Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition

Abstract

:1. Introduction

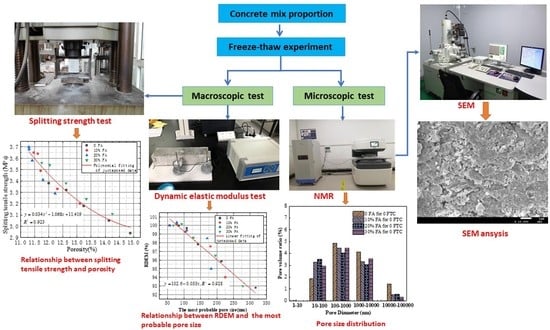

2. Experimental Program

2.1. Materials

2.2. Freeze–Thaw Test

2.3. Splitting Tensile Strength Test

2.4. Microscopic Test

3. Experimental Results

3.1. Surface Change

3.2. Mass Loss and RDEM

3.3. Split Tensile Strength

3.4. SEM Analysis

3.5. NMR Analysis

3.5.1. Porosity Evolution

3.5.2. Pore Size Distribution Evolution

4. Discussion

4.1. Relationship between RDEM and Pore Structure

4.2. Relationship between Splitting Tensile Strength and Pore Structure

4.3. Mechanism of the Effect of FA Content on the Mechanical Properties of Concrete

5. Conclusions

- (1)

- The effect of FA on the strength of concrete under freeze–thaw cycles mainly includes the changes in initial strength and frost resistance durability of concrete. After 100 FTCs, the splitting tensile strength of the test pieces with an FA content of 0, 10%, 20% and 30% are 2.94 MPa, 3.24 MPa, 3.47 MPa and 3.15 MPa, respectively. The splitting tensile strength of the concrete with an FA content of 20% is the highest, reflecting the best frost resistance.

- (2)

- The frost resistance of concrete is mainly affected by the content of pores with a pore diameter lower than 100 nm. The filling and secondary hydration of FA can improve the porosity and PSD of concrete to some extent, but excessive FA content will affect the secondary reaction and the formation of hydrated calcium silicate gel. 20% FA concrete has the lowest initial porosity, more pores below 100 nm, and more uniform pores, so it has the largest initial splitting tensile strength and the best frost resistance.

- (3)

- In the process of FTC, there is a nonlinear negative correlation between RDEM and porosity of concrete with different FA contents, and there is a linear negative correlation between the splitting strength and the most probable pore size. These relationships indicate that the strength of concrete under FTC is mainly controlled by porosity, and FA content affects the evolution of porosity during freeze–thaw cycles.

- (4)

- This study provides a certain reference for the improvement of initial strength and frost resistance of concrete in cold regions, and gives the suggested FA parameters, which can provide a new idea for concrete mix proportion design based on durability.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Baykal, G.; Saygili, A. A New Technique to Improve Freeze-Thaw Durability of Fly Ash. Fuel 2012, 102, 221–226. [Google Scholar] [CrossRef]

- Mao, J.; Zhang, Z.; Liu, Z.; Sun, C. Damage Analysis of Concrete Subjected to Freeze-Thaw Cycles and Chloride Ion Erosion. Key Eng. Mater. 2012, 489, 464–467. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Zhao, Y. Effect of Coupled Deterioration by Freeze-Thaw Cycle and Carbonation on Concrete Produced with Coarse Recycled Concrete Aggregates. J. Ceram. Soc. Japan 2017, 125, 36–45. [Google Scholar] [CrossRef] [Green Version]

- Shang, H.; Yi, T. Freeze-Thaw Durability of Air-Entrained Concrete. Sci. World J. 2013, 2013, 650791. [Google Scholar] [CrossRef] [Green Version]

- Pigeon, M. Durability of Concrete in Cold Climates; CRC Press: Boca Raton, FL, USA, 1995. [Google Scholar] [CrossRef]

- Qin, X.; Meng, S.; Cao, D.; Tu, Y.; Sabourova, N.; Grip, N. Evaluation of Freeze-Thaw Damage on Concrete Material and Prestressed Concrete Specimens. Constr. Build. Mater. 2016, 125, 892–904. [Google Scholar] [CrossRef]

- Gooi, S.; Mousa, A.A.; Kong, D. A Critical Review and Gap Analysis on the Use of Coal Bottom Ash as a Substitute Constituent in Concrete. J. Clean. Prod. 2020, 268, 121752. [Google Scholar] [CrossRef]

- Li, Y.; Wang, R.; Li, S.; Zhao, Y.; Qin, Y. Resistance of Recycled Aggregate Concrete Containing Low- and High-Volume Fly Ash against the Combined Action of Freeze–Thaw Cycles and Sulfate Attack. Constr. Build. Mater. 2018, 166, 23–34. [Google Scholar] [CrossRef]

- Lu, X.C.; Guan, B.; Chen, B.F.; Zhang, X.; Xiong, B.B. The Effect of Freeze-Thaw Damage on Corrosion in Reinforced Concrete. Adv. Mater. Sci. Eng. 2021, 2021, 9924869. [Google Scholar] [CrossRef]

- Luo, Y.; Wu, Y.; Ma, S.; Zheng, S.; Zhang, Y.; Chu, P.K. Utilization of Coal Fly Ash in China: A Mini-Review on Challenges and Future Directions. Environ. Sci. Pollut. Res. 2021, 28, 18727–18740. [Google Scholar] [CrossRef]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A Comprehensive Review on the Applications of Coal Fly Ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef] [Green Version]

- Güllü, H.; Fedakar, H.İ. Use of Factorial Experimental Approach and Effect Size on the CBR Testing Results for the Usable Dosages of Wastewater Sludge Ash with Coarse-Grained Material. Eur. J. Environ. Civ. Eng. 2018, 22, 42–63. [Google Scholar] [CrossRef]

- Gao, Y.M.; Shim, H.S.; Hurt, R.H.; Suuberg, E.M.; Yang, N.Y.C. Effects of Carbon on Air Entrainment in Fly Ash Concrete: The Role of Soot and Carbon Black. Energy Fuels 1997, 11, 457–462. [Google Scholar] [CrossRef]

- Baert, G.; Poppe, A.; De Belie, N. Strength and Durability of High-Volume Fly Ash Concrete. Struct. Concr. 2008, 9, 101–108. [Google Scholar] [CrossRef]

- Topçu, I.B.; Canbaz, M. Effect of Different Fibers on the Mechanical Properties of Concrete Containing Fly Ash. Constr. Build. Mater. 2007, 21, 1486–1491. [Google Scholar] [CrossRef]

- Wang, R.; Zhang, Q.; Li, Y. Deterioration of Concrete under the Coupling Effects of Freeze–Thaw Cycles and Other Actions: A Review. Constr. Build. Mater. 2022, 319, 126045. [Google Scholar] [CrossRef]

- Benli, A.; Turk, K.; Kina, C. Influence of Silica Fume and Class F Fly Ash on Mechanical and Rheological Properties and Freeze-Thaw Durability of Self-Compacting Mortars. J. Cold Reg. Eng. 2018, 32, 2–9. [Google Scholar] [CrossRef]

- Islam, M.M.; Alam, M.T.; Islam, M.S. Effect of Fly Ash on Freeze–Thaw Durability of Concrete in Marine Environment. Aust. J. Struct. Eng. 2018, 19, 146–161. [Google Scholar] [CrossRef]

- Kadapure, S.A.; Kulkarni, G.S.; Prakash, K.B. Study on Properties of Bacteria-Embedded Fly Ash Concrete. Asian J. Civ. Eng. 2019, 20, 627–636. [Google Scholar] [CrossRef]

- Feng, Y.; Wang, D.; Li, J. Study on the Effect of Large Amount of Fly Ash on Frost Resistance of Concrete. Hans J. Civ. Eng. 2019, 8, 1039–10440. [Google Scholar] [CrossRef]

- Zhang, S.; Tian, B.; Chen, B.; Lu, X.; Xiong, B.; Shuang, N. The Influence of Freeze–Thaw Cycles and Corrosion on Reinforced Concrete and the Relationship between the Evolutions of the Microstructure and Mechanical Properties. Materials 2022, 15, 6215. [Google Scholar] [CrossRef]

- Liu, L.; Shen, D.; Chen, H.; Sun, W.; Qian, Z.; Zhao, H.; Jiang, J. Analysis of Damage Development in Cement Paste Due to Ice Nucleation at Different Temperatures. Cem. Concr. Compos. 2014, 53, 1–9. [Google Scholar] [CrossRef]

- Modarres, C.; Astorga, N.; Droguett, E.L.; Meruane, V. Convolutional Neural Networks for Automated Damage Recognition and Damage Type Identification. Struct. Control Health Monit. 2018, 25, e2230. [Google Scholar] [CrossRef]

- Li, W.Z.; Shi, J.Z.S. Development of Microscopic Structure of Concrete Exposed to Freeze-Thaw Cycles. WANFANG Data 2012, 1, 13–14. [Google Scholar] [CrossRef]

- Wang, R.; Hu, Z.; Li, Y.; Wang, K.; Zhang, H. Review on the Deterioration and Approaches to Enhance the Durability of Concrete in the Freeze–Thaw Environment. Constr. Build. Mater. 2022, 321, 126371. [Google Scholar] [CrossRef]

- Zhou, K.P.; Li, B.; Li, J.L.; Deng, H.W.; Bin, F. Microscopic Damage and Dynamic Mechanical Properties of Rock under Freeze-Thaw Environment. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2015, 25, 1254–1261. [Google Scholar] [CrossRef]

- Li, J.-I.; Zhou, K.-P.; Liu, W.-J.; Deng, H.-W. NMR Research on Deterioration Characteristics of Microscopic Structure of Sandstones in Freeze–Thaw Cycles. Trans. Nonferrous Met. Soc. China (Engl. Ed.) 2016, 26, 2997–3003. [Google Scholar] [CrossRef]

- Wang, X.X.; Shen, X.D.; Wang, H.L.; Zhao, H.X. Nuclear Magnetic Resonance Analysis of Air Entraining Natural Pumice Concrete Freeze-Thaw Damage. Adv. Mater. Res. 2014, 919–921, 1939–1943. [Google Scholar] [CrossRef]

- DL/T 5016-1999; Design Code for Concrete Face Rockfill Dams. China Renewable Energy Engineering Institute: Beijing, China, 1999.

- GB/T 50082-2009; Standard for Test Methods of Long-Term Performance and Durability of Ordinary Concrete. Ministry of Construction of the People’s Republic of China: Beijing, China, 2009. (In Chinese)

- Shang, H.; Song, Y.; Ou, J. Behavior of Air-Entrained Concrete after Freeze-Thaw Cycles. Acta Mech. Solida Sin. 2009, 22, 261–266. [Google Scholar] [CrossRef]

- Wang, X.; Shen, X.; Wang, H.; Gao, C.; Zhang, T. Nuclear Magnetic Resonance Analysis of Freeze-Thaw Damage in Natural Pumice Concrete. Mater. Constr. 2016, 66, e087. [Google Scholar] [CrossRef]

- Gran, H.C.; Hansen, E.W. Effects of Drying and Freeze/Thaw Cycling Probed by 1H-NMR. Cem. Concr. Res. 1997, 27, 1319–1331. [Google Scholar] [CrossRef]

- Yao, X.; Zhang, M.; Guan, J.; Li, L.; Bai, W.; Liu, Z. Research on the Corrosion Damage Mechanism of Concrete in Two Freeze-Thaw Environments. Adv. Civ. Eng. 2020, 2020, 8839386. [Google Scholar] [CrossRef]

- Wang, Y.; Liu, Z.; Fu, K.; Li, Q.; Wang, Y. Experimental Studies on the Chloride Ion Permeability of Concrete Considering the Effect of Freeze–Thaw Damage. Constr. Build. Mater. 2020, 236, 117556. [Google Scholar] [CrossRef]

- Zhang, W.; Pi, Y.; Kong, W.; Zhang, Y.; Wu, P.; Zeng, W. Influence of Damage Degree on the Degradation of Concrete under Freezing-Thawing Cycles. Constr. Build. Mater. 2020, 260, 119903. [Google Scholar] [CrossRef]

- Yang, D. Influence of Fly Ash Content and Fineness on Concrete Strength. Bulk Cem. 2019, 4, 88–100. [Google Scholar]

- Fu, Y.; Cai, L.; Yonggen, W. Freeze-Thaw Cycle Test and Damage Mechanics Models of Alkali-Activated Slag Concrete. Constr. Build. Mater. 2011, 25, 3144–3148. [Google Scholar] [CrossRef]

- Fa-Ming, L.; Chuan-Qing, F. Influence of Freeze-Thaw Cycle on SFRC with Different Fly Ash Mixing. In Proceedings of the 2011 International Conference on Electric Technology and Civil Engineering (ICETCE), Lushan, China, 22–24 April 2011; pp. 1310–1313. [Google Scholar] [CrossRef]

- Powers, T.C. Absorption of Water by Portland Cement Paste during the Hardening Process. Ind. Eng. Chem. Res. 1935, 27, 790–794. [Google Scholar] [CrossRef]

- Xiao, S.; Zhu, L. Study on Effects of Voids on Macro-Mechanical Properties of Concrete. Shenyang Jianzhu Daxue Xuebao (Ziran Kexue Ban)/J. Shenyang Jianzhu Univ. (Nat. Sci.) 2016, 32, 608–618. [Google Scholar] [CrossRef]

- Fan, Y.N.; Du, H.X.; Shi, L.N. The Fractal Characteristics of C80 High Performance Concrete Pore Structure Subject to High Temperatures. IOP Conf. Ser. Earth Environ. Sci. 2020, 510, 052016. [Google Scholar] [CrossRef]

| Cement | FA | Sand | Stone | Water | Dosage of FA | Water-Reducing Agent | Air-Entraining Agent |

|---|---|---|---|---|---|---|---|

| 340 | 0 | 553 | 1291 | 136 | 0% | 1% | 0.02% |

| 306 | 34 | 553 | 1291 | 136 | 10% | 1% | 0.02% |

| 272 | 68 | 553 | 1291 | 136 | 20% | 1% | 0.02% |

| 238 | 102 | 553 | 1291 | 136 | 30% | 1% | 0.02% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, S.; Chen, B.; Tian, B.; Lu, X.; Xiong, B. Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition. Buildings 2022, 12, 2113. https://doi.org/10.3390/buildings12122113

Zhang S, Chen B, Tian B, Lu X, Xiong B. Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition. Buildings. 2022; 12(12):2113. https://doi.org/10.3390/buildings12122113

Chicago/Turabian StyleZhang, Shuhua, Bofu Chen, Bin Tian, Xiaochun Lu, and Bobo Xiong. 2022. "Effect of Fly Ash Content on the Microstructure and Strength of Concrete under Freeze–Thaw Condition" Buildings 12, no. 12: 2113. https://doi.org/10.3390/buildings12122113