Prediction of Strength Properties of Filling Packets in Selected Cooling Towers

Abstract

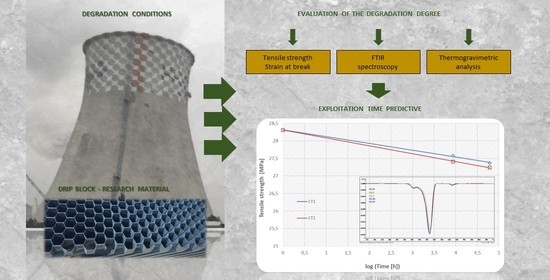

:1. Introduction

2. Experimental

2.1. Preparation of Samples for Tensile Strength Tests

2.2. Research Methodology

2.2.1. Strength Tests

2.2.2. Spectroscopic Test

2.2.3. Thermogravimetric Research

3. Results and Discussion

3.1. Analysis of the Results of Endurance Tests

3.2. Analysis of the Results of Structure Research

3.3. Forecast of Durability and Suitability for Further Operation of the Drip Blocks

4. Conclusions

- The strength properties depend on the area of operation. The test samples taken from the central part were characterized by the lowest tensile strength and the highest elongation. It may be the result of an uneven impact of the exploitation environment. The outer areas showed the higher strength, with the left side of the cooler showing the highest values. The spectra obtained confirmed the greatest changes were in the CT1_C region (a decrease of intensity in relation to the spectrum of reference samples). This is related to the effect of heat (increased temperature) in the central part of the drip blocks, and this additionally favored the formation of sediments.

- The determined dependency functions (Formulas (1)–(4)) make it possible to forecast the strength properties in the assumed 10-year period of operation in cooling towers. It was observed that the change in strain at break was about 23%, while for the tensile strength it was about 4%. The size of the changes was also confirmed by the intensity of the FTIR spectra in characteristic areas (i.e., 964, 1153, 1380 and 2840–2880 cm−1) and by thermogravimetric analysis The observed changes were linear in the adopted coordinates and the approximation curves did not show a break inflexion, which forecasts a safe operation of the drip blocks in the assumed period of 10 years.

- The evaluation of the results of the TGA analyses shows that irrespective of the location of the film in the drip blocks of chimney linings, the value of the decomposition temperature remains similar. No significant effect of the polypropylene film location on the course of its decomposition was observed, and more importantly no significant decrease in the value of the decomposition temperature (Tmax2) was observed for any of the tested samples.

- The location of the film in the drip blocks of the cooling tower, especially in its central part, slightly affects the values of the temperature and mass loss characterizing the first mass loss only and the sample remaining after decomposition of the sample coming from only one of the two analyzed cooling towers.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Wiles, D.M.; Scott, G. Polyolefins with controlled environmental degradability. Polym. Degrad. Stab. 2006, 91, 1581–1592. [Google Scholar] [CrossRef]

- Jachowicz, T. Natural aging of polyethylene pipes. Forecasting selected properties. Plast. Process. 2004, 2, 36. [Google Scholar]

- Fiebig, J.; Gahleitner, M.; Paulik, C.; Wolfschwenger, J. Ageing of polypropylene: Processes and consequences. Polym. Test. 1999, 18, 257–266. [Google Scholar] [CrossRef]

- Bamford, C.H.; Tipper, C.F.H. Degradation of Polymers; Series: Comprehensive Chemical Kinetic; Elsevier: New York, NY, USA, 1975; Volume 14. [Google Scholar]

- Bertin, D.; Leblanc, M.; Marque, S.R.A.; Siri, D. Polypropylene degradation: Theoretical and experimental investigations. Polym. Degrad. Stab. 2010, 95, 782–791. [Google Scholar] [CrossRef]

- Sobków, D.; Czaja, K. Influence of accelerated ageing conditions on the process of polyolefins degradation. Polimery 2003, 9, 627–632. [Google Scholar] [CrossRef]

- Sobków, D.; Barton, J.; Czaja, K.; Sudoł, M.; Mazoń, B. Studies of material resistance against natural environmental factors. Chem. Sci.-Tech.-Mark. 2014, 68, 347–350. [Google Scholar]

- Hensley, J.C. Cooling Tower Fundamentals; SPX Cooling Technologies, Inc.: Overland Park, KS, USA, 2009. [Google Scholar]

- Evans, J.; Petterson, B. 18-29: Fundamentals of Compression Testing Cooling Tower Fill Packs for Load Capacity. In Proceedings of the Cooling Technology Institute Annual Conference, Houston, TX, USA, 4–8 February 2018. [Google Scholar]

- Woicke, N.; Dierenfeld, D. Time and Temperature Dependent Deformation Behavior of PP Fills. CTI J. 2018, 39, 16–24. [Google Scholar]

- Woicke, N. 19-15, Deformation Behavior of Cooling Tower Fills. In Proceedings of the Cooling Technology Institute Annual Conference, New Orleans, LA, USA, 10–14 February 2019; pp. 215–227. [Google Scholar]

- Woicke, N. 17-09, Time and Temperature Dependent Mechanical Behavior of PP Fills. In Proceedings of the Cooling Technology Institute Annual Conference, New Orleans, LA, USA, 5–9 February 2017. [Google Scholar]

- Woicke, N.; Dierenfeld, D. Mechanical Behavior of Polymer Fills. In Proceedings of the Cooling Technology Institute Annual Conference, Houston, TX, USA, 7–11 February 2016. [Google Scholar]

- Boev, E.V.; Ivanov, S.P.; Afanasenko, V.G.; Nikolaev, E.A. Polymeric drop-film sprinklers for cooling towers. Chem. Pet. Eng. 2009, 45, 454–459. [Google Scholar] [CrossRef]

- Boev, E.V.; Ivanov, S.P.; Boev, A.V. Design development of a polymeric atmospheric film-type sprayer for cooling towers. Chem. Pet. Eng. 2007, 43, 572–574. [Google Scholar] [CrossRef]

- Boev, E.V. Improving the efficiency of cooling tower sprinklers. IOP Conf. Ser. Mater. Sci. Eng. 2019, 537, 032017. [Google Scholar] [CrossRef]

- Boev, E.V. Sprinklers of cooling towers. J. Phys. Conf. Ser. 2020, 1515, 022069. [Google Scholar] [CrossRef]

- Buecker, B. Understand the Importance of Correct Cooling Tower Fill. Chem. Process. 2018, 80, 20–24. [Google Scholar]

- Celina, M.; Gillen, K.T.; Assink, R.A. Accelerated aging and lifetime prediction: Review of non-Arrhenius behaviour due to two competing processes. Polym. Degrad. Stab. 2005, 90, 395–404. [Google Scholar] [CrossRef]

- Gahleitner, T.M.; Fiebig, J.; Wolfschwenger, J.; Dreiling, G.; Paulik, C. Post-crystallization and physical aging of polypropylene: Material and processing effects. J. Macromol. Sci. Part B 2002, 41, 833–849. [Google Scholar] [CrossRef]

- Law, A.; Simon, L.; Lee-Sullivan, P. Effects of thermal aging on isotactic polypropylene crystallinity. Polym. Eng. Sci. 2008, 48, 627–633. [Google Scholar] [CrossRef]

- Grabmann, M.K.; Wallner, G.M.; Maringer, L.; Buchberger, W.; Nitsche, D. Hot air aging behavior of polypropylene random copolymers. J. Appl. Polym. Sci. 2019, 136, 47350. [Google Scholar] [CrossRef] [Green Version]

- Rabek, J.F. Polymer Photodegradation: Mechanisms and Experimental Methods; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Rojek, M. Methodology of diagnostic testing of polymeric matrix laminate composite materials. Sci. Int. J. World Acad. Mater. Manuf. Eng. Publ. Sci. Monogr. Pol. 2011, 2, 11–31. [Google Scholar]

- Davis, T.E.; Tobias, R.L.; Peterli, E.B. Thermal degradation of polypropylene. J. Polym. Sci. 1962, 56, 485–499. [Google Scholar] [CrossRef]

- Gao, Z.; Kaneko, T.; Amasaki, I.; Nakada, M. A kinetic study of thermal degradation of polypropylene. Polym. Degrad. Stab. 2003, 80, 269–274. [Google Scholar] [CrossRef]

- Sližová, M.; Stašek, M.; Raab, M. Polypropylene after thirty years of storage: Mechanical proof of heterogeneous aging. Polym. J. 2020, 52, 775–781. [Google Scholar] [CrossRef]

- Zweifel, H. Stabilization of Polymeric Materials; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar] [CrossRef]

- Hamid, S.H. Handbook of Polymer Degradation; Taylor & Francis Group: Abingdon, UK, 2020. [Google Scholar] [CrossRef]

- Song, D.; Gao, J.; Li, X.; Lu, L. Evaluation of aging behavior of polypropylene in natural environment by principal component analysis. Polym. Test. 2014, 33, 131–137. [Google Scholar] [CrossRef]

- Ibhadon, I. Physical aging in isotactic polypropylene. J. Appl. Pol. Sci. 1996, 62, 1843–1846. [Google Scholar] [CrossRef]

- Tolinski, M. Additives for Polyolefins, Getting the Most Out of Polypropylene, Polyethylene and TPO, 2nd ed.; Elsevier Inc.: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Vohlídal, J. Polymer degradation: A short review. Chem. Teach. Int. 2020, 3, 213–220. [Google Scholar] [CrossRef]

- Leja, K.; Lewandowicz, G. Polymer biodegradation and biodegradable polymers—A review. Pol. J. Environ. Stud. 2010, 19, 255–266. [Google Scholar]

- Mannheim, V.; Simenfalvi, Z. Total Life Cycle of Polypropylene Products: Reducing Environmental Impacts in the Manufacturing Phase. Polymers 2020, 12, 1901. [Google Scholar] [CrossRef] [PubMed]

- Rjeb, A.; Letarte, S.; Tajounte, L.; El Idrissi, M.C.; Adnot, A.; Roy, D.; Claire, Y.; Kaloustian, J. Polypropylene natural aging studied by X-ray photoelectron spectroscopy. J. Electron. Spectrosc. Relat. Phenom. 2000, 107, 221–230. [Google Scholar] [CrossRef]

- Brzozowska-Stanuch, A.; Rabiej, S.; Stanuch, W. The influence of accelerated weathering conditions—UV radiation and temperature on polyamides and polypropylene. Tech. Trans. Mech. 2009, 106, 43–49. [Google Scholar]

- ISO 527-2:2012: Plastics—Determination of Tensile Properties—Part 2: Test Conditions for Moulding and Extrusion Plastics; International Organization for Standardization: Geneva, Switzerland, 2012.

- ISO 3167:2014 Plastics—Multipurpose Test Specimens; International Organization for Standardization: Geneva, Switzerland, 2014.

- Martin, R. Ageing of Composites; Woodhead Publishing Limited: Cambridge, UK, 2008. [Google Scholar]

- Jachowicz, T.; Sikora, R. Methods of forecasting of the changes of polymeric products properties. Polimery 2006, 51, 11–18. [Google Scholar] [CrossRef]

| Sample Determination | Temp. of the First Mass Loss Step (°C) | Temp. of the Second Mass Loss Step (°C) | Temp. of the Third Mass Loss Step (°C) | Temp. at 3% (M/M) Sample Mass Loss (°C) | Temp. at 5% (M/M) Sample Mass Loss (°C) | Temp. at 10% (M/M) Sample Mass Loss (°C) | Temp. at 15% (M/M) Sample Mass Loss (°C) |

|---|---|---|---|---|---|---|---|

| Tmax1 | Tmax2 | Tmax3 | T3% | T5% | T10% | T15% | |

| CT1_LS | 358.7 | 468.1 | 627.9 | 357.6 | 373.7 | 408.3 | 426.8 |

| CT1_C | 367.6 | 472.8 | 623.8 | 369.1 | 386.0 | 419.5 | 435.9 |

| CT1_RS | 361.5 | 466.8 | 621.8 | 360.3 | 373.9 | 414.0 | 431.3 |

| CT2_C | 360.7 | 469.8 | 623.8 | 362.4 | 380.9 | 414.0 | 431.5 |

| CT2_RS | 362.3 | 470.0 | 627.2 | 363.7 | 379.2 | 412.7 | 429.9 |

| Sample Determination | First Mass Loss (%) (m/m) | Second Mass Loss (%) (m/m) | Third Mass Loss (%) (m/m) | Mass Residue at 900 °C |

|---|---|---|---|---|

| mL,1 | mL,2 | mL,3 | mR,900 | |

| CT1_LS | 5.5 | 78.6 | 1.6 | 14.3 |

| CT1_C | 5.4 | 70.0 | 1.8 | 22.8 |

| CT1_RS | 6.2 | 78.2 | 1.2 | 14.4 |

| CT2_C | 4.4 | 77.7 | 2.2 | 15.7 |

| CT2_RS | 5.6 | 77.8 | 2.0 | 14.6 |

| Property | CT1 | CT2 |

|---|---|---|

| Tensile strength (MPa) | 27.36 | 27.19 |

| Strain at break (%) | 353.91 | 351.86 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chomiak, M.; Rojek, M.; Stabik, J.; Szymiczek, M. Prediction of Strength Properties of Filling Packets in Selected Cooling Towers. Polymers 2021, 13, 3840. https://doi.org/10.3390/polym13213840

Chomiak M, Rojek M, Stabik J, Szymiczek M. Prediction of Strength Properties of Filling Packets in Selected Cooling Towers. Polymers. 2021; 13(21):3840. https://doi.org/10.3390/polym13213840

Chicago/Turabian StyleChomiak, Monika, Maciej Rojek, Józef Stabik, and Małgorzata Szymiczek. 2021. "Prediction of Strength Properties of Filling Packets in Selected Cooling Towers" Polymers 13, no. 21: 3840. https://doi.org/10.3390/polym13213840