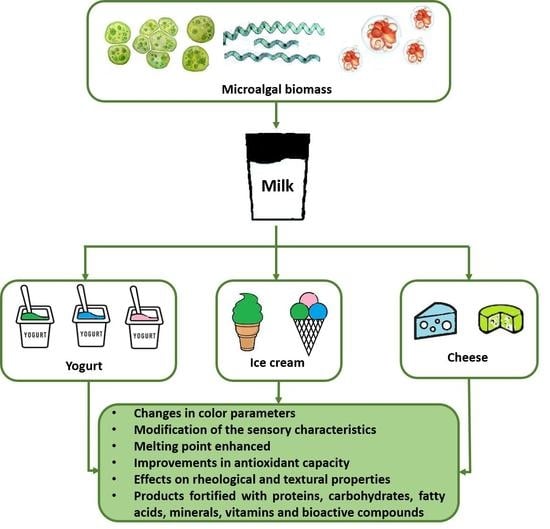

Innovative and Healthier Dairy Products through the Addition of Microalgae: A Review

Abstract

:1. Introduction

2. Applications of Microalgal Biomass and Its Derivatives in Yogurt

2.1. Changes in the Physicochemical Composition

2.2. Changes in Color Parameters

2.3. Effect on Antioxidant Properties

2.4. Changes in Growth of Starter and Probiotic Cultures

2.5. Effects on Syneresis, Texture and Viscosity

2.6. Effect on Sensory Properties

3. Applications of Microalgal Biomass and Its Derivatives in Ice Cream

3.1. Changes in the Physicochemical Composition

3.2. Changes in Color Parameters

3.3. Effect on Rheology Parameters

3.4. Effect on Sensory Properties

4. Applications of Microalgal Biomass in Cheeses

4.1. Changes in the Physicochemical Composition

4.2. Changes in Color Parameters

4.3. Effect on Textural Properties

4.4. Effect on the Antioxidant Activity

4.5. Changes in the Sensory Properties

5. Other Dairy Products

6. Regulation Issues of Microalgal Biomass or Derivates in Dairy Products

7. Final Remarks

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Mata, T.M.; Martins, A.A.; Caetano, N.S. Microalgae for biodiesel production and other applications: A review. Renew. Sustain. Energy Rev. 2010, 14, 217–232. [Google Scholar] [CrossRef] [Green Version]

- Vuppaladadiyam, A.; Prinsen, P.; Raheem, A.; Luque, R.; Zhao, M. Sustainability analysis of microalgae production systems: A review on resource with unexploited high-value reserves. Environ. Sci. Technol. 2018, 52, 14031–14049. [Google Scholar] [CrossRef] [PubMed]

- Arashiro, L.T.; Boto-Ordóñez, M.; Van Hulle, S.W.H.; Ferrer, I.; Garfí, M.; Rousseau, D.P.L. Natural pigments from microalgae grown in industrial wastewater. Bioresour Technol. 2020, 303, 122894. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pina-Pérez, M.C.; Brück, W.M.; Brück, T.; Beyrer, M. The Role of Alternative and Innovative Food Ingredients and Products in Consumer Wellness. In Microalgae as Healthy Ingredients for Functional Foods, 1st ed.; Galanakis, C., Ed.; Academic Press: London, UK, 2019; pp. 103–137. [Google Scholar]

- Adarme-Vega, T.C.; Lim, D.K.Y.; Timmins, M.; Vernen, F.; Li, Y.; Schenk, P.M. Microalgal biofactories: A promising approach towards sustainable omega-3 fatty acid production. Microb. Cell Factories 2012, 111, 1–10. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Li, Z.; Anbuchezhian, R.; Karuppiah, V. Prospect of marine algae for production of industrially important chemicals. In Algal Biorefinery an Integr Approac, 1st ed.; Debabrata, D., Ed.; Springer: New Delhi, India, 2016; pp. 95–217. [Google Scholar]

- Torres-Tiji, Y.; Fields, F.J.; Mayfield, S.P. Microalgae as a future food source. Biotechnol. Adv. 2020, 41, 107536. [Google Scholar] [CrossRef]

- Morais Junior, W.G.; Gorgich, M.; Corrêa, P.S.; Martins, A.A.; Mata, T.M.; Caetano, N.S. Microalgae for biotechnological applications: Cultivation, harvesting and biomass processing. Aquaculture 2020, 528, 7355–7362. [Google Scholar] [CrossRef]

- Becker, E.W. Micro-algae as a source of protein. Biotechnol Adv. 2007, 25, 207–210. [Google Scholar] [CrossRef]

- Chacón-Lee, T.L.; González-Mariño, G.E. Microalgae for “healthy” foods-possibilities and challenges. Compr. Rev. Food Sci. Food Saf. 2010, 9, 655–675. [Google Scholar] [CrossRef]

- Bernaerts, T.M.M.; Gheysen, L.; Foubert, I.; Hendrickx, M.E.; Van Loey, A.M. The potential of microalgae and their biopolymers as structuring ingredients in food: A review. Biotechnol. Adv. 2019, 37, 107419. [Google Scholar] [CrossRef]

- Ran, C.; Zhou, X.; Yao, C.; Zhang, Y.; Kang, W.; Liu, X. Swine digestate treatment by prior nitrogen-starved Chlorella vulgaris: The effect of over-compensation strategy on microalgal biomass production and nutrient removal. Sci. Total Environ. 2021, 768, 1444–1462. [Google Scholar] [CrossRef]

- Mehariya, S.; Goswami, R.K.; Karthikeysan, O.P.; Verma, P. Microalgae for high-value products: A way towards green nutraceutical and pharmaceutical compounds. Chemosphere 2021, 280, 130553. [Google Scholar] [CrossRef] [PubMed]

- Rodrigues-Sousa, A.E.; Nunes, I.V.O.; Muniz-Junior, A.B.; Carvalho, J.C.M.; Mejia-da-Silva, L.C.; Matsudo, M.C. Nitrogen supplementation for the production of Chlorella vulgaris biomass in secondary effluent from dairy industry. Biochem. Eng. J. 2021, 165, 107818. [Google Scholar] [CrossRef]

- Safi, C.; Cabas Rodriguez, L.; Mulder, W.J.; Engelen-Smit, N.; Spekking, W.; van den Broek, L.A.M. Energy consumption and water-soluble protein release by cell wall disruption of Nannochloropsis gaditana. Bioresour Technol. 2017, 239, 204–210. [Google Scholar] [CrossRef] [PubMed]

- Fattore, N.; Bellan, A.; Pedroletti, L.; Vitulo, N.; Morosinotto, T. Acclimation of photosynthesis and lipids biosynthesis to prolonged nitrogen and phosphorus limitation in Nannochloropsis gaditana. Algal Res. 2021, 58, 102368. [Google Scholar] [CrossRef]

- Nogueir, N.; Nascimento, F.J.A.; Cunha, C.; Cordeiro, N. Nannochloropsis gaditana grown outdoors in annular photobioreactors: Operation strategies. Algal Res. 2020, 48, 101913. [Google Scholar] [CrossRef]

- Shanthi, G.; Premalatha, M.; Anantharaman, N. Potential utilization of fish waste for the sustainable production of microalgae rich in renewable protein and phycocyanin-Arthrospira platensis/Spirulina. J. Clean Prod. 2021, 294, 126106. [Google Scholar] [CrossRef]

- Batista de Oliveira, T.T.; Miranda dos Reis, I.; Bastos de Souza, M.; da Silva Bispo, E.; Fonseca Maciel, L.; Druzian, J.I. Microencapsulation of Spirulina sp. LEB-18 and its incorporation in chocolate milk: Properties and functional potential. LWT 2021, 148, 111674. [Google Scholar] [CrossRef]

- Morais, E.G.; de Druzian, J.I.; Nunes, I.L.; Morais, M.G.; Costa, J.A.V. Glycerol increases growth, protein production and alters the fatty acids profile of Spirulina (Arthrospira) sp. LEB 18. Process Biochem. 2019, 76, 40–45. [Google Scholar] [CrossRef]

- Xing, G.L.; Yuan, H.L.; Yang, J.S.; Li, J.Y.; Gao, Q.X.; Li, W.L. Integrated analyses of transcriptome, proteome and fatty acid profilings of the oleaginous microalga Auxenochlorella protothecoides UTEX 2341 reveal differential reprogramming of fatty acid metabolism in response to low and high temperatures. Algal Res. 2018, 33, 16–27. [Google Scholar] [CrossRef]

- Polat, E.; Yüksel, E.; Altınbaş, M. Effect of different iron sources on sustainable microalgae-based biodiesel production using Auxenochlorella protothecoides. Renew Energy 2020, 162, 1970–1978. [Google Scholar] [CrossRef]

- Bohutskyi, P.; Ketter, B.; Chow, S.; Adams, K.J.; Betenbaugh, M.J.; Allnutt, F.C.T. Anaerobic digestion of lipid-extracted Auxenochlorella protothecoides biomass for methane generation and nutrient recovery. Bioresour. Technol. 2015, 183, 229–239. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Jung, J.M.; Kim, J.Y.; Jung, S.; Choi, Y.E.; Kwon, E.E. Quantitative study on lipid productivity of Euglena gracilis and its biodiesel production according to the cultivation conditions. J. Clean Prod. 2021, 291, 125218. [Google Scholar] [CrossRef]

- Zhu, J.; Tan, X.; Hafid, H.S.; Wakisaka, M. Enhancement of biomass yield and lipid accumulation of freshwater microalga Euglena gracilis by phenolic compounds from basic structures of lignin. Bioresour. Technol. 2021, 321, 124441. [Google Scholar] [CrossRef] [PubMed]

- Kottuparambil, S.; Thankamony, R.L.; Agusti, S. Euglena as a potential natural source of value-added metabolites. A review. Algal Res. 2019, 37, 154–159. [Google Scholar] [CrossRef]

- Kumudha, A.; Sarada, R. Characterization of vitamin B12 in Dunaliella salina. J. Food Sci. Technol. 2016, 53, 888. [Google Scholar] [CrossRef] [Green Version]

- Mixson Byrd, S.; Burkholder, J.A.M. Environmental stressors and lipid production in Dunaliella spp. II. Nutrients, pH, and light under optimal or low salinity. J. Exp. Mar. Biol. Ecol. 2017, 487, 33–44. [Google Scholar] [CrossRef] [Green Version]

- Pereira, H.; Silva, J.; Santos, T.; Gangadhar, K.N.; Raposo, A.; Nunes, C. Nutritional potential and toxicological evaluation of Tetraselmis sp. CtP4 microalgal biomass produced in industrial photobioreactors. Molecules 2019, 24, 3192. [Google Scholar] [CrossRef] [Green Version]

- Schulze, P.S.C.; Pereira, H.G.C.; Santos, T.F.C.; Schueler, L.; Guerra, R.; Barreira, L.A. Effect of light quality supplied by light emitting diodes (LEDs) on growth and biochemical profiles of Nannochloropsis oculata and Tetraselmis chuii. Algal Res. 2016, 16, 387–398. [Google Scholar] [CrossRef]

- Qazi, W.M.; Balance, S.; Uhlen, A.K.; Kousoulaki, K.; Haugen, J.E.; Rieder, A. Protein enrichment of wheat bread with the marine green microalgae Tetraselmis chuii–Impact on dough rheology and bread quality. LWT 2021, 143, 111115. [Google Scholar] [CrossRef]

- Gill, I.; Valivety, R. Polyunsaturated fatty acids, part 1: Occurrence, biological activities and applications. Trends Biotechnol. 1997, 15, 401–409. [Google Scholar] [CrossRef]

- Raja, R.; Coelho, A.; Hemaiswarya, S.; Kumar, P.; Carvalho, I.S.; Alagarsamy, A. Applications of microalgal paste and powder as food and feed: An update using text mining tool. Beni-Suef Univ. J. Basic Appl. Sci. 2018, 7, 740–747. [Google Scholar] [CrossRef]

- López Rocha, C.J.; Álvarez-Castillo, E.; Estrada Yáñez, M.R.; Bengoechea, C.; Guerrero, A.; Orta Ledesma, M.T. Development of bioplastics from a microalgae consortium from wastewater. J. Environ. Manag. 2020, 263, 110353. [Google Scholar] [CrossRef] [PubMed]

- Khoo, K.S.; Chew, K.W.; Yew, G.Y.; Leong, W.H.; Chai, Y.H.; Show, P.L. Recent advances in downstream processing of microalgae lipid recovery for biofuel production. Bioresour. Technol. 2020, 304, 122996. [Google Scholar] [CrossRef] [PubMed]

- Ndimba, B.K.; Ndimba, R.J.; Johnson, T.S.; Waditee-Sirisattha, R.; Baba, M.; Sirisattha, S. Biofuels as a sustainable energy source: An update of the applications of proteomics in bioenergy crops and algae. J. Proteom. 2013, 93, 234–244. [Google Scholar] [CrossRef]

- Khemiri, S.; Khelifi, N.; Nunes, M.C.; Ferreira, A.; Gouveia, L.; Smaali, I. Microalgae biomass as an additional ingredient of gluten-free bread: Dough rheology, texture quality and nutritional properties. Algal Res. 2020, 50, 101998. [Google Scholar] [CrossRef]

- Matos, J.; Cardoso, C.; Bandarra, N.M.; Afonso, C. Microalgae as healthy ingredients for functional food: A review. Food Funct. 2017, 8, 2672–2685. [Google Scholar] [CrossRef]

- Tunick, M.H.; Van Hekken, D.L. Dairy products and health: Recent insights. J. Agric. Food Chem. 2015, 63, 9381–9388. [Google Scholar] [CrossRef]

- Thomas, J.; Beeren, C. Consumer perception of additives in dairy products. In Reference Module in Food Science, 2nd ed.; Fuquay, J., Ed.; Academic Press: San Diego, CA, USA, 2011; pp. 41–48. [Google Scholar]

- Cosentino, C.; Colonna, M.A.; Musto, M.; Dimotta, A.; Freschi, P.; Tarricone, S.; Ragni, M.; Paolino, R. Effects of dietary supplementation with extruded linseed and oregano in autochthonous goat breeds on the fatty acid profile of milk and quality of Padraccio cheese. J. Dairy Sci. 2021, 104, 1445–1453. [Google Scholar] [CrossRef]

- Moore, L.L.; Bradlee, M.L.; Gao, D.; Singer, M.R. Effects of average childhood dairy intake on adolescent bone health. J. Pediatr. 2008, 153, 667–673. [Google Scholar] [CrossRef] [Green Version]

- Iuliano, S.; Hill, T.R. Dairy foods and bone accrual during growth and development. In Milk and Dairy Foods, 1st ed.; Givens, D., Ed.; Academic Press: San Diego, CA, USA, 2011; pp. 299–322. [Google Scholar]

- Lana, A.; Banegas, J.R.; Guallar-Castillón, P.; Rodríguez-Artalejo, F.; Lopez-Garcia, E. Association of dairy consumption and 24-hour blood pressure in older adults with hypertension. Am. J. Med. 2018, 131, 1238–1249. [Google Scholar] [CrossRef]

- Kouvari, M.; Panagiotakos, D.B.; Chrysohoou, C.; Georgousopoulou, E.N.; Yannakoulia, M.; Tousoulis, D. Dairy products, surrogate markers, and cardiovascular disease; a sex-specific analysis from the ATTICA prospective study. Nutr. Metab. Cardiovasc. Dis. 2020, 30, 2194–2206. [Google Scholar] [CrossRef]

- Kris-Etherton, P.M.; Grieger, J.A.; Hilpert, K.F.; West, S.G. Milk products, dietary patterns and blood pressure management. J. Am. Coll. Nutr. 2009, 28, 103S–119S. [Google Scholar] [CrossRef] [PubMed]

- Rosa, M.C.; Carmo, M.R.S.; Balthazar, C.F.; Guimarães, J.T.; Esmerino, E.A.; Freitas, M.Q. Dairy products with prebiotics: An overview of the health benefits, technological and sensory properties. Int. Dairy J. 2021, 117, 105009. [Google Scholar] [CrossRef]

- Scott, K.P.; Grimaldi, R.; Cunningham, M.; Sarbini, S.R.; Wijeyesekera, A.; Tang, M.L.K. Developments in understanding and applying prebiotics in research and practice—an ISAPP conference paper. J. Appl. Microbiol. 2020, 127, 934–949. [Google Scholar] [CrossRef] [PubMed]

- Virgilio, N.; De Donno, R.; Bandini, E.; Napolitano, A.; Fogliano, V.; Vitaglione, P. Milk protein enriched beverage reduces post-exercise energy intakes in women with higher levels of cognitive dietary restraint. Food Res. Int. 2019, 118, 58–64. [Google Scholar] [CrossRef] [PubMed]

- Atallah, A.; Morsy, O.; Dalia, G. Characterization of functional low-fat yogurt enriched with whey protein concentrate, Ca-caseinate and Spirulina. Int. J. Food Prop. 2020, 23, 78–91. [Google Scholar] [CrossRef]

- Silva, S.C.; Fernandes, I.P.; Barros, L.; Fernandes, Â.; Alves, J.M.; Calhelha, R.C. Spray-dried Spirulina platensis as an effective ingredient to improve yogurt formulations: Testing different encapsulating solutions. J. Funct. Foods. 2019, 60, 103427. [Google Scholar] [CrossRef] [Green Version]

- Beheshtipour, H.; Mortazavian, A.M.; Haratian, P.; Khosravi-Darani, K. Effects of Chlorella vulgaris and Arthrospira platensis addition on viability of probiotic bacteria in yogurt and its biochemical properties. Eur. Food Res. Technol. 2012, 235, 719–728. [Google Scholar] [CrossRef]

- Matos, J.; Afonso, C.; Cardoso, C.; Serralheiro, M.L.; Bandarra, N.M. Yogurt enriched with Isochrysis galbana: An innovative functional food. Foods 2021, 10, 1458. [Google Scholar] [CrossRef]

- Robertson, R.C.; Gracia Mateo, M.R.; O’Grady, M.N.; Guihéneuf, F.; Stengel, D.B.; Ross, R.P. An assessment of the techno-functional and sensory properties of yoghurt fortified with a lipid extract from the microalga Pavlova lutheri. Innov. Food Sci. Emerg. Technol. 2016, 37, 237–246. [Google Scholar] [CrossRef]

- Mohammadi-Gouraji, E.; Soleimanian-Zad, S.; Ghiaci, M. Phycocyanin-enriched yogurt and its antibacterial and physicochemical properties during 21 days of storage. LWT 2019, 102, 230–236. [Google Scholar] [CrossRef]

- Barkallah, M.; Dammak, M.; Louati, I.; Hentati, F.; Hadrich, B.; Mechichi, T. Effect of Spirulina platensis fortification on physicochemical, textural, antioxidant and sensory properties of yogurt during fermentation and storage. LWT 2017, 84, 323–330. [Google Scholar] [CrossRef]

- Alizadeh Khaledabad, M.; Ghasempour, Z.; Kia, E.M.; Bari, M.R.; Zarrin, R. Probiotic yoghurt functionalised with microalgae and Zedo gum: Chemical, microbiological, rheological and sensory characteristics. Int. J. Dairy Technol. 2020, 73, 67–75. [Google Scholar] [CrossRef]

- Bchir, B.; Felfoul, I.; Bouaziz, M.A.; Gharred, T.; Yaich, H.; Noumi, E. Investigation of physicochemical, nutritional, textural, and sensory properties of yoghurt fortified with fresh and dried Spirulina (Arthrospira platensis). Int. Food Res. J. 2019, 26, 65–76. [Google Scholar]

- Kissoudi, M.; Sarakatsianos, I.; Samanidou, V. Isolation and purification of food-grade C-phycocyanin from Arthrospira platensis and its determination in confectionery by HPLC with diode array detection. J. Sep. Sci. 2018, 41, 975–981. [Google Scholar] [CrossRef]

- Moreira, I.; Passos, T.S.; Chiapinni, C.; Silveira, G.K.; Souza, J.C.M.; Coca-Vellarde, L.G. Colour evaluation of a phycobiliprotein-rich extract obtained from Nostoc PCC9205 in acidic solutions and yogurt. J. Sci. Food Agric. 2012, 92, 598–605. [Google Scholar] [CrossRef]

- Azarikia, F.; Wu, B.; Abbasi, S.; McClements, D.J. Stabilization of biopolymer microgels formed by electrostatic complexation: Influence of enzyme (laccase) cross-linking on pH, thermal, and mechanical stability. Food Res. Int. 2015, 78, 18–26. [Google Scholar] [CrossRef]

- Gauthier, M.R.; Senhorinho, G.N.A.; Scott, J.A. Microalgae under environmental stress as a source of antioxidants. Algal Res. 2020, 52, 102104. [Google Scholar] [CrossRef]

- Khan, I.T.; Nadeem, M.; Imran, M.; Ullah, R.; Ajmal, M.; Jaspal, M.H. Antioxidant properties of milk and dairy products: A comprehensive review of the current knowledge. Lipids Health Dis. 2019, 18, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Mendiola, J.A.; Jaime, L.; Santoyo, S.; Reglero, G.; Cifuentes, A.; Ibañez, E. Screening of functional compounds in supercritical fluid extracts from Spirulina platensis. Food Chem. 2007, 102, 1357–1367. [Google Scholar] [CrossRef]

- Parada, J.; Zulpa de Caire, G.; Zaccaro, M. Lactic acid bacteria growth promoters from Spirulina platensis. Int. J. Food Microbiol. 1998, 45, 225–228. [Google Scholar] [CrossRef]

- Mortazavian, A.M.; Ghorbanipour, S.; Mohammadifar, M.A.; Mohammadi, M. Biochemical properties and viable probiotic population of yogurt at different bacterial inoculation rates and incubation temperatures. Philipp. Agric. Sci. 2011, 94, 155–160. [Google Scholar]

- Mortazavian, A.M.; Khosrokhavar, R.; Rastegar, H.; Mortazaei, G.R. Effects of dry matter standardization order on biochemical and microbiological characteristics of freshly made probiotic doogh (Iranian fermented milk drink). Ital. J. Food Sci. 2010, 22, 98–104. [Google Scholar]

- Silva, F.; Junior, N.; Gomes, R.; Dos Santos Pozza, M.; Britten, M.; Matumoto-Pintro, P. Physical, microbiological and rheological properties of probiotic yogurt supplemented with grape extract. J. Food Sci. Technol. 2017, 54, 1608–1615. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Dimitrellou, D.; Kandylis, P.; Kourkoutas, Y. Assessment of freeze-dried immobilized Lactobacillus casei as probiotic adjunct culture in yogurts. Foods 2019, 8, 374. [Google Scholar] [CrossRef] [Green Version]

- Hanou, S.; Boukhemis, M.; Benatallah, L.; Djeghri, B.; Zidoune, M.N. Effect of ginger powder addition on fermentation kinetics, rheological properties and bacterial viability of dromedary yogurt. Adv. J. Food Sci. Technol. 2016, 10, 667–673. [Google Scholar] [CrossRef]

- Malik, P.; Kempanna, C.; Paul, A. Quality characteristics of ice cream enriched with Spirulina powder. Int. J. Food Nutr. Sci. 2012, 2, 44–50. [Google Scholar]

- Estrada, J.D.; Boeneke, C.; Bechtel, P.; Sathivel, S. Developing a strawberry yogurt fortified with marine fish oil. J. Dairy Sci. 2011, 94, 5760–5769. [Google Scholar] [CrossRef] [Green Version]

- Tamjidi, F.; Nasirpour, A.; Shahedi, M. Physicochemical and sensory properties of yogurt enriched with microencapsulated fish oil. Food Sci. Technol. Int. 2012, 18, 381–390. [Google Scholar] [CrossRef]

- Guarda, A.; Rosell, C.M.; Benedito, C.; Galotto, M.J. Different hydrocolloids as bread improvers and antistaling agents. Food Hydrocoll. 2004, 18, 241–247. [Google Scholar] [CrossRef]

- Guzmán-González, M.; Morais, F.; Ramos, M.; Amigo, L. Influence of skimmed milk concentrate replacement by dry dairy products in a low fat set-type yoghurt model system. I: Use of whey protein concentrates, milk protein concentrates and skimmed milk powder. J. Sci. Food Agric. 1999, 79, 1117–1122. [Google Scholar] [CrossRef]

- Durmaz, Y.; Kilicli, M.; Toker, O.S.; Konar, N.; Palabiyik, I.; Tamtürk, F. Using spray-dried microalgae in ice cream formulation as a natural colorant: Effect on physicochemical and functional properties. Algal Res. 2020, 47, 101811. [Google Scholar] [CrossRef]

- Balensiefer, C.; Tiepo, V.; Gottardo, F.M.; Bertol, C.D.; Reinehr, C.O.; Colla, L.M. Addition of Spirulina platensis in handmade ice cream: Phisicochemical and sensory effects. Braz. J. Dev. 2021, 7, 88106–88123. [Google Scholar]

- Agustini, T.W.; Ma’ruf, W.F.; Widayat, A.; Suzery, M.; Hadiyanto, L.; Benjakul, S. Application of Spirulina platensis on ice cream and soft cheese with respect to their nutritional and sensory perspectives. J. Teknol. 2016, 78, 245–251. [Google Scholar] [CrossRef] [Green Version]

- Campos Assumpção de Amarante, M.; Cavalcante Braga, A.R.; Sala, L.; Juliano, B.; Kalil, S. Colour stability and antioxidant activity of C-phycocyanin-added ice creams after in vitro digestion. Food Res. Int. 2020, 137, 109602. [Google Scholar] [CrossRef]

- Rodrigues, E.F.; Vendruscolo, L.P.; Bonfante, K.; Reinehr, C.O.; Colla, E.; Colla, L.M. Phycocyanin as substitute for texture ingredients in ice creams. Br. Food J. 2020, 122, 693–707. [Google Scholar] [CrossRef]

- Muse, M.R.; Hartel, R.W. Ice cream structural elements that affect melting rate and hardness. J. Dairy Sci. 2004, 87, 1–10. [Google Scholar] [CrossRef]

- Marshall, R.T.; Arbuckle, W. Ice Cream, 5th ed.; Chapman & Hill: New York, NY, USA, 1996; pp. 37–38. [Google Scholar]

- Robinson, R. Encyclopedia of Food Microbiology, 2nd ed.; Academic Press: New York, NY, USA, 2014; p. 3248. [Google Scholar]

- Fradique, M.; Batista, A.P.; Nunes, M.C.; Gouveia, L.; Bandarra, N.M.; Raymundo, A. Isochrysis galbana and Diacronema vlkianum biomass incorporation in pasta products as PUFA’s source. LWT-Food Sci. Technol. 2013, 50, 312–319. [Google Scholar] [CrossRef] [Green Version]

- Bernaerts, T.M.M.; Gheysen, L.; Kyomugasho, C.; Jamsazzadeh, Z.; Vandionant, S.; Foubert, I. Comparison of microalgal biomasses as functional food ingredients: Focus on the composition of cell wall related polysaccharides. Algal Res. 2018, 1, 150–161. [Google Scholar] [CrossRef]

- Safi, C.; Charton, M.; Pignolet, O.; Pontalier, P.; Safi, C.; Charton, M. Evaluation of the protein quality of Porphyridium cruentum. J. Appl. Psychol. 2013, 25, 497–501. [Google Scholar] [CrossRef] [Green Version]

- Silva, L.A.; Kuhn, K.R.; Moraes, C.C.; Burkert, C.A.; Kalil, S.J. Experimental design as a tool for optimization of C-phycocyanin purification by precipitation from Spirulina platensis. J. Braz. Chem. Soc. 2009, 20, 5–12. [Google Scholar] [CrossRef] [Green Version]

- Sert, D.; Mercan, E. High-pressure homogenisation of sheep milk ice cream mix: Physicochemical and microbiological characterisation. LWT 2021, 1, 112148. [Google Scholar] [CrossRef]

- Kurt, A.; Atalar, I. Effects of quince seed on the rheological, structural and sensory characteristics of ice cream. Food Hydrocoll. 2018, 1, 186–195. [Google Scholar] [CrossRef]

- Cosentino, C.; Faraone, D.; Paolino, R.; Freschi, P.; Musto, D. Short communication: Sensory profile and acceptability of a cow milk cheese manufactured by adding jenny milk. J. Dairy Sci. 2016, 99, 228–233. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, A.G.; Abo-El-Khair, B.E.; Shalaby, S.M. Quality of novel healthy processed cheese analogue enhanced with marine microalgae Chlorella vulgaris biomass. World Appl. Sci. J. 2013, 23, 914–925. [Google Scholar]

- Tohamy, M.M.; Ali, M.A.; Shaaban, H.A.G.; Mohamad, A.G.; Hasanain, A.M. Production of functional spreadable processed cheese using Chlorella vulgaris. Acta Sci. Pol. Technol. Aliment. 2018, 17, 347–358. [Google Scholar]

- Bosnea, L.; Terpou, A.; Pappa, E.; Kondyli, E.; Mataragas, M.; Markou, G. Incorporation of Spirulina platensis on traditional greek soft cheese with respect to its nutritional and sensory perspectives. Proceedings 2020, 70, 99. [Google Scholar] [CrossRef]

- Mohamed, A.G.; Abd El-Salam, B.A.E.Y.; Gafour, W.A.E.M. Quality characteristics of processed cheese fortified with Spirulina powder. Pak. J. Biol. Sci. 2020, 23, 533–541. [Google Scholar] [CrossRef] [Green Version]

- Golmakani, M.T.; Soleimanian-Zad, S.; Alavi, N.; Nazari, E.; Eskandari, M.H. Effect of Spirulina (Arthrospira platensis) powder on probiotic bacteriologically acidified feta-type cheese. J. Appl. Phycol. 2019, 31, 1085–1094. [Google Scholar] [CrossRef]

- Mohamed, A.; Darwish, I. Physicochemical properties, bioactive compounds and antioxidant activity of Kareish cheese fortified with Spirulina platensis. World J. Dairy Food Sci. 2017, 12, 71–78. [Google Scholar]

- Muir, D.D.; Tamime, A.Y.; Shenana, M.E.; Dawood, A.H. Processed cheese analogues incorporating fat-substitutes: Composition, microbiological quality and flavour changes during storage at 5 °C. LWT-Food Sci. Technol. 1999, 32, 41–49. [Google Scholar] [CrossRef]

- Cunha, C.R.; Dias, A.I.; Viotto, W.H. Microstructure, texture, colour and sensory evaluation of a spreadable processed cheese analogue made with vegetable fat. Food Res. Int. 2010, 43, 723–729. [Google Scholar] [CrossRef]

- Savello, P.A.; Ernstrom, C.A.; Kalab, M. Microstructure and meltability of model process cheese made with rennet and acid casein. J. Dairy Sci. 1989, 72, 1–11. [Google Scholar] [CrossRef]

- Awad, R.A.; Abdel-Hamid, L.B.; El-Shabrawy, S.A.; Singh, R.K. Physical and sensory properties of block processed cheese with formulated emulsifying salt mixtures. Int. J. Food Prop. 2004, 7, 429–448. [Google Scholar] [CrossRef]

- Ghaeni, M.; Roomiani, L. Review for Application and medicine effects of Spirulina, Spirulina platensis microalgae. J. Adv. Agric. Technol. 2016, 3, 114–117. [Google Scholar] [CrossRef]

- Guimarães, J.T.; Balthazar, C.F.; Silva, R.; Rocha, R.S.; Graça, J.S.; Esmerino, E.A. Impact of probiotics and prebiotics on food texture. Curr. Opin. Food Sci. 2020, 33, 38–44. [Google Scholar] [CrossRef]

- Yang, X.; Li, A.; Li, X.; Sun, L.; Guo, Y. An overview of classifications, properties of food polysaccharides and their links to applications in improving food textures. Trends Food Sci. Technol. 2020, 102, 1–15. [Google Scholar] [CrossRef]

- Raymundo, A.; Gouveia, L.; Batista, A.P.; Empis, J.; Sousa, I. Fat mimetic capacity of Chlorella vulgaris biomass in oil-in-water food emulsions stabilized by pea protein. Food Res. Int. 2005, 38, 961–965. [Google Scholar] [CrossRef] [Green Version]

- Blas-Valdivia, V.; Ortiz-Butrón, R.; Pineda-Reynoso, M.; Hernández-Garcia, A.; Cano-Europa, E. Chlorella vulgaris administration prevents HgCl2-caused oxidative stress and cellular damage in the kidney. J. Appl. Phycol. 2011, 23, 53–58. [Google Scholar] [CrossRef]

- Fox, P.F.; Guinee, T.P.; Cogan, T.M.; McSweeney, P.L.H. Biochemistry of cheese ripening. In Fundamentals of Cheese Science, 2nd ed.; Fox, P.F., Guinee, T.P., Cogan, T.M., McSweeney, P.L.H., Eds.; Springer: Boston, MA, USA, 2017; pp. 391–442. [Google Scholar]

- Bao, J.; Zhang, X.; Zheng, J.H.; Ren, D.F.; Lu, J. Mixed fermentation of Spirulina platensis with Lactobacillus plantarum and Bacillus subtilis by random-centroid optimization. Food Chem. 2018, 264, 64–72. [Google Scholar] [CrossRef]

- Vlasenko, I.; Bandura, V.; Semko, T.; Fialkovska, L.; Ivanishcheva, O.; Palamarchuk, V. Innovative approaches to the development of a new sour milk product. Slovak J. Food Sci. 2021, 15, 970–981. [Google Scholar] [CrossRef]

- Manuelian, C.; Currò, S.; Penasa, M.; Cassandro, M.; De Marchi, M. Characterization of major and trace minerals, fatty acid composition, and cholesterol content of protected designation of origin cheeses. J. Dairy Sci. 2017, 100, 384–395. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Martelli, F.; Alinovi, M.; Bernini, V.; Gatti, M.; Bancalari, E. Arthrospira platensis as natural fermentation booster for milk and soy fermented beverage. Foods 2020, 9, 350. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Varga, L.; Szigeti, J.; Kovács, R.; Földes, T.; Buti, S. Influence of a Spirulina platensis biomass on the microflora of fermented ABT milks during storage (R1). J. Dairy Sci. 2002, 85, 1031–1038. [Google Scholar] [CrossRef]

- Mohamed, H.; Sayed, E.; Mohamed, Z.; Gaber, A. Applicability of using edible algae (Spirulina platensis) to prepare high protein quality Labenah. J. Biol. Sci. 2019, 19, 143–147. [Google Scholar] [CrossRef] [Green Version]

- Laela, N.; Mohamad, A.; Fulyani, F. The effect of kefir-spirulina on glycemic status and antioxidant activity in hyperglycemia rats. Slovak J. Food Sci. 2021, 15, 101–110. [Google Scholar] [CrossRef]

- European Food Safety Authority (EFSA). Regulation (EC) No 258/97 of the European Parliament and of the Council of 27 January 1997 concerning novel foods and novel food ingredients. Off. J. Eur. Union 1997, 43, 1–6. [Google Scholar]

- European Food Safety Authority (EFSA). Commission Implementing Regulation (EU) 2017/2470 of 20 December 2017 establishing the Union list of novel foods in accordance with Regulation (EU) 2015/2283 of the European Parliament and of the Council on novel foods. Off. J. Eur. Union 2017, 60, 72–201. [Google Scholar]

- United States Food and Drug Administration (FDA). GRAS Notices. 2022. Available online: https://www.cfsanappsexternal.fda.gov/scripts/fdcc/?set=GRASNotices (accessed on 22 February 2022).

- Food Safety and Standards Authority of India (FSSAI). Food Safety and Standards (Health Supplements, Nutraceuticals, Food for Special Dietary Use, Food for Special Medical Purpose, Functional Food, and Novel Food) Regulations. 2016. Available online: https://fssai.gov.in/upload/uploadfiles/files/Nutraceuticals_Regulations.pdf (accessed on 23 February 2022).

- Australia New Zealand Food Authority (ANZFA). Application 428: DHA-Rich Marine Micro-Algae (Schizochytrium sp.) and DHA-Rich Oil Derived from Schizochytrium sp. as Novel Food Ingredients. 2002. Available online: https://www.foodstandards.gov.au/code/applications/documents/A428_FAR.pdf (accessed on 24 February 2022).

- United States Food and Drug Administration (FDA). CFR-Code of Federal Regulations Title 21: 101 Food Labelling. 2016. Available online: https://www.accessdata.fda.gov/scripts/cdrh/cfdocs/cfcfr/cfrsearch.cfm (accessed on 24 February 2022).

- Sheyma, K.; Ines, B.; Nadia, B.; Mondher, M.; Issam, S.; Nadia, K. Effects of growth medium variation on the nutri-functional properties of microalgae used for the enrichment of ricotta. Food Technol. Biotechnol. 2021, in press. [Google Scholar]

- European Food Safety Authority (EFSA). Regulation (EC) No 1924/2006 of the European Parliament and of the Council of 20 December 2006 on nutrition and health claims made on foods. Off. J. Eur. Union 2006, 49, 9–25. [Google Scholar]

| Physicochemical Composition | Species | ||||||

|---|---|---|---|---|---|---|---|

| Chlorella vulgaris1 | Nannochloropsis gaditana2 | Arthrospira platensis3 | Auxenochlorella protothecoides4 | Euglena gracilis5 | Dunaliella bardawil6 | Tetraselmis chuii7 | |

| Protein (% dry matter) | 12–44 | 18–50 | 50–70 | 6–43 | 41–47 | 29–31 | 11–46 |

| Lipid (% dry matter) | 22–46 | 10–17 | 8–9.3 | 7–59 | 13–23 | 10–19 | 0.3–23 |

| Carbohydrate (% dry matter) | 24–39 | 15–31 | 13–48 | 15–35 | 34–43 | 11–12 | 30–54 |

| Pigments | |||||||

| Lutein (mg/kg) | 0.2–5 | n.r | n.r | n.r | n.r | 4.2–6.7 | 624 |

| Chlorophyll (mg/L) | 6–18 | 0.3–2.3 | 5–14 | 0.1–4 | 1–5.3 | 7.9–9.1 | 353–400 |

| Phycocyanin (mg/mL) | n.r | n.r | 0.5–2.3 | n.r | n.r | n.r | n.r |

| Beta-carotene (mg/g) | n.r | 0.1–2.9 | n.r | 0.1–1.1 | 0.1–52 | 0.8–1.5 | 0.1–1 |

| Vitamins (mg/kg) | |||||||

| B2 | 20–34 | 25–62 | 34–81 | n.r | n.r | n.r | 5.3 |

| B3 | 0.2–0.3 | 51–70 | 0.1–55 | n.r | n.r | n.r | 80 |

| B9 | 0.7–1 | 17–26 | 2.6–7.9 | n.r | n.r | n.r | 200 |

| B12 | 0.3–2.4 | 0.9–1.7 | 1.6 –3.2 | n.r | n.r | 0.42 | 78–195 |

| E | n.r | n.r | n.r | n.r | 0.2–1.6 | 1.5–2 | 0.2 |

| C | n.r | n.r | n.r | n.r | 0.9–1.3 | 1.8–2.2 | 0.8 |

| Fatty acids (% total fatty acids) | |||||||

| C16:0 (palmitic) | 20–30 | 13–41 | 43–57 | 11–25 | 14–16 | 15–17 | 19–36 |

| C18:3 n-3 (alpha-linolenic) | 22–24 | 0.9–3 | 1.3–23 | 2.4–30 | 0.1–0.3 | 22–31 | 22–28 |

| C18:3 (linolenic) | 26–28 | 0.3–7.4 | 14–19 | 22–35 | n.r | 3.2–3.7 | n.r |

| C16:2 (hexadecadienoic) | 12–23 | 0.1–2 | 2.2–6 | 0.4–3.5 | 1–2.5 | 12–14 | 1.8–5 |

| C18:1 (oleic) | 29–33 | 1.6–7.3 | 1–19 | 7.6–50 | 3.7–6.4 | 5.3–8.9 | 12.5–20 |

| Microalgae or Derivate | Addition Rate | Physicochemical, Sensory, Rheology, Textural or Functional Characteristics | References |

|---|---|---|---|

| Chlorella vulgaris | 0.25, 0.50 and 1% (w/v) BFP | Final acidity (°D) and final redox potential (mv) were higher than the controls, pH and acetic acid (%) values were not different compared to the controls. Oral texture and feel in the mouth, appearance and nonoral texture were lower than the control. | Beheshtipour et al. [52] |

| Isochrysis galbana | 2% (w/w) AFP | Protein and ash percentages were higher than the controls, lipid content (%) was not different compared to the control. Levels of ω3-fatty acids were higher than the control. | Matos et al. [53] |

| Pavlova lutheri | 0.25 and 0.5% (w/v) AFP | Moisture, carbohydrate, protein and fat contents were not different compared to the control. pH values during storage (28 days) were similar to the control. Addition rate in the treatments was negatively correlated with color, liking of flavor, liking of texture and overall acceptability. | Robertson et al. [54] |

| Phycocyanin from Arthrospira platensis | 2, 4 and 8% (w/w) BFP | Treatments showed pH values higher than the control during 21 days of storage. Supplemented yogurts showed a lower viscosity compared to the control during 21 days of storage. Treatment with 4% of phycocyanin was the most accepted by the panelists. | Mohammadi et al. [55] |

| Arthrospira platensis | 0.25, 0.50, 0.75 and 1% (w/v) BFP | Total solids, protein, ash and fat contents were higher than the control. There was a reduction in pH values of the treatments compared to the control. Fortified samples exhibited lower firmness compared to the control. Yogurts containing 2% of A. platensis had the highest score for acceptability. | Barkallah et al. [56] |

| Arthrospira platensis | 1.% (w/w) AFP | Moisture, fat, protein, lactose, and ash levels were higher compared to the control. pH values in fortified samples were greater than the control as well. | Da Silva et al. [51] |

| Arthrospira platensis | 0.13, 0.25, 0.38 and 0.5% (w/v) BFP | Acidity levels in fortified yogurt were greater than the control during 16 days of storage. Overall acceptability decreased with higher amounts of A. platensis. The antioxidant capacity was reduced during storage. | Alizadeh et al. [57] |

| Arthrospira platensis | 1% (w/w) BFP | Ash, total solid, fat, and protein contents had an increase compared to the control. There were no significative changes in the acidity and pH values. Total phenolic content and total antioxidant activity were increased in treatments with A. platensis. Apparent viscosity values of fortified samples were greater than the control. | Atallah et al. [50] |

| Spirulina platensis | 0.1, 0.3 and 0.5% (w/v) BFP | Solid content, protein, fat, ash, carbohydrate and acidity levels in supplemented yogurts were higher than the control. There was a reduction in the pH values compared to the control. There was an increase in hardness and viscosity values of fortified samples compared to the control. | Bchir et al. [58] |

| Microalgae or Derivate | Addition Rate | Physicochemical, Sensory, Rheological, Textural or Functional Characteristics | References |

|---|---|---|---|

| Nannochloropsis oculata | 0.1, 0.2 and 0.3% (w/w) | Fortified samples were greenish in color. There were no changes in the melting behavior of fortified samples. Consistency index (K) values of the samples were close to the control. | Durmaz et al. [76] |

| Arthrospira platensis | 0.075, 0.15, 0.23 and 0.3% (w/w) | Acidity in supplemented ice cream was increased compared to the control. pH values of fortified samples were lower than the control sample. Higher amounts of microalgae resulted in a decrease of the viscosity. Overrun in supplemented samples was enhanced compared to control. | Malik et al. [71] |

| Arthrospira platensis | Pure and microencapsulated with maltodextrin or Arabic gum | Protein, fat and total solid were increased in ice cream with microencapsulated or pure Spirulina compared to control. Overall acceptability was higher in ice cream without microencapsulated or pure Spirulina. Melting time in samples with pure microalgae was lower than samples with microencapsulated Spirulina. | Balensiefer et al. [77] |

| Arthrospira platensis | 0.6 and 1.2% | Total solid, protein and fat content were increased in enriched ice cream compared to control. Ice cream overrun and melting point were higher in fortified samples. Sensory analysis showed that the panelists preferred ice cream without microalgae. | Agustini et al. [78] |

| Diacronema vlkianum | 0.1, 0.2 and 0.3% (w/w) | Supplemented ice cream was greenish in color. The panelists found a bitter taste in enriched samples. Ice cream with microalgae showed lower K values than the control. | Durmaz et al. [76] |

| Phycocyanin from Arthrospira platensis | 0.025% | Fortified ice cream was bluish in color (negative values of b*) whereas control samples were yellowish in color (positive values of b*). Antioxidant capacity of supplemented samples was improved after digestion compared to control. | Campos et al. [79] |

| Porphyridium cruentum | 0.1, 0.2 and 0.3% (w/w) | Protein, fat and total solid were increased in ice cream with microencapsulated or pure Spirulina compared to control. Phenolic compounds increased with greater amounts of microalgae. A higher quantity of microalgae adversely affected the ice cream general sensory parameters. | Durmaz et al. [76] |

| Phycocyanin from Arthrospira platensis | 0.013% | There was no difference in the fat content of supplemented samples compared to control. Melting time in samples with phycocyanin was lower compared to control. Overall acceptability was higher in non-fortified samples. | Rodrigues et al. [80] |

| Microalgae | Addition Rate | Physicochemical, Sensory, Rheology, Textural or Functional Characteristics | References |

|---|---|---|---|

| Chlorella vulgaris | 1, 2 and 3% (w/w) | There were significant differences between the control and cheese analogue enhanced by 3% C. vulgaris biomass in all the chemical components (moisture, fat, carbohydrate and salt content). The microalgae protein and carbohydrates promoted the increase of firmness and the decrease of oil separation indexes of the cheeses. | Mohamed et al. [91] |

| Chlorella vulgaris | 2, 4 and 6% (w/w) | The pH of the cheeses increased with the percentage of microalgae added. The addition of microalgae to the processed cheese increased the degree of meltability compared with the control sample before and after storage. | Tohamy et al. [92] |

| Arthrospira platensis | 0.5, 1 and 1.5% (w/w) | The increase in the amount of microalgae led to a reduction in moisture and an increase in protein and fat content in soft cheese. Cheeses fortified with Spirulina showed higher values of β-carotene than then control. | Agustini et al. [78] |

| Arthrospira platensis | 0.25, 0.5 and 1% (w/w) | There was an increase in the protein and fat content in supplemented samples compared to control. Cheeses with 0.25% and 0.5% incorporated Spirulina were mostly preferred by the panelists. | Bosnea et al. [93] |

| Arthrospira maxima | 1, 2 and 3% (w/w). | pH of fortified samples decreased slightly compared to the control. Fat, protein and solid total content were increased in samples with 3% of microalgae. Antioxidant capacity was enhanced in supplemented samples at storage compared to the control. Overall acceptability had high scores for all treatments and control. | Mohamed et al. [94] |

| Arthrospira platensis | 0.5, 1 and 1.5% (w/w) | Protein and ash content of enriched cheeses were not affected by microalgae addition. The L* values of Spirulina-fortified samples decreased by increasing microalgae concentration. Spirulina-fortified samples showed significantly lower degrees of hardness than the control, both at the beginning and end of storage. | Golmakani et al. [95] |

| Arthrospira platensis | 0.5, 1 and 1.5% (w/w) | Fat and protein content of the supplemented cheeses was improved by microalgae addition compared to the control. The addition of microalgae to the cheese increased the phenolic compound and flavonoid content and also the antioxidant capacity. | Mohamed [96] |

| Food Authority | Microalgae or Derivate | Food Category | Maximum Levels or Maximum Daily Intake | Additional Specific Labelling Requirements | References |

|---|---|---|---|---|---|

| EFSA (EU) | Arthrospira platensis | Milk and dairy products | Unlimited a | - | EC 258/97 [114] |

| Chlorella luteoviridis | Milk and dairy products | Unlimited a | - | EC 258/97 [114] | |

| Chlorella pyrenoidosa | Milk and dairy products | Unlimited a | - | EC 258/97 [114] | |

| Chlorella vulgaris | Milk and dairy products | Unlimited a | - | EC 258/97 [114] | |

| Euglena gracilis | Yogurt and yogurt beverages | 0.15 g/100 g | Labelling must content the term “dried biomass of Euglena gracilis algae”. | EC 2017/2470 [115] | |

| Schizochytrium sp. oil rich in DHA and EPA | Dairy products except milk-based beverages | 0.6 g/100 g for cheese; 0.2 g/100 g for milk products (including milk, fromage frais and yogurt products) | Labelling must content the term “oil from the microalgae Schizochytrium sp.” | EC 2017/2470 [115] | |

| Ulkenia sp. Algal oil rich in DHA | Milk-based beverages | 0.06 g/100 mL of DHA | Labelling must content the term “oil from the micro-algae Ulkenia sp.” | EC 2017/2470 [115] | |

| FDA (USA) | Dunaliella bardawil | Low-fat cheese, spreadable cheese and cottage cheese | 0.01 g/100 g | - | GNR 276 [116] |

| Arthrospira platensis | Milk and dairy products | 3 g per serving b | - | GNR 417 [116] | |

| Euglena gracilis | Milk and dairy products | 0.208 g/100 g for prebiotic and yogurt beverages; 0.222 g/100 g for yogurt | - | GNR 697 [116] | |

| Chlorella protothecoides | Milk and dairy products | 1 g/100 g for milk; 1.35 g/100 g for yogurt, cheese and ice cream | - | GNR 519 [116] | |

| Chlorella vulgaris | Milk | 1.5 g/100 g | - | GNR 396 [116] | |

| Prototheca moriformis structuring fat | Milk and dairy products | 20 g/100 g for butter; 2 g/100 g for milk products | - | GNR 673 [116] | |

| FSSAI (India) | Chlorella vulgaris | Milk and dairy products | 4 g per day | - | FSSAI [117] |

| Arthrospira platensis | Milk and dairy products | 3 g per day | - | FSSAI [117] | |

| Phycocyanin from Arthrospira platensis dried powder | Milk and dairy products | 50 mg per day | - | FSSAI [117] | |

| Astaxanthin powder from Haematococcus pluvalis | Milk and dairy products | 4 mg per day | - | FSSAI [117] | |

| ANZFA (Australia and New Zealand) | Schizochytrium sp. | Milk products | 0.075 g/100 g | - | A428 [118] |

| Schizochytrium sp. oil rich in DHA | Milk products | 260 mg of DHA per day in Australia; 280 mg of DHA per day in New Zealand | - | A428 [118] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hernández, H.; Nunes, M.C.; Prista, C.; Raymundo, A. Innovative and Healthier Dairy Products through the Addition of Microalgae: A Review. Foods 2022, 11, 755. https://doi.org/10.3390/foods11050755

Hernández H, Nunes MC, Prista C, Raymundo A. Innovative and Healthier Dairy Products through the Addition of Microalgae: A Review. Foods. 2022; 11(5):755. https://doi.org/10.3390/foods11050755

Chicago/Turabian StyleHernández, Héctor, Maria Cristiana Nunes, Catarina Prista, and Anabela Raymundo. 2022. "Innovative and Healthier Dairy Products through the Addition of Microalgae: A Review" Foods 11, no. 5: 755. https://doi.org/10.3390/foods11050755