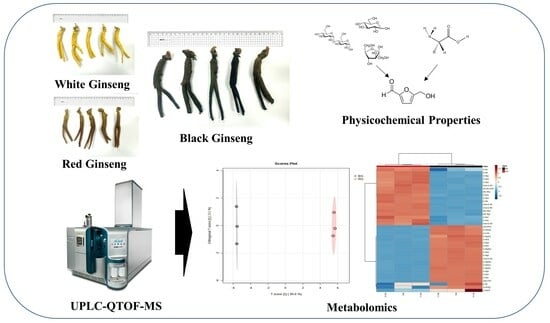

Structural Identification of Ginsenoside Based on UPLC-QTOF-MS of Black Ginseng (Panax Ginseng C.A. Mayer)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials and Equipment

2.2. Steam Processing and Appearance Observation

2.3. Sample Preparation

2.3.1. Benzo[a]pyrene

2.3.2. Free Sugar

2.3.3. Free Amino Acid

2.3.4. Ginsenoside Metabolite

2.4. Analysis of BAP by HPLC-FLD

2.5. Analysis of Free Sugar by HPLC-RID

2.6. Analysis of free Amino Acids by UPLC-MS/MS

2.7. Analysis of Ginsenoside Metabolite by UPLC-QTOF-MS

2.8. Statistical Analysis

3. Results

3.1. Appearance Change Characteristics of BG

3.2. Analysis of BG Ginsenoside Metabolites

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nam, K.-Y. The comparative understanding between red ginseng and white ginseng processed ginsengs (panax ginseng C.A. Meyer). J. Ginseng Res. 2005, 29, 1. [Google Scholar]

- Jo, E.-J.; Kang, S.-J.; Kim, A.-J. Effects of Steam-And Dry-Processing Temperatures on the Benzo(a)pyrene Content of Black and Red Ginseng. Korean J. Food Nutr. 2009, 22, 199–204. [Google Scholar]

- Ko, S.-R.; Choi, K.-J.; Han, K.-W. Comparison of proximate composition, mineral nutrient, amino acid and free sugar contents of several panax species. Korean J. Ginseng Sci. 1996, 20, 36–41. [Google Scholar]

- Hong, H.D.; Kim, Y.C.; Rho, J.H.; Kim, K.T.; Lee, Y.C. Changes on physiological properties of Panax ginseng C. A. Meyer during repeated steaming process. J. Ginseng Res. 2007, 31, 221–229. [Google Scholar]

- Nam, K.Y.; Lee, N.R.; Moon, B.D.; Song, G.Y.; Shin, H.S.; Choi, J.E. Changes of Ginsenoside and Color from Black Ginseng Prepared by Steaming-Drying Cycles. Korean J. Med. Sci. 2012, 20, 27–35. [Google Scholar] [CrossRef]

- Chang, J.-K.; Park, C.-K.; Shim, K.-H. Chang in chemical components of red ginseng processed from the fresh ginseng stored at low temperature. Korean J. Food Preserv. 2003, 10, 158–161. [Google Scholar]

- Jin, Y.; Kim, Y.J.; Jeon, J.N.; Wang, C.; Min, J.W.; Jung, S.Y.; Yang, D.C. Changes of ginsenosides and physiochemical properties in ginseng by new 9 repetitive steaming and drying process. Korean J. Plant Res. 2012, 25, 473–481. [Google Scholar]

- Kim, E.J.; Jung, I.H.; Van Le, T.K.; Jeong, J.J.; Kim, N.J.; Kim, D.H. Ginsenosides Rg5 and Rh3 protect scopolamine-induced memory deficits in mice. J. Ethnopharmacol. 2013, 146, 294–299. [Google Scholar] [CrossRef]

- Francis, G.; Kerem, Z.; Makkar, H.P.; Becker, K. The biological action of saponins in animal systems: A review. Br. J. Nutr. 2002, 88, 587–605. [Google Scholar] [CrossRef]

- Lee, H.; Park, D.; Yoon, M. Korean red ginseng (Panax ginseng) prevents obesity by inhibiting angiogenesis in high fat diet-induced obese C57BL/6J mice. Food Chem. Toxicol. 2013, 53, 402–408. [Google Scholar]

- Kim, H.J.; Lee, J.Y.; You, B.R.; Kim, H.R.; Choi, J.E.; Nam, K.Y.; Moon, B.D.; Kim, M.R. Antioxidant activities of ethanol extracts from black ginseng prepared by steamingdrying cycles. J. Korean Soc. Food Sci. Nutr. 2011, 40, 156–162. [Google Scholar] [CrossRef]

- Metwaly, A.M.; Lianlian, Z.; Luqi, H.; Deqiang, D. Black Ginseng and Its Saponins: Preparation, Phytochemistry and Pharmacological Effects. Molecules 2019, 24, 1856. [Google Scholar] [CrossRef]

- Nam, K.-Y.; Kim, Y.-S.; Shon, M.-Y.; Park, J.-D. Recent advances in studies on chemical constituents and biological activities korean black ginseng (panax ginseng C.A. Meyer). Korean J. Pharmacogn. 2015, 46, 173–188. [Google Scholar]

- FOOD CODE, Chapter 8 General Test Methods, 9. Analysis Method for Hazardous Substances in Food, 9.5 Benzo[a]pyrene, Ministry of Food and Drug Safety, Korean. 2023. Available online: https://various.foodsafetykorea.go.kr/fsd/#/ (accessed on 1 January 2023).

- Oh, H.B.; Lee, J.W.; Lee, D.E.; Na, S.C.; Jeong, D.E.; Hwang, D.I.; Kim, Y.S.; Park, C.B. Characteristics of Black Ginseng (Panax ginseng C.A. Mayer) Production Using Ginseng Stored at Low Temperature after Harvest. Metabolite 2021, 11, 98. [Google Scholar] [CrossRef]

- Herbert, A.S. Handbook of Biochemistry, 2nd ed.; Chemical Rudder Co.: Cleveland, OH, USA, 1980; p. 21. [Google Scholar]

- Park, H.W.; In, G.; Kim, J.H.; Cho, B.G.; Han, G.H.; Chnag, I.M. Metabolomic approach for discrimination of processed ginseng genus (Panax ginseng and Panax quinquefolius) using UPLC-QTOF MS. J. Ginseng Res. 2014, 38, 59–65. [Google Scholar] [CrossRef]

- Maillard, L.C. Formation of melanoidins in a methodical way. Compt. Rend. 1912, 154, 66. [Google Scholar]

- Kim, H.J.; Jo, J.S.; Nam, S.H.; Park, S.H.; Mheen, K.C. Free sugar distribution in ginseng plant and change of it’s content in the root with dehydration. Korean J. Ginseng Sci. 1983, 7, 44–50. [Google Scholar]

- Jee, H.K.; Cho, Y.J.; Kim, C.T.; Jang, Y.S.; Kim, C.J. Increase of Solubility of Ginseng Radix by Extrusion Cooking. Korean J. Food Sci. Technol. 2006, 38, 361–368. [Google Scholar]

- Shin, J.Y.; Choi, E.H.; Wee, J.J. New methods for separation of crude ginseng saponins. Korean J. Food Sci. Technol. 2001, 33, 166–172. [Google Scholar]

- Do, J.-H.; Kim, S.-D.; Oh, H.-I.; Hong, S.-K. Effect of Sugars, Amino acids and Inorganic Nitrogenous Compounds on the Acceleration of Browning in Ginseng. J. Korean Agric. Chem. Soc. 1982, 25, 161–165. [Google Scholar]

- Sung, Y.J.; Park, C.J.; Kim, B.R.; Shin, S.J. Conversion of Fructose to 5-HMF (5-hydroxymethylfurfural) in DMSO (dimethylsulfoxide) solvent. J. Korea TAPPI 2013, 45, 21–26. [Google Scholar]

- Nakagawa, K.; Maeda, H.; Yamaya, Y.; Tonosaki, Y. Maillard Reaction Intermediates and Related Phytochemicals in Black Garlic Determined by EPR and HPLC Analysis. Molecules 2020, 25, 4578. [Google Scholar] [CrossRef] [PubMed]

- Worley, B.; Powers, R. PCA as a practical indicator of OPLS-DA model reliability. Curr. Metabolomics 2016, 4, 97–103. [Google Scholar] [PubMed]

- Banerjee, P.; Ghosh, S.; Dutta, M.; Subramani, E.; Khalpada, J.; RoyChoudhury, S.; Chakravarty, B.; Chaudhury, K. Identification of Key Contributory Factors Responsible For Vascular Dysfunction in Idiopathic Recurrent Spontaneous Miscarriage. PLoS ONE 2013, 8, e80940. [Google Scholar] [CrossRef]

- Oh, H.-L.; Kim, C.-R.; Kim, N.-Y.; Jeon, H.-L.; Doh, E.-S.; Kim, M.-R. Characteristics and antioxidant activities of rehmanniae radix powder. J. Korean Soc. Food Sci. Nutr. 2013, 42, 62–67. [Google Scholar] [CrossRef]

- Shahidi, F.; Wanasundara, P.K. Phenolic antioxidants. Crit. Rev. Food Sci. Nutr. 1992, 32, 67–103. [Google Scholar] [CrossRef]

- Lim, J.H.; Wen, T.C.; Matsuda, S.; Tanaka, J.; Maeda, N.; Peng, H.; Aburaya, J.; Ishihara, K.; Sakanaka, M. Protection of is chemic hippocampal neurons by ginsenoside Rb1, a main ingredient of ginseng root. Neurosci. Res. 1997, 28, 191–200. [Google Scholar] [CrossRef]

- Han, B.-H.; Park, M.-H.; Han, Y.-N.; Suh, D.-Y. Chemical and biochemical studies on non-saponin constituents of korean ginseng. Korean J. Ginseng Sci. 1992, 16, 228–234. [Google Scholar]

- Kim, H.-J.; Jo, J.-S. Studies on the physicochemical properties of korean ginseng (panax ginseng, C.M. Meyer) root starch. Korean J. Ginseng Sci. 1984, 8, 2. [Google Scholar]

- Yoon, D.H.; Shin, W.C.; Lee, Y.-S.; Kim, S.M.; Baek, M.-I.; Lee, D.Y. A Comparative Study on Processed Panax ginseng Products using HR-MAS NMR-Based Metabolomics. Molecules 2020, 25, 1390. [Google Scholar] [CrossRef]

- Jang, J.K.; Shim, K.H. Physicochemical Properties of Freeze Dried Ginseng from the Fresh Ginseng at Low Temperature. Korean J. Ginseng Sci. 1994, 18, 60–65. [Google Scholar]

- Kim, M.H.; Hong, H.D.; Kim, Y.C.; Rhee, Y.K.; Kim, K.T.; Rho, J.H. Ginsenoside Changes in Red Ginseng Manufactured by Acid Impregnation Treatment. J. Ginseng Res. 2010, 34, 93–97. [Google Scholar]

| Free Sugar | Steaming Times | ||

|---|---|---|---|

| 2022 MWG | 2022 MRG | 2022 MBG | |

| Rhamnose | N.D | N.D | 87.42 ± 6.96 |

| Xylose | N.D | N.D | 20.38 ± 2.78 **** |

| Fructose | 2.71 ± 0.25 | 2.81 ± 0.24 | 32.31 ± 2.65 **** |

| Glucose | 3.06 ± 0.27 | 3.18 ± 0.34 | 19.16 ± 0.86 **** |

| Sucrose | 147.05 ± 1.65 | 74.32 ± 1.89 **** | 10.28 ± 0.56 **** |

| Maltose | 82.43 ± 4.01 | 76.75 ± 7.45 | 10.74 ± 1.02 **** |

| Free Amino Acid | 2022-MWG | 2022-MRG | 2022-MBG |

|---|---|---|---|

| L-alanine | 4.68 ± 0.19 | 5.19 ± 0.26 | 4.92 ± 0.26 |

| L-Arginine | 15.49 ± 0.37 | 16.71 ± 0.68 * | 5.24 ± 0.12 **** |

| L-Aspartic acid | 7.96 ± 0.51 | 7.81 ± 0.41 | 6.63 ± 0.30 * |

| L-Cystine | 0.95 ± 0.04 | 0.94 ± 0.05 | 0.63 ± 0.02 *** |

| L-Glutamic acid | 7.10 ± 0.05 | 4.68 ± 0.10 **** | 4.76 ± 0.09 **** |

| Glycine | 3.06 ± 0.15 | 3.05 ± 0.05 | 3.10 ± 0.25 |

| L-Histidine | 3.07 ± 0.04 | 3.05 ± 0.05 | 1.91 ± 0.02 **** |

| L-Isoleucine | 4.84 ± 0.07 | 5.03 ± 0.13 | 4.78 ± 0.09 |

| L-Leucine | 2.33 ± 0.09 | 2.35 ± 0.11 | 2.23 ± 0.01 |

| L-Lysine | 4.23 ± 0.09 | 3.15 ± 0.08 **** | 0.97 ± 0.01 **** |

| L-Methionine | 0.68 ± 0.04 | 0.84 ± 0.06 * | 0.86 ± 0.05 ** |

| L-Phenylalanine | 3.67 ± 0.04 | 3.82 ± 0.07 * | 3.63 ± 0.03 |

| L-Proline | 2.97 ± 0.05 | 2.68 ± 0.03 *** | 2.57 ± 0.05 *** |

| L-Serine | 3.26 ± 0.13 | 3.35 ± 0.06 | 3.07 ± 0.06 |

| L-Threonine | 4.23 ± 0.09 | 4.25 ± 0.16 | 3.91 ± 0.08 * |

| L-Tyrosine | 2.88 ± 0.09 | 2.99 ± 0.03 | 2.38 ± 0.09 *** |

| L-Valine | 2.87 ± 0.04 | 2.83 ± 0.04 | 2.75 ± 0.04 * |

| Peak No. | tR (min) | Identified Compounds | Molecular Formula | Theoretical Exact Mass (Da) | Precursor Ion/or Adduct Ions | Mean Measured Mass (Da) | Mass Error (ppm) |

|---|---|---|---|---|---|---|---|

| 1 | 9.65 | Ginsenoside Re4 | C47H80O18 | 933.5417 | 933.5417[M+H+], 955.5236[M+Na+] | 955.52463 | 1 |

| 2 | 9.68 | Notoginsenoside R3 isomer | C48H82O19 | 962.5450 | 963.5523[M+H+], 985.5342[M+Na+] | 985.53504 | 0.8 |

| 3 | 9.97 | 20-O-glucoginsenoside Rf | C48H82O19 | 962.5450 | 985.5342[M+Na+] | 985.5308 | −3.5 |

| 4 | 10.52 | Notoginsenoside R1 | C48H80O18 | 932.5339 | 955.5236[M+Na+] | 955.5202 | −3.7 |

| 5 | 11.699 | Ginsenoside Rg1 | C42H72O14 | 800.4922 | 823.4814[M+Na+] | 823.47802 | −4.1 |

| 6 | 11.792 | Ginsenoside Re | C48H82O18 | 946.5501 | 947.5573[M+H+], 969.5393[M+Na+] | 969.53561 | −3.8 |

| 7 | 13.26 | Malonyl-ginsenoside Rg1 | C45H74O17 | 886.4926 | 887.4998[M+H+], 909.4818[M+Na+] | 909.48202 | 0.2 |

| 8 | 14.292 | Malonyl-ginsenoside Re | C51H84O21 | 1032.5500 | 1033.5577[M+H+], 1055.5397[M+Na+] | 1055.54048 | 0.7 |

| 9 | 14.62 | Vinaginsenoside R8 | C48H82O19 | 962.5445 | 963.55231[M+H+], 985.53425[M+Na+] | 985.5356 | 1.4 |

| 10 | 16.85 | Vinaginsenoside R4 | C48H82O19 | 962.5445 | 963.55231[M+H+], 985.53425[M+Na+] | 985.53597 | 1.7 |

| 11 | 17.6 | Vinaginsenoside R1 | C44H74O15 | 842.5022 | 843.51005[M+H+], 865.49199[M+Na+] | 865.49287 | 1 |

| 12 | 18.349 | Pseudoginsenoside F11 | C42H72O14 | 800.4922 | 801.4994[M+H+], 823.4814[M+Na+] | 823.47777 | −4.4 |

| 13 | 18.384 | Ginsenoside Rf | C42H72O14 | 800.4922 | 801.4994[M+H+], 823.4775[M+Na+] | 823.47753 | −4.7 |

| 14 | 18.484 | Pseudoginsenoside RT5 | C36H62O10 | 654.4338 | 655.4415[M+H+], 677.4235[M+Na+] | 677.42414 | 0.9 |

| 15 | 19.628 | Notoginsenoside R2 | C41H70O13 | 770.4816 | 771.48892[M+H], 793.47086[M+Na] | 793.4676 | −4.1 |

| 16 | 20.23 | Notoginsenoside R4(s) | C59H100O27 | 1240.6452 | 1241.6524[M+H+], 1263.6344[M+Na+] | 1263.62963 | −3.8 |

| 17 | 20.9 | Ginsenoside Rg2(s) | C42H72O13 | 770.4816 | 785.5045[M+H+], 807.4865[M+Na+] | 807.48683 | 1.7 |

| 18 | 20.93 | Ginsenoside Rh1(s) | C36H62O9 | 784.4973 | 785.5045[M+H+], 807.4865[M+Na+] | 807.48683 | 0.4 |

| 19 | 20.965 | Ginsenoside Rg2(r) | C42H72O13 | 638.4394 | 661.4286[M+Na+] | 661.42859 | 0 |

| 20 | 21.34 | Ginsenoside Rh1(r) | C36H62O9 | 784.4973 | 785.5045[M+H+], 807.4865[M+Na+] | 807.4868 | 0.4 |

| 21 | 21.67 | Ginsenoside F3 | C41H70O13 | 770.4816 | 771.4889[M+H+] | 771.48649 | −3.1 |

| 22 | 21.83 | Ginsenoside F1 | C36H62O9 | 638.4394 | 639.4466[M+H+], 661.4286[M+Na+] | 661.4286 | 1.9 |

| 23 | 21.87 | Ginsenoside Ra2 | C58H98O26 | 638.4394 | 1211.6419[M+H+], 1233.6238[M+Na+] | 1233.62517 | 1.8 |

| 24 | 21.98 | Ginsenoside Ra3 | C59H100O27 | 1210.6346 | 1241.6524[M+H+], 1263.6344[M+Na]+ | 1263.63442 | 1.1 |

| 25 | 22.24 | Ginsenoside F5 | C41H70O13 | 1240.6452 | 771.48892[M+H], 793.47086[M+Na] | 793.47221 | 1.7 |

| 26 | 22.32 | Notoginsenoside R4(r) | C59H100O27 | 1240.6452 | 1241.6524[M+H+], 1263.6344[M+Na+] | 1263.63638 | 1.6 |

| 27 | 22.396 | Ginsenoside Rb1 | C54H92O23 | 1108.6029 | 1109.6102[M+H+], 1131.5921[M+Na+] | 1131.5928 | 0.6 |

| 28 | 22.95 | Malonyl Ginsenoside Ra3 | C62H102O30 | 1326.6450 | 1327.6528[M+H+], 1349.6348[M+Na+] | 1349.63545 | 0.5 |

| 29 | 23.13 | Malonyl Ginsenoside Rb1 | C57H94O26 | 1194.6033 | 1195.6106[M+H+], 1217.5925[M+Na+] | 1217.59302 | 0.4 |

| 30 | 23.2 | Ginsenoside Ro | C48H76O19 | 1078.5924 | 1079.5996[M+H+], 1101.5816[M+Na+] | 1101.5813 | −0.3 |

| 31 | 23.3 | Ginsenoside Rc | C53H90O22 | 956.4981 | 957.5053[M+H+], 975.5397[M+H++NH4+], 979.4873[M+Na+] | 979.48822 | 0.9 |

| 32 | 23.468 | Ginsenoside Ra1 | C58H98O26 | 1210.6346 | 1211.6419[M+H+], 1233.6238[M+Na+] | 1233.62397 | 0.1 |

| 33 | 23.985 | Malonyl Ginsenoside Ra2/ra1 | C61H100O29 | 1296.6345 | 1297.6423[M+H+], 1319.6242[M+Na+] | 1319.62522 | 0.7 |

| 34 | 24.122 | Malonyl Ginsenoside Rc | C56H92O25 | 1164.5928 | 1165.6000[M+H+], 1188.5898[M+H+Na+] | 1188.58585 | −3.3 |

| 35 | 24.345 | Ginsenoside Rb2 | C53H90O22 | 1078.5924 | 1079.5996[M+H+], 1101.5816[M+Na+] | 1101.58222 | 0.6 |

| 36 | 24.515 | Malonyl ginsenoside Rb1 isomer | C57H94O26 | 1194.6028 | 1195.6106[M+H+], 1217.5925[M+Na+] | 1217.59381 | 1 |

| 37 | 24.75 | Pseudo ginsenoside RT1 | C47H74O18 | 926.4870 | 927.49479[M+H+], 944.52134[M+NH4+] | 944.52255 | 1.3 |

| 38 | 24.752 | Ginsenoside Rb3 | C53H90O22 | 1078.5924 | 1079.5996[M+H+], 1101.5816[M+Na+] | 1101.58357 | 1.8 |

| 39 | 24.968 | Malonyl Ginsenoside Rb3 | C56H92O25 | 1164.5922 | 1165.6000[M+H+], 1187.5819[M+Na+] | 1187.582 | 0 |

| 40 | 25.072 | Malonyl Ginsenoside Rb2 | C56H92O25 | 1164.5928 | 1165.6000[M+H+], 1187.5819[M+Na+] | 1187.58208 | 0.1 |

| 41 | 25.433 | Malonyl Ginsenoside Rb3 isomer | C56H92O25 | 1164.5922 | 1165.6000[M+H+], 1187.5819[M+Na+] | 1187.582 | 0 |

| 42 | 26.372 | Ginsenoside Rd | C48H82O18 | 946.5501 | 947.5573[M+H+], 969.5393[M+Na+] | 969.54125 | 2 |

| 43 | 26.616 | Ginsenoside Rs1 | C55H92O23 | 1120.6024 | 1121.6102[M+H+], 1143.5921[M+Na+] | 1143.59365 | 1.3 |

| 44 | 27.07 | Malonyl Ginsenoside Rd isomer | C51H84O21 | 1032.5505 | 1033.5577[M+H+], 1055.5397[M+Na+] | 1055.5406 | 0.8 |

| 45 | 27.47 | Malonyl Ginsenoside Rd | C51H84O21 | 1032.5500 | 1033.5577[M+H+], 1055.5397[M+Na+] | 1055.53985 | 0.1 |

| 46 | 27.607 | Ginsenoside Rs2 | C55H92O23 | 1120.6024 | 1121.6102[M+H+] | 1121.60602 | −3.7 |

| 47 | 28.359 | Gypenoside XVII | C48H82O18 | 946.5501 | 969.5393[M+Na+] | 969.5398 | 0.5 |

| 48 | 29.48 | Ginsenoside Ra7 | C57H94O23 | 1146.6180 | 1147.6258[M+H+] | 1169.60771 | −0.1 |

| 49 | 29.712 | Notoginsenoside Fe | C47H80O17 | 916.5390 | 917.5468[M+H+], 939.5287[M+Na+] | 939.51939 | −10 |

| 50 | 30.486 | Ginsenoside Rg6 | C42H70O12 | 766.4867 | 767.4940[M+H+], 789.4759[M+Na+] | 789.47806 | 2.7 |

| 51 | 30.498 | Ginsenoside Ra8 | C57H94O23 | 1146.6180 | 1147.6258[M+H+], 1169.6078[M+Na+] | 1169.60795 | 0.1 |

| 52 | 30.695 | Vinaginsenoside R16 | C47H80O17 | 916.5390 | 917.5468[M+H+], 939.5287[M+Na+] | 939.5298 | 1.1 |

| 53 | 31.17 | Ginsenoside Rd2 | C47H80O17 | 916.5390 | 917.54683[M+H+], 939.52877[M+Na] | 939.53091 | 2.3 |

| 54 | 31.18 | Ginsenoside Rg4 | C42H70O12 | 766.4867 | 767.4940[M+H+], 789.4759[M+Na+] | 789.47808 | 2.7 |

| 55 | 31.23 | Gypenoside L | C42H72O14 | 800.4922 | 801.4994[M+H+], 823.4814[M+Na+] | 823.47816 | −4 |

| 56 | 31.51 | Ginsenoside Rk3 | C36H60O8 | 620.4288 | 621.4361[M+H+], 643.4180[M+Na+] | 643.41944 | 2.2 |

| 57 | 32.488 | Ginsenoside Rh4 | C36H60O8 | 620.4288 | 621.4361[M+H+], 643.4180[M+Na+] | 643.42013 | 3.2 |

| 58 | 32.83 | Vinaginsenoside R3 | C48H82O17 | 930.5547 | 931.56248[M+H+], 953.54442[M+Na+] | 953.54494 | 0.5 |

| 59 | 33.7 | Ginsenoside F2 | C42H72O13 | 784.4973 | 785.5045[M+H+], 807.4865[M+Na+] | 807.4893 | 3.5 |

| 60 | 33.98 | Ginsenoside Z-R1 | C42H66O14 | 794.4447 | 812.47908[M+NH4+], 817.43448[M+Na+] | 812.48052 | 1.8 |

| 61 | 34.865 | 3-Acetyl-ginsenoside F1 | C38H64O10 | 680.4494 | 681.45722[M+H+], 703.43917[M+Na+] | 703.44024 | 1.5 |

| 62 | 36.068 | Ginsenoside Rg3(s) | C42H72O13 | 784.4973 | 785.5045[M+H+], 807.4865[M+Na+] | 807.48781 | 1.6 |

| 63 | 36.749 | Ginsenoside Rg3(r) | C42H72O13 | 784.4973 | 785.5045[M+H+], 807.4865[M+Na+] | 807.48771 | 1.5 |

| 64 | 37.115 | Protopanaxatriol | C30H52O4 | 476.3866 | 477.3938[M+H+], 499.3757[M+Na+] | 499.37701 | 2.5 |

| 65 | 39.19 | Ginsenoside MC | C41H70O12 | 754.4867 | 755.4940[M+H+], 777.4759[M+Na+] | 777.47753 | 2 |

| 66 | 40.061 | Ginsenoside CY | C41H70O12 | 754.4867 | 755.4940[M+H+], 777.4759[M+Na+] | 777.47797 | 2.6 |

| 67 | 40.79 | Ginsenoside Rs3 | C44H74O14 | 826.5073 | 827.51513[M+H+], 849.49708[M+Na+] | 849.49804 | 1.1 |

| 68 | 41.56 | Ginsenoside Rs4 | C44H72O13 | 808.4967 | 809.50457[M+H+], 831.48651[M+Na+] | 809.50558 | 1.2 |

| 69 | 43.59 | Ginsenoside Rk1 | C42H70O12 | 766.4867 | 767.4940[M+H+], 789.4759[M+Na+] | 789.47753 | 2 |

| 70 | 44.786 | Ginsenoside Rg5 | C42H70O12 | 766.4867 | 767.4940[M+H+], 789.4759[M+Na+] | 789.47768 | 2.2 |

| 71 | 45.863 | Ginsenoside CK | C36H62O8 | 622.4445 | 623.4517[M+H+], 645.4336[M+Na+] | 645.43508 | 2.2 |

| 72 | 47.211 | Ginsenoside Rh2(s) | C36H62O8 | 622.4445 | 623.4517[M+H+], 645.4336[M+Na+] | 645.4345 | 1.3 |

| 73 | 47.798 | Ginsenoside Rh2(r) | C36H62O8 | 622.4445 | 623.4517[M+H+], 645.4336[M+Na+] | 645.43508 | 2.2 |

| 74 | 48.11 | Pseudo ginsenoside Rh2 | C36H62O8 | 622.4439 | 623.45175[M+H]+, 645.43369[M+Na+] | 645.43447 | 1.2 |

| 75 | 49.34 | Ginsenoside Rs5 | C44H72O13 | 808.4967 | 809.50457[M+H+], 831.48651[M+Na+] | 831.48782 | 1.6 |

| 76 | 52.171 | Ginsenoside Rk2 | C36H60O7 | 604.4339 | 627.4231[M+Na+] | 627.42291 | −0.3 |

| 77 | 52.62 | Ginsenoside Rh3 | C36H60O7 | 604.4339 | 627.4231[M+Na+] | 627.42329 | 0.3 |

| 78 | 56.123 | Protopanaxadiol | C30H52O3 | 460.3916 | 461.3989[M+H+], 483.3808[M+Na+] | 483.3809 | 0.1 |

| 79 | 60.9 | Ginsenoside Rs6/Rs7 | C38H62O9 | 662.4388 | 663.4466[M+H+], 685.4286[M+Na+] | 685.43639 | 11.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oh, H.-B.; Jeong, D.-E.; Lee, D.-E.; Yoo, J.-H.; Kim, Y.-S.; Kim, T.-Y. Structural Identification of Ginsenoside Based on UPLC-QTOF-MS of Black Ginseng (Panax Ginseng C.A. Mayer). Metabolites 2024, 14, 62. https://doi.org/10.3390/metabo14010062

Oh H-B, Jeong D-E, Lee D-E, Yoo J-H, Kim Y-S, Kim T-Y. Structural Identification of Ginsenoside Based on UPLC-QTOF-MS of Black Ginseng (Panax Ginseng C.A. Mayer). Metabolites. 2024; 14(1):62. https://doi.org/10.3390/metabo14010062

Chicago/Turabian StyleOh, Hyo-Bin, Da-Eun Jeong, Da-Eun Lee, Jong-Hee Yoo, Young-Soo Kim, and Tae-Young Kim. 2024. "Structural Identification of Ginsenoside Based on UPLC-QTOF-MS of Black Ginseng (Panax Ginseng C.A. Mayer)" Metabolites 14, no. 1: 62. https://doi.org/10.3390/metabo14010062