Penetration of a Pulsed Guided Streamer Discharge into Micrometer-Sized Capillary Tubes

Abstract

:1. Introduction

2. Materials and Methods

3. Results

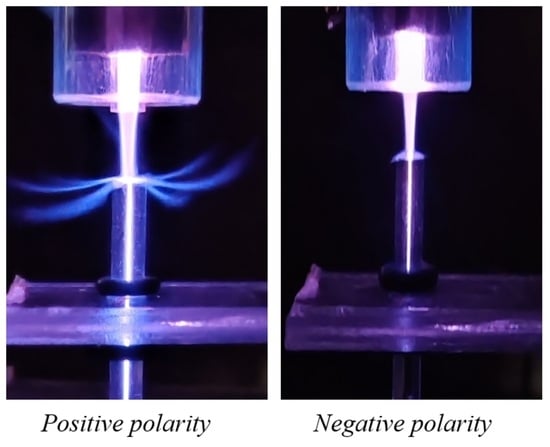

3.1. Plasma Characteristics

3.2. Overview of the Streamer Penetration and Propagation through the Capillary

3.3. Guided Streamer Penetration into Capillary Tubes

3.4. Streamer Propagation in Capillary Tubes

3.5. Radial Offset Study

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sakudo, A.; Yagyu, Y.; Onodera, T. Disinfection and Sterilization Using Plasma Technology: Fundamentals and Future Perspectives for Biological Applications. Int. J. Mol. Sci. 2019, 20, 5216. [Google Scholar] [CrossRef] [PubMed]

- Laroussi, M. Cold plasma in medicine and healthcare: The new frontier in low temperature plasma applications. Front. Phys. 2020, 8, 74. [Google Scholar] [CrossRef]

- Kim, J.Y.; Wei, Y.; Li, J.; Kim, S.-O. 15-μm-sized single-cellular-level and cell-manipulatable microplasma jet in cancer therapies. Biosens. Bioelectron. 2010, 26, 555–559. [Google Scholar] [CrossRef] [PubMed]

- Wang, R.; Li, W.; Zhang, C.; Ren, C.; Ostrikov, K.; Shao, T. Thin insulating film deposition on copper by atmospheric-pressure plasmas. Plasma Process. Polym. 2017, 14, 1600248. [Google Scholar] [CrossRef]

- Kondeti, V.S.S.K.; Gangal, U.; Yatom, S.; Bruggeman, P.J. Ag+ reduction and silver nanoparticle synthesis at the plasma–liquid interface by an RF driven atmospheric pressure plasma jet: Mechanisms and the effect of surfactant. J. Vac. Sci. Technol. A 2017, 35, 061302. [Google Scholar] [CrossRef]

- Naidis, G.V. Modelling of plasma bullet propagation along a helium jet in ambient air. J. Phys. D Appl. Phys. 2011, 44, 215203. [Google Scholar] [CrossRef]

- Lu, X.; Naidis, G.V.; Laroussi, M.; Reuter, S.; Graves, D.B.; Ostrikov, K. Reactive species in non-equilibrium atmospheric-pressure plasmas: Generation, transport, and biological effects. Phys. Rep. 2016, 630, 1–84. [Google Scholar] [CrossRef]

- Babaeva, N.Y.; Naidis, G.V. Universal nature and specific features of streamers in various dielectric media. J. Phys. D Appl. Phys. 2021, 54, 223002. [Google Scholar] [CrossRef]

- Brahme, A.; Chang, Z.; Zhao, N.; Kondeti, V.S.S.K.; Bruggeman, P.J. Penetration of Ar and He RF-driven plasma jets into micrometer-sized capillary tubes. J. Phys. D Appl. Phys. 2018, 51, 414002. [Google Scholar] [CrossRef]

- Weltmann, K.D.; Kindel, E.; Woedtke, T.; Hähnel, M.; Stieber, M.; Brandenburg, R. Atmospheric-pressure plasma sources: Prospective tools for plasma medicine. Pure Appl. Chem. 2010, 82, 1223–1237. [Google Scholar] [CrossRef]

- Zhang, Q.; Bogaerts, A. Propagation of a plasma streamer in catalyst pores. Plasma Sources Sci. Technol. 2018, 27, 035009. [Google Scholar] [CrossRef]

- Hensel, K.; Martišovitš, V.; Machala, Z.; Janda, M.; Leštinský, M.; Tardiveau, P.; Mizuno, A. Electrical and Optical Properties of AC Microdischarges in Porous Ceramics. Plasma Process. Polym. 2007, 4, 682–693. [Google Scholar] [CrossRef]

- Shashurin, A.; Shneider, M.N.; Keidar, M. Measurements of streamer head potential and conductivity of streamer column in the cold non-equilibrium atmospheric plasmas. Plasma Sources Sci Technol. 2012, 21, 034006. [Google Scholar] [CrossRef]

- Nijdam, S.; Teunissen, J.; Ebert, U. The physics of streamer discharge phenomena. Plasma Sources Sci. Technol. 2020, 29, 103001. [Google Scholar] [CrossRef]

- Lu, X.; Ostrikov, K. Guided ionization waves: The physics of repeatability. Appl. Phys. Rev. 2018, 5, 031102. [Google Scholar] [CrossRef]

- Ran, J.; Luo, H.; Yue, Y.; Wang, X. Measurement of the First Townsend’s Ionization Coefficients in Helium, Air, and Nitrogen at Atmospheric Pressure. J. Phys. Soc. Jpn. 2014, 83, 074503. [Google Scholar] [CrossRef]

- Schmidt-Bleker, A.; Norberg, S.A.; Winter, J.; Johnsen, E.; Reuter, S.; Weltmann, K.D.; Kushner, M.J. Propagation Mechanisms of Guided Streamers in Plasma Jets: The Influence of Electronegativity of the Surrounding Gas. Plasma Sources Sci. Technol. 2015, 24, 035022. [Google Scholar] [CrossRef]

- Pinchuk, M.; Nikiforov, A.; Snetov, V.; Chen, Z.; Leys, C.; Stepanova, O. Role of charge accumulation in guided streamer evolution in helium DBD plasma jets. Sci. Rep. 2021, 11, 17286. [Google Scholar] [CrossRef]

- Jiang, C.; Chen, M.T.; Gundersen, M.A. Polarity-induced asymmetric effects of nanosecond pulsed plasma jets. J. Phys. D Appl. Phys. 2009, 42, 232002. [Google Scholar] [CrossRef]

- Ning, W.; Dai, D.; Li, L. Ignition properties of helium discharges in dielectric tubes with radius from 50 µm to 3 mm. Plasma Process. Polym. 2018, 15, 1800010. [Google Scholar] [CrossRef]

- Wu, S.; Wu, F.; Lui, C.; Lui, X.; Chen, Y.; Shao, T.; Zhang, C. The effects of the tube diameter on the discharge ignition and the plasma properties of atmospheric-pressure microplasma confined inside capillary. Plasma Process. Polym. 2019, 16, 1800176. [Google Scholar] [CrossRef]

- Ning, W.; Dai, D.; Zhang, Y. Inducing discharges in a micrometer catalyst channel by a helium atmospheric pressure plasma jet. Appl. Phys. Lett. 2019, 114, 054104. [Google Scholar] [CrossRef]

- Kruszelnicki, J.; Ma, R.; Kushner, M.J. Propagation of atmospheric pressure plasmas through interconnected pores in dielectric materials. J. Appl. Phys. 2021, 129, 143302. [Google Scholar] [CrossRef]

- Jánský, J.; Bourdon, A. Surface charge deposition inside a capillary glass tube by an atmospheric pressure discharge in air. Eur. Phys. J. Appl. Phys. 2011, 55, 13810. [Google Scholar] [CrossRef]

- Jánský, J.; Delliou, P.; Tholin, F.; Tardiveau, P.; Bourdon, A.; Pasquiers, S. Experimental and numerical study of the propagation of a discharge in a capillary tube in air at atmospheric pressure. J. Phys. D Appl. Phys. 2011, 44, 335201. [Google Scholar] [CrossRef]

- Van Doremaele, E.R.W.; Kondeti, V.S.S.K.; Bruggeman, P.J. Effect of plasma on gas flow and air concentration in the effluent of a pulsed cold atmospheric pressure helium plasma jet. Plasma Sources Sci. Technol. 2018, 27, 095006. [Google Scholar] [CrossRef]

- Klarenaar, B.L.M.; Guaitella, O.; Engeln, R.; Sobota, A. How dielectric, metallic and liquid targets influence the evolution of electron properties in a pulsed He jet measured by Thomson and Raman scattering. Plasma Sources Sci. Technol. 2018, 27, 085004. [Google Scholar] [CrossRef]

- Naidis, G.V. Simulation of streamers propagating along helium jets in ambient air: Polarity-induced effects. Appl. Phys. Lett. 2011, 98, 141501. [Google Scholar] [CrossRef]

- Hagelaar, G.J.M.; Pitchford, L.C. Solving the Boltzmann equation to obtain electron transport coefficients and rate coefficients for fluid models. Plasma Sources Sci. Technol. 2005, 14, 722–733. [Google Scholar] [CrossRef]

- Viegas, P.; Slikboer, E.; Obrusník, A.; Bonaventura, X.; Sobota, A.; Garcia-Caurel, E.; Guaitella, O.; Bourdon, A. Investigation of a plasma–target interaction through electric field characterization examining surface and volume charge contributions: Modeling and experiment. Plasma Sources Sci. Technol. 2018, 27, 094002. [Google Scholar] [CrossRef]

- Lu, X.; Naidis, G.V.; Laroussi, M.; Ostrikov, K. Guided ionization waves: Theory and experiments. Phys. Rep. 2014, 540, 123–166. [Google Scholar] [CrossRef]

- Pechereau, F.; Bourdon, A. Influence of the polarity of the applied voltage on the reignition of a discharge below a dielectric layer in air at atmospheric pressure. J. Phys. D Appl. Phys. 2014, 47, 445206. [Google Scholar] [CrossRef]

- Naidis, G.V. Positive and negative streamers in air: Velocity-diameter relation. Phys. Rev. E 2009, 79, 057401. [Google Scholar] [CrossRef] [PubMed]

- Loeb, L.B. Ionization waves of potential gradient. Science 1965, 148, 1417–1426. [Google Scholar] [CrossRef]

- Wu, S.; Lu, X.; Yue, Y.; Dong, X.; Pei, X. Effects of the tube diameter on the propagation of helium plasma plume via electric field measurement. Phys. Plasmas 2016, 23, 103506. [Google Scholar] [CrossRef]

- Sretenović, G.B.; Krstić, I.B.; Kovačević, V.V.; Obradović, B.M.; Kuraica, M.M. The isolated head model of the plasma bullet/streamer propagation: Electric field-velocity relation. J. Phys. D Appl. Phys. 2014, 47, 355201. [Google Scholar] [CrossRef]

- Xiong, Z.; Robert, E.; Sarron, V.; Pouvesle, J.M.; Kushner, M.J. Atmospheric-pressure plasma transfer across dielectric channels and tubes. J. Phys. D Appl. Phys. 2013, 46, 155203. [Google Scholar] [CrossRef]

| Plasma Parameters | Positive Polarity | Negative Polarity |

|---|---|---|

| Gas Temperature (Tgas) (K) | 300 ± 15 | 295 ± 15 |

| Electron Temperature (Te) (eV) | 0.9–1.5 | - |

| Electron Density (ne) (cm−3) | (3.3–5.1) × 1013 | (3.1–3.8) × 1013 |

| Streamer Head Electric Field (kV/cm) | 45 | 15 |

| Streamer Channel Electric Field (kV/cm) | 1 | 3 |

| Debye Length (λD) (μm) | 1–2.5 | 1.3–2.7 * |

| Capillary Diameter | Propagation Speed (mm/ns) | Penetration Delay (ns) | ||

|---|---|---|---|---|

| Positive Polarity | Negative Polarity | Positive Polarity | Negative Polarity | |

| Free jet | 0.231 ± 0.002 | 0.196 ± 0.008 | - | - |

| 500 μm | 0.186 ± 0.009 | 0.131 ± 0.002 | 24 ± 7 | 15 ± 7 |

| 250 μm | 0.142 ± 0.004 | 0.126 ± 0.004 | 24 ± 7 | 15 ± 7 |

| 150 μm | 0.072 ± 0.002 | 0.085 ± 0.001 | 66 ± 7 | 12 ± 7 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jain, S.; Bruggeman, P.J. Penetration of a Pulsed Guided Streamer Discharge into Micrometer-Sized Capillary Tubes. Plasma 2023, 6, 663-679. https://doi.org/10.3390/plasma6040046

Jain S, Bruggeman PJ. Penetration of a Pulsed Guided Streamer Discharge into Micrometer-Sized Capillary Tubes. Plasma. 2023; 6(4):663-679. https://doi.org/10.3390/plasma6040046

Chicago/Turabian StyleJain, Samyak, and Peter J. Bruggeman. 2023. "Penetration of a Pulsed Guided Streamer Discharge into Micrometer-Sized Capillary Tubes" Plasma 6, no. 4: 663-679. https://doi.org/10.3390/plasma6040046