± 0.01 | 7.46 ± 0.15 | 0.24 ± 0.01 | 90.40 ± 0.76 | 62.58 ± 0.34 | 27.82 ± 0.42 |

| CA-4-16 | 4.76 ± 0.05 | 0.17 ± 0.01 | 1.61 ± 0.01 | 63.47 ± 0.54 | 19.52 ± 0.19 | 0.48 ± 0.01 | 6.78 ± 0.32 | 0.28 ± 0.01 | 89.94 ± 1.06 | 63.64 ± 0.55 | 26.30 ± 0.51 |

| CA-4-32 | 5.02 ± 0.25 | 0.18 ± 0.01 | 1.70 ± 0.01 | 66.42 ± 0.66 | 17.92 ± 0.34 | 0.51 ± 0.01 | 5.31 ± 0.22 | 0.30 ± 0.01 | 89.83 ± 1.23 | 66.60 ± 0.67 | 23.23 ± 0.56 |

| CA-7-0 | 4.51 ± 0.02 | 0.15 ± 0.01 | 1.49 ± 0.02 | 62.43 ± 0.33 | 20.36 ± 0.27 | 0.45 ± 0.01 | 7.46 ± 0.15 | 0.24 ± 0.01 | 90.40 ± 0.76 | 62.58 ± 0.34 | 27.82 ± 0.42 |

| CA-7-16 | 4.58 ± 0.06 | 0.16 ± 0.01 | 1.68 ± 0.01 | 63.96 ± 0.34 | 19.60 ± 0.05 | 0.46 ± 0.01 | 6.60 ± 0.21 | 0.24 ± 0.01 | 90.32 ± 0.61 | 64.12 ± 0.35 | 26.20 ± 0.26 |

| CA-7-32 | 5.01 ± 0.05 | 0.17 ± 0.01 | 1.78 ± 0.01 | 65.41 ± 0.52 | 18.23 ± 0.16 | 0.50 ± 0.01 | 5.74 ± 0.10 | 0.33 ± 0.01 | 89.55 ± 0.79 | 65.58 ± 0.53 | 23.97 ± 0.26 |

| TB-2-0 | 4.51 ± 0.02 | 0.15 ± 0.01 | 1.49 ± 0.02 | 62.43 ± 0.33 | 20.36 ± 0.27 | 0.45 ±0.01 | 7.46 ± 0.15 | 0.24 ± 0.01 | 90.40 ± 0.76 | 62.58 ± 0.34 | 27.82 ± 0.42 |

| TB-2-16 | 4.87 ± 0.06 | 0.15 ± 0.01 | 1.60 ± 0.01 | 64.16 ± 0.58 | 19.15 ± 0.43 | 0.50 ±0.01 | 6.41 ± 0.35 | 0.26 ± 0.01 | 89.87 ± 1.37 | 64.31 ± 0.59 | 25.56 ± 0.78 |

| TB-2-32 | 5.16 ± 0.02 | 0.17 ± 0.01 | 1.72 ± 0.01 | 66.36 ± 0.44 | 17.64 ± 0.58 | 0.55 ± 0.01 | 5.13 ± 0.26 | 0.33 ± 0.01 | 89.30 ± 1.29 | 66.53 ± 0.45 | 22.77 ± 0.84 |

| ECN (Dimensionless) | |||||

|---|---|---|---|---|---|

| Conditions/h | C | CA-2 | CA-4 | CA-7 | TB-2 |

| 0 | 16.13 ± 0.01 c | 16.14 ± 0.01 c | 16.13 ± 0.01 e | 16.13 ± 0.01 b | 16.13 ± 0.01 a |

| 8 | 16.17 ± 0.01 b | 16.18 ± 0.01 b | 16.13 ± 0.01 d | 16.20 ± 0.01 a | 16.18 ± 0.01 b |

| 16 | 16.17 ± 0.02 b | 16.15 ± 0.01 c | 16.17 ± 0.01 c | 16.20 ± 0.01 a | 16.18 ± 0.01 b |

| 24 | 16.21 ± 0.01 a | 16.18 ± 0.01 b | 16.21 ± 0.01 b | 16.20 ± 0.01 a | 16.21 ± 0.01 a |

| 32 | 16.23 ± 0.01 a | 16.22 ± 0.01 a | 16.26 ± 0.01 a | 16.22 ± 0.01 a | 16.22 ± 0.01 a |

| TPC (%) | |||||

| 0 | 7.00 ± 0.50 e | 7.50 ± 0.50 e | 7.50 ± 0.50 e | 7.50 ± 0.50 e | 7.50 ± 0.50 e |

| 8 | 11.00 ± 0.50 d | 10.50 ± 0.50 d | 10.50 ± 0.50 d | 10.50 ± 0.50 d | 10.00 ± 0.50 d |

| 16 | 18.50 ± 0.50 c | 16.50 ± 0.50 c | 17.00 ± 0.50 c | 16.00 ± 0.50 c | 17.50 ± 0.50 c |

| 24 | 23.00 ± 0.50 b | 22.00 ± 0.50 b | 23.00 ± 0.50 b | 20.50 ± 0.50 b | 22.00 ± 0.50 b |

| 32 | 35.50 ± 0.50 a | 32.50 ± 0.50 a | 30.50 ± 0.50 a | 26.00 ± 0.50 a | 32.00 ± 0.50 a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhu, Y.; Chai, C.; Xue, Y.; Wang, Y.; Duan, Z. A Novel Model for Evaluating the Natural Antioxidant Carnosic Acid to Improve the Stability of Rapeseed Oil in the Thermal Degradation. Antioxidants 2024, 13, 296. https://doi.org/10.3390/antiox13030296

Zhu Y, Chai C, Xue Y, Wang Y, Duan Z. A Novel Model for Evaluating the Natural Antioxidant Carnosic Acid to Improve the Stability of Rapeseed Oil in the Thermal Degradation. Antioxidants. 2024; 13(3):296. https://doi.org/10.3390/antiox13030296

Chicago/Turabian StyleZhu, Yingdan, Chengliang Chai, Yalin Xue, Yong Wang, and Zhangqun Duan. 2024. "A Novel Model for Evaluating the Natural Antioxidant Carnosic Acid to Improve the Stability of Rapeseed Oil in the Thermal Degradation" Antioxidants 13, no. 3: 296. https://doi.org/10.3390/antiox13030296