Sensors for Fault Diagnosis, Fault Tolerance and Resilient Control

A topical collection in Sensors (ISSN 1424-8220). This collection belongs to the section "Physical Sensors".

Viewed by 27443

Share This Topical Collection

Editor

Dr. Mien Van

Dr. Mien Van

Dr. Mien Van

Dr. Mien Van

E-Mail

Website

Guest Editor

School of Electronics, Electrical Engineering and Computer Science, Queen's University Belfast, Belfast BT7 1NN, UK

Interests: industrial robot; human-robot interaction; fault diagnosis; robot-vision system; machine learning and pattern recognition

Special Issues, Collections and Topics in MDPI journals

Topical Collection Information

Dear Colleagues,

The presence of faults/failures in mechanical systems generate many adverse consequences, including damage to system components and endangerment of humans’ working conditions. The early detection of faults could potentially reduce the severe impacts and increase the safety and reliability of systems. Therefore, the development of fault detection and diagnosis (FDD) methodologies for mechanical systems to detect the faults is of paramount importance. In addition, in highly automated systems such as unmanned autonomous vehicles, where maintenance and repair of the faulty systems cannot be carried out immediately, it is necessary to employ fault-tolerant control and/or resilient control to ensure the desired missions can be completed despite the presence of faults in the system.

This Special Issue focuses on fault diagnosis, fault tolerance, and resilient design for mechanical and industrial systems. The topics include but are not limited to:

- Model-based and data-driven fault diagnosis methods;

- Fault detection, isolation, and accommodation;

- Fault tolerant control and fault recovery;

- Design for reliability, safety, and resilience;

Dr. Mien Van

Guest Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Sensors is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript.

The Article Processing Charge (APC) for publication in this open access journal is 2600 CHF (Swiss Francs).

Submitted papers should be well formatted and use good English. Authors may use MDPI's

English editing service prior to publication or during author revisions.

Keywords

- fault diagnosis

- fault tolerance

- fault recovery

- resilient control

- condition monitoring

- resilient system design

- modelling and simulation

- closed-loop monitoring

- model based methods

- data driven methods

Published Papers (9 papers)

Open AccessArticle

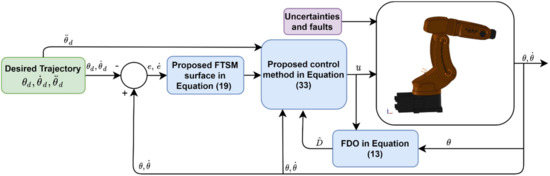

A Novel Active Fault-Tolerant Tracking Control for Robot Manipulators with Finite-Time Stability

by

Thanh Nguyen Truong, Anh Tuan Vo, Hee-Jun Kang and Mien Van

Cited by 15 | Viewed by 1902

Abstract

Many terminal sliding mode controllers (TSMCs) have been suggested to obtain exact tracking control of robotic manipulators in finite time. The ordinary method is based on TSMCs that secure trajectory tracking under the assumptions such as the known robot dynamic model and the

[...] Read more.

Many terminal sliding mode controllers (TSMCs) have been suggested to obtain exact tracking control of robotic manipulators in finite time. The ordinary method is based on TSMCs that secure trajectory tracking under the assumptions such as the known robot dynamic model and the determined upper boundary of uncertain components. Despite tracking errors that tend to zero in finite time, the weakness of TSMCs is chattering, slow convergence speed, and the need for the exact robot dynamic model. Few studies are handling the weakness of TSMCs by using the combination between TSMCs and finite-time observers. In this paper, we present a novel finite-time fault tolerance control (FTC) method for robotic manipulators. A finite-time fault detection observer (FTFDO) is proposed to estimate all uncertainties, external disturbances, and faults accurately and on time. From the estimated information of FTFDO, a novel finite-time FTC method is developed based on a new finite-time terminal sliding surface and a new finite-time reaching control law. Thanks to this approach, the proposed FTC method provides a fast convergence speed for both observation error and control error in finite time. The operation of the robot system is guaranteed with expected performance even in case of faults, including high tracking accuracy, small chattering behavior in control input signals, and fast transient response with the variation of disturbances, uncertainties, or faults. The stability and finite-time convergence of the proposed control system are verified that they are strictly guaranteed by Lyapunov theory and finite-time control theory. The simulation performance for a FARA robotic manipulator proves the proposed control theory’s correctness and effectiveness.

Full article

►▼

Show Figures

Open AccessArticle

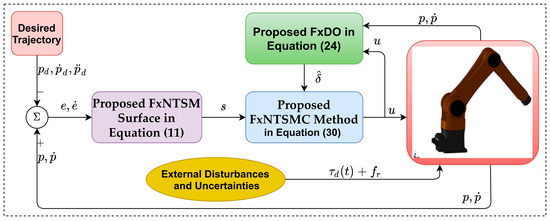

A Robust Observer-Based Control Strategy for n-DOF Uncertain Robot Manipulators with Fixed-Time Stability

by

Anh Tuan Vo, Thanh Nguyen Truong, Hee-Jun Kang and Mien Van

Cited by 13 | Viewed by 2058

Abstract

In this paper, a robust observer-based control strategy for n-DOF uncertain robot manipulators with fixed-time stability was developed. The novel fixed-time nonsingular sliding mode surface enables control errors to converge to the equilibrium point quickly within fixed time without singularity. The development of

[...] Read more.

In this paper, a robust observer-based control strategy for n-DOF uncertain robot manipulators with fixed-time stability was developed. The novel fixed-time nonsingular sliding mode surface enables control errors to converge to the equilibrium point quickly within fixed time without singularity. The development of the novel fixed-time disturbance observer based on a uniform robust exact differentiator also allows uncertain terms and exterior disturbances to be proactively addressed. The designed observer can accurately approximate uncertain terms within a fixed time and contribute to significant chattering reduction in the traditional sliding mode control. A robust observer-based control strategy was formulated, according to a combination of the fixed-time nonsingular terminal sliding mode control method and the designed observer, to yield global fixed time stability for n-DOF uncertain robot manipulators. The proposed controller proved definitively that it was able to obtain global stabilization in fixed time. The approximation capability of the proposed observer, the convergence of the proposed sliding surface, and the effectiveness of the proposed control strategy in fixed time were fully confirmed by simulation performance on an industrial robot manipulator.

Full article

►▼

Show Figures

Open AccessArticle

Novel Bearing Fault Diagnosis Using Gaussian Mixture Model-Based Fault Band Selection

by

Andrei S. Maliuk, Alexander E. Prosvirin, Zahoor Ahmad, Cheol Hong Kim and Jong-Myon Kim

Cited by 23 | Viewed by 2708

Abstract

This paper proposes a Gaussian mixture model-based (GMM) bearing fault band selection (GMM-WBBS) method for signal processing. The proposed method benefits reliable feature extraction using fault frequency oriented Gaussian mixture model (GMM) window series. Selecting exclusively bearing fault frequency harmonics, it eliminates the

[...] Read more.

This paper proposes a Gaussian mixture model-based (GMM) bearing fault band selection (GMM-WBBS) method for signal processing. The proposed method benefits reliable feature extraction using fault frequency oriented Gaussian mixture model (GMM) window series. Selecting exclusively bearing fault frequency harmonics, it eliminates the interference of bearing normal vibrations in the lower frequencies, bearing natural frequencies, and the higher frequency contents that prove to be useful only for anomaly detection but do not provide any insight into the bearing fault location. The features are extracted from time- and frequency- domain signals that exclusively contain the bearing fault frequency harmonics. Classification is done using the Weighted KNN algorithm. The experiments performed with the data containing the vibrations recorded from artificially damaged bearings show the positive effect of utilizing the proposed GMM-WBBS signal processing to filter out the discriminative data of uncertain origin. All comparison methods retrofitted with the proposed method demonstrated classification performance improvements when provided with vibration data with suppressed bearing natural frequencies and higher frequency contents.

Full article

►▼

Show Figures

Open AccessArticle

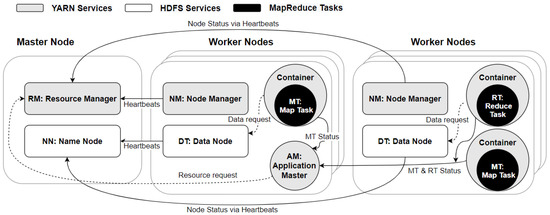

Experimental Analysis in Hadoop MapReduce: A Closer Look at Fault Detection and Recovery Techniques

by

Muntadher Saadoon, Siti Hafizah Ab Hamid, Hazrina Sofian, Hamza Altarturi, Nur Nasuha, Zati Hakim Azizul, Asmiza Abdul Sani and Adeleh Asemi

Cited by 7 | Viewed by 4276

Abstract

Hadoop MapReduce reactively detects and recovers faults after they occur based on the static heartbeat detection and the re-execution from scratch techniques. However, these techniques lead to excessive response time penalties and inefficient resource consumption during detection and recovery. Existing fault-tolerance solutions intend

[...] Read more.

Hadoop MapReduce reactively detects and recovers faults after they occur based on the static heartbeat detection and the re-execution from scratch techniques. However, these techniques lead to excessive response time penalties and inefficient resource consumption during detection and recovery. Existing fault-tolerance solutions intend to mitigate the limitations without considering critical conditions such as fail-slow faults, the impact of faults at various infrastructure levels and the relationship between the detection and recovery stages. This paper analyses the response time under two main conditions: fail-stop and fail-slow, when they manifest with node, service, and the task at runtime. In addition, we focus on the relationship between the time for detecting and recovering faults. The experimental analysis is conducted on a real Hadoop cluster comprising MapReduce, YARN and HDFS frameworks. Our analysis shows that the recovery of a single fault leads to an average of 67.6% response time penalty. Even though the detection and recovery times are well-turned, data locality and resource availability must also be considered to obtain the optimum tolerance time and the lowest penalties.

Full article

►▼

Show Figures

Open AccessArticle

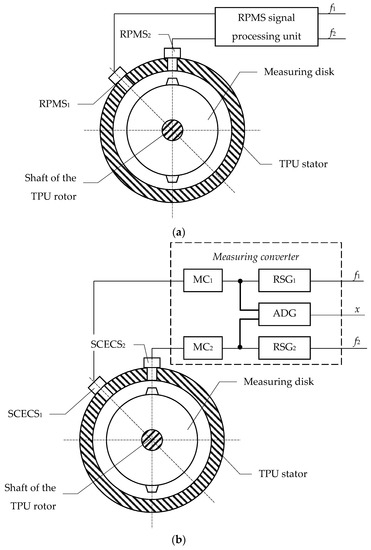

Wear Diagnostics of the Thrust Bearing of NK-33 Turbo-Pump Unit on the Basis of Single-Coil Eddy Current Sensors

by

Viktor Belosludtsev, Sergey Borovik, Valeriy Danilchenko and Yuriy Sekisov

Cited by 3 | Viewed by 2261

Abstract

The problem of early wear diagnostics of the combined journal-and-thrust bearing of the turbo-pump unit (TPU) of the liquid-propellant rocket engine NK-33 is considered. A feature of the problem is the significant restriction on modifications of the power plant’s design. The original solution

[...] Read more.

The problem of early wear diagnostics of the combined journal-and-thrust bearing of the turbo-pump unit (TPU) of the liquid-propellant rocket engine NK-33 is considered. A feature of the problem is the significant restriction on modifications of the power plant’s design. The original solution based on replacing the standard induction sensors of the turbo-pump rotational speed currently used in TPU by single-coil eddy current sensors (SCECS) with sensitive elements in the form of a segment of a linear conductor is proposed. The SCECS provide the monitoring of the axial displacement of the shaft in the thrust bearing, which characterizes the state of the unit and increases with the bearing wear. The function of the TPU shaft’s rotational speed measuring also remains. The article describes the proposed approach as well as a laboratory prototype of the system for early detection of the TPU thrust bearing’s wear. The results of the prototype research that confirm the feasibility of the proposed approach are analyzed.

Full article

►▼

Show Figures

Open AccessArticle

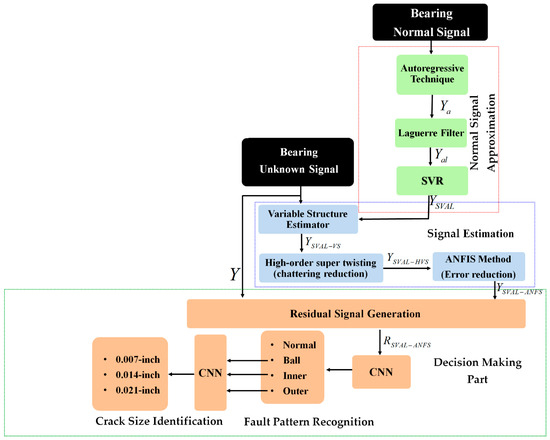

Deep Learning-Based Adaptive Neural-Fuzzy Structure Scheme for Bearing Fault Pattern Recognition and Crack Size Identification

by

Farzin Piltan, Bach Phi Duong and Jong-Myon Kim

Cited by 5 | Viewed by 1955

Abstract

Bearings are complex components with onlinear behavior that are used to mitigate the effects of inertia. These components are used in various systems, including motors. Data analysis and condition monitoring of the systems are important methods for bearing fault diagnosis. Therefore, a deep

[...] Read more.

Bearings are complex components with onlinear behavior that are used to mitigate the effects of inertia. These components are used in various systems, including motors. Data analysis and condition monitoring of the systems are important methods for bearing fault diagnosis. Therefore, a deep learning-based adaptive neural-fuzzy structure technique via a support vector autoregressive-Laguerre model is presented in this study. The proposed scheme has three main steps. First, the support vector autoregressive-Laguerre is introduced to approximate the vibration signal under normal conditions and extract the state-space equation. After signal modeling, an adaptive neural-fuzzy structure observer is designed using a combination of high-order variable structure techniques, the support vector autoregressive-Laguerre model, and adaptive neural-fuzzy inference mechanism for normal and abnormal signal estimation. The adaptive neural-fuzzy structure observer is the main part of this work because, based on the difference between signal estimation accuracy, it can be used to identify faults in the bearings. Next, the residual signals are generated, and the signal conditions are detected and identified using a convolution neural network (CNN) algorithm. The effectiveness of the proposed deep learning-based adaptive neural-fuzzy structure technique by support vector autoregressive-Laguerre model was analyzed using the Case Western Reverse University (CWRU) bearing vibration dataset. The proposed scheme is compared to five state-of-the-art techniques. The proposed algorithm improved the average pattern recognition and crack size identification accuracy by 1.99%, 3.84%, 15.75%, 5.87%, 30.14%, and 35.29% compared to the combination of the high-order variable structure technique with the support vector autoregressive-Laguerre model and CNN, the combination of the variable structure technique with the support vector autoregressive-Laguerre model and CNN, the combination of RAW signal and CNN, the combination of the adaptive neural-fuzzy structure technique with the support vector autoregressive-Laguerre model and support vector machine (SVM), the combination of the high-order variable structure technique with the support vector autoregressive-Laguerre model and SVM, and the combination of the variable structure technique with the support vector autoregressive-Laguerre model and SVM, respectively.

Full article

►▼

Show Figures

Open AccessEditor’s ChoiceArticle

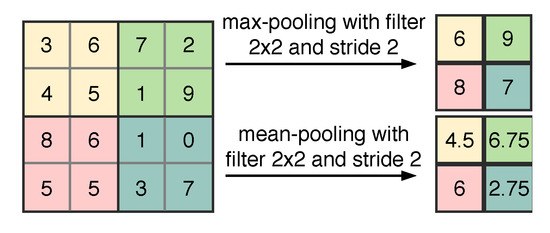

A Deep Neural Network-Based Feature Fusion for Bearing Fault Diagnosis

by

Duy Tang Hoang, Xuan Toa Tran, Mien Van and Hee Jun Kang

Cited by 32 | Viewed by 4205

Abstract

This paper presents a novel method for fusing information from multiple sensor systems for bearing fault diagnosis. In the proposed method, a convolutional neural network is exploited to handle multiple signal sources simultaneously. The most important finding of this paper is that a

[...] Read more.

This paper presents a novel method for fusing information from multiple sensor systems for bearing fault diagnosis. In the proposed method, a convolutional neural network is exploited to handle multiple signal sources simultaneously. The most important finding of this paper is that a deep neural network with wide structure can extract automatically and efficiently discriminant features from multiple sensor signals simultaneously. The feature fusion process is integrated into the deep neural network as a layer of that network. Compared to single sensor cases and other fusion techniques, the proposed method achieves superior performance in experiments with actual bearing data.

Full article

►▼

Show Figures

Open AccessArticle

Construction of a Sensitive and Speed Invariant Gearbox Fault Diagnosis Model Using an Incorporated Utilizing Adaptive Noise Control and a Stacked Sparse Autoencoder-Based Deep Neural Network

by

Cong Dai Nguyen, Alexander E. Prosvirin, Cheol Hong Kim and Jong-Myon Kim

Cited by 17 | Viewed by 2869

Abstract

Gearbox fault diagnosis based on the analysis of vibration signals has been a major research topic for a few decades due to the advantages of vibration characteristics. Such characteristics are used for early fault detection to guarantee the enhanced safety of complex systems

[...] Read more.

Gearbox fault diagnosis based on the analysis of vibration signals has been a major research topic for a few decades due to the advantages of vibration characteristics. Such characteristics are used for early fault detection to guarantee the enhanced safety of complex systems and their cost-effective operation. There exist many fault diagnosis models that have been developed for classifying various fault types in gearboxes. However, the classification results of the conventional fault classification models degrade when they are applied to gearbox systems with multi-level tooth cut gear (MTCG) faults operating under variable shaft speeds. These conditions cause difficulty in discriminating the gear fault types. Due to the improved computational capabilities of modern systems, the application of deep neural networks (DNNs) is getting popular in a variety of research fields, such as image and natural language processing. DNNs are capable of improving the classification results even when addressing complex problems such as diagnosing gearbox MTCG faults. In this research, an adaptive noise control (ANC) and a stacked sparse autoencoder–based deep neural network (SSA-DNN) are used to construct a sensitive fault diagnosis model that can diagnose a gearbox system with MTCG fault types under varying shaft rotation speeds, despite its complicatedness. An ANC is applied to gear vibration characteristics to remove a significant level of noise along the frequency spectrum of vibration signals to fix the most fault-informative components of each fault case. Next, the autoencoder learns the gear faults characteristic features from these fault-informative components to separate the fault types considered in this study. Furthermore, the implementation of the SSA-DNN is substituted for feature extraction, feature selection, and the classification processes in traditional fault diagnosis schemes by high-performance unity. The experimental results show that the proposed model outperforms conventional methodologies with higher classification accuracy.

Full article

►▼

Show Figures

Open AccessArticle

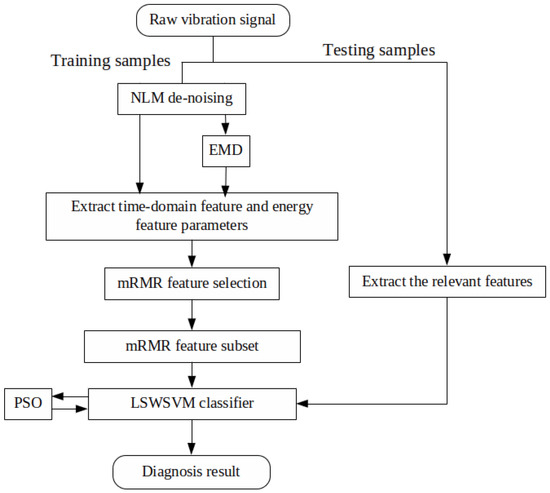

Bearing Fault Diagnosis Using a Particle Swarm Optimization-Least Squares Wavelet Support Vector Machine Classifier

by

Mien Van, Duy Tang Hoang and Hee Jun Kang

Cited by 36 | Viewed by 3190

Abstract

Bearing is one of the key components of a rotating machine. Hence, monitoring health condition of the bearing is of paramount importace. This paper develops a novel particle swarm optimization (PSO)-least squares wavelet support vector machine (PSO-LSWSVM) classifier, which is designed based on

[...] Read more.

Bearing is one of the key components of a rotating machine. Hence, monitoring health condition of the bearing is of paramount importace. This paper develops a novel particle swarm optimization (PSO)-least squares wavelet support vector machine (PSO-LSWSVM) classifier, which is designed based on a combination between a PSO, a least squares procedure, and a new wavelet kernel function-based support vector machine (SVM), for bearing fault diagnosis. In this work, bearing fault classification is transformed into a pattern recognition problem, which consists of three stages of data processing. Firstly, a rich information dataset is built by extracting the features from the signals, which are decomposed by the nonlocal means (NLM) and empirical mode decomposition (EMD). Secondly, a minimum-redundancy maximum-relevance (mRMR) method is employed to determine a subset of feature that can provide an optimal performance. Thirdly, a novel classifier, namely LSWSVM, is proposed with the aid of a PSO, to provide higher classification accuracy. The key innovative science of this work is to propropose a new classifier with the aid of an new wavelet kernel type to increase the classification precision of bearing fault diagnosis. The merit features of the proposed approach are demonstrated based on a benchmark bearing dataset and a comprehensive comparison procedure.

Full article

►▼

Show Figures