Space-Borne Monitoring of NOx Emissions from Cement Kilns in South Korea

Abstract

:1. Introduction

2. Data and Methodology

2.1. Satellite

2.2. Surface Monitoring and Field Campaign

2.3. Model and Emissions

2.4. Conservative Downscaling

3. Results

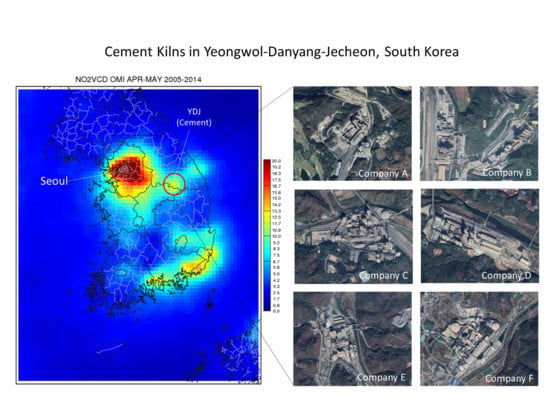

3.1. Space-Borne Monitoring

3.2. Surface Monitoring

3.3. In-Situ Measurements

3.4. Impact Assessment by Model

4. Discussion

- The OMI NO2 VCD detected signals from the South Korean cement industry. Additionally, application of the downscaling technique helped pinpoint small-scale, local emission sources.

- Emission rates from the South Korean cement industry need further investigation. The model simulation can explain only half of currently observed OMI NO2 VCDs. Although this study only described NOx emissions, such emissions may indicate other emissions that could be an important subject of future research.

- Observations from surface-monitoring sites and aircraft measurements also support the detections by satellite. We also suggest that additional, continuous surface-monitoring sites be established downwind of cement factories to monitor their emissions. On-site measurements, if available, should be made available to the public for further investigation.

- Modeling analyses demonstrate that cement industry emissions have significant impact even with the current emissions inventory. We estimate that actual emissions exceed current inventories by more than a factor of two, suggesting significant environmental impacts, both on surface ozone (up to approximately 4 ppb) and PM2.5 (up to approximately 2 μg/m3).

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Abu-Allaban, M.; Abu-Qudais, H. Impact Assessment of Ambient Air Quality by Cement Industry: A Case Study in Jordan. Aerosol Air Qual. Res. 2011, 11, 802–810. [Google Scholar] [CrossRef]

- Dong, Z.; Bank, M.S.; Spengler, J.D. Assessing Metal Exposures in a Community near a Cement Plant in the Northeast U.S. Int. J. Environ. Res. Public Health 2015, 12, 952–969. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Mehraj, S.S.; Bhat, G.A.; Balkhi, H.M.; Gul, T. Health risks for population living in the neighborhood of a cement factory. Afr. J. Environ. Sci. Technol. 2013, 7, 1044–1052. [Google Scholar] [CrossRef]

- Oguntoke, O.; Awanu, A.E.; Annegarn, H.J. Impact of cement factory operations on air quality and human health in Ewekoro Local Government Area, South-Western Nigeria. Int. J. Environ. Stud. 2012, 69, 934–945. [Google Scholar] [CrossRef]

- Rovira, J.; Flores, J.; Schuhmacher, M.; Nadal, M.; Domingo, J.L. Long-Term Environmental Surveillance and Health Risks of Metals and PCDD/Fs Around a Cement Plant in Catalonia, Spain. Hum. Ecol. Risk Assess. An Int. J. 2015, 21, 514–532. [Google Scholar] [CrossRef] [Green Version]

- Schuhmacher, M.; Domingo, J.L.; Garreta, J. Pollutants emitted by a cement plant: Health risks for the population living in the neighborhood. Environ. Res. 2004, 95, 198–206. [Google Scholar] [CrossRef]

- Cho, S.H.; Kim, H.W.; Han, Y.J.; Kim, W.J. Characteristics of Fine Particles Measured in Two Different Functional Areas and Identification of Factors Enhancing Their Concentrations. J. Korean Soc. Atmos. Environ. 2016, 32, 100–113. [Google Scholar] [CrossRef]

- Han, Y.J.; Kim, H.W.; Cho, S.H.; Kim, P.R.; Kim, W.J. Metallic elements in PM2.5 in different functional areas of Korea: Concentrations and source identification. Atmos. Res. 2015, 153, 416–428. [Google Scholar] [CrossRef]

- Lee, H.S.; Lee, C.G.; Kim, D.H.; Song, H.S.; Jung, M.S.; Kim, J.Y.; Park, C.H.; Ahn, S.C.; Yu, S. Do Emphysema prevalence related air pollution caused by a cement plant. Ann. Occup. Environ. Med. 2016, 28, 17. [Google Scholar] [CrossRef] [Green Version]

- Won, J.H.; Lee, T.G. Estimation of total annual mercury emissions from cement manufacturing facilities in Korea. Atmos. Environ. 2012, 62, 265–271. [Google Scholar] [CrossRef]

- Leem, J.H.; Kim, S.T.; Kim, H.C. Public-health impact of outdoor air pollution for 2(nd) air pollution management policy in Seoul metropolitan area, Korea. Ann. Occup. Environ. Med. 2015, 27, 7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kim, S.H.; Lee, C.G.; Song, H.S.; Lee, H.S.; Jung, M.S.; Kim, J.Y.; Park, C.H.; Ahn, S.C.; Yu, S. Do Ventilation impairment of residents around a cement plant. Ann. Occup. Environ. Med. 2015, 27, 3. [Google Scholar] [CrossRef] [Green Version]

- Andres, R.J.; Marland, G.; Fung, I.; Matthews, E. A 1° × 1° distribution of carbon dioxide emissions from fossil fuel consumption and cement manufacture, 1950–1990. Glob. Biogeochem. Cycles 1996, 10, 419–429. [Google Scholar] [CrossRef]

- Benhelal, E.; Zahedi, G.; Shamsaei, E.; Bahadori, A. Global strategies and potentials to curb CO2 emissions in cement industry. J. Clean. Prod. 2013, 51, 142–161. [Google Scholar] [CrossRef]

- Ke, J.; McNeil, M.; Price, L.; Khanna, N.Z.; Zhou, N. Estimation of CO2 emissions from China’s cement production: Methodologies and uncertainties. Energy Policy 2013, 57, 172–181. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Zhu, Q.; Geng, Y. Trajectory and driving factors for GHG emissions in the Chinese cement industry. J. Clean. Prod. 2013, 53, 252–260. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. CARBON D IOXIDE E MISSIONS FROM THE G LOBAL C EMENT I NDUSTRY 1. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- Conesa, J.A.; Gálvez, A.; Mateos, F.; Martín-Gullón, I.; Font, R. Organic and inorganic pollutants from cement kiln stack feeding alternative fuels. J. Hazard. Mater. 2008, 158, 585–592. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- Schuhmacher, M.; Nadal, M.; Domingo, J.L. Environmental monitoring of PCDD/Fs and metals in the vicinity of a cement plant after using sewage sludge as a secondary fuel. Chemosphere 2009, 74, 1502–1508. [Google Scholar] [CrossRef]

- Rovira, J.; Mari, M.; Nadal, M.; Schuhmacher, M.; Domingo, J.L. Partial replacement of fossil fuel in a cement plant: Risk assessment for the population living in the neighborhood. Sci. Total Environ. 2010, 408, 5372–5380. [Google Scholar] [CrossRef] [PubMed]

- Prisciandaro, M.; Mazziotti, G.; Veglió, F. Effect of burning supplementary waste fuels on the pollutant emissions by cement plants: A statistical analysis of process data. Resour. Conserv. Recycl. 2003, 39, 161–184. [Google Scholar] [CrossRef]

- TEMIS. Available online: http://www.temis.nl/airpollution/no2.html (accessed on 17 August 2020).

- Levelt, P.; van den Oord, G.H.J.; Dobber, M.R.; Malkki, A.; Stammes, P.; Lundell, J.O.V.; Saari, H. The ozone monitoring instrument. IEEE Trans. Geosci. Remote Sens. 2006, 44, 1093–1101. [Google Scholar] [CrossRef]

- Boersma, K.F.; Eskes, H.J.; Brinksma, E.J. Error analysis for tropospheric NO2 retrieval from space. J. Geophys. Res. 2004, 109, D04311. [Google Scholar] [CrossRef]

- Boersma, K.F.; Eskes, H.J.; Veefkind, J.P.; Brinksma, E.J.; van der A, R.J.; Sneep, M.; van den Oord, G.H.J.; Levelt, P.F.; Stammes, P.; Gleason, J.F.; et al. Near-real time retrieval of tropospheric NO2 from OMI. Atmos. Chem. Phys. 2007, 7, 2103–2118. [Google Scholar] [CrossRef] [Green Version]

- AirKorea. Available online: https://www.airkorea.or.kr/index (accessed on 17 August 2020).

- KORUS-AQ. Available online: https://espo.nasa.gov/korus-aq/content/KORUS-AQ (accessed on 17 August 2020).

- Kim, H.C.; Kim, E.; Bae, C.; Cho, J.H.; Kim, B.-U.; Kim, S. Regional contributions to particulate matter concentration in the Seoul metropolitan area, South Korea: Seasonal variation and sensitivity to meteorology and emissions inventory. Atmos. Chem. Phys. 2017, 17, 10315–10332. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.C.; Kim, S.; Kim, B.-U.; Jin, C.-S.; Hong, S.; Park, R.; Son, S.-W.; Bae, C.; Bae, M.; Song, C.-K.; et al. Recent increase of surface particulate matter concentrations in the Seoul Metropolitan Area, Korea. Sci. Rep. 2017, 7, 4710. [Google Scholar] [CrossRef] [Green Version]

- Kim, B.-U.; Bae, C.; Kim, H.C.; Kim, E.; Kim, S. Spatially and chemically resolved source apportionment analysis: Case study of high particulate matter event. Atmos. Environ. 2017, 162, 55–70. [Google Scholar] [CrossRef]

- Kim, B.-U.; Kim, O.; Kim, H.C.; Kim, S. Influence of fossil-fuel power plant emissions on the surface fine particulate matter in the Seoul Capital Area, South Korea. J. Air Waste Manag. Assoc. 2016, 66, 863–873. [Google Scholar] [CrossRef] [Green Version]

- Byun, D.; Schere, K.L. Review of the Governing Equations, Computational Algorithms, and Other Components of the Models-3 Community Multiscale Air Quality (CMAQ) Modeling System. Appl. Mech. Rev. 2006, 59, 51. [Google Scholar] [CrossRef]

- Carter, W.P.L. Documentation of the SAPRC-99 Chemical Mechanism for VOC Reactivity Assessment. Assessment 1999, 1, 329. [Google Scholar]

- Zhang, Q.; Streets, D.G.; Carmichael, G.R.; He, K.B.; Huo, H.; Kannari, A.; Klimont, Z.; Park, I.S.; Reddy, S.; Fu, J.S.; et al. Asian emissions in 2006 for the NASA INTEX-B mission. Atmos. Chem. Phys. 2009, 9, 5131–5153. [Google Scholar] [CrossRef] [Green Version]

- Li, M.; Zhang, Q.; Kurokawa, J.; Woo, J.-H.; He, K.; Lu, Z.; Ohara, T.; Song, Y.; Streets, D.G.; Carmichael, G.R.; et al. MIX: A mosaic Asian anthropogenic emission inventory under the international collaboration framework of the MICS-Asia and HTAP. Atmos. Chem. Phys. 2017, 17, 935–963. [Google Scholar] [CrossRef] [Green Version]

- Jang, Y.; Lee, Y.; Kim, J.; Kim, Y.; Woo, J.-H. Improvement China Point Source for Improving Bottom-Up Emission Inventory. Asia-Pac. J. Atmos. Sci. 2019. [Google Scholar] [CrossRef]

- Lee, D.; Lee, Y.-M.; Jang, K.-W.; Yoo, C.; Kang, K.-H.; Lee, J.-H.; Jung, S.-W.; Park, J.-M.; Lee, S.-B.; Han, J.-S.; et al. Korean National Emissions Inventory System and 2007 Air Pollutant Emissions. Asian J. Atmos. Environ. 2011, 5, 278–291. [Google Scholar] [CrossRef] [Green Version]

- Guenther, A.; Karl, T.; Harley, P.; Wiedinmyer, C.; Palmer, P.I.; Geron, C. Estimates of global terrestrial isoprene emissions using MEGAN (Model of Emissions of Gases and Aerosols from Nature). Atmos. Chem. Phys. 2006, 6, 3181–3210. [Google Scholar] [CrossRef] [Green Version]

- Kim, E.; Kim, B.-U.; Kim, H.; Kim, S. The Variability of Ozone Sensitivity to Anthropogenic Emissions with Biogenic Emissions Modeled by MEGAN and BEIS3. Atmosphere 2017, 8, 187. [Google Scholar] [CrossRef] [Green Version]

- Napelenok, S.L.; Pinder, R.W.; Gilliland, A.B.; Martin, R.V. A method for evaluating spatially-resolved NOx emissions using Kalman filter inversion, direct sensitivities, and space-based NO2 observations. Atmos. Chem. Phys. 2008, 8, 5603–5614. [Google Scholar] [CrossRef] [Green Version]

- Beirle, S.; Platt, U.; Wenig, M.; Wagner, T. Highly resolved global distribution of tropospheric NO2 using GOME narrow swath mode data. Atmos. Chem. Phys. 2004, 4, 1913–1924. [Google Scholar] [CrossRef] [Green Version]

- Hilboll, A.; Richter, A.; Burrows, J.P. Long-term changes of tropospheric NO2 over megacities derived from multiple satellite instruments. Atmos. Chem. Phys. 2013, 13, 4145–4169. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.C.; Lee, P.; Judd, L.; Pan, L.; Lefer, B. OMI NO2 column densities over North American urban cities: The effect of satellite footprint resolution. Geosci. Model Dev. 2016, 9, 1111–1123. [Google Scholar] [CrossRef] [Green Version]

- Valin, L.C.; Russell, A.R.; Hudman, R.C.; Cohen, R.C. Effects of model resolution on the interpretation of satellite NO2 observations. Atmos. Chem. Phys. 2011, 11, 11647–11655. [Google Scholar] [CrossRef] [Green Version]

- Kim, H.C.; Kim, S.; Lee, S.-H.; Kim, B.-U.; Lee, P. Fine-Scale Columnar and Surface NOx Concentrations over South Korea: Comparison of Surface Monitors, TROPOMI, CMAQ and CAPSS Inventory. Atmosphere 2020, 11, 101. [Google Scholar] [CrossRef] [Green Version]

| Region | Danyang | Yeongwol | Jecheon | ||||

| Company | A | B | C | D | E | F | |

| Kilns | 4 | 5 | 6 | 2 | 5 | 4 | |

| Capacity (tons/year) | 2,904,000 | 9,686,000 | 7,131,000 | 3,960,000 | 3,537,000 | 4,146,000 | |

| NOx Emission (tons/year) | CAPSS 2007 | 1195 | 7650 | 6185 | 6839 | 3560 | 5312 |

| CAPSS 2010 | 785 | 9652 | 5129 | 7089 | 3946 | 5448 | |

| CAPSS 2013 | 1036 | 8913 | 7579 | 6926 | 3812 | 7863 | |

| Code | SCC1 | SCC2 | SCC3 | SCC4 |

|---|---|---|---|---|

| 03021300 | Industrial Combustion | Furnace | Cement | |

| 03022000 | Industrial Combustion | Furnace | Misc. | |

| 03010100 | Industrial Combustion | Combustion facilities | 1–3 class boiler | |

| 04990201 | Industrial processes | Misc. manufacturing | Cement (Carbon removing) | Point source |

| 04080202 | Industrial processes | Ammonia consumption | SNCR | Industrial |

| 09010201 | Waste disposal | Waste incinerator | Industrial waste | <200 kg/h |

| Provinces | CO | NOx | VOC | NH3 | SOx | PM10 | PM2.5 | PMC |

|---|---|---|---|---|---|---|---|---|

| Gangwon-do | 767 | 40,973 | 92 | 93 | 6847 | 83 | 35 | 65 |

| Chungcheongbuk-do | 63 | 25,637 | 45 | 4 | 3885 | 120 | 61 | 72 |

| Chungcheongnam-do | 8 | 23 | 1 | |||||

| Jeollabuk-do | 3 | 2 | ||||||

| Jeollnam-do | 22 | 1036 | 3 | 785 | 1 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.C.; Bae, C.; Bae, M.; Kim, O.; Kim, B.-U.; Yoo, C.; Park, J.; Choi, J.; Lee, J.-b.; Lefer, B.; et al. Space-Borne Monitoring of NOx Emissions from Cement Kilns in South Korea. Atmosphere 2020, 11, 881. https://doi.org/10.3390/atmos11080881

Kim HC, Bae C, Bae M, Kim O, Kim B-U, Yoo C, Park J, Choi J, Lee J-b, Lefer B, et al. Space-Borne Monitoring of NOx Emissions from Cement Kilns in South Korea. Atmosphere. 2020; 11(8):881. https://doi.org/10.3390/atmos11080881

Chicago/Turabian StyleKim, Hyun Cheol, Changhan Bae, Minah Bae, Okgil Kim, Byeong-Uk Kim, Chul Yoo, Jinsoo Park, Jinsoo Choi, Jae-bum Lee, Barry Lefer, and et al. 2020. "Space-Borne Monitoring of NOx Emissions from Cement Kilns in South Korea" Atmosphere 11, no. 8: 881. https://doi.org/10.3390/atmos11080881