Solidification Processing of Metallic Materials in Static Magnetic Field: A Review

Abstract

:1. Introduction

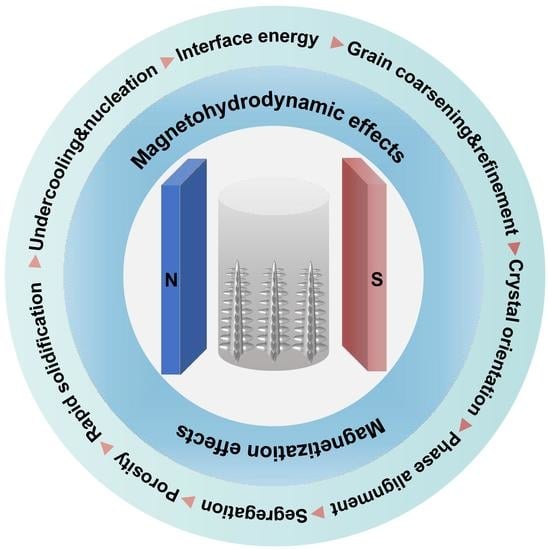

2. Principles of SMF-Regulated Metal Solidification

2.1. Magnetohydrodynamic Effect

2.2. Magnetization Effect

3. SMF-Regulated Metal Solidification

3.1. SMF Effects

3.1.1. SMF-Induced Undercooling

3.1.2. Additional Interfacial Tension Induced by SMF

3.1.3. Dendrite Coarsening in SMF

3.1.4. SMF-Induced Grain Refinement

3.1.5. SMF-Controlled Segregation

3.1.6. SMF-Controlled Porosity

3.1.7. Crystal Orientation in SMF

3.2. Possible Application of SMF to Rapid Solidification

3.3. Application of Synchrotron X-ray Imaging to Solidification with SMF

4. Conclusions and Perspective

- (1)

- Development of low-cost and large-bore strong magnets

- (2)

- Development of in-situ SMF testing devices for high temperature

- (3)

- Fundamentals of magnetic effects

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Kurz, W.; Fisher, D.J. Fundamentals of Solidification, 3rd ed.; Trans Tech Pubications: Aedermannsdorf, Switzerland, 1992; pp. 1–15. [Google Scholar]

- Flemings, M.C. Solidification processing. Metall. Mater. Trans. B 1974, 5, 2121–2134. [Google Scholar] [CrossRef]

- Asta, M.; Beckermann, C.; Karma, A.; Kurz, W.; Napolitano, R.; Plapp, M.; Purdy, G.; Rappaz, M.; Trivedi, R. Solidification microstructures and solid-state parallels: Recent developments, future directions. Acta Mater. 2009, 57, 941–971. [Google Scholar] [CrossRef] [Green Version]

- Chen, G.; Zheng, G.; Qi, Z.; Zhang, J.; Li, P.; Cheng, J.; Zhang, Z. Research progress on controlled solidification and its applications. Acta Metall. Sin. 2018, 54, 669–681. [Google Scholar]

- Suthar, J.; Persis, J.; Gupta, R. Critical parameters influencing the quality of metal castings: A systematic literature review. Int. J. Qual. Reliab. Manage. 2021; ahead-of-print. [Google Scholar] [CrossRef]

- Eskin, D.G.; Mi, J. Solidification Processing of Metallic Alloys under External Fields, 1st ed.; Springer: Cham, Switzerland, 2018; pp. 75–275. [Google Scholar]

- Hu, S.; Chen, L.; Zhou, Q.; Wang, J. Research progress in effects of physical fields on solidified structure of metals. Spec. Cast. Nonferr. Alloy. 2018, 38, 717–720. [Google Scholar]

- Asai, S. Recent development and prospect of electromagnetic processing of materials. Sci. Technol. Adv. Mat. 2000, 1, 191–200. [Google Scholar] [CrossRef]

- Cho, S.; Thomas, B.G. Electromagnetic forces in continuous casting of steel slabs. Metals 2019, 9, 471. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Ren, Z. Thermoelectric magnetic effect and its effect on the solidification structure under static magnetic fields. Mater. China 2014, 33, 349–354. [Google Scholar]

- Magomedov, M.N. On the magnetic-field-induced changes in the parameters of phase transitions. Tech. Phys. Lett. 2002, 28, 116–118. [Google Scholar] [CrossRef]

- Ren, Z.; Lei, Z.; Li, C.; Xuan, W.; Zhong, Y.; Li, X. New study and development on electromagnetic field technology in metallurgical processes. Acta Metall. Sin. 2020, 56, 583–600. [Google Scholar]

- Zhao, Z.; Chai, Y.; Zheng, S.; Wang, L.; Xiao, Y. Electromagnetic field assisted metallic materials processing: A review. Steel Res. Int. 2017, 88, 1600273. [Google Scholar] [CrossRef]

- Liu, T.; Wang, Q.; Liu, F.; Li, G.; He, J. Nucleation behavior of bulk Ni–Cu alloy and pure Sb in high magnetic fields. J. Cryst. Growth 2011, 321, 167–170. [Google Scholar] [CrossRef]

- Koyama, K.; Mitsui, Y.; Choi, E.S.; Ikehara, Y.; Palm, E.C.; Watanabe, K. Change of the equilibrium state of ferromagnetic MnBi by high magnetic fields. J. Alloy. Compd. 2011, 509, L78–L80. [Google Scholar] [CrossRef]

- Li, C.; Cao, Y.; Lippmann, S.; Ren, Z.; Rettenmayr, M. Reduced wettability of solids by a liquid Ga–in–Sn alloy in a steady magnetic field. J. Phys. Chem. C 2018, 122, 27451–27455. [Google Scholar] [CrossRef]

- He, S.; Zhan, T.; Li, C.; Xuan, W.; Wang, J.; Ren, Z. Enhanced dendrite coarsening and microsegregation in Al-Cu alloy under a steady magnetic field. Mater. Trans. 2019, 60, 1921–1927. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Gagnoud, A.; Fautrelle, Y.; Ren, Z.; Moreau, R.; Zhang, Y.; Esling, C. Dendrite fragmentation and columnar-to-equiaxed transition during directional solidification at lower growth speed under a strong magnetic field. Acta Mater. 2012, 60, 3321–3332. [Google Scholar] [CrossRef]

- Li, X.; Gagnoud, A.; Ren, Z.; Fautrelle, Y.; Debray, F. Effect of strong magnetic field on solid solubility and microsegregation during directional solidification of Al-Cu alloy. J. Mater. Res. 2013, 28, 2810–2818. [Google Scholar] [CrossRef]

- Zheng, T.; Zhou, B.; Wang, J.; Shuai, S.; Zhong, Y.; Ren, W.; Ren, Z.; Debray, F.; Beaugnon, E. Compression properties enhancement of Al-Cu alloy solidified under a 29 T high static magnetic field. Mater. Sci. Eng. A 2018, 733, 170–178. [Google Scholar] [CrossRef]

- Vives, C.; Perry, C. Effects of magnetically damped convection during the controlled solidification of metals and alloys. Int. J. Heat Mass Transf. 1987, 30, 479–496. [Google Scholar] [CrossRef]

- Shercliff, J.A. Thermoelectric magnetohydrodynamics. J. Fluid Mech. 1979, 91, 231–251. [Google Scholar] [CrossRef]

- Khine, Y.Y.; Walker, J.S. Thermoelectric magnetohydrodynamic effects during bridgman semiconductor crystal growth with a uniform axial magnetic field. J. Cryst. Growth 1999, 183, 150–158. [Google Scholar] [CrossRef]

- Li, X.; Gagnoud, A.; Ren, Z.; Fautrelle, Y.; Moreau, R. Investigation of thermoelectric magnetic convection and its effect on solidification structure during directional solidification under a low axial magnetic field. Acta Mater. 2009, 57, 2180–2197. [Google Scholar] [CrossRef]

- Asai, S. Electromagnetic Processing of Materials, 1st ed.; Springer: Dordrecht, The Netherlands, 2012; pp. 113–150. [Google Scholar]

- Ren, Z.; Wang, J.; Zhao, R. Orientation and alignment during materials processing under high magnetic fields. Chin. Phys. B 2019, 28, 048301. [Google Scholar] [CrossRef]

- Zhou, G. Nucleation thermodynamics of oxide during metal oxidation. Appl. Phys. Lett. 2009, 94, 201905. [Google Scholar] [CrossRef]

- Sun, Z.H.I.; Guo, X.; Guo, M.; Li, C.; Vleugels, J.; Ren, Z.; Van der Biest, O.; Blanpain, B. Strong magnetic field effect on surface tension associated with an interfacial magnetic pressure. J. Phys. Chem. C 2012, 116, 17676–17681. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; He, S.; Wang, J.; Xuan, W.; Li, X.; Zhong, Y.; Ren, Z. Enhanced undercooling of para- and diamagnetic metal melts in steady magnetic field. Jpn. J. Appl. Phys. 2018, 57, 80301. [Google Scholar] [CrossRef]

- Guo, R.; Li, C.; He, S.; Wang, J.; Xuan, W.; Li, X.; Zhong, Y.; Ren, Z. Effect of steady magnetic field on undercooling of Al-Cu alloy melts. Europhys. Lett. 2019, 126, 46001. [Google Scholar] [CrossRef]

- Guo, R.; Shuai, S.; Zhao, R.; Li, C.; Li, X.; Zhong, Y.; Wang, J.; Ren, Z. Enhanced degradation in grain refinement of inoculated 2024 Al alloy in steady magnetic field. Metall. Mater. Trans. A 2020, 51, 4584–4591. [Google Scholar] [CrossRef]

- Wang, J.; He, Y.; Li, J.; Kou, H.; Beaugnon, E. Reexaminations of the effects of magnetic field on the nucleation of undercooled Cu melt. Jpn. J. Appl. Phys. 2016, 55, 105601. [Google Scholar] [CrossRef]

- Wang, J.; He, Y.; Li, J.; Kou, H.; Beaugnon, E. Strong magnetic field effect on the nucleation of a highly undercooled Co-Sn melt. Sci. Rep. 2017, 7, 4958. [Google Scholar] [CrossRef] [Green Version]

- Iino, M.; Fujimura, Y. Surface tension of heavy water under high magnetic fields. Appl. Phys. Lett. 2009, 94, 1641. [Google Scholar] [CrossRef]

- Li, C.; Chen, L.; Ren, Z. Surface tensions of non-polar liquids in high magnetic fields. J. Mol. Liq. 2013, 181, 51–54. [Google Scholar] [CrossRef]

- Böyük, U.; Engin, S.; Maraşlı, N. Novel experimental technique to observe equilibrated grain boundary groove shapes in opaque alloys. J. Alloy. Compd. 2009, 476, 213–219. [Google Scholar] [CrossRef]

- Glicksman, M.E.; Vold, C.L. Determination of absolute solid-liquid interfacial free energies in metals. Acta Metall. 1969, 17, 1–11. [Google Scholar] [CrossRef]

- Gündüz, M.; Hunt, J.D. The measurement of solid-liquid surface energies in the Al-Cu, Al-Si and Pb-Sn systems. Acta Metall. 1985, 33, 1651–1672. [Google Scholar] [CrossRef]

- Maeda, K.; Niitsu, A.; Morito, H.; Shiga, K.; Fujiwara, K. In situ observation of grain boundary groove at the crystal/melt interface in Cu. Scr. Mater. 2018, 146, 169–172. [Google Scholar] [CrossRef]

- Maraşli, N.; Hunt, J.D. Solid-liquid surface energies in the Al-CuAl2, Al-NiAl3 and Al-Ti systems. Acta Mater. 1996, 44, 1085–1096. [Google Scholar] [CrossRef]

- Liu, T.; Xiao, Y.; Lu, Z.; Hirota, N.; Li, G.; Yuan, S.; Wang, Q. Wetting Behaviors of molten melt drops on polycrystalline Al2O3 substrates in high magnetic fields. J. Mater. Sci. Technol. 2020, 41, 187–190. [Google Scholar] [CrossRef]

- Huang, C.; Shuai, S.; Wang, P.; Liu, X.; Wang, J.; Ren, Z. The effect of static magnetic field on solid-liquid interfacial free energy of Al-Cu alloy system. Scr. Mater. 2020, 187, 232–236. [Google Scholar] [CrossRef]

- Gao, J.; Han, M.; Kao, A.; Pericleous, K.; Alexandrov, D.V.; Galenko, P.K. Dendritic growth velocities in an undercooled melt of pure nickel under static magnetic fields: A test of theory with convection. Acta Mater. 2016, 103, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Gao, J.; Kao, A.; Bojarevics, V.; Pericleous, K.; Galenko, P.K.; Alexandrov, D.V. Modeling of convection, temperature distribution and dendritic growth in glass-fluxed nickel melts. J. Cryst. Growth. 2017, 471, 66–72. [Google Scholar] [CrossRef]

- Basaran, M. Dendrite coarsening and microsegregation in Al-Cu alloys. Metall. Trans. A 1981, 12, 1235–1243. [Google Scholar] [CrossRef]

- Combeau, H.; Drezet, J.M.; Mo, A.; Rappaz, M. Modeling of microsegregation in macrosegregation computations. Metall. Mater. Trans. A 1996, 27, 2314–2327. [Google Scholar] [CrossRef]

- Kirkwood, D.H. Microsegregation. Mater. Sci. Eng. 1984, 65, 101–109. [Google Scholar] [CrossRef]

- Kraft, T.; Chang, Y.A. Discussion of “effect of dendrite arm coarsening on microsegregation”. Metall. Mater. Trans. A 1998, 29, 2447–2449. [Google Scholar] [CrossRef]

- Lacaze, J.; Lesoult, G. Modelling the development of microsegregation during solidification of an Al-Cu-Mg-Si alloy. ISIJ Int. 1995, 35, 658–664. [Google Scholar] [CrossRef] [Green Version]

- Mortensen, A. On the influence of coarsening on microsegregation. Metall. Trans. A 1989, 20, 247–253. [Google Scholar] [CrossRef]

- Terzi, S.; Salvo, L.; Suery, M.; Dahle, A.K.; Boller, E. Coarsening mechanisms in a dendritic Al–10% Cu alloy. Acta Mater. 2010, 58, 20–30. [Google Scholar] [CrossRef]

- Voller, V.R. A model of microsegregation during binary alloy solidification. Int. J. Heat Mass Tran. 2000, 43, 2047–2052. [Google Scholar] [CrossRef]

- Li, X.; Fautrelle, Y.; Ren, Z. Influence of thermoelectric effects on the solid–liquid interface shape and cellular morphology in the mushy zone during the directional solidification of Al-Cu alloys under a magnetic field. Acta Mater. 2007, 55, 3803–3813. [Google Scholar] [CrossRef]

- Moreau, R.; Laskar, O.; Tanaka, M.; Camel, D. Thermoelectric magnetohydrodynamic effects on solidification of metallic alloys in the dendritic regime. Mater. Sci. Eng. A 1993, 173, 93–100. [Google Scholar] [CrossRef]

- Tewari, S.N.; Shah, R. Macrosegregation during dendritic arrayed growth of hypoeutectic Pb-Sn alloys: Influence of primary arm spacing and mushy zone length. Metall. Mater. Trans. A 1996, 27, 1353–1362. [Google Scholar] [CrossRef] [Green Version]

- Zhong, H.; Li, C.; Ren, Z.; Rettenmayr, M.; Zhong, Y.; Yu, J.; Wang, J. Effect of interdendritic thermoelectric magnetic convection on evolution of tertiary dendrite during directional solidification. J. Cryst. Growth 2016, 439, 66–73. [Google Scholar] [CrossRef]

- Bhadeshia, H.K.D.H. Steels for bearings. Prog. Mater. Sci. 2012, 57, 268–435. [Google Scholar] [CrossRef]

- Dong, Z.; Jiang, B.; Mei, Z.; Zhang, C.; Zhou, L.; Liu, Y. Effect of carbide distribution on the grain refinement in the steel for large-size bearing ring. Steel Res. Int. 2016, 87, 745–751. [Google Scholar] [CrossRef]

- Grong, Ø.; Kolbeinsen, L.; van der Eijk, C.; Tranell, G. Microstructure control of steels through dispersoid metallurgy using novel grain refining alloys. ISIJ Int. 2006, 46, 824–831. [Google Scholar] [CrossRef] [Green Version]

- Qiu, H.; Wang, L.; Hanamura, T.; Torizuka, S. Physical interpretation of grain refinement-induced variation in fracture mode in ferritic steel. ISIJ Int. 2013, 53, 382–384. [Google Scholar] [CrossRef] [Green Version]

- Jin, T.N.; Nie, Z.R.; Guo-Fu, X.U. Effects of cooling rate on solidification behavior of dilute Al-Sc and Al-Sc-Zr solid solution. T. Nonferr. Metal. Soc. 2004, 14, 58–62. [Google Scholar]

- Kivi, M.; Holappa, L.; Iung, T. Addition of dispersoid titanium oxide inclusions in steel and their influence on grain refinement. Metall. Mater. Trans. B 2010, 41, 1194–1204. [Google Scholar] [CrossRef]

- Sasaki, M.; Ohsasa, K.; Kudoh, M.; Matsuura, K. Refinement of austenite grain in carbon steel by addition of titanium and boron. ISIJ Int. 2008, 48, 340–343. [Google Scholar] [CrossRef] [Green Version]

- Li, X.; Fautrelle, Y.; Zaidat, K.; Gagnoud, A.; Ren, Z.; Moreau, R.; Zhang, Y.; Esling, C. Columnar-to-equiaxed transitions in Al-based alloys during directional solidification under a high magnetic field. J. Cryst. Growth 2010, 312, 267–272. [Google Scholar] [CrossRef]

- Li, X.; Ren, Z.; Shen, Y.; Fautrelle, Y. Effect of Thermoelectric magnetic force on the array of dendrites during directional solidification of Al-Cu alloys in a high magnetic field. Phil. Mag. Lett. 2012, 92, 675–682. [Google Scholar] [CrossRef]

- Yu, J.; Du, D.; Ren, Z.; Fautrelle, Y.; Moreau, R.; Li, X. Influence of an axial magnetic field on microstructures and alignment in directionally solidified Ni-based superalloy. ISIJ Int. 2017, 57, 337–342. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Zhang, Z.; Xuan, W.; Wang, J.; Yu, J.; Ren, Z. Grain refinement during directionally solidifying GCr18Mo steel at low pulling speeds under an axial static magnetic field. Acta Metall. Sin-Engl. 2018, 31, 681–691. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Ren, Z.; Zhang, Z.; Ren, X. Columnar to equiaxed transition during directionally solidifying GCr18Mo steel affected by thermoelectric magnetic force under an axial static magnetic field. ISIJ Int. 2019, 59, 60–68. [Google Scholar] [CrossRef]

- Kobayashi, Y.; Todoroki, H.; Mizuno, K. Problems in solidification model for microsegregation analysis of Fe-Cr-Ni-Mo-Cu alloys. ISIJ Int. 2019, 59, 277–282. [Google Scholar] [CrossRef] [Green Version]

- Lynch, P.C.; Grimm, T.J. Reducing Microsegregation in next-generation high-strength low-alloy cast steels. Int. J. Metalcast. 2019, 13, 783–792. [Google Scholar] [CrossRef]

- Hou, L.; Dai, Y.; Fautrelle, Y.; Li, Z.; Ren, Z.; Esling, C.; Li, X. Evolution of microstructure and microsegregation in Ni-Mn-Ga alloys directionally solidified under axial magnetic field. J. Alloy. Compd. 2018, 758, 54–61. [Google Scholar] [CrossRef]

- Ren, W.; Lu, L.; Yuan, G.; Xuan, W.; Zhong, Y.; Yu, J.; Ren, Z. The effect of magnetic field on precipitation phases of single-crystal Nickel-base superalloy during directional solidification. Mater. Lett. 2013, 100, 223–226. [Google Scholar] [CrossRef]

- Song, J.Y.; Zhao, X.; Zhang, Y.D.; Esling, C.; Zuo, L. Influence of a high magnetic field on the solubility of ferrite and the amount of pearlite. Steel Res. Int. 2011, 82, 836–838. [Google Scholar] [CrossRef]

- Zhang, T.; Ren, W.; Dong, J.; Li, X.; Ren, Z.; Cao, G.; Zhong, Y.; Deng, K.; Lei, Z.; Guo, J. Effect of high magnetic field on the primary dendrite arm spacing and segregation of directionally solidified superalloy DZ417G. J. Alloy. Compd. 2009, 487, 612–617. [Google Scholar] [CrossRef]

- He, S.; Li, C.; Guo, R.; Xuan, W.; Wang, J.; Ren, Z. Evolution of microsegregation in directionally solidified Al-Cu alloys under steady magnetic field. J. Alloy. Compd. 2019, 800, 41–49. [Google Scholar] [CrossRef]

- Hardin, R.A.; Beckermann, C. Effect of porosity on the stiffness of cast steel. Metall. Mater. Trans. A 2007, 38, 2992–3006. [Google Scholar] [CrossRef]

- Dong, Q.; Zhang, J.; Wang, B.; Zhao, X. Shrinkage porosity and its alleviation by heavy reduction in continuously cast strand. J. Mater. Process. Tech. 2016, 238, 81–88. [Google Scholar] [CrossRef]

- Li, J.; Wang, B.; Ma, Y.; Cui, J. Effect of complex electromagnetic stirring on inner quality of high carbon steel bloom. Mater. Sci. Eng. A 2006, 425, 201–204. [Google Scholar] [CrossRef]

- Li, Y.; Li, L.; Zhang, J. Study and application of a simplified soft reduction amount model for improved internal quality of continuous casting bloom. Steel Res. Int. 2017, 88, 1700176. [Google Scholar] [CrossRef]

- Zeng, J.; Chen, W.; Zhang, S.; Li, Y.; Wang, Q. Development and application of final permanent magnet stirring during continuous casting of high carbon rectangular billet. ISIJ Int. 2015, 55, 2142–2149. [Google Scholar] [CrossRef] [Green Version]

- Hou, Y.; Shuai, S.; Dong, Y.; Xuan, W.; Wang, J.; Zhang, Z.; Ren, X.; Ren, Z. Effect of thermoelectric magnetic convection on shrinkage porosity at the final stage of solidification of GCr18Mo steel under axial static magnetic field. Metall. Mater. Trans. B 2019, 50, 881–889. [Google Scholar] [CrossRef]

- Mikelson, A.E.; Karklin, Y.K. Control of crystallization processes by means of magnetic fields. J. Cryst. Growth 1981, 52, 524–529. [Google Scholar] [CrossRef]

- Molodov, D.A.; Konijnenberg, P.J. Grain boundary and grain structure control through application of a high magnetic field. Scr. Mater. 2006, 54, 977–981. [Google Scholar] [CrossRef]

- Zheng, T.; Zhong, Y.; Lei, Z.; Ren, W.; Ren, Z.; Wang, H.; Wang, Q.; Debray, F.; Beaugnon, E.; Fautrelle, Y. Effects of high static magnetic field on crystal orientation and magnetic property of Bi-5Wt.% Zn alloys. Mater. Lett. 2015, 140, 68–70. [Google Scholar] [CrossRef]

- Wang, H.; Ren, Z.; Deng, K.; Xu, K. Effects of a static magnetic field on solidification structure of MnBi Phase in semi-solidified Bi-Mn alloy. Acta Metall. Sin. 2002, 38, 41–46. [Google Scholar]

- Han, Y.; Ban, C.; Guo, S.; Liu, X.; Ba, Q.; Cui, J. Alignment behavior of primary Al3Fe Phase in Al-Fe alloy under a high magnetic field. Mater. Lett. 2007, 61, 983–986. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, Q.; Liu, T.; Gao, P.; Yuan, Y.; He, J. Effects of high magnetic fields on the crystal orientation and magnetostriction of a TbFe2 based alloy during treatment in the semi-solid state. J. Alloy. Compd. 2014, 590, 110–115. [Google Scholar] [CrossRef]

- Cheng, L.; Zhang, N.; Yang, P.; Mao, W.M. Retaining {100} texture from initial columnar grains in electrical steels. Scr. Mater. 2012, 67, 899–902. [Google Scholar] [CrossRef]

- Sha, Y.H.; Sun, C.; Zhang, F.; Patel, D.; Chen, X.; Kalidindi, S.R.; Zuo, L. Strong cube recrystallization texture in silicon steel by twin-roll casting process. Acta Mater. 2014, 76, 106–117. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, Y.; Shen, Z.; Zheng, T.; Dong, L.; Ren, W.; Lei, Z.; Ren, Z. Effect of an axial high static magnetic field on the crystal orientation and magnetic property of Fe-4.5 Wt% Si alloy during bulk solidification. Mater. Lett. 2019, 247, 189–192. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, Y.; Shen, Z.; Dong, L.; Zheng, T.; Ren, W.; Lei, Z.; Ren, Z. Effect of a transverse weak magnetic field on the texture evolution and magnetic property of Fe-1.0 Wt.% Si alloy during bulk solidification. Mater. Res. Express 2019, 6, 066105. [Google Scholar] [CrossRef]

- Liu, C.; Zhong, Y.; Shen, Z.; Dong, L.; Zheng, T.; Ren, W.; Lei, Z.; Ren, Z. Magnetic field–dependent microstructure evolution and magnetic property of Fe–6.5 Si–0.05 B alloy during solidification. J. Mater. Res. 2019, 34, 4076–4084. [Google Scholar] [CrossRef]

- DebRoy, T.; Wei, H.L.; Zuback, J.S.; Mukherjee, T.; Elmer, J.W.; Milewski, J.O.; Beese, A.M.; Wilson-Heid, A.; De, A.; Zhang, W. Additive manufacturing of metallic components-process, structure and properties. Prog. Mater. Sci. 2018, 92, 112–224. [Google Scholar] [CrossRef]

- Frazier, W.E. Metal additive manufacturing: A review. J. Mater. Eng. Perform. 2014, 23, 1917–1928. [Google Scholar] [CrossRef]

- Murphy, S.V.; Atala, A. 3D bioprinting of tissues and organs. Nat. Biotechnol. 2014, 32, 773–785. [Google Scholar] [CrossRef] [PubMed]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part B-Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Li, X.P.; Ji, G.; Chen, Z.; Addad, A.; Wu, Y.; Wang, H.W.; Vleugels, J.; Van Humbeeck, J.; Kruth, J.P. Selective laser melting of nano-TiB2 decorated AlSi10Mg alloy with high fracture strength and ductility. Acta Mater. 2017, 129, 183–193. [Google Scholar] [CrossRef]

- Yu, J.; Rombouts, M.; Maes, G.; Motmans, F. Material properties of Ti6Al4V parts produced by laser metal deposition. Phys. Procedia 2012, 39, 416–424. [Google Scholar] [CrossRef]

- Zhao, R.; Chen, C.; Shuai, S.; Hu, T.; Fautrelle, Y.; Liao, H.; Lu, J.; Wang, J.; Ren, Z. Enhanced mechanical properties of Ti6Al4V alloy fabricated by laser additive manufacturing under static magnetic field. Mater. Res. Lett. 2022, 10, 530–538. [Google Scholar] [CrossRef]

- Liu, X.; Yu, J.; Shuai, S.; Xuan, W.; Wang, J.; Ren, Z. Cell-to-dendrite transition induced by a static transverse magnetic field during lasering remelting of the Nickel-based superalloy. Metall. Mater. Trans. B 2018, 49, 3211–3219. [Google Scholar] [CrossRef]

- Nie, J.; Chen, C.; Shuai, S.; Liu, X.; Zhao, R.; Wang, J.; Liao, H.; Ren, Z. Effect of static magnetic field on the evolution of residual stress and microstructure of laser remelted Inconel 718 superalloy. J. Therm. Spray Techn. 2020, 29, 1410–1423. [Google Scholar] [CrossRef]

- Zhu, W.; Yu, S.; Chen, C.; Shi, L.; Xu, S.; Shuai, S.; Hu, T.; Liao, H.; Wang, J.; Ren, Z. Effects of static magnetic field on the microstructure of selective laser melted Inconel 625 superalloy: Numerical and experiment investigations. Metals 2021, 11, 1846. [Google Scholar] [CrossRef]

- Kang, N.; Yuan, H.; Coddet, P.; Ren, Z.; Bernage, C.; Liao, H.; Coddet, C. On the texture, phase and tensile properties of commercially pure Ti produced via selective laser melting assisted by static magnetic field. Mater. Sci. Eng. C 2017, 70, 405–407. [Google Scholar] [CrossRef] [PubMed]

- Cai, B.; Wang, J.; Kao, A.; Pericleous, K.; Phillion, A.B.; Atwood, R.C.; Lee, P.D. 4D synchrotron X-ray tomographic quantification of the transition from cellular to dendrite growth during directional solidification. Acta Mater. 2016, 117, 160–169. [Google Scholar] [CrossRef]

- Daudin, R.; Terzi, S.; Lhuissier, P.; Tamayo, J.; Scheel, M.; Babu, N.H.; Eskin, D.G.; Salvo, L. Particle-induced morphological modification of Al alloy equiaxed dendrites revealed by sub-second in situ microtomography. Acta Mater. 2017, 125, 303–310. [Google Scholar] [CrossRef] [Green Version]

- Song, Z.; Magdysyuk, O.V.; Sparks, T.; Chiu, Y.; Cai, B. Revealing Growth Mechanisms of Faceted Al2Cu Intermetallic Compounds Via High-Speed Synchrotron X-Ray Tomography. Acta Mater. 2022, 231, 117903. [Google Scholar] [CrossRef]

- Fautrelle, Y.; Wang, J.; Salloum-Abou-Jaoude, G.; Abou-Khalil, L.; Reinhart, G.; Li, X.; Ren, Z.M.; Nguyen-Thi, H. Thermo-electric-magnetic hydrodynamics in solidification: In situ observations and theory. JOM 2018, 70, 764–771. [Google Scholar] [CrossRef] [Green Version]

- Wang, J.; Fautrelle, Y.; Ren, Z.M.; Li, X.; Nguyen-Thi, H.; Mangelinck-Noel, N.; Salloum, A.; Zhong, Y.B.; Kaldre, I.; Bojarevics, A. Thermoelectric magnetic force acting on the solid during directional solidification under a static magnetic field. Appl. Phys. Lett. 2012, 101, 1331–1333. [Google Scholar]

- Wang, J.; Fautrelle, Y.; Ren, Z.M.; Nguyen-Thi, H.; Salloum Abou Jaoude, G.; Reinhart, G.; Mangelinck-Noël, N.; Li, X.; Kaldre, I. Thermoelectric magnetic flows in melt during directional solidification. Appl. Phys. Lett. 2014, 104, 121916. [Google Scholar]

- Wang, J.; Fautrelle, Y.; Nguyen-Thi, H.; Reinhart, G.; Liao, H.; Li, X.; Zhong, Y.; Ren, Z. Thermoelectric magnetohydrodynamic flows and their induced change of solid–liquid interface shape in static magnetic field-assisted directional solidification. Metallur. Mater. Trans. A 2016, 47, 1169–1179. [Google Scholar] [CrossRef]

- Yasuda, H.; Inoue, K.; Minami, Y.; Nagira, T.; Yoshiya, M.; Uesugi, K.; Umetani, K. Direct observation of thermoelectric magnetic convection in unidirectionally solidified Al-Cu alloys. J. Iron Steel Res. Int. 2012, 19, 34–39. [Google Scholar]

- Wang, J.; Lin, X.; Fautrelle, Y.; Nguyen-Thi, H.; Ren, Z. Motion of solid grains during magnetic field-assisted directional solidification. Metall. Mater. Trans. B 2018, 49, 861–865. [Google Scholar] [CrossRef]

- Abou-Khalil, L.; Wang, J.; Salloum-Abou-Jaoude, G.; Garrido, M.; Li, X.; Ren, Z.; Reinhart, G.; Nguyen-Thi, H.; Fautrelle, Y. Investigation of thermo-electro-magnetic force on equiaxed grain motion during upward directional solidification. Int. J. Therm. Sci. 2019, 145, 106047. [Google Scholar] [CrossRef]

- Cai, B.; Kao, A.; Boller, E.; Magdysyuk, O.V.; Atwood, R.C.; Vo, N.T.; Pericleous, K.; Lee, P.D. Revealing the Mechanisms by Which Magneto-Hydrodynamics Disrupts Solidification Microstructures. Acta Mater. 2020, 196, 200–209. [Google Scholar] [CrossRef]

- Li, X.; Fautrelle, Y.; Gagnoud, A.; Moreau, R.; Du, D.; Ren, Z.; Lu, X. EBSD study on the effect of a strong axial magnetic field on the microstructure and crystallography of Al-Ni alloys during solidification. Metall. Mater. Trans. A 2016, 47, 1180–1197. [Google Scholar] [CrossRef]

- Shuai, S.; Lin, X.; Dong, Y.; Hou, L.; Liao, H.; Wang, J.; Ren, Z. Three dimensional dendritic morphology and orientation transition induced by high static magnetic field in directionally solidified Al-10 Wt.%Zn alloy. J. Mater. Sci. Technol. 2019, 35, 1587–1592. [Google Scholar] [CrossRef]

- Cao, J.; Shuai, S.; Huang, C.; Hu, T.; Chen, C.; Wang, J.; Ren, Z. 4D synchrotron X-Ray tomographic study of the influence of transverse magnetic field on iron intermetallic compounds precipitation behavior during solidification of Al-Si-Fe alloy. Intermetallics 2022, 143, 107471. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hou, Y.; Gao, Z.; Li, C. Solidification Processing of Metallic Materials in Static Magnetic Field: A Review. Metals 2022, 12, 1778. https://doi.org/10.3390/met12111778

Hou Y, Gao Z, Li C. Solidification Processing of Metallic Materials in Static Magnetic Field: A Review. Metals. 2022; 12(11):1778. https://doi.org/10.3390/met12111778

Chicago/Turabian StyleHou, Yuan, Zhanyong Gao, and Chuanjun Li. 2022. "Solidification Processing of Metallic Materials in Static Magnetic Field: A Review" Metals 12, no. 11: 1778. https://doi.org/10.3390/met12111778