Batch Fabrication of a Polydimethylsiloxane Based Stretchable Capacitive Strain Gauge Sensor for Orthopedics

Abstract

:1. Introduction

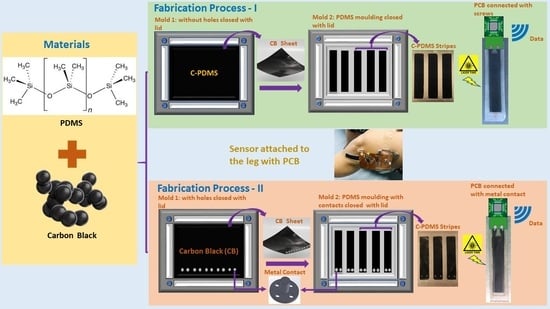

2. Functioning Principle of the Sensor

3. Materials and Fabrication Methods

3.1. Batch Manufacturing Process I

3.2. Batch Manufacturing Process II

4. Experimental Test

5. Result and Discussion

5.1. Surface Analysis of C-PDMS Sheets

5.2. Scanning Electron Microscope Images (SEM)

5.3. Process Validation through Characterization

5.4. Analysis of Electrical Contact Robustness and Reliability

5.5. Fabrication of Patient-Customizable Sensing Patches

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Ramakrishna, V.A.S.; Chamoli, U.; Rajan, G.; Mukhopadhyay, S.C.; Prusty, B.G.; Diwan, A.D. Smart orthopaedic implants: A targeted approach for continuous postoperative evaluation in the spine. J. Biomech. 2020, 104, 109690. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.; Wang, H.; Zhao, W.; Zhang, M.; Qin, H.; Xie, Y. Flexible, Stretchable Sensors for Wearable Health Monitoring: Sensing Mechanisms, Materials, Fabrication Strategies and Features. Sensors 2018, 18, 645. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Strauss, G.L.; van Janse Rensburg, D.; Grant, C.; van Jansen Rensburg, A.; Velleman, M.; Fletcher, L. Anterior Cruciate ligament injuries of the knee. S. Afr. J. Sports Med. 2018, 30, 1–6. [Google Scholar] [CrossRef]

- Zens, M.; Ruhhammer, J.; Goldschmidtboeing, F.; Woias, P.; Mayr, H.O.; Niemeyer, P.; Bernstein, A. Novel measurement technique for knee joint laxities using polymeric capacitive strain gauges. In Proceedings of the 2014 IEEE International Symposium on Medical Measurements and Applications (MeMeA), Lisbon, Portugal, 11–12 June 2014; IEEE: Piscataway, NJ, USA, 2014; pp. 1–6, ISBN 978-1-4799-2921-4. [Google Scholar]

- Jayathilaka, W.A.D.M.; Qi, K.; Qin, Y.; Chinnappan, A.; Serrano-García, W.; Baskar, C.; Wang, H.; He, J.; Cui, S.; Thomas, S.W.; et al. Significance of Nanomaterials in Wearables: A Review on Wearable Actuators and Sensors. Adv. Mater. 2019, 31, e1805921. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Fang, L.; Sun, B.; Li, X.; Kang, S.H. Review—Recent Progress in Flexible and Stretchable Piezoresistive Sensors and Their Applications. J. Electrochem. Soc. 2020, 167, 37561. [Google Scholar] [CrossRef]

- Souri, H.; Banerjee, H.; Jusufi, A.; Radacsi, N.; Stokes, A.A.; Park, I.; Sitti, M.; Amjadi, M. Wearable and Stretchable Strain Sensors: Materials, Sensing Mechanisms, and Applications. Adv. Intell. Syst. 2020, 2, 2000039. [Google Scholar] [CrossRef]

- Shintake, J.; Piskarev, Y.; Jeong, S.H.; Floreano, D. Ultrastretchable Strain Sensors Using Carbon Black-Filled Elastomer Composites and Comparison of Capacitive versus Resistive Sensors. Adv. Mater. Technol. 2018, 3, 1700284. [Google Scholar] [CrossRef] [Green Version]

- Shintake, J.; Nagai, T.; Ogishima, K. Sensitivity Improvement of Highly Stretchable Capacitive Strain Sensors by Hierarchical Auxetic Structures. Front. Robot. AI 2019, 6, 127. [Google Scholar] [CrossRef] [Green Version]

- Amjadi, M.; Kyung, K.-U.; Park, I.; Sitti, M. Stretchable, Skin-Mountable, and Wearable Strain Sensors and Their Potential Applications: A Review. Adv. Funct. Mater. 2016, 26, 1678–1698. [Google Scholar] [CrossRef]

- Mayr, H.O.; Stöhr, A. Aktueller Stand der instrumentellen Messung der Knielaxität. Arthroskopie 2010, 23, 56–61. [Google Scholar] [CrossRef]

- Ahldén, M.; Samuelsson, K.; Fu, F.H.; Musahl, V.; Karlsson, J. Rotatory Knee Laxity. Clin. Sports Med. 2013, 32, 37–46. [Google Scholar] [CrossRef]

- Zens, M.; Niemeyer, P.; Bernstein, A.; Feucht, M.J.; Kühle, J.; Südkamp, N.P.; Woias, P.; Mayr, H.O. Novel approach to dynamic knee laxity measurement using capacitive strain gauges. Knee Surg. Sports Traumatol. Arthrosc. 2015, 23, 2868–2875. [Google Scholar] [CrossRef]

- Mulligan, E.P.; McGuffie, D.Q.; Coyner, K.; Khazzam, M. The reliability and diagnostic accuracy of assessing the translation endpoint during the lachman test. Int. J. Sports Phys. Ther. 2015, 10, 52–61. [Google Scholar]

- Lange, T.; Freiberg, A.; Dröge, P.; Lützner, J.; Schmitt, J.; Kopkow, C. The reliability of physical examination tests for the diagnosis of anterior cruciate ligament rupture—A systematic review. Man. Ther. 2015, 20, 402–411. [Google Scholar] [CrossRef]

- Kuroda, R.; Hoshino, Y.; Kubo, S.; Araki, D.; Oka, S.; Nagamune, K.; Kurosaka, M. Similarities and differences of diagnostic manual tests for anterior cruciate ligament insufficiency: A global survey and kinematics assessment. Am. J. Sports Med. 2012, 40, 91–99. [Google Scholar] [CrossRef]

- Branch, T.P.; Mayr, H.O.; Browne, J.E.; Campbell, J.C.; Stoehr, A.; Jacobs, C.A. Instrumented examination of anterior cruciate ligament injuries: Minimizing flaws of the manual clinical examination. Arthroscopy 2010, 26, 997–1004. [Google Scholar] [CrossRef]

- Parameswaran, C.; Gupta, D. Large area flexible pressure/strain sensors and arrays using nanomaterials and printing techniques. Nano Converg. 2019, 6, 28. [Google Scholar] [CrossRef] [Green Version]

- Zeiser, R.; Fellner, T.; Wilde, J. Capacitive strain gauges on flexible polymer substrates for wireless, intelligent systems. J. Sens. Sens. Syst. 2014, 3, 77–86. [Google Scholar] [CrossRef] [Green Version]

- Ma, Z.; Zhang, Y.; Zhang, K.; Deng, H.; Fu, Q. Recent progress in flexible capacitive sensors: Structures and properties. Nano Mater. Sci. 2022, in press. [Google Scholar] [CrossRef]

- Qin, J.; Yin, L.-J.; Hao, Y.-N.; Zhong, S.-L.; Zhang, D.-L.; Bi, K.; Zhang, Y.-X.; Zhao, Y.; Dang, Z.-M. Flexible and Stretchable Capacitive Sensors with Different Microstructures. Adv. Mater. 2021, 33, e2008267. [Google Scholar] [CrossRef]

- Zhu, Y.; Chen, X.; Chu, K.; Wang, X.; Hu, Z.; Su, H. Carbon Black/PDMS Based Flexible Capacitive Tactile Sensor for Multi-Directional Force Sensing. Sensors 2022, 22, 628. [Google Scholar] [CrossRef] [PubMed]

- Ruhhammer, J.; Zens, M.; Goldschmidtboeing, F.; Seifert, A.; Woias, P. Highly elastic conductive polymeric MEMS. Sci. Technol. Adv. Mater. 2015, 16, 3–5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, J.; Zheng, J.; Gao, Q.; Zhang, J.; Zhang, J.; Omisore, O.; Wang, L.; Li, H. Polydimethylsiloxane (PDMS)-Based Flexible Resistive Strain Sensors for Wearable Applications. Appl. Sci. 2018, 8, 345. [Google Scholar] [CrossRef] [Green Version]

- Hu, M.; Gao, Y.; Jiang, Y.; Zeng, H.; Zeng, S.; Zhu, M.; Xu, G.; Sun, L. High-performance strain sensors based on bilayer carbon black/PDMS hybrids. Adv. Compos. Hybrid Mater. 2021, 4, 514–520. [Google Scholar] [CrossRef]

- Szydzik, C.; Niego, B.; Dalzell, G.; Knoerzer, M.; Ball, F.; Nesbitt, W.S.; Medcalf, R.L.; Khoshmanesh, K.; Mitchell, A. Fabrication of complex PDMS microfluidic structures and embedded functional substrates by one-step injection moulding. RSC Adv. 2016, 6, 87988–87994. [Google Scholar] [CrossRef]

- Gong, X.; Wen, W. Polydimethylsiloxane-based conducting composites and their applications in microfluidic chip fabrication. Biomicrofluidics 2009, 3, 012007-3–012007-9. [Google Scholar] [CrossRef] [Green Version]

- Melika Eklund, N.K. Silicone-Based Carbon Black Silicone-Based Carbon Black Composite for Epidermal Electrodes. Master’s Thesis, Uppsala Universitet, Uppsala, Sweden, 2019. [Google Scholar]

- Hu, J.; Yu, J.; Li, Y.; Liao, X.; Yan, X.; Li, L. Nano Carbon Black-Based High Performance Wearable Pressure Sensors. Nanomaterials 2020, 10, 664. [Google Scholar] [CrossRef] [Green Version]

- Seghir, R.; Arscott, S. Controlled mud-crack patterning and self-organized cracking of polydimethylsiloxane elastomer surfaces. Sci. Rep. 2015, 5, 14787. [Google Scholar] [CrossRef]

- Lee, K.J.; Fosser, K.A.; Nuzzo, R.G. Fabrication of Stable Metallic Patterns Embedded in Poly(dimethylsiloxane) and Model Applications in Non-Planar Electronic and Lab-on-a-Chip Device Patterning. Adv. Funct. Mater. 2005, 15, 557–566. [Google Scholar] [CrossRef]

- Ryspayeva, A.; Jones, T.D.; Esfahani, M.N.; Shuttleworth, M.P.; Harris, R.A.; Kay, R.W.; Desmulliez, M.P.; Marques-Hueso, J. A rapid technique for the direct metallization of PDMS substrates for flexible and stretchable electronics applications. Microelectron. Eng. 2019, 209, 35–40. [Google Scholar] [CrossRef] [Green Version]

- Sheeparamatti, B.; Hansi, P.; Aibbigeri, V.; Meti, N. Study of Capacitance in Electrostatic Comb-Drive Actuators. In Proceedings of the 2015 COMSOL Conference, Boston, MA, USA, 7–9 October 2015; pp. 1–2. [Google Scholar]

- Niu, X.; Peng, S.; Liu, L.Y.; Wen, W.; Sheng, P. Characterizing and Patterning of PDMS-Based Conducting Composites. Adv. Mater. 2007, 19, 2682–2686. [Google Scholar] [CrossRef]

- Brunne, J.; Kazan, S.; Wallrabe, U. In-plane DEAP stack actuators for optical MEMS applications. In Electroactive Polymer Actuators and Devices (EAPAD) 2011, Proceedings of the SPIE Smart Structures and Materials + Nondestructive Evaluation and Health Monitoring, San Diego, CA, USA, 6 March 2011; Bar-Cohen, Y., Carpi, F., Eds.; SPIE: Bellingham, WA, USA, 2011; p. 79761U. [Google Scholar]

- Zens, M. Kapazitive Polydimethylsiloxansensoren für Biomechanische Anwendungen. Master’s Thesis, Technical University of Freiburg, Freiburg, Germany, 21 March 2016. [Google Scholar]

| Parameters | Values |

|---|---|

| Equation | |

| Plot | Concatenated Data |

| Intercept | 180.07 ± 0.81 |

| B1 | −6.55 ± 0.34 |

| B2 | 0.19 ± 0.03 |

| Residual sum of squares | 164.13 |

| R-Square (COD) | 0.98 |

| Batches | Sensors | RMSE |

|---|---|---|

| Batch 1 | Sensor 1 | 1.12 |

| Sensor 2 | 0.96 | |

| Batch 2 | Sensor 1 | 0.32 |

| Sensor 2 | 2.99 | |

| Batch 3 | Sensor 1 | 2.21 |

| Sensor 2 | 0.49 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sheeja Prakash, K.; Mayr, H.O.; Agrawal, P.; Agarwal, P.; Seidenstuecker, M.; Rosenstiel, N.; Woias, P.; Comella, L.M. Batch Fabrication of a Polydimethylsiloxane Based Stretchable Capacitive Strain Gauge Sensor for Orthopedics. Polymers 2022, 14, 2326. https://doi.org/10.3390/polym14122326

Sheeja Prakash K, Mayr HO, Agrawal P, Agarwal P, Seidenstuecker M, Rosenstiel N, Woias P, Comella LM. Batch Fabrication of a Polydimethylsiloxane Based Stretchable Capacitive Strain Gauge Sensor for Orthopedics. Polymers. 2022; 14(12):2326. https://doi.org/10.3390/polym14122326

Chicago/Turabian StyleSheeja Prakash, Karthika, Hermann Otto Mayr, Prachi Agrawal, Priyank Agarwal, Michael Seidenstuecker, Nikolaus Rosenstiel, Peter Woias, and Laura Maria Comella. 2022. "Batch Fabrication of a Polydimethylsiloxane Based Stretchable Capacitive Strain Gauge Sensor for Orthopedics" Polymers 14, no. 12: 2326. https://doi.org/10.3390/polym14122326