Unmalted Cereals, Oenological Yeasts, and In-Bottle Sugar Addition as Synergic Strategies to Enhance the Quality of Craft Beers

Abstract

:1. Introduction

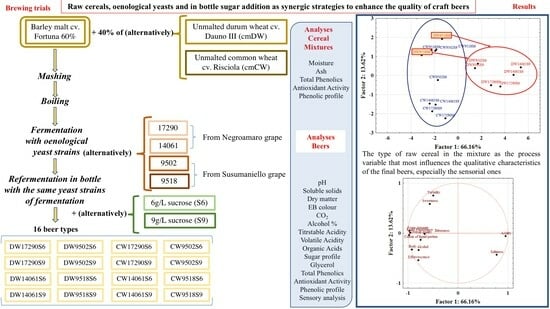

2. Materials and Methods

2.1. Ingredients Used in the Brewing Trials

2.2. Brewing Procedure

2.3. Analyses of the Cereal Mixtures

2.4. Analyses of Beers

2.4.1. Basic Analyses

2.4.2. Organic Acids, Sugars, and Glycerol

2.4.3. Total Phenolic Content, Phenolic Profile, and Antioxidant Activity

2.4.4. Sensory Descriptive Analysis

2.4.5. Statistical Analysis

3. Results and Discussion

3.1. Characteristics of the Cereal Mixtures

3.2. Physico-Chemical Characteristics of the Beers

3.2.1. Physico-Chemical Indices and Concentrations of Sugars, Glycerol, and Organic Acid

3.2.2. Phenolic Component and Antioxidant Activity

3.2.3. PCA Applied to the Beer Physical and Chemical Characteristics

3.2.4. Sensory Characteristics

3.3. Principal Component Analysis Applied to the Beer Sensory Characteristics

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- De Simone, N.; Russo, P.; Tufariello, M.; Fragasso, M.; Solimando, M.; Capozzi, V.; Grieco, F.; Spano, G. Autochthonous biological resources for the production of regional craft beers: Exploring possible contributions of cereals, hops, microbes, and other ingredients. Foods 2021, 10, 1831. [Google Scholar] [CrossRef] [PubMed]

- Siesto, G.; Pietrafesa, R.; Tufariello, M.; Gerardi, C.; Grieco, F.; Capece, A. Application of microbial cross-over for the production of Italian grape ale (IGA), a fruit beer obtained by grape must addition. Food Biosci. 2023, 52, 102487. [Google Scholar] [CrossRef]

- Baiano, A.; Fiore, A.; la Gatta, B.; Tufariello, M.; Gerardi, C.; Grieco, F. Single and interactive effects of unmalted cereals, hops, and yeasts on quality of white-inspired craft beers. Beverages 2023, 9, 9. [Google Scholar] [CrossRef]

- Brewers Association. Brewers Association Style Guidelines. Available online: https://www.brewersassociation.org/edu/brewers-association-beer-style-guidelines/ (accessed on 3 August 2023).

- Belcar, J.; Buczek, J.; Kapusta, I.; Gorzelany, J. Quality and pro-healthy properties of belgian witbier-style beers relative to the cultivar of winter wheat and raw materials used. Foods 2022, 11, 1150. [Google Scholar] [CrossRef]

- Depraetere, S.A.; Delvaux, F.; Coghe, S.; Delvaux, F.R. Wheat variety and barley malt properties: Influence on haze intensity and foam stability of wheat beer. J. Inst. Brew. 2004, 110, 200–206. [Google Scholar] [CrossRef]

- Grieco, F.; Tristezza, M.; Vetrano, C.; Bleve, G.; Panico, E.; Mita, G.; Logrieco, A. Exploitation of autochthonous microorganism potential to enhance the quality of Apulian wines. Ann. Microbiol. 2011, 61, 67–73. [Google Scholar] [CrossRef]

- Tufariello, M.; Chiriatti, M.A.; Grieco, F.; Perrotta, C.; Capone, S.; Rampino, P.; Tristezza, M.; Mita, G. Influence of autochthonous Saccharomyces cerevisiae strains on volatile profile of Negroamaro wines. LWT-Food Sci. Technol. 2014, 58, 35–48. [Google Scholar] [CrossRef]

- Cardoso Viana, A.; Colombo Pimentel, T.; Borges do Vale, R.; Santos Clementino, L.; Thayná, E.; Ferreira, J.; Magnani, M.; dos Santos Lima, M. American pale Ale craft beer: Influence of brewer’s yeast strains on the chemical composition and antioxidant capacity. LWT-Food Sci. Technol. 2021, 152, 112317. [Google Scholar] [CrossRef]

- Canonico, L.; Comitini, F.; Ciani, M. Dominance and influence of selected Saccharomyces cerevisiae strains on the analytical profile of craft beer refermentation. J. Inst. Brew. 2014, 120, 262–267. [Google Scholar] [CrossRef]

- Marconi, O.; Rossi, S.; Galgano, F.; Sileonic, V.; Perretti, G. Influence of yeast strain, priming solution and temperature on beer bottle conditioning. J. Sci. Food Agric. 2016, 96, 4106–4115. [Google Scholar] [CrossRef]

- Pietrafesa, R.; Siesto, G.; Tufariello, M.; Palombi, L.; Baiano, A.; Gerardi, C.; Braghieri, A.; Genovese, F.; Grieco, F.; Capece, A. A multivariate approach to explore the volatolomic and sensory profiles of craft Italian Grape Ale beers produced with novel Saccharomyces cerevisiae strains. Front. Microbiol. 2023, 14, 1234884. [Google Scholar] [CrossRef] [PubMed]

- Vanbeneden, N.; Vanderputten, D.; Vanderhaegen, B.; Derdelinckx, G.; Van Landschoot, A. Influence of the sugar composition of the added extract on the refermentation of beer in bottles. J. Am. Soc. Brew. Chem. 2006, 64, 206–213. [Google Scholar] [CrossRef]

- Tristezza, M.; Fantastico, L.; Vetrano, C.; Bleve, G.; Corallo, D.; Mita, G.; Grieco, F. Molecular and technological characterization of Saccharomyces cerevisiae strains isolated from natural fermentation of Susumaniello grape must in Apulia, Southern Italy. Int. J. Microbiol. 2014, 897428. [Google Scholar] [CrossRef]

- Thesseling, F.A.; Bircham, P.W.; Mertens, S.; Voordeckers, K.; Verstrepen, K.J. A hands-on guide to brewing and analyzing beer in the laboratory. Curr. Protoc. Microbiol. 2019, 54, e91. [Google Scholar] [CrossRef] [PubMed]

- Law 1354. Disciplina Igienica della Produzione e del Commercio Della Birra; Gazzetta Ufficiale della Repubblica Italiana 1962. p. 234. Available online: https://www.gazzettaufficiale.it/atto/serie_generale/caricaDettaglioAtto/originario?atto.dataPubblicazioneGazzetta=1962-09-17&atto.codiceRedazionale=062U1354 (accessed on 19 December 2023).

- AACC. American Association of Cereal Chemists. Official Methods: 44-15.02 Moisture—Air-Oven Methods; 08-01.01 Ash—Basic Method. In AACC International Approved Methods Analysis, 11th ed.; Cereals & Grains Association: St. Paul, MN, USA, 2012. [Google Scholar]

- Gandolpho, B.C.G.; Almeida, A.R.; Gandolpho, G.M.; Freitas, D.Z.; Gasparini, O.C.; Machado, M.H.; Barreto, P.L.M. Optimization of brewing waste’s (trub) phenolic compounds extraction by ultrasound assisted using response surface methodology. Química Nova 2021, 44, 478–483. [Google Scholar] [CrossRef]

- Almeida da Rosa, A.; Ferreira Geraldo, M.R.; Ribeiro, L.F.; Vieira Silva, M.; de Oliveira Brisola Maciel, M.V.; Haminiuk, C.W.I. Bioactive compounds from brewer’s spent grain: Phenolic compounds, fatty acids and in vitro antioxidant capacity. Acta Sci. Technol. 2017, 39, 269–277. [Google Scholar] [CrossRef]

- Brand-Williams, W.; Cuvelier, M.E.; Berset, C. Use of a free radical method to evaluate antioxidant activity. LWT-Food Sci. Technol. 1995, 28, 25–30. [Google Scholar] [CrossRef]

- da Costa Jardim, C.; De Souza, D.; Kasper Machado, I.C.; Massochin Nunes Pinto, L.; de Souza Ramos, R.C.; Garavaglia, J. Sensory profile, consumer preference and chemical composition of craft beers from Brazil. Beverages 2018, 4, 106. [Google Scholar] [CrossRef]

- European Brewery Convention. Method 9.6—Colour of beer: Spectrophotometric method. In Analytica-EBC; Schweizer Brauerei-Rundschau: Zürich, Switzerland, 1975. [Google Scholar]

- Coelho, E.M.; da Silva Padilha, C.V.; Miskinis, G.A.; de Sá, A.G.B.; Pereira, G.E.; de Azevêdo, L.C.; dos Santos Lima, M. Simultaneous analysis of sugars and organic acids in wine and grape juices by HPLC: Method validation and characterization of products from northeast Brazil. J. Food Comp. Anal. 2018, 66, 160–167. [Google Scholar] [CrossRef]

- Singleton, V.L.; Rossi, J.A. Colorimetry of total phenolics with phosphomolybdic-phosphotungstic acid reagents. Am. J. Enol. Vitic. 1965, 16, 144–158. [Google Scholar] [CrossRef]

- ISO 11035:1994; Sensory Analysis—Identification and Selection of Descriptors for Establishing a Sensory profile By a Multidimensional Approach. Available online: https://www.iso.org/standard/19015.html (accessed on 9 January 2024).

- ISO 5496:2006; Sensory Analysis—Methodology Initiation and Training of Assessors in the Detection and Recognition of Odours. Available online: https://www.iso.org/standard/44247.html (accessed on 9 January 2024).

- ISO 3972:2011; Sensory analysis—Methodology–Method of Investigating Sensitivity of Taste. Available online: https://www.iso.org/standard/50110.html (accessed on 9 January 2024).

- ISO 8586:2021; Sensory Analysis—Selection and Training of Sensory Assessors. Available online: https://www.iso.org/standard/76667.html (accessed on 9 January 2024).

- Puri, R.; Khamrui, K.; Khetra, Y.; Malhotra, R.; Devraja, H.C. Quantitative descriptive analysis and principal component analysis for sensory characterization of Indian milk product cham-cham. J. Food Sci. Technol. 2016, 53, 1238–1246. [Google Scholar] [CrossRef] [PubMed]

- Rachoñ, L.; Szumilo, G. Comparison of chemical composition of selected winter wheat species. J. Element. 2009, 14, 135–146. [Google Scholar] [CrossRef]

- Negrão, R.; Costa, R.; Duarte, D.; Gomes, T.T.; Coelho, P.; Guimarães, J.T.; Guardão, L.; Azevedo, I.; Soares, R. Xanthohumol-supplemented beer modulates angiogenesis and inflammation in a skin wound healing model. Involvement of local adipocytes. J. Cell. Biochem. 2012, 113, 100–109. [Google Scholar] [CrossRef]

- Pulvirenti, A.; De Vero, L.; Blaiotta, G.; Sidari, R.; Iosca, G.; Gullo, M.; Caridi, A. Selection of wine Saccharomyces cerevisiae strains and their screening for the adsorption activity of pigments, phenolics and ochratoxin A. Fermentation 2020, 6, 80. [Google Scholar] [CrossRef]

- Boukid, F.; Folloni, S.; Sforza, S.; Vittadini, E.; Prandi, B. Current trends in ancient grains-based foodstuffs: Insights into nutritional aspects and technological applications. Compr. Rev. Food Sci. Food Saf. 2018, 17, 123–136. [Google Scholar] [CrossRef] [PubMed]

- Alfeo, V.; De Francesco, G.; Sileoni, V.; Blangiforti, S.; Palmeri, R.; Aerts, G.; Perretti, G.; Todaro, A. Physicochemical properties, sugar profile, and non-starch polysaccharides characterization of old wheat malt landraces. J. Food Comp. Anal. 2021, 102, 103997. [Google Scholar] [CrossRef]

- Aslankoohi, E.; Rezaei, M.N.; Vervoort, Y.; Courtin, C.M.; Verstrepen, K.J. Glycerol production by fermenting yeast cells is essential for optimal bread dough fermentation. PLoS ONE 2015, 10, e0119364. [Google Scholar] [CrossRef]

- Zhao, X.; Procopio, S.; Becker, T. Flavor impacts of glycerol in the processing of yeast fermented beverages: A review. J. Food Sci. Technol. 2015, 52, 7588–7598. [Google Scholar] [CrossRef]

- Delvaux, F.; Delvaux, F.R.; Delcour, J.A. Characterization of the colloidal haze in commercial and pilot scale Belgian white beers. J. Inst. Brew. 2000, 4, 221–227. [Google Scholar] [CrossRef]

- Xu, K.; Guo, M.; Du, J.; Zhang, Z.A. Cloudy wheat beer enriched with okra [Abelmoschus esculentus (L.) Moench]: Effects on volatile compound and sensorial attributes. Int. J. Food Prop. 2018, 21, 289–300. [Google Scholar] [CrossRef]

- Radonjic, S.; Maraš, V.; Raievic, J.; Košmerl, T. Wine or Beer? Comparison, changes and improvement of polyphenolic compounds during technological phases. Molecules 2020, 25, 4960. [Google Scholar] [CrossRef] [PubMed]

- Romano, G.; Tufariello, M.; Calabriso, N.; Del Coco, L.; Fanizzi, F.P.; Blanco, A.; Carluccio, M.A.; Grieco, F.; Laddomada, B. Pigmented cereals and legume grains as healthier alternatives for brewing beers. Food Biosci. 2023, 52, 102463. [Google Scholar] [CrossRef]

- Blasco, L.; Viñas, M.; Villa, T.G. Proteins influencing foam formation in wine and beer: The role of yeast. Int. Microbiol. 2011, 14, 61–71. [Google Scholar] [PubMed]

- Mascia, I.; Fadda, C.; Dostálek, P.; Olšovská, J.; Del Caro, A. Preliminary characterization of an Italian craft durum wheat beer. J. Inst. Brew. 2014, 120, 495–499. [Google Scholar] [CrossRef]

- Douglas, P.; Meneses, F.J.; Jiranek, V. Filtration, haze and foam characteristics of fermented wort mediated by yeast strain. J. Appl. Microbiol. 2006, 100, 58–64. [Google Scholar] [CrossRef]

| Beer Acronyms | Cereal Mixture | S. cerevisiae Strain | Sugar Levels |

|---|---|---|---|

| DW-17290-S6 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Negroamaro (17290) | 6 g/L |

| DW-17290-S9 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Negroamaro (17290) | 9 g/L |

| DW-14061-S6 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Negroamaro (14061) | 6 g/L |

| DW-14061-S9 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Negroamaro (14061) | 9 g/L |

| DW-9502-S6 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Susumaniello (9502) | 6 g/L |

| DW-9502-S9 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Susumaniello (9502) | 9 g/L |

| DW-9518-S6 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Susumaniello (9518) | 6 g/L |

| DW-9518-S9 | 60% malted barley-40% unmalted durum wheat (DW) | Isolated from Susumaniello (9518) | 9 g/L |

| CW-17290-S6 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Negroamaro (17290) | 6 g/L |

| CW-17290-S9 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Negroamaro (17290) | 9 g/L |

| CW-14061-S6 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Negroamaro (14061) | 6 g/L |

| CW-14061-S9 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Negroamaro (14061) | 9 g/L |

| CW-9502-S6 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Susumaniello (9502) | 6 g/L |

| CW-9502-S9 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Susumaniello (9502) | 9 g/L |

| CW-9518-S6 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Susumaniello (9518) | 6 g/L |

| CW-9518-S9 | 60% malted barley-40% unmalted common wheat (CW) | Isolated from Susumaniello (9518) | 9 g/L |

| Beer Acronyms | Color (EBC) | Alcohol Content (%) | CO2 (g/L) | Soluble Solids (Brix) | Sugars (mg/mL) | Glycerol (mg/L) | ||||

|---|---|---|---|---|---|---|---|---|---|---|

| Maltodextrins | Maltotriose | Maltose | Glucose | Fructose | ||||||

| Interactive effects (Cereal mixtures × Yeasts × Sugar levels) | ||||||||||

| DW-17290-S6 | 6.6 ± 0.1 a | 4.09 ± 0.02 bc | 6.75 ± 0.25 ef | 6.7 ± 0.1 i | 23.98 ± 0.76 h | 2.83 ± 0.25 fg | 3.91 ± 0.15 h | 10.77 ± 0.50 j | 0.99 ± 0.16 ad | 2.40 ± 0.09 ac |

| DW-17290-S9 | 6.6 ± 0.0 a | 6.64 ± 0.01 f | 7.53 ± 0.07 h | 6.0 ± 0.2 f | 28.88 ± 0.15 i | 4.89 ± 0.48 h | 10.05 ± 1.32 i | 8.38 ± 0.90 i | 1.21 ± 0.06 df | 2.60 ± 0.05 d |

| DW-14061-S6 | 6.7 ± 0.0 a | 3.10 ± 0.10 a | 6.60 ± 0.05 e | 7.8 ± 0.1 j | 12.60 ± 0.90 b | 16.54 ± 0.6 j | 3.49 ± 0.02 gh | 3.84 ± 0.09 ef | 4.55 ± 0.29 g | 2.31 ± 0.11 ab |

| DW-14061-S9 | 6.7 ± 0.0 a | 3.27 ± 0.05 a | 6.63 ± 0.13 e | 7.5 ± 0.0 k | 15.09 ± 0.04 e | 14.73 ± 0.40 i | 3.42 ± 036 fg | 4.72 ± 0.11 h | 5.66 ± 0.45 h | 2.48 ± 0.31 bd |

| DW-9502-S6 | 7.4 ± 0.1 c | 4.52 ± 0.10 cd | 7.00 ± 0.25 fg | 6.1 ± 0.1 fg | 33.09 ± 0.35 j | 2.45 ± 0.17 bd | 3.04 ± 0.07 ef | 12.27 ± 0.42 k | 1.13 ± 0.08 cf | 2.20 ± 0.18 a |

| DW-9502-S9 | 7.2 ± 0.0 b | 4.77 ± 0.02 d | 7.10 ± 0.10 g | 6.3 ± 0.1 gh | 29.73 ± 0.89 i | 2.61 ± 0.09 df | 2.80 ± 0.05 ce | 18.64 ± 0.67 l | 1.30 ± 0.11 f | 2.51 ± 0.09 cd |

| DW-9518-S6 | 8.4 ± 0.3 d | 5.80 ± 0.09 e | 4.60 ± 0.10 a | 4.6 ± 0.2 d | 16.28 ± 0.70 f | 2.54 ± 0.15 cf | 2.39 ± 0.24 bd | 4.27 ± 0.39 g | 0.96 ± 0.09 ac | 3.35 ± 0.07 ef |

| DW-9518-S9 | 8.0 ± 0.2 d | 6.06 ± 0.04 ef | 4.63 ± 0.28 a | 4.8 ± 0.2 d | 18.14 ± 0.67 g | 2.33 ± 0.30 ad | 2.50 ± 0.37 bd | 0.54 ± 0.16 a | 0.86 ± 0.17 ab | 3.38 ± 0.07 ef |

| CW-17290-S6 | 8.2 ± 0.1 d | 6.47 ± 0.04 f | 4.95 ± 0.05 b | 3.8 ± 0.2 a | 14.78 ± 1.40 de | 2.08 ± 0.16 a | 1.61 ± 0.09 a | 3.17 ± 0.10 b | 1.05 ± 0.09 be | 3.37 ± 0.04 ef |

| CW-17290-S9 | 7.3 ± 0.0 bc | 4.31 ± 0.02 bd | 5.13 ± 0.13 b | 4.7 ± 0.d | 14.00 ± 0.71 cd | 2.59 ± 0.15 df | 2.21 ± 0.04 b | 4.18 ± 0.09 fg | 1.22 ± 0.03 ef | 3.79 ± 0.33 gh |

| CW-14061-S6 | 8.3 ± 0.1 d | 6.27 ± 0.0 ef | 5.90 ± 0.10 d | 4.1 ± 0.1 b | 13.72 ± 0.40 cd | 2.19 ± 0.25 ab | 2.82 ± 0.14 de | 3.34 ± 0.15 bc | 0.97 ± 0.06 ac | 3.31 ± 0.02 ef |

| CW-14061-S9 | 7.4 ± 1.2 c | 6.20 ± 0.02 ef | 6.13 ± 0.03 d | 4.6 ± 0.3 d | 15.83 ± 0.57 ef | 2.24 ± 0.20 ac | 2.76 ± 0.18 ce | 3.09 ± 0.04 b | 1.12 ± 0.27 cf | 3.42 ± 0.18 ef |

| CW-9502-S6 | 9.2 ± 0.1 e | 6.28 ± 0.03 ef | 5.88 ± 0.18 d | 4.4 ± 0.1 c | 8.90 ± 1.57 a | 2.86 ± 0.18 fg | 2.18 ± 0.09 b | 3.76 ± 0.31 de | 0.79 ± 0.12 a | 3.27 ± 0.21 e |

| CW-9502-S9 | 8.1 ± 0.0 d | 6.19 ± 0.04 ef | 6.08 ± 0.13 d | 5.3 ± 0.2 e | 12.30 ± 1.81 b | 2.95 ± 0.10 g | 2.46 ± 0.07 bd | 3.30 ± 0.10 bc | 0.86 ± 0.06 ab | 3.50 ± 0.21 f |

| CW-9518-S6 | 8.0 ± 0.1 d | 6.15 ± 0.03 ef | 4.60 ± 0.10 a | 5.3 ± 0.1 e | 13.67 ± 0.98 c | 2.48 ± 0.07 be | 2.37 ± 0.11 bc | 3.71 ± 0.07 ce | 1.09 ± 0.22 cf | 3.78 ± 0.16 g |

| CW-9518-S9 | 8.3 ± 0.1 d | 3.73 ± 1.55 ab | 5.45 ± 0.45 c | 6.4 ± 0.1 h | 17.68 ± 0.58 g | 2.79 ± 0.13 eg | 2.32 ± 0.01 b | 3.38 ± 0.08 bd | 1.06 ± 0.22 be | 3.98 ± 0.15 h |

| Significance | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of cereal mixtures | ||||||||||

| DW | 7.2 a | 4.78 a | 6.35 b | 6.2 b | 22.22 b | 6.12 b | 3.95 b | 7.93 b | 2.08 b | 2.65 a |

| CW | 8.1 b | 5.70 b | 5.51 a | 4.8 a | 13.86 a | 2.52 a | 2.34 a | 3.49 a | 1.02 a | 3.55 b |

| Significance | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of yeasts | ||||||||||

| 17290 | 7.2 a | 5.38 b | 6.09 b | 5.3 a | 20.41 c | 3.09 c | 4.45 d | 6.62 c | 1.12 b | 3.04 b |

| 14061 | 7.3 a | 4.70 a | 6.31 c | 6.0 c | 14.31 a | 8.93 d | 3.12 c | 3.75 b | 3.08 c | 2.88 a |

| 9502 | 8.0 b | 5.44 b | 6.51 d | 5.5 b | 21.00 d | 2.72 b | 2.62 b | 9.49 d | 1.02 b | 2.87 a |

| 9518 | 8.2 b | 5.43 b | 4.82 a | 5.3 a | 16.44 b | 2.54 a | 2.39 a | 2.97 a | 0.99 a | 3.62 c |

| Significance | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of sugar levels | ||||||||||

| S6 | 7.9 a | 5.33 a | 5.78 a | 5.3 a | 17.12 a | 4.25 a | 2.73 a | 5.64 a | 1.44 a | 3.00 a |

| S9 | 7.4 a | 5.14 a | 6.09 b | 5.7 b | 18.96 b | 4.39 b | 3.57 b | 5.78 b | 1.66 b | 3.21 b |

| Significance | ns | ns | Y | Y | Y | Y | Y | Y | Y | Y |

| Beer Acronyms | pH | Titratable Acidity (g/L) | Volatile Acidity (g/L) | Organic Acids (mg/mL) | ||||

|---|---|---|---|---|---|---|---|---|

| Citric | Malic | Succinic | Lactic | Acetic | ||||

| Interactive effects (cereal mixtures ×yeasts × sugar levels) | ||||||||

| DW-17290-S6 | 4.17 ± 0.02 cd | 3.51 ± 0.08 i | 2.19 ± 0.02 c | 0.86 ± 0.03 fg | 0.92 ± 0.06 c | 7.15 ± 0.11 h | 0.72 ± 0.02 ce | 3.95 ± 0.09 j |

| DW-17290-S9 | 4.01 ± 0.01 b | 1.56 ± 0.02 e | 0.35 ± 0.02 a | 0.63 ± 0.08 c | 0.71 ± 0.05 b | 4.64 ± 0.20 d | 0.64 ± 0.07 b | 3.84 ± 0.09 j |

| DW-14061-S6 | 3.79 ± 0.06 a | 6.30 ± 0.04 k | 4.32 ± 0.01 d | 0.90 ± 0.07 h | 1.20 ± 0.04 e | 7.92 ± 0.08 i | 0.77 ± 0.03 fg | 1.89 ± 0.02 cd |

| DW-14061-S9 | 3.79 ± 0.03 a | 6.50 ± 0.03 l | 5.58 ± 0.06 e | 0.65 ± 0.04 c | 0.85 ± 0.02 c | 5.10 ± 0.19 e | 0.58 ± 0.03 a | 1.40 ± 0.06 a |

| DW-9502-S6 | 3.97 ± 0.06 b | 3.36 ± 0.03 h | 2.17 ± 006 c | 1.04 ± 0.12 i | 1.39 ± 0.08 f | 8.14 ± 0.07 i | 0.74 ± 0.04 df | 3.22 ± 0.16 i |

| DW-9502-S9 | 3.97 ± 0.06 b | 3.75 ± 0.03 j | 2.22 ± 0.06 c | 0.86 ± 0.07 fg | 0.88 ± 0.12 c | 3.94 ± 0.23 c | 0.84 ± 0.02 hi | 2.79 ± 0.04 h |

| DW-9518-S6 | 4.40 ± 002 h | 1.30 ± 0.0 c | 0.32 ± 0.02 a | 0.78 ± 0.06 d | 0.72 ± 0.03 b | 3.20 ± 0.20 b | 0.75 ± 0.04 df | 1.61 ± 0.08 ac |

| DW-9518-S9 | 4.39 ± 0.03 h | 1.46 ± 0.02 d | 0.38 ± 0.02 a | 0.49 ± 0.02 a | 0.64 ± 0.04 ab | 2.70 ± 0.11 a | 0.70 ± 0.02 cd | 1.54 ± 0.01 ab |

| CW-17290-S6 | 4.29 ± 0.04 fg | 1.79 ± 0.01 g | 0.22 ± 0.03 a | 0.83 ± 0.02 df | 1.06 ± 0.08 d | 5.23 ± 0.29 e | 0.69 ± 0.03 bc | 2.30 ± 0.35 ef |

| CW-17290-S9 | 4.25 ± 0.08 ef | 3.71 ± 0.02 j | 2.18 ± 0.08 c | 0.90 ± 0.03 gh | 1.10 ± 0.17 de | 5.88 ± 0.30 f | 0.68 ± 0.03 bc | 2.41 ± 0.52 eg |

| CW-14061-S6 | 4.32 ± 0.0 g | 1.50 ± 0.01 d | 1.23 ± 0.99 b | 0.85 ± 0.06 eg | 0.91 ± 0.10 c | 6.21 ± 0.33 g | 0.82 ± 0.04 gh | 2.50 ± 0.62 fh |

| CW-14061-S9 | 4.21 ± 0.02 de | 1.17 ± 0.00 b | 0.30 ± 0.01 a | 0.79 ± 0.03 de | 0.88 ± 0.10 c | 7.00 ± 0.48 h | 0.88 ± 0.02 i | 2.50 ± 0.53 fh |

| CW-9502-S6 | 4.24 ± 0.04 ef | 1.46 ± 0.03 d | 0.33 ± 0.03 a | 0.56 ± 0.03 b | 0.69 ± 0.13 ab | 4.12 ± 0.09 c | 0.99 ± 0.03 j | 2.12 ± 0.08 de |

| CW-9502-S9 | 4.22 ± 0.04 de | 1.66 ± 0.01 f | 0.29 ± 0.01 a | 0.94 ± 0.03 h | 0.92 ± 0.05 c | 5.69 ± 0.20 f | 1.28 ± 0.05 l | 2.73 ± 0.25 gh |

| CW-9518-S6 | 4.12 ± 0.01 c | 1.34 ± 0.01 c | 0.30 ± 0.01 a | 0.68 ± 0.02 c | 0.57 ± 0.14 a | 3.46 ± 0.30 b | 0.77 ± 0.05 ef | 1.80 ± 0.00 bc |

| CW-9518-S9 | 4.11 ± 0.07 c | 1.12 ± 0.0 a | 0.35 ± 0.01 a | 0.82 ± 0.03 df | 1.12 ± 0.16 de | 4.77 ± 0.17 d | 1.08 ± 0.08 h | 2.22 ± 0.02 ef |

| Significance | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of cereal mixtures | ||||||||

| DW | 4.06 a | 3.47 b | 2.19 b | 0.77 a | 0.91 a | 5.35 a | 0.72 a | 2.53 b |

| CW | 4.22 b | 1.72 a | 0.65 a | 0.80 a | 0.90 a | 5.29 a | 0.90 b | 2.32 a |

| Significance | Y | Y | Y | ns | ns | ns | Y | Y |

| Single effect of yeasts | ||||||||

| 17290 | 4.18 c | 2.64 c | 1.23 b | 0.80 b | 0.95 b | 5.72 c | 0.68 a | 3.13 d |

| 14061 | 4.03 a | 3.87 d | 2.85 c | 0.80 b | 0.96 b | 6.56 d | 0.76 b | 2.07 b |

| 9502 | 4.10 b | 2.56 b | 1.25 b | 0.85 c | 0.97 b | 5.47 b | 0.96 d | 2.71 c |

| 9518 | 4.25 d | 1.30 a | 0.33 a | 0.69 a | 0.76 a | 3.53 a | 0.82 c | 1.79 a |

| Significance | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of sugar levels | ||||||||

| S6 | 4.16 b | 2.57 a | 1.38 a | 0.81 b | 0.93 b | 5.68 b | 0.78 a | 2.42 a |

| S9 | 4.12 a | 2.62 b | 1.45 a | 0.76 a | 0.89 a | 4.96 a | 0.83 b | 2.43 a |

| Significance | Y | Y | ns | Y | Y | Y | Y | ns |

| Beer Acronyms | TPC (mg/L) | AA (mmol Trolox/L) | Phenolics (mg/L) | |||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Gallic Acid | 4-HBA | Catechin | Vanillic Acid | Caffeic Acid | Syringic Acid | Epicatechin | Chlorogenic Acid | EGC | Ferulic Acid | p-Coumaric Acid | Sinapic Acid | EG | Rutin | Resveratrol | Rosmarinic Acid | Quercetin | Kaempferol | |||

| Interactive effects (cereal mixtures × yeasts × sugar levels) | ||||||||||||||||||||

| DW-17290-S6 | 439 ± 12 e | 0.57 ± 0.01 ab | 7.3 ± 0.3 i | 1.9 ± 0.1 h | 0.5 ± 0.1 bd | 4.8 ± 0.0 g | 0.9 ± 0.0 c | 0.6 ± 0.0 e | 7.8 ± 0.0 d | 10.3 ± 0.1 g | 9.4 ± 0.5 e | 1.8 ± 0.0 b | 1.2 ± 0.0 b | 4.8 ± 0.3 d | 6.0 ± 0.2 g | 0.9 ± 0.1 a | 1.6 ± 0.0 ab | 8.5 ± 0.8 e | 1.6 ± 0.0 e | 6.5 ± 0.3 g |

| DW-17290-S9 | 449 ± 23 e | 0.88 ± 0.04 e | 7.1 ± 0.1 hi | 2.1 ± 0.0 i | 1.0 ± 0.0 f | 2.0 ± 0.1 b | 1.2 ± 0.0 e | 0.2 ± 0.c | 6.9 ± 0.0 a | 6.4 ± 0.2 d | 3.9 ± 0.2 a | 1.9 ± 0.0 c | 1.2 ± 0.0 b | 2.9 ± 0.1 a | 2.7 ± 0.2 a | 0.9 ± 0.0 a | 1.4 ± 0.0 a | 4.8 ± 0.2 a | 1.3 ± 0.0 b | 6.3 ± 0.4 g |

| DW-14061-S6 | 433 ± 12 e | 0.55 ± 0.02 a | 6.8 ± 0.0 g | 1.9 ± 0.1 h | 0.2 ± 0.1 a | 3.6 ± 0.0 d | 1.0 ± 0.0 d | 0.1 ± 0.0 b | 9.5 ± 0.1 f | 12.4 ± 0.6 h | 3.8 ± 0.3 a | 1.8 ± 0.0 b | 1.2 ± 0.0 b | 4.8 ± 0.2 d | 2.6 ± 0.1 a | 1.1 ± 0.1 ab | 1.5 ± 0.0 ab | 8.9 ± 0.1 ef | 1.4 ± 0.0 c | 5.9 ± 0.5 fg |

| DW-14061-S9 | 429 ± 8 e | 0.87 ± 0.06 de | 6.8 ± 0.0 g | 1.9 ± 0.1 h | 1.0 ± 0.1 f | 3.0 ± 0.4 c | 1.3 ± 0.0 e | 0.2 ± 0.1 c | 9.0 ± 0.3 e | 6.8 ± 0.0 de | 10.6 ± 0.8 f | 2.0 ± 0.0 c | 1.4 ± 0.0 c | 4.9 ± 0.2 d | 5.3 ± 0.0 f | 1.3 ± 0.0 b | 1.7 ± 0.0 b | 6.8 ± 0.2 c | 1.6 ± 0.1 e | 4.9 ± 0.0 e |

| DW-9502-S6 | 375 ± 50 dc | 0.98 ± 0.11 f | 6.7 ± 0.1 fg | 1.9 ± 0.0 h | 0.5 ± 0.1 bc | 3.9 ± 0.1 e | 1.0 ± 0.0 d | 0.4 ± 0.0 d | 7.0 ± 0.1 ab | 4.8 ± 0.2 a | 4.2 ± 0.1 a | 1.8 ± 0.0 b | 1.1 ± 0.0 ab | 4.2 ± 0.0 c | 4.8 ± 0.2 de | 1.2 ± 0.0 b | 1.6 ± 0.0 ab | 8.5 ± 0.8 e | 1.4 ± 0.0 c | 2.5 ± 0.0 b |

| DW-9502-S9 | 422 ± 19 de | 0.78 ± 0.04 bd | 7.0 ± 0.0 h | 1.7 ± 0.1 f | 0.5 ± 0.0 bd | 3.6 ± 0.2 d | 1.1 ± 0.0 d | 0.2 ± 0.1 c | 7.3 ± 0.2 bc | 5.9 ± 0.1 bc | 6.8 ± 0.1 c | 1.9 ± 0.0 c | 1.2 ± 0.0 b | 3.7 ± 0.2 b | 5.3 ± 0.0 f | 1.4 ± 0.0 b | 1.6 ± 0.0 ab | 9.0 ± 0.3 f | 1.3 ± 0.0 b | 2.5 ± 0.1 b |

| DW-9518-S6 | 394 ± 13 cd | 0.76 ± 0.02 bc | 6.0 ± 0.1 d | 1.5 ± 0.0 e | 0.6 ± 0.1 cd | 2.2 ± 0.1 b | 1.2 ± 0.1 e | nd a | 7.2 ± 0.1 b | 7.7 ± 0.4 f | 5.0 ± 0.1 b | 2.0 ± 0.0 c | 1.0 ± 0.0 ab | 4.8 ± 0.2 d | 4.6 ± 0.0 d | 1.3 ± 0.2 b | 1.6 ± 0.0 ab | 9.1 ± 0.1 f | 1.6 ± 0.0 e | 8.3 ± 0.0 h |

| DW-9518-S9 | 382 ± 3 bc | 0.82 ± 0.06 ce | 6.2 ± 0.1 e | 0.9 ± 0.1 b | 0.7 ± 0.0 e | 2.2 ± 0.2 b | 0.9 ± 0.0 c | 0.1 ± 0.0 b | 7.5 ± 0.3 c | 7.0 ± 0.1 e | 4.0 ± 0.0 a | 1.9 ± 0.0 c | 0.9 ± 0.0 a | 2.9 ± 0.2 a | 4.3 ± 0.1 c | 1.1 ± 0.0 ab | 1.5 ± 0.0 ab | 5.8 ± 0.2 b | 1.5 ± 0.0 d | 2.0 ± 0.1 a |

| CW-17290-S6 | 375 ± 22 ac | 0.84 ± 0.03 ce | 3.5 ± 0.0 a | 0.8 ± 0.1 a | 2.1 ± 0.1 h | 6.0 ± 0.1 h | 1.5 ± 0.0 g | 0.7 ± 0.0 ef | 10.0 ± 0.1 g | 13.9 ± 0.2 i | 10.9 ± 0.7 f | 1.9 ± 0.0 c | 1.2 ± 0.0 b | 4.5 ± 0.2 cd | 5.9 ± 0.0 g | 2.5 ± 0.1 c | 1.4 ± 0.0 a | 8.3 ± 0.6 e | 1.6 ± 0.0 e | 8.9 ± 0.2 i |

| CW-17290-S9 | 362 ± 17 ab | 0.79 ± 00.02 be | 6.2 ± 0.1 e | 1.1 ± 0.0 c | 0.7 ± 0.0 e | 0.3 ± 0.0 a | 1.0 ± 0.0 d | 0.5 ± 0.0 de | 7.2 ± 0.1 b | 14.0 ± 0.1 i | 6.6 ± 0.0 c | 1.8 ± 0.0 b | 1.0 ± 0.0 ab | 4.6 ± 0.1 cd | 5.0 ± 0.2 e | 2.8 ± 0.1 d | 1.6 ± 0.0 ab | 4.6 ± 0.0 a | 1.4 ± 0.0 c | 9.2 ± 0.2 i |

| CW-14061-S6 | 378 ± 3 bc | 0.52 ± 0.05 a | 6.3 ± 0.0 e | 1.7 ± 0.0 fg | 1.5 ± 0.0 g | 3.5 ± 0.2 d | 0.9 ± 0.0 c | 0.4 ± 0.0 d | 8.0 ± 0.1 d | 6.1 ± 0.6 cd | 7.9 ± 0.1 d | 1.8 ± 0.0 b | 1.5 ± 0.0 c | 4.6 ± 0.4 cd | 4.9 ± 0.7 e | 1.2 ± 0.0 b | 1.5 ± 0.0 ab | 6.3 ± 0.7 bc | 1.4 ± 0.0 c | 3.5 ± 0.1 c |

| CW-14061-S9 | 372 ± 15 ac | 0.69 ± 0.10 b | 6.2 ± 0.0 e | 1.5 ± 0.0 e | 0.6 ± 0.0 d | 2.3 ± 0.1 b | 1.0 ± 0.0 d | 0.3 ± 0.0 c | 7.3 ± 0.1 bc | 7.6 ± 0.0 f | 10.7 ± 0.8 f | 1.9 ± 0.0 c | 1.0 ± 0.0 ab | 3.7 ± 0.2 b | 5.0 ± 0.1 e | 1.2 ± 0.0 b | 1.5 ± 0.0 ab | 7.5 ± 0.0 d | 1.4 ± 0.0 c | 5.1 ± 0.5 e |

| CW-9502-S6 | 360 ± 10 ab | 0.78 ± 0.08 bd | 5.7 ± 0.1 bc | 1.1 ± 0.0 c | 0.8 ± 0.0 e | 4.1 ± 0.1 f | 0.7 ± 0.0 a | 0.4 ± 0.0 d | 7.0 ± 0.0 ab | 12.3 ± 0.0 h | 6.8 ± 0.3 c | 1.7 ± 0.0 a | 1.0 ± 0.0 ab | 3.9 ± 0.4 b | 3.9 ± 0.2 b | 1.4 ± 0.0 b | 1.5 ± 0.0 ab | 4.60 ± 0.0 a | 1.2 ± 0.0 a | 4.8 ± 0.1 e |

| CW-9502-S9 | 360 ± 12 ab | 0.75 ± 0.10 bc | 5.9 ± 0.0 cd | 1.8 ± 0.0 g | 0.8 ± 0.0 e | 4.2 ± 0.2 f | 0.7 ± 0.0 a | 0.8 ± 0.0 g | 7.1 ± 0.0 ab | 10.9 ± 0.1 g | 6.5 ± 0.3 c | 1.8 ± 0.0 b | 1.0 ± 0.0 ab | 3.7 ± 0.0 b | 5.3 ± 0.0 f | 0.9 ± 0.0 a | 1.5 ± 0.0 ab | 4.5 ± 0.3 a | 1.2 ± 0.0 a | 5.2 ± 0.5 e |

| CW-9518-S6 | 345 ± 6 a | 0.70 ± 0.02 b | 5.5 ± 0.1 b | 1.2 ± 0.1 d | 0.3 ± 0.0 a | 2.2 ± 0.0 b | 0.8 ± 0.0 b | 0.7 ± 0.0 f | 7.5 ± 0.1 c | 5.5 ± 0.2 b | 6.3 ± 0.1 c | 1.7 ± 0.0 a | 1.1 ± 0.1 ab | 3.9 ± 0.3 b | 3.8 ± 0.1 b | 0.9 ± 0.0 a | 1.5 ± 0.0 ab | 4.4 ± 0.1 a | 1.4 ± 0.0 c | 4.2 ± 0.30 d |

| CW-9518-S9 | 355 ± 9 ab | 0.74 ± 0.04 bc | 6.6 ± 0.1 f | 1.4 ± 0.0 e | 0.5 ± 0.0 b | 3.7 ± 0.2 d | 1.4 ± 0.0 f | 0.7 ± 0.1 fg | 9.9 ± 0.2 g | 6.2 ± 0.6 d | 9.2 ± 0.5 e | 1.7 ± 0.0 a | 1.2 ± 0.0 b | 2.8 ± 0.2 a | 3.7 ± 0.3 b | 1.0 ± 0.0 a | 1.6 ± 0.0 ab | 7.9 ± 0.0 e | 1.6 ± 0.0 e | 8.6 ± 0.0 h |

| Signif. | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of cereal mixtures | ||||||||||||||||||||

| DW | 415 b | 0.78 b | 6.7 b | 1.7 b | 0.9 b | 3.2 a | 1.1 b | 0.2 a | 7.8 a | 7.7 a | 6.0 a | 1.9 b | 1.2 b | 4.1 b | 4.5 a | 1.2 a | 1.6 b | 7.7 b | 1.5 b | 4.7 a |

| CW | 343 a | 0.70 a | 5.7 a | 1.3 a | 0.6 a | 3.3 b | 1.0 a | 0.6 b | 8.0 b | 9.6 b | 8.1 b | 1.8 a | 1.1 a | 4.0 a | 4.7 b | 1.5 b | 1.5 a | 6.0 a | 1.4 a | 6.2 b |

| Signif. | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of yeasts | ||||||||||||||||||||

| 17290 | 406 b | 0.77 b | 6.0 a | 1.5 b | 1.1 d | 3.3 c | 1.2 c | 0.5 d | 8.0 b | 11.1 c | 7.7 b | 1.8 a | 1.1 a | 4.2 c | 4.9 c | 1.8 c | 1.5 a | 6.6 a | 1.4 b | 7.7 d |

| 14061 | 403 b | 0.66 a | 6.5 c | 1.7 d | 0.8 c | 3.1 b | 1.1 b | 0.2 a | 8.5 c | 8.2 b | 8.3 c | 1.9 b | 1.3 b | 4.5 d | 4.5 b | 1.2 b | 1.6 b | 7.4 b | 1.4 b | 4.8 b |

| 9502 | 379 a | 0.81 c | 6.3 b | 1.6 c | 0.6 b | 4.0 d | 0.9 a | 0.5 cd | 7.1 a | 8.5 b | 6.1 a | 1.8 a | 1.1 a | 3.9 b | 4.8 c | 1.2 b | 1.5 a | 6.6 a | 1.3 a | 3.7 a |

| 9518 | 369 a | 0.71 b | 6.1 a | 1.3 a | 0.5 a | 2.6 a | 1.1 b | 0.4 b | 8.0 b | 6.6 a | 6.1 a | 1.8 a | 1.1 a | 3.6 a | 4.1 a | 1.1 a | 1.5 a | 6.8 a | 1.5 b | 5.8 c |

| Signif. | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of sugar levels | ||||||||||||||||||||

| S6 | 387 a | 0.7 a | 6.0 a | 1.5 a | 0.8 a | 3.8 b | 1.0 a | 0.4 a | 8.0 b | 9.1 b | 6.8 a | 1.8 a | 1.2 a | 4.4 b | 4.6 a | 1.3 a | 1.5 a | 7.3 b | 1.4 a | 5.6 a |

| S9 | 391 a | 0.8 a | 6.5 b | 1.6 a | 0.7 a | 2.7 a | 1.1 a | 0.3 a | 7.8 a | 8.1 a | 7.3 b | 1.9 a | 1.1 a | 3.7 a | 4.6 a | 1.3 a | 1.5 a | 6.4 a | 1.4 a | 5.5 a |

| Signif. | ns | ns | Y | ns | ns | Y | ns | ns | Y | Y | Y | ns | ns | Y | ns | ns | ns | Y | ns | ns |

| Beer Acronyms | Color | Foam | Turbidity | Gustatory Characteristics | Tactile Characteristics | Overall Quality | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Foam | Liquid | Amount | Persist. | Sweetn. | Bittern. | Saltiness | Acidity/Sourness | Alcohol. | Effervesc. | Body | |||

| Interactive effects (cereal mixtures × yeasts × sugar levels) | |||||||||||||

| DW-17290-S6 | 1.0 ± 0.0 a | 2.0 ± 0.6 ab | 1.8 ± 0.4 b | 1.2 ± 0.4 a | 2.0 ± 0.0 a | 2.2 ± 0.4 ab | 2.0 ± 0.0 a | 2.8 ± 0.4 b | 3.2 ± 0.4 c | 2.7 ± 0.5 ab | 2.5 ± 0.5 a | 2.3 ± 0.5 bc | 2.3 ± 1.0 abc |

| DW-17290-S9 | 1.0 ± 0.0 a | 1.7 ± 0.8 a | 2.3 ± 0.5 bc | 1.5 ± 0.5 a | 2.0 ± 0.0 a | 2.2 ± 0.4 ab | 2.3 ± 0.5 ab | 2.7 ± 0.5 b | 3.3 ± 0.5 cd | 2.7 ± 0.5 ab | 2.8 ± 0.4 ab | 2. 3 ± 0.5 ab | 3.0 ± 0.9 cd |

| DW-14061-S6 | 1.0 ± 0.0 a | 1.8 ± 0.8 ab | 1.0 ± 0.0 a | 1.0 ± 0.0 a | 2.2 ± 0.4 ab | 2.0 ± 0.0 a | 2.3 ± 0.8 ac | 2.7 ± 0.5 b | 4.0 ± 0.0 d | 2.5 ± 0.5 ab | 2.3 ± 0.5 a | 2.2 ± 0.4 ab | 1.7 ± 0.8 a |

| DW-14061-S9 | 1.0 ± 0.0 a | 1.7 ± 0.8 a | 1.0 ± 0.0 a | 1.0 ± 0.0 a | 2.2 ± 0.4 ab | 2.2 ± 0.4 ab | 2.2 ± 0.4 ab | 2.8 ± 0.8 b | 3.8 ± 0.4 cd | 2.3 ± 0.5 a | 2.3 ± 0.5 a | 2.0 ± 0.0 a | 1.8 ± 0.8 ab |

| DW-9502-S6 | 1.0 ± 0.0 a | 2.0 ± 0.0 ab | 3.0 ± 0.0 cd | 2.3 ± 0.5 b | 2.3 ± 0.5 ac | 2.0 ± 0.0 a | 2.8 ± 0.4 b | 2.3 ± 0.5 ab | 3.0 ± 0.9 cd | 2.3 ± 0.5 a | 2.7 ± 0.5 ab | 2.3 ± 0.5 ab | 2.7 ± 0.8 bc |

| DW-9502-S9 | 1.0 ± 0.0 a | 2.0 ± 0.6 ab | 3.2 ± 0.8 de | 2.7 ± 0.8 bc | 2.2 ± 0.4 ab | 2.3 ± 0.5 ab | 2.5 ± 0.5 ab | 2.5 ± 0.8 ab | 3.0 ± 0.6 c | 2.5 ± 0.5 ab | 2.8 ± 0.8 ab | 2.3 ± 0.5 ab | 3.0 ± 0.6 cd |

| DW-9518-S6 | 1.0 ± 0.0 a | 2.2 ± 0.8 ab | 4.7 ± 0.5 gh | 4.2 ± 0.8 fg | 3.7 ± 0.8 e | 2.5 ± 0.5 ab | 3.0 ± 0.9 c | 2.3 ± 0.5 ab | 2.3 ± 0.5 a | 2.8 ± 0.4 ab | 3.5 ± 0.5 c | 3.2 ± 0.8 b | 4.2 ± 0.8 e |

| DW-9518-S9 | 1.0 ± 0.0 a | 1.8 ± 0.8 ab | 4.8 ± 0.4 h | 4.3 ± 0.5 fg | 2.8 ± 1.0 bd | 2.8 ± 0.8 c | 2.5 ± 0.5 ac | 2.3 ± 0.5 ab | 2.3 ± 0.5 a | 2.7 ± 0.5 ab | 2.8 ± 0.8 ab | 2.8 ± 0.8 ab | 3.8 ± 0.8 de |

| CW-17290-S6 | 1.0 ± 0.0 a | 2.3 ± 0.5 ab | 3.8 ± 1.0 ef | 3.3 ± 0.5 de | 2.0 ± 0.0 a | 2.2 ± 0.4 ab | 2.7 ± 0.8 ac | 2.7 ± 0.5 b | 2.8 ± 0.4 b | 2.8 ± 0.4 ab | 3.7 ± 0.8 c | 3.3 ± 0.8 b | 3.8 ± 0.8 de |

| CW-17290-S9 | 1.0 ± 0.0 a | 2.3 ± 0.8 ab | 4.5 ± 0.5 fh | 4.0 ± 0.6 fg | 2.0 ± 0.0 a | 2.0 ± 0.0 a | 2.8 ± 0.4 bc | 2.3 ± 0.5 ab | 2.3 ± 0.5 a | 3.0 ± 0.6 b | 3.5 ± 0.8 c | 3.2 ± 0.8 b | 3.8 ± 0.4 de |

| CW-14061-S6 | 1.0 ± 0.0 a | 2.3 ± 0.5 ab | 4.7 ± 0.8 gh | 4.5 ± 0.8 g | 2.0 ± 0.0 a | 2.5 ± 0.5 ab | 2.5 ± 0.5 ac | 2.5 ± 0.5 ab | 2.3 ± 0.5 a | 2.8 ± 0.4 ab | 3.8 ± 0.4 c | 3.3 ± 0.5 b | 4.2 ± 0.8 e |

| CW-14061-S9 | 1.0 ± 0.0 a | 2.2 ± 0.8 ab | 4.3 ± 1.0 fh | 4.3 ± 0.5 fg | 2.0 ± 0.0 a | 2.3 ± 0.05 ab | 2.5 ± 0.5 ac | 2.5 ± 0.5 ab | 2.3 ± 0.5 a | 3.0 ± 0.6 b | 3.5 ± 0.8 ab | 3.2 ± 0.8 b | 4.2 ± 1.0 e |

| CW-9502-S6 | 1.0 ± 0.5 a | 2.0 ± 0.9 ab | 4.8 ± 0.4 h | 4.5 ± 0.5 g | 2.7 ± 1.0 ad | 2.2 ± 0.4 ab | 2.7 ± 0.5 bc | 2.4 ± 0.5 ab | 2.2 ± 0.4 a | 2.7 ± 0.5 ab | 3.3 ± 0.5 ab | 3.2 ± 0.4 b | 3.8 ± 0.8 de |

| CW-9502-S9 | 1.0 ± 0.0 a | 2.2 ± 0.8 ab | 4.8 ± 0.4 h | 4.5 ± 0.5 g | 2.8 ± 0.8 bd | 2.7 ± 0.5 b | 2.5 ± 0.5 ac | 2.3 ± 0.5 ab | 2.2 ± 0.4 a | 2.8 ± 0.4 ab | 2.8 ± 1.0 ab | 2.8 ± 1.0 ab | 3.8 ± 1.0 de |

| CW-9518-S6 | 1.0 ± 0.0 a | 2.5 ± 0.8 b | 4.2 ± 0.8 fh | 3.2 ± 0.4 cd | 3.3 ± 0.8 de | 2.5 ± 0.5 ab | 2.5 ± 0.5 ac | 2.3 ± 0.5 ab | 2.3 ± 0.5 ab | 2.8 ± 0.4 ab | 2.8 ± 0.8 ab | 2.8 ± 0.8 ab | 4.2 ± 1.0 e |

| CW-9518-S9 | 1.0 ± 0.0 a | 2.5 ± 0.5 b | 4.0 ± 0.6 fg | 3.8 ± 0.8 ef | 3.0 ± 1.1 ce | 2.7 ± 0.5 b | 2.5 ± 0.5 ac | 2.2 ± 0.4 a | 2.5 ± 0.5 ab | 2.8 ± 0.4 ab | 3.0 ± 0.9 b | 3.0 ± 0.6 ab | 4.0 ± 0.6 e |

| Significance | ns | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y | Y |

| Single effect of cereal mixtures | |||||||||||||

| DW | 1.0 a | 1.9 a | 2.7 a | 2.3 a | 2.4 a | 2.3 a | 2.5 a | 2.6 a | 3.1 b | 2.6 a | 2.7 a | 2.4 a | 2.8 a |

| CW | 1.0 a | 2.3 b | 4.4 b | 4.0 b | 2.5 a | 2.4 a | 2.6 a | 2.4 a | 2.4 a | 2.8 b | 3.3 b | 3.1 b | 4.0 b |

| Significance | ns | Y | Y | Y | ns | ns | ns | ns | Y | Y | Y | Y | Y |

| Single effect of yeasts | |||||||||||||

| 17290 | 1.0 a | 2.1 a | 3.1 b | 2.5 a | 2.0 a | 2.1 a | 2.5 ab | 2.6 b | 2.9 b | 2.8 a | 3.1 a | 2.8 a | 3.2 a |

| 14061 | 1.0 a | 2.0 a | 2.7 a | 2.7 a | 2.1 a | 2.2 a | 2.4 a | 2.6 b | 3.1 b | 2.7 a | 3.0 a | 2.7 a | 3.0 a |

| 9502 | 1.0 a | 2.1 a | 3.9 c | 3.5 b | 2.5 b | 2.3 a | 2.6 b | 2.4 ab | 2.6 a | 2.6 a | 2.9 a | 2.7 a | 3.3 a |

| 9518 | 1.0 a | 2.2 a | 4.4 d | 3.9 c | 3.2 c | 2.6 b | 2.5 ba | 2.3 a | 2.4 a | 2.8 a | 3.0 a | 3.0 b | 4.0 b |

| Significance | ns | ns | Y | Y | Y | Y | Y | Y | Y | ns | ns | Y | Y |

| Single effect of sugar levels | |||||||||||||

| S6 | 1.0 a | 2.1 a | 3.5 a | 3.0 a | 2.5 a | 2.2 a | 2.6 a | 2.5 a | 2.8 a | 2.7 a | 3.1 a | 2.8 a | 3.3 a |

| S9 | 1.0 a | 2.0 a | 3.6 b | 3.3 b | 2.4 a | 2.4 a | 2.5 a | 2.5 a | 2.7 a | 2.7 a | 2.9 a | 2.7 a | 3.4 a |

| Significance | ns | ns | Y | Y | ns | ns | ns | ns | ns | ns | ns | ns | ns |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Baiano, A.; Fiore, A.; Gatta, B.l.; Capozzi, V.; De Simone, N.; Gerardi, C.; Grieco, F. Unmalted Cereals, Oenological Yeasts, and In-Bottle Sugar Addition as Synergic Strategies to Enhance the Quality of Craft Beers. Beverages 2024, 10, 8. https://doi.org/10.3390/beverages10010008

Baiano A, Fiore A, Gatta Bl, Capozzi V, De Simone N, Gerardi C, Grieco F. Unmalted Cereals, Oenological Yeasts, and In-Bottle Sugar Addition as Synergic Strategies to Enhance the Quality of Craft Beers. Beverages. 2024; 10(1):8. https://doi.org/10.3390/beverages10010008

Chicago/Turabian StyleBaiano, Antonietta, Anna Fiore, Barbara la Gatta, Vittorio Capozzi, Nicola De Simone, Carmela Gerardi, and Francesco Grieco. 2024. "Unmalted Cereals, Oenological Yeasts, and In-Bottle Sugar Addition as Synergic Strategies to Enhance the Quality of Craft Beers" Beverages 10, no. 1: 8. https://doi.org/10.3390/beverages10010008