Polyimide

A topical collection in Polymers (ISSN 2073-4360). This collection belongs to the section "Polymer Chemistry".

Viewed by 9698Editor

Interests: high performance polyimide; fuel cell proton exchange membrane; POSS based hybrid polymer

Topical Collection Information

Dear Colleagues

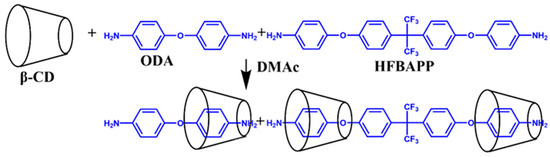

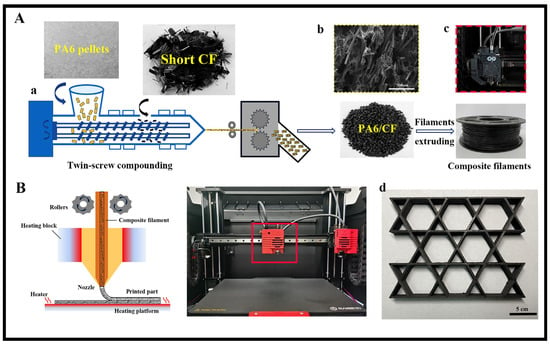

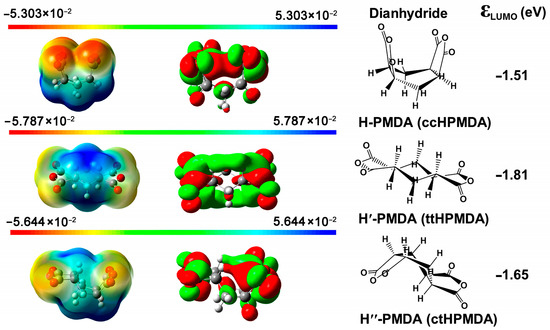

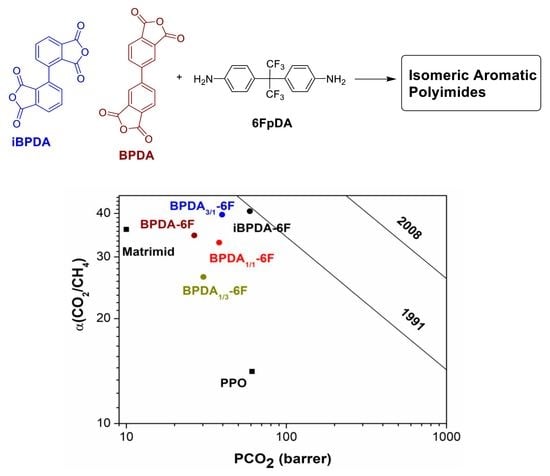

Polyimides (PI) are an important high-performance polymer with excellent thermal stability, mechanical strength and toughness, high electric insulating properties, low dielectric constants and dissipation factors, and high radiation and wear resistance, among other properties, and they can be processed into a variety of materials, including films, fibers, carbon fiber composites, engineering plastics, foams, porous membranes, coatings and varnishes, etc. Polyimides have found widespread use in a variety of high-tech domains, including electric insulation, microelectronics and optoelectronics, the aerospace and aviation industries, etc. Dupont released the first commercial polyimide material in the late 1960s after developing an effective synthetic pathway to high-molecular-weight polyimides. Even today, however, the most popular polyimide production processes are not totally understood. This is because numerous reaction conditions, such as solvent, moisture, impurity, temperature, and others, have a considerable impact on the polymerization reaction of aromatic dianhydrides with aromatic diamines. The molecular weights of the produced polyimides can be affected by the addition mode of monomers.

In recent years, there have been many publications on polyimide materials. In order to reflect the current state of the art on the subject and to explore potential future developments, the present Special Issue welcomes submissions on all aspects of high-performance polymers, ranging from the synthesis and characterization to structural modification, processing, and new functions and applications.

Dr. Chenliang Gong

Collection Editor

Manuscript Submission Information

Manuscripts should be submitted online at www.mdpi.com by registering and logging in to this website. Once you are registered, click here to go to the submission form. Manuscripts can be submitted until the deadline. All submissions that pass pre-check are peer-reviewed. Accepted papers will be published continuously in the journal (as soon as accepted) and will be listed together on the collection website. Research articles, review articles as well as short communications are invited. For planned papers, a title and short abstract (about 100 words) can be sent to the Editorial Office for announcement on this website.

Submitted manuscripts should not have been published previously, nor be under consideration for publication elsewhere (except conference proceedings papers). All manuscripts are thoroughly refereed through a single-blind peer-review process. A guide for authors and other relevant information for submission of manuscripts is available on the Instructions for Authors page. Polymers is an international peer-reviewed open access semimonthly journal published by MDPI.

Please visit the Instructions for Authors page before submitting a manuscript. The Article Processing Charge (APC) for publication in this open access journal is 2700 CHF (Swiss Francs). Submitted papers should be well formatted and use good English. Authors may use MDPI's English editing service prior to publication or during author revisions.

Keywords

- high-performance polymers

- thermally stable polymers

- aromatic polymers

- aramids

- polyimides and other heterocyclic polymers

- applications