Adsorption, Surface Viscoelasticity, and Foaming Properties of Silk Fibroin at the Air/Water Interface

Abstract

:1. Introduction

2. Preparation and Features of Aqueous Silk Fibroin Solution

3. The Adsorption of Silk Fibroin at the Air/Water Interface

3.1. Ellipsometry

3.2. Surface Tension

4. The Surface Viscoelasticity of Silk Fibroin Adsorption Layers at the Air/Water Interface

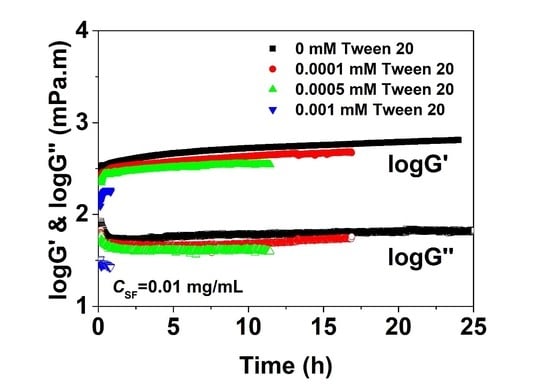

4.1. Surface Dilatational Rheology

4.2. Surface Shear Rheology

4.3. Nonlinear Fracture of SF Surface Layers

5. The Foaming Properties of Aqueous Silk Fibroin Solutions

5.1. Foamability

5.2. Foam Stability

6. Conclusions and Perspectives

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Narsimhan, G.; Xiang, N. Role of proteins on formation, drainage, and stability of liquid food foams. Annu. Rev. Food Sci. Technol. 2018, 9, 45–63. [Google Scholar] [CrossRef] [PubMed]

- Lech, F.J.; Steltenpool, P.; Meinders, M.B.J.; Sforza, S.; Gruppen, H.; Wierenga, P.A. Identifying changes in chemical, interfacial and foam properties of β-lactoglobulin-sodium dodecyl sulphate mixtures. Colloid Surf. A Physicochem. Eng. Asp. 2014, 462, 34–44. [Google Scholar] [CrossRef]

- Zhang, H.H.; Xu, G.Y.; Liu, T.; Xu, L.; Zhou, Y.W. Foam and interfacial properties of Tween 20-bovine serum albumin systems. Colloid Surf. A Physicochem. Eng. Asp. 2013, 416, 23–31. [Google Scholar] [CrossRef]

- Peng, D.F.; Yang, J.C.; Li, J.; Tang, C.; Li, B. Foams stabilized by β-Lactoglobulin amyloid fibrils: Effect of pH. J. Agric. Food Chem. 2017, 65, 10658–10665. [Google Scholar] [CrossRef]

- Dombrowski, J.; Gschwendtner, M.; Saalfeld, D.; Kulozik, U. Salt-dependent interaction behavior of β-Lactoglobulin molecules in relation, to their surface and foaming properties. Colloid Surf. A Physicochem. Eng. Asp. 2018, 558, 455–462. [Google Scholar] [CrossRef]

- Damodaran, S. Functional properties. In Food Proteins: Properties and Characterization; VCH Publications: New York, NY, USA, 1996; pp. 167–234. [Google Scholar]

- Wilde, P.J. Interfaces: Their role in foam and emulsion behaviour. Curr. Opin. Colloid Interface Sci. 2000, 5, 176–181. [Google Scholar] [CrossRef]

- Brüchner-Gühmann, M.; Heiden-Hecht, T.; Sözer, N.; Drusch, S. Foaming characteristics of oat protein and modification by partial hydrolysis. Eur. Food Res. Technol. 2018, 244, 2095–2106. [Google Scholar] [CrossRef]

- Martin, A.H.; Bos, M.A.; van Vliet, T. Interfacial rheology properties and conformational aspects of soy glycinin at the air/water interface. Food Hydrocoll. 2002, 16, 63–71. [Google Scholar] [CrossRef]

- Martin, A.H.; Grolle, K.; Bos, M.A.; Stuart, M.A.C.; van Vliet, T. Network forming properties of various proteins adsorbed at the air/water interface in relation to foam stability. J. Colloid Interf. Sci. 2002, 254, 175–183. [Google Scholar] [CrossRef]

- Dombrowski, J.; Gschwendtner, M.; Kulozik, U. Evaluation of structural characteristics determining surface and foaming properties of β-lactoglobulin aggregates. Colloids Surf. A Physicochem. Eng. Asp. 2017, 516, 286–295. [Google Scholar] [CrossRef]

- Dombrowski, J.; Johler, F.; Warncke, M.; Kulozik, U. Correlation between bulk characteristics of aggregated β-lactoglobulin and its surface and foaming properties. Food Hydrocoll. 2016, 61, 318–328. [Google Scholar] [CrossRef]

- Engelhardt, K.; Lexis, M.; Gochev, G.; Konnerth, C.; Miller, R.; Willenbacher, N.; Peukert, W.; Braunschweig, B. pH effects on the molecular structure of β-lactoglobulin modified air-water interfaces and its impact on foam rheology. Langmuir 2013, 29, 11646–11655. [Google Scholar] [CrossRef] [PubMed]

- Braunschweig, B.; Schulze-Zachau, F.; Nagel, E.; Engelhardt, K.; Stoyanov, S.; Gochev, G.; Khristov, K.; Mileva, E.; Exerowa, D.; Miller, R.; et al. Specific effects of Ca2+ ions and molecular structure of β-lactoglobulin interfacial layers that drive macroscopic foam stability. Soft Matter 2016, 12, 5995–6004. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jaganathan, M.; Dhathathreyan, A.; Selvaraju, C.; Miller, R. Jones-Ray effect on the organization of lysozyme in the presence of NaNO3 at an air/water interface: Is it a cause or consequence? RSC Adv. 2015, 5, 100638–100645. [Google Scholar] [CrossRef]

- Ruíz-Henestrosa, V.P.; Sánchez, C.C.; Patino, J.M.R. Adsorption and foaming characteristics of soy globulins and Tween 20 mixed systems. Ind. Eng. Chem. Res. 2008, 47, 2876–2885. [Google Scholar] [CrossRef]

- Ruíz-Henestrosa, V.P.; Sánchez, C.C.; Patino, J.M.R. Formulation engineering can improve the interfacial and foaming properties of soy globulins. J. Agric. Food Chem. 2007, 55, 6339–6348. [Google Scholar] [CrossRef]

- Gunning, P.A.; Mackie, A.R.; Gunning, A.P.; Woodward, N.C.; Wilde, P.J.; Morris, V.J. Effect of surfactant type on surfactant-protein interactions at the air-water interface. Biomacromolecules 2004, 5, 984–991. [Google Scholar] [CrossRef]

- Alahverdjieva, V.S.; Grigoriev, D.O.; Fainerman, V.B.; Aksenenko, E.V.; Miller, R.; Möhwald, H. Competitive adsorption from mixed hen egg-white lysozyme/surfactant solutions at the air-water interface studied by tensiometry, ellipsometry, and surface dilational rheology. J. Phys. Chem. B 2008, 112, 2136–2143. [Google Scholar] [CrossRef]

- Petkov, J.T.; Gurkov, T.D.; Campbell, B.E.; Borwankar, R.P. Dilatational and shear elasticity of gel-like protein layers on air/water interface. Langmuir 2000, 16, 3703–3711. [Google Scholar] [CrossRef]

- Zhang, Q.; Wang, N.; Hu, R.Q.; Pi, Y.P.; Feng, J.Q.; Wang, H.; Zhuang, Y.; Xu, W.L.; Yang, H.J. Wet spinning of bletilla striata polysaccharide/silk fibroin hybrid fibers. Mater. Lett. 2015, 161, 576–579. [Google Scholar] [CrossRef]

- Teimouri, A.; Azadi, M.; Emadi, R.; Lari, J.; Chermahini, A.N. Preparation, characterization, degradation and biocompatibility of different silk fibroin based composite scaffolds prepared by freeze-drying method for tissue engineering application. Polym. Degrad. Stab. 2015, 121, 18–29. [Google Scholar] [CrossRef]

- Sangkert, S.; Meesane, J.; Kamonmattayakul, S.; Chai, W.L. Modified silk fibroin scaffolds with collagen/decellularized pulp for bone tissue engineering in cleft palate: Morphological structures and biofunctionalities. Mater. Sci. Eng. C 2016, 58, 1138–1149. [Google Scholar] [CrossRef] [PubMed]

- Elia, R.; Michelson, C.D.; Perera, A.L.; Brunner, T.F.; Harsono, M.; Leisk, G.G.; Kugel, G.; Kaplan, D.L. Electrodeposited silk coatings for bone implants. J. Biomed. Mater. Res. B Appl. Biomater. 2014, 103, 1602–1609. [Google Scholar] [CrossRef] [Green Version]

- Zhong, T.Y.; Jiang, Z.J.; Wang, P.; Bie, S.Y.; Zhang, F.; Zuo, B.Q. Silk fibroin/copolymer composite hydrogels for the controlled and sustained release of hydrophobic/hydrophilic drugs. Int. J. Pharm. 2015, 494, 264–270. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.H.; Dicko, C.; Bain, C.D.; Gong, Z.G.; Jacobs, R.M.J.; Shao, Z.Z.; Terry, A.E.; Vollrath, F. Behavior of silk protein at the air-water interface. Soft Matter 2012, 8, 9705–9712. [Google Scholar] [CrossRef]

- Valluzzi, R.; Gido, S.P.; Muller, W.; Kaplan, D.L. Orientation of silk III at the air-water interface. Int. J. Biol. Macromol. 1999, 24, 237–242. [Google Scholar] [CrossRef]

- He, S.J.; Valluzzi, R.; Gido, S.P. SilkⅠStructure in Bombyx Mori Silk Foams. Int. J. Biol. Macromol. 1999, 24, 187–195. [Google Scholar] [CrossRef]

- Maniglio, D.; Bonani, W.; Migliaresi, C.; Motta, A. Silk fibroin porous scaffolds by N2O foaming. J. Biomat. Sci. Polym. Ed. 2018, 29, 491–506. [Google Scholar] [CrossRef]

- Bellas, E.; Lo, T.J.; Fournier, E.P.; Brown, J.E.; Abbott, R.D.; Gil, E.S.; Marra, K.G.; Rubin, J.P.; Leisk, G.G.; Kaplan, D.L. Injectable silk foams for soft tissue regeneration. Adv. Healthc. Mater. 2015, 4, 452–459. [Google Scholar] [CrossRef]

- Qin, K.; Pereira, R.F.P.; Coradin, T.; Bermudez, V.; Fernandes, F.M. Biomimetic silk macroporous materials for drug delivery obtained via ice-templating. ACS Appl. Bio Mater. 2022, 5, 2556–2566. [Google Scholar] [CrossRef]

- Chambre, L.; Parker, R.N.; Allardyce, B.J.; Valente, F.; Rajkhowa, R.; Dilley, R.J.; Wang, X.; Kaplan, D.L. Tunable biodegradable silk-based memory foams with controlled release of antibiotics. ACS Appl. Bio Mater. 2020, 3, 2466–2472. [Google Scholar] [CrossRef] [PubMed]

- Nogueira, G.M.; Weska, R.F.; Vieira, W.C., Jr.; Polakiewicz, B.; Rodas, A.C.D.; Higa, O.Z.; Beppu, M.M. A new method to prepare porous silk fibroin membranes suitable for tissue scaffolding applications. J. Appl. Polym. Sci. 2009, 114, 617–623. [Google Scholar] [CrossRef]

- Qiao, X.Y.; Miller, R.; Schneck, E.; Sun, K. Foaming properties and the dynamics of adsorption and surface rheology of silk fibroin at the air/water interface. Colloid Surf. A Physicochem. Eng. Asp. 2020, 591, 124553. [Google Scholar] [CrossRef]

- Qiao, X.Y.; Miller, R.; Schneck, E.; Sun, K. Influence of pH on the surface and foaming properties of aqueous silk fibroin solutions. Soft Matter 2020, 16, 3695–3704. [Google Scholar] [CrossRef]

- Qiao, X.Y.; Miller, R.; Schneck, E.; Sun, K. Influence of salt addition on the surface and foaming properties of silk fibroin. Colloid Surf. A Physicochem. Eng. Asp. 2021, 609, 125621. [Google Scholar] [CrossRef]

- Qiao, X.Y.; Miller, R.; Schneck, E.; Sun, K. Influence of surfactant charge and concentration on the surface and foaming properties of biocompatible silk fibroin. Mater. Chem. Phys. 2022, 281, 125920. [Google Scholar] [CrossRef]

- Matsumoto, A.; Chen, J.S.; Collette, A.L.; Kim, U.K.; Altman, G.H.; Cebe, P.; Kaplan, D.L. Mechanisms of silk fibroin sol-gel transitions. J. Phys. Chem. B 2006, 110, 21630–21638. [Google Scholar] [CrossRef] [PubMed]

- Mitropoulos, V.; Mütze, A.; Fischer, P. Mechanical properties of protein adsorption layers at the air/water and oil/waer interface: A comparison in light of the thermodynamical stability of proteins. Adv. Colloid Interface Sci. 2014, 206, 195–206. [Google Scholar] [CrossRef]

- Piazza, L.; Auser, N.D.; Gigli, J.; Windhab, E.J.; Fischer, P. Interfacial rheology of soy proteins-high methoxyl pectin films. Food Hydrocoll. 2009, 23, 2125–2131. [Google Scholar] [CrossRef]

- Wan, Z.L.; Yang, X.Q.; Sagis, L.M.C. Contribution of long fibrils and peptides to surface and foaming behavior of soy protein fibril system. Langmuir 2016, 32, 8092–8101. [Google Scholar] [CrossRef]

- Mahmood, M.E.; Al-Koofee, D.A.F. Effect of temperature changes on critical micelle concentration for tween series surfactant. Glob. J. Sci. Front. Res. Chem. 2013, 13, 1–7. [Google Scholar]

- Fuguet, E.; Ràfols, C.; Rosés, M.; Bosch, E. Critical micelle concentration of surfactants in aqueous buffered and unbuffered systems. Anal. Chim. Acta 2005, 548, 95–100. [Google Scholar] [CrossRef]

- Miller, R.; Fainerman, V.B.; Aksenenko, E.V.; Leser, M.E.; Michel, M. Dynamic surface tension and adsorption kinetics of β-casein at the solution/air interface. Langmuir 2004, 20, 771–777. [Google Scholar] [CrossRef] [PubMed]

- Johnston, E.R.; Miyagi, Y.; Chuah, J.A.; Numata, K.; Serban, M.A. Interplay between silk fibroin’s structure and its adhesive properties. ACS Biomater. Sci. Eng. 2018, 4, 2815–2824. [Google Scholar] [CrossRef] [PubMed]

- Hill, K.; Horváth-Szanics, E.; Hajós, G.; Kiss, É. Surface and interfacial properties of water-soluble wheat proteins. Colloid Surf. A Physicochem. Eng. Asp. 2008, 319, 180–187. [Google Scholar] [CrossRef]

- Song, K.B.; Damodaran, S. Influence of electrostatic forces on the adsorption of succinylated beta-lactoglobulin at the air-water interface. Langmuir 1991, 7, 2737–2742. [Google Scholar] [CrossRef]

- Ulaganathan, V.; Retzlaff, I.; Won, J.Y.; Gochev, G.; Gehin-Delval, C.; Leser, M.; Noskov, B.A.; Miller, R. β-Lactoglobulin adsorption layers at the water/air surface: 1. Adsorption kinetics and surface pressure isotherm: Effect of pH and ionic strength. Colloid Surf. A Physicochem. Eng. Asp. 2017, 519, 153–160. [Google Scholar] [CrossRef]

- Miller, R.; Ferri, J.K.; Javadi, A.; Krägel, J.; Mucic, N.; Wüstneck, R. Rheology of interfacial layers. Colloid Polym. Sci. 2010, 288, 937–950. [Google Scholar] [CrossRef]

- Mahmoudi, N.; Gaillard, C.; Boué, F.; Axelos, M.A.V.; Riaublanc, A. Self-similar assemblies of globular whey proteins at the air-water interface: Effect of the structure. J. Colloid Interf. Sci. 2010, 345, 54–63. [Google Scholar] [CrossRef]

- Ruíz-Henestrosa, V.P.; Sánchez, C.C.; Escobar, M.D.M.Y.; Jiménez, J.J.P.; Rodríguez, F.M.; Patino, J.M.R. Interfacial and foaming characteristics of soy globulins as a function of pH and ionic strength. Colloid Surf. A Physicochem. Eng. Asp. 2007, 309, 202–215. [Google Scholar] [CrossRef]

- Bai, S.; Liu, S.; Zhang, C.; Xu, W.; Lu, Q.; Han, H.; Zhu, H. Controllable transition of silk fibroin nanostructures: An insight into in vitro silk self-assembly process. Acta Biomater. 2013, 9, 7806–7813. [Google Scholar] [CrossRef] [PubMed]

- Fainerman, V.B.; Kovalchuk, V.I.; Aksenenko, E.V.; Zinkovych, I.I.; Makievski, A.V.; Nikolenko, M.V.; Miller, R. Dilational viscoelasticity of proteins solutions in dynamic conditions. Langmuir 2018, 34, 6678–6686. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.; Li, Y.Y.; Wang, J.; Zhang, Y. Interfacial behavior of alkaline protease at the air-water and oil-water interfaces. Appl. Surf. Sci. 2018, 433, 1128–1136. [Google Scholar] [CrossRef]

- Rühs, P.A.; Scheuble, N.; Windhab, E.J.; Fischer, P. Protein adsorption and interfacial rheology interfering in dilational experiment. Eur. Phys. J. Spec. Top. 2013, 222, 47–60. [Google Scholar] [CrossRef]

- Lech, F.J.; Delahaije, R.J.; Meinders, M.B.J.; Gruppen, H.; Wierenga, P.A. Identification of critical concentrations determining foam ability and stability of β-lactoglobulin. Food Hydrocoll. 2016, 57, 46–54. [Google Scholar] [CrossRef]

- Lexis, M.; Willenbacher, N. Relating foam and interfacial rheological properties of β-lactoglobulin solutions. Soft Matter 2014, 10, 9626–9636. [Google Scholar] [CrossRef] [Green Version]

- Roth, S.; Murray, B.S.; Dickinson, E. Interfacial shear rheology of aged and heat-treated β-lactoglobulin films: Displacement by nonionic surfactant. J. Agric. Food Chem. 2000, 48, 1491–1497. [Google Scholar] [CrossRef]

- Engelhardt, K.; Weichsel, U.; Kraft, E.; Segets, D.; Peukert, W.; Braunschweig, B. Mixed layers of β-lactoglobulin and SDS at air-water interfaces with tunable intermolecular interactions. J. Phys. Chem. B 2014, 118, 4098–4105. [Google Scholar] [CrossRef]

- Marinova, K.G.; Basheva, E.S.; Nenova, B.; Temelska, M.; Mirarefi, A.Y.; Campbell, B.; Ivanov, I.B. Physico-chemical factors controlling the foamability and foam stability of milk proteins: Sodium caseinate and whey protein concentrates. Food Hydrocoll. 2009, 23, 1864–1876. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qiao, X.; Miller, R.; Schneck, E.; Sun, K. Adsorption, Surface Viscoelasticity, and Foaming Properties of Silk Fibroin at the Air/Water Interface. Colloids Interfaces 2022, 6, 40. https://doi.org/10.3390/colloids6030040

Qiao X, Miller R, Schneck E, Sun K. Adsorption, Surface Viscoelasticity, and Foaming Properties of Silk Fibroin at the Air/Water Interface. Colloids and Interfaces. 2022; 6(3):40. https://doi.org/10.3390/colloids6030040

Chicago/Turabian StyleQiao, Xiuying, Reinhard Miller, Emanuel Schneck, and Kang Sun. 2022. "Adsorption, Surface Viscoelasticity, and Foaming Properties of Silk Fibroin at the Air/Water Interface" Colloids and Interfaces 6, no. 3: 40. https://doi.org/10.3390/colloids6030040