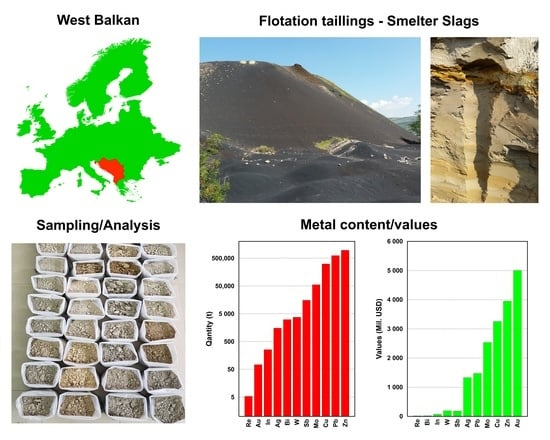

Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region

Abstract

:1. Introduction

2. Materials and Methods

2.1. Study Area

2.2. Data Collection

2.3. Laboratory Analysis

3. Results

3.1. Overview of Secondary Raw Deposits in the West Balkan Region

3.2. Potentially Prospective SRM Deposits

4. Discussion

4.1. Locations and Metals for Potential Recovery

4.2. Economical Potential of Historical Waste Landfills

4.3. Recovery Methods

4.4. Environmental Protection of Historical Waste Landfills

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- European Comission. Critical Raw Materials Resilience: Charting a Path towards greater Security and Sustainability; European Comission: Brussels, Belgium, 2021. [Google Scholar]

- Bobba, S.; Carrara, S.; Huisman, J.; Mathieux, F.; Pavel, C. Critical Raw Materials for Strategic Technologies and Sectors in the EU—A Foresight Study; Publications Office of the European Union: Luxembourg, 2020. [Google Scholar]

- Schüler, D. GREAT Insights; ECDPM: Mestreech, The Netherlands, 2017; pp. 40–42. [Google Scholar]

- EUROSTAT China-EU—International Trade in Goods Statistics. Available online: https://ec.europa.eu/eurostat (accessed on 28 March 2022).

- Spooren, J.; Binnemans, K.; Björkmalm, J.; Breemersch, K.; Dams, Y.; Folens, K.; González-Moya, M.; Horckmans, L.; Komnitsas, K.; Kurylak, W.; et al. Near-zero-waste processing of low-grade, complex primary ores and secondary raw materials in Europe: Technology development trends. Resour. Conserv. Recycl. 2020, 160, 104919. [Google Scholar] [CrossRef]

- Rankin, W.J. Towards zero waste. AusIMM Bull. 2015, 2015, 32–37. [Google Scholar] [CrossRef]

- Ranđelović, D.; Mutić, J.; Marjanović, P.; Đorđević, T.; Kašanin-Grubin, M. Geochemical distribution of selected elements in flotation tailings and soils/sediments from the dam spill at the abandoned antimony mine Stolice, Serbia. Environ. Sci. Pollut. Res. 2020, 27, 6253–6268. [Google Scholar] [CrossRef] [PubMed]

- Araya, N.; Kraslawski, A.; Cisternas, L.A. Towards mine tailings valorization: Recovery of critical materials from Chilean mine tailings. J. Clean. Prod. 2020, 263, 121555. [Google Scholar] [CrossRef]

- United Nations Sustainable Development Goals (SDGs). Available online: https://www.un.org/sustainabledevelopment/sustainable-development-goals/? (accessed on 12 April 2022).

- El Wali, M.; Golroudbary, S.R.; Kraslawski, A. Impact of recycling improvement on the life cycle of phosphorus. Chin. J. Chem. Eng. 2019, 27, 1219–1229. [Google Scholar] [CrossRef]

- Can Sener, S.E.; Thomas, V.M.; Hogan, D.E.; Maier, R.M.; Carbajales-Dale, M.; Barton, M.D.; Karanfil, T.; Crittenden, J.C.; Amy, G.L. Recovery of Critical Metals from Aqueous Sources. ACS Sustain. Chem. Eng. 2021, 9, 11616–11634. [Google Scholar] [CrossRef]

- Akinbile, B.J.; Makhubela, B.C.E.; Ambushe, A.A. Phytomining of valuable metals: Status and prospective-a review. Int. J. Environ. Anal. Chem. 2021, 2021, 1–21. [Google Scholar] [CrossRef]

- Zglinicki, K.; Szamałek, K.; Wołkowicz, S. Critical minerals from post-processing tailing. A case study from Bangka island, Indonesia. Minerals 2021, 11, 352. [Google Scholar] [CrossRef]

- Hefni, M.; Ahmed, H.A.M.; Omar, E.S.; Ali, M.A. The potential re-use of saudi mine tailings in mine backfill: A path towards sustainable mining in Saudi Arabia. Sustainability 2021, 13, 6204. [Google Scholar] [CrossRef]

- Rybak, J.; Adigamov, A.; Kongar-syuryun, C.; Khayrutdinov, M.; Tyulyaeva, Y. Renewable-resource technologies in mining and metallurgical enterprises providing environmental safety. Minerals 2021, 11, 1145. [Google Scholar] [CrossRef]

- European Comission—Directorate—General for Economic and Financial Affairs. The Western Balkans in Transition; European Commission: Brussels, Belgium, 2009. [Google Scholar]

- Dabrowski, M.; Myachenkova, Y. The Western Balkans on the Road to the European Union; European Commission: Bruegel, Brussels, 2018. [Google Scholar]

- Egerer, H.; Peck, P.; Sandei, P.C.; Simonett, O. Mining and Environment in the Western Balkans; Stuhlberge, C., Ed.; UNEP: Vienna, Austria, 2009. [Google Scholar]

- Féraud, J.; Deschamps, Y. French Scientific Cooperation 2007–2008 on the Trepča Lead- Zinc-Silver Mine and the Gold Potential of Novo Brdo/Artana Tailings (Kosovo); BRGM: Orléans, France, 2009. [Google Scholar]

- Veselaj, T.; Berisha, A.; Hyseni-Spahiu, M.; Gashi, P.; Bejta, S. Environmental Hotspots in Kosovo; Kosovo Environmental Protection Agency: Prishtinë, Kosovo, 2011. [Google Scholar]

- Peck, P.; Stuhlberger, C.; Tremblay, G.; Davé, N. Albanian Mining-Related Risks: Identification and Verification of “Mining Environmental Hot Spots"; UNEP: Lund, Sweden; Geneva, Switzerland; Ottawa, ON, Canada, 2008. [Google Scholar]

- Butterman, W.C.; Amey, E.B. Mineral Commodity Profiles—Gold; USGS: Reston, VA, USA, 2005. [Google Scholar]

- Butterman, W.C.; Hilliard, H.E. Mineral Commodity Profiles—Silver; USGS: Reston, VA, USA, 2004. [Google Scholar]

- Lusty, P.A.; Hannis, S.D. Commodity Profile: Copper; BGS: Nottingham, UK, 2009. [Google Scholar]

- Klochko, K. 2017 Minerals Yearbook Lead; USGS: Reston, VA, USA, 2021. [Google Scholar]

- Thomas, C.L. 2017 Minerals Yearbook Zinc; USGS: Reston, VA, USA, 2020. [Google Scholar]

- Désirée, P.E. 2018 Minerals Yearbook Molybdenum; USGS: Reston, VA, USA, 2018. [Google Scholar]

- Šajn, R.; Ristović, I.; Čeplak, B. Mining, processing and smelter waste landfills from Albania, Bosnia & Hercegovina, Montenegro, North Macedonia and Serbia as a potential source of valuable metals. Geol. Croat. 2022. submitted. [Google Scholar]

- Vuković, A.; Mandić, M.V. Study on Climate Change in the Western Balkans Region; Regional Cooperation Council Secretariat: Sarajevo, Bosnia and Herzegovina, 2018. [Google Scholar]

- Crampton, R.J. The Balkans Since the Second World War, 1st ed.; Routledge: Oxfordshire, UK, 2014. [Google Scholar]

- The World Bank GDP. Available online: https://www.worldbank.org/en/home (accessed on 12 April 2022).

- Čeperković, M.; Gaub, F. Balkan Futures Three Scenarios for 2025; Čeperković, M., Gaub, F., Eds.; EU Institute for Security Studies: Paris, France, 2018. [Google Scholar]

- Judah, T. Bye-Bye, Balkans: A Region in Critical Demographic Decline. Available online: https://balkaninsight.com/2019/10/14/bye-bye-balkans-a-region-in-critical-demographic-decline/ (accessed on 28 March 2022).

- Heinrich, C.A.; Neubauer, F. Cu-Au-Pb-Zn-Ag metallogeny of the Alpine-Balkan-Carpathian-Dinaride geodynamic province. Miner. Depos. 2002, 37, 533–540. [Google Scholar] [CrossRef]

- Reichl, C.; Schatz, M.; Zsak, G. World Mining Data 2020; Federal Ministry of Agriculture, Regions and Tourism: Vienna, Austria, 2020; Volume 35. [Google Scholar]

- Radusinović, S.; Jestrović, D. Circular Economy in mineral by-products management: Opportunities for resource recovery and LCA—Montenegro case. In Proceedings of the 1st International Slovenian Conference of Mining and Mineral Deposits, Ljubljana, Slovenia, 23–24 May 2019; pp. 1–19. [Google Scholar]

- Barandovski, L.; Stafilov, T.; Šajn, R.; Frontasyeva, M.; Andonovska, K.B. Atmospheric heavy metal deposition in North Macedonia from 2002 to 2010 studied by moss biomonitoring technique. Atmosphere 2020, 11, 929. [Google Scholar] [CrossRef]

- The Independent Commission for Mines and Minerals Mineral deposits. Available online: https://kosovo-mining.org/?lang=en (accessed on 12 April 2022).

- Website 1 Project RESEERVE. Available online: https://reseerve.eu/ (accessed on 12 March 2022).

- Website 2 Project RIS-CuRE. Available online: http://ris-cure.zag.si/ (accessed on 12 March 2022).

- Website 3 Project RECOVER. Available online: http://ris-recover.zag.si/ (accessed on 12 March 2022).

- Grieco, G.; Sinojmeri, A.; Bussolesi, M.; Cocomazzi, G.; Cavallo, A. Environmental impact variability of copper tailing dumps in fushe arrez (Northern albania): The role of pyrite separation during flotation. Sustainability 2021, 13, 9643. [Google Scholar] [CrossRef]

- Bureau Veritas Commodities Canada Ltd. Mining Laboratory Services. Available online: https://www.bvna.com/mining-laboratory-services (accessed on 23 March 2022).

- Statisica Mining, Metals & Minerals. Available online: https://www.statista.com/ (accessed on 12 April 2022).

- Chemical Elements. Available online: www.britannica.com (accessed on 1 March 2022).

- Stafilov, T.; Šajn, R. Geochemical atlas of the Republic of Macedonia; Faculty of Natural Sciences and Mathematics, Ss. Cyril and Methodius University, Skopje, Republic of Macedonia: Skopje, North Macedonia, 2016; ISBN 978-608-4762-04-1. [Google Scholar]

- Wang, R.; Li, H.; Sun, H. Bismuth: Environmental pollution and health effects. In Encyclopedia of Environmental Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 415–423. [Google Scholar]

- Koutsospyros, A.D.; Koutsospyros, D.A.; Strigul, N.; Braida, W.; Christodoulatos, C. Tungsten: Environmental pollution and health effects. In Encyclopedia of Environmental Health; Elsevier: Amsterdam, The Netherlands, 2019; pp. 161–169. [Google Scholar]

- Barceloux, D.G.; Barceloux, D. Molybdenum. J. Toxicol. Clin. Toxicol. 1999, 37, 231–237. [Google Scholar] [CrossRef]

- Leybourne, M.I.; Cameron, E.M. Source, transport, and fate of rhenium, selenium, molybdenum, arsenic, and copper in groundwater associated with porphyry-Cu deposits, Atacama Desert, Chile. Chem. Geol. 2008, 247, 208–228. [Google Scholar] [CrossRef]

- John, D.A.; Seal, R.R.I.; Polyak, D.E. Rhenium, Chapter P of Critical mineral resources of the United States. In Economic and Environmental Geology and Prospects for Future Supply; Schulz, K.J., DeYoung, J.H., Seal, R.R., II, Bradley, D.C., Eds.; U.S. Geological Survey: Reston, VA, USA, 2017; pp. 1–49. [Google Scholar]

- Kesler, S.E.; Chryssoulis, S.L.; Simon, G. Gold in porphyry copper deposits: Its abundance and fate. Ore Geol. Rev. 2002, 21, 103–124. [Google Scholar] [CrossRef]

- Titley, S.R. Characteristics of high-temperature, carbonate-hosted replacement ores and some comparisons with Mississippi Valley-type ores. Soc. Econ. Geol. Spec. Publ. 1996, 4, 244–254. [Google Scholar]

- Wang, D.; Mathur, R.; Zheng, Y.; Qiu, K.; Wu, H. Redox-controlled antimony isotope fractionation in the epithermal system: New insights from a multiple metal stable isotopic combination study of the Zhaxikang Sb–Pb–Zn–Ag deposit in Southern Tibet. Chem. Geol. 2021, 584, 120541. [Google Scholar] [CrossRef]

- Website 4 Trading Economics. Available online: https://tradingeconomics.com/commodities (accessed on 28 March 2022).

- Website 5 Shanghai Metals Market (SMM). Available online: https://www.metal.com/price/ (accessed on 28 March 2022).

- Website 6 USGS. Available online: https://www.usgs.gov/ (accessed on 28 March 2022).

- Website 7 Metalary. Available online: https://www.metalary.com/ (accessed on 28 March 2022).

- Matinde, E.; Simate, G.S.; Ndlovu, S. Mining and metallurgical wastes: A review of recycling and re-use practices. J. S. Afr. Inst. Min. Metall. 2018, 118, 825–844. [Google Scholar] [CrossRef]

- Gomez, D.V.; Salgado, E.S.; Mejías, O.; Pat-Espadas, A.M.; Pinedo Torres, L.A.; Jackson, L.; Parbhakar-Fox, A. Data Integration of Critical Elements from Mine Waste in Mexico, Chile and Australia. Minerals 2022, 12, 122. [Google Scholar]

- Araya, N.; Ramírez, Y.; Kraslawski, A.; Cisternas, L.A. Feasibility of re-processing mine tailings to obtain critical raw materials using real options analysis. J. Environ. Manag. 2021, 284, 112060. [Google Scholar] [CrossRef] [PubMed]

- Gutiérrez-Gutiérrez, S.C.; Coulon, F.; Jiang, Y.; Wagland, S. Rare earth elements and critical metal content of extracted landfilled material and potential recovery opportunities. Waste Manag. 2015, 42, 128–136. [Google Scholar] [CrossRef]

- Krishnan, S.; Zulkapli, N.S.; Kamyab, H.; Taib, S.M.; Din, M.F.B.M.; Majid, Z.A.; Chaiprapat, S.; Kenzo, I.; Ichikawa, Y.; Nasrullah, M.; et al. Current technologies for recovery of metals from industrial wastes: An overview. Environ. Technol. Innov. 2021, 22, 101525. [Google Scholar] [CrossRef]

- Altinkaya, P.; Liipo, J.; Kolehmainen, E.; Haapalainen, M.; Leikola, M.; Lundström, M. Leaching of Trace Amounts of Metals from Flotation Tailings in Cupric Chloride Solutions. Min. Metall. Explor. 2019, 36, 335–342. [Google Scholar] [CrossRef]

- Xiang, J.; Huang, Q.; Lv, W.; Pei, G.; Lv, X.; Bai, C. Recovery of tailings from the vanadium extraction process by carbothermic reduction method: Thermodynamic, experimental and hazardous potential assessment. J. Hazard. Mater. 2018, 357, 128–137. [Google Scholar] [CrossRef] [PubMed]

- Syed, S. Recovery of gold from secondary sources-A review. Hydrometallurgy 2012, 115–116, 30–51. [Google Scholar] [CrossRef]

- Rossini, G.; Bernardes, A.M. Galvanic sludge metals recovery by pyrometallurgical and hydrometallurgical treatment. J. Hazard. Mater. 2006, 131, 210–216. [Google Scholar] [CrossRef] [PubMed]

- Gunarathne, V.; Rajapaksha, A.U.; Vithanage, M.; Alessi, D.S.; Selvasembian, R.; Naushad, M.; You, S.; Oleszczuk, P.; Ok, Y.S. Hydrometallurgical processes for heavy metals recovery from industrial sludges. Crit. Rev. Environ. Sci. Technol. 2022, 52, 1022–1062. [Google Scholar] [CrossRef]

- Krebs, W.; Brombacher, C.; Bosshard, P.P.; Bachofen, R.; Brandl, H. Microbial recovery of metals from solids. FEMS Microbiol. Rev. 1997, 20, 605–617. [Google Scholar] [CrossRef]

- Sethurajan, M.; van Hullebusch, E.D.; Nancharaiah, Y.V. Biotechnology in the management and resource recovery from metal bearing solid wastes: Recent advances. J. Environ. Manag. 2018, 211, 138–153. [Google Scholar] [CrossRef] [PubMed]

- Peiravi, M.; Dehghani, F.; Ackah, L.; Baharlouei, A.; Godbold, J.; Liu, J.; Mohanty, M.; Ghosh, T. A Review of Rare-Earth Elements Extraction with Emphasis on Non-conventional Sources: Coal and Coal Byproducts, Iron Ore Tailings, Apatite, and Phosphate Byproducts. Min. Metall. Explor. 2021, 38, 1–26. [Google Scholar] [CrossRef]

- Susaj, E.; Kucaj, E.; Laçi, E.; Susaj, L. Environmental Impacts Assessment of Chromium Minings in Bulqiza Area, Albania. Eur. J. Interdiscip. Stud. 2017, 9, 35–41. [Google Scholar] [CrossRef]

- Alijagić, J.; Šajn, R.; Rokavec, D. Impact assessment of mining and metallurgical activities on the distribution of trace elements in the Stavnja Valley, Bosnia and Herzegovina. Int. J. Energy Environ. Econ. 2015, 23, 351–412. [Google Scholar]

- Paçarizi, M.; Stafilov, T.; Šajn, R.; Tašev, K.; Sopaj, F. Estimation of Elements’ Concentration in Air in Kosovo through Mosses as Biomonitors. Atmosphere 2021, 12, 415. [Google Scholar] [CrossRef]

- Mihailovski, S.; Mircovski, V.; Ilijovski, Z. Pollution with Cr6+ of groundwater and surface water from the industrial dump jugohrom-jegunovce—The Republic of North Macedonia. Rud. Geol. Naft. Zb. 2021, 36, 121–129. [Google Scholar] [CrossRef]

- Krivokapić, M. Study on the evaluation of (Heavy) metals in water and sediment of skadar lake (montenegro), with bcf assessment and translocation ability (ta) by trapa natans and a review of sdgs. Water 2021, 13, 876. [Google Scholar] [CrossRef]

- Japan International Cooperation Agency; Ministry of Agriculture Forestry and Water Economy; Former Yugoslav Republic of Macedonia. The Study on Capacity Development for Soil Contamination Management Related to Mining in the Former Yugoslav Republic of Macedonia, Final Report Volume II Main Report; Japan International Cooperation Agency: Tokyo, Japan, March 2008.

- UNEP. From Conflict to Sustainable Development Assessment of Environmental Hot Spots Serbia and Montenegro; UNEP: Geneva, Switzerland, 2004; Available online: https://reliefweb.int/sites/reliefweb.int/files/resources/assessment_0.pdf (accessed on 18 March 2022).

- Jusufi, G.; Ukaj, M. Migration and economic development in Western Balkan countries: Evidence from Kosovo. Posl. Izvr.-Bus. Excell. 2020, 14, 135–158. [Google Scholar] [CrossRef]

- Zeneli, V. Economic Development in the Western Balkans: On the Road to Competitive Market Economies? Connect. Q. J. 2014, 13, 53–64. [Google Scholar] [CrossRef]

| Location | Remark | Country | Deposit Type | Deposit Status | Main Elements | Surface (ha) | Quantity (Mt) | Element |

|---|---|---|---|---|---|---|---|---|

| Fushë Arrëz | 8 | Albania | FT | Abandoned | Cu | 19 | 3.1 | Au, Cu |

| Kukës | 4 | Albania | SSL | Abandoned | Cu | 13 | 3 | Cu |

| Rehove | 4 | Albania | FT | Abandoned | Cu | 4 | 0.6 | Cu |

| Reps | 4 | Albania | FT | Abandoned | Cu | 5 | 3.7 | Cu |

| Rreshen | 4 | Albania | FT | Abandoned | Cu | 3 | 0.5 | Cu |

| Sase I | 1 | B and H | FT | Abandoned | Pb/Zn | 6 | 1 | - |

| Sase II | 1 | B and H | FT | Active | Pb/Zn | 4 | 1 | Zn |

| Veovača | 1 | B and H | FT | Abandoned | Pb/Zn | 6 | 2 | Ag |

| Badovac | 6 | Kosovo * | FT | Abandoned | Pb/Zn | 9 | 8 | Ag, Au, Pb |

| Kišnica | 5 | Kosovo * | FT | Abandoned | Pb/Zn | 49 | 2 | Ag, Au, Bi, Pb, Zn |

| Leposavić I | 6 | Kosovo * | FT | Abandoned | Pb/Zn | 12 | 2.7 | - |

| Leposavić II | 6 | Kosovo * | FT | Active | Pb/Zn | 21 | 3.7 | - |

| Novo Brdo | 5 | Kosovo * | FT | Abandoned | Pb/Zn | 3 | 0.5 | Ag, Au, Pb, Zn |

| Gornje polje I | 6 | Kosovo * | FT | Abandoned | Pb/Zn | 26 | 9 | Au |

| Gornje polje II | 6 | Kosovo * | FT | Abandoned | Pb/Zn | 32 | 11 | Ag, Au, Bi, Pb, W |

| Gornje Polje III | 6 | Kosovo * | SSL | Abandoned | Pb/Zn | 6 | 2.5 | Ag, Bi, Cu, Pb, Sb, Zn |

| Žarkov potok | 5 | Kosovo * | FT | Abandoned | Pb/Zn | 23 | 10 | Ag, Au, Bi, Zn |

| Žitkovac | 6 | Kosovo * | FT | Abandoned | Pb/Zn | 28 | 12 | Ag, Au, Bi, Pb, W |

| K. Mitrovica | 6 | Kosovo * | SSL | Abandoned | Pb/Zn | 29 | 3 | Ag, Au, Bi |

| Gradac | 3 | Montenegro | FT | Abandoned | Pb/Zn | 13 | 3 | - |

| Probištip I | 2 | N. Macedonia | FT | Abandoned | Pb/Zn | 24 | 7 | Ag, In, Pb, Zn |

| Probištip II | 2 | N. Macedonia | FT | Abandoned | Pb/Zn | 40 | 12 | Ag, Au |

| Probištip III | 2 | N. Macedonia | FT | Active | Pb/Zn | 33 | 11 | - |

| Sasa I | 2 | N. Macedonia | FT | Abandoned | Pb/Zn | 12 | 5 | - |

| Sasa II | 2 | N. Macedonia | FT | Abandoned | Pb/Zn | 12 | 5 | - |

| Sasa III | 2 | N. Macedonia | FT | Active | Pb/Zn | 23 | 10 | Pb |

| Toranica | 2 | N. Macedonia | FT | Active | Pb/Zn | 14 | 10 | Pb |

| Veles | 3 | N. Macedonia | SSL | Abandoned | Pb/Zn | 4 | 1.8 | Ag, Cu, In, Pb, Zn |

| Lojane | 2 | N. Macedonia | FT | Abandoned | Sb | 2 | 0.5 | Sb |

| Bor I | 3 | Serbia | FT | Abandoned | Cu | 18 | 8 | Au, Cu |

| Bor II | 3 | Serbia | FT | Abandoned | Cu | 37 | 22 | Au, Cu |

| Bor III | 1 | Serbia | FT | Active | Cu | 71 | 50 | Cu, Mo, Re, Zn |

| Bor IV | - | Serbia | SSL | Active | Cu | 19 | 15 | - |

| Bor V | - | Serbia | SSL | Active | Cu | 9 | 2 | - |

| Grot | 1 | Serbia | FT | Active | Pb/Zn | 26 | 5.5 | - |

| Lece | 7 | Serbia | FT | Active | Pb/Zn | 23 | 2.7 | Au, In, Zn |

| Rudnica I | 1 | Serbia | FT | Abandoned | Pb/Zn | 11 | 3 | Cu |

| Rudnica II | - | Serbia | FT | Abandoned | Pb/Zn | 9 | 2.5 | - |

| Rudnik | 1 | Serbia | FT | Active | Pb/Zn | 41 | 8.7 | Ag, Pb |

| Veliki Majdan I | - | Serbia | FT | Abandoned | Pb/Zn | 2 | 0.8 | - |

| Veliki Majdan II | - | Serbia | FT | Active | Pb/Zn | 3 | 1.1 | - |

| Zajača | 1 | Serbia | SSL | Closed | Sb | 5 | 0.6 | Ag, Sb |

| Location | Remark | Ag (g/t) | Au (g/t) | Bi (g/t) | Cu (%) | In (g/t) | Mo (g/t) | Pb (%) | Re (g/t) | Sb (g/t) | W (g/t) | Zn (%) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fushë Arrëz | 8 | 1.6 | 0.79 | - | 0.18 | - | 9.0 | <0.10 | - | 6.1 | - | <0.10 |

| Kukës | 4 | - | - | - | 0.17 | - | - | - | - | - | - | - |

| Rehove | 4 | - | - | - | 0.15 | - | - | - | - | - | - | - |

| Reps | 4 | - | - | - | 0.18 | - | - | - | - | - | - | - |

| Rreshen | 4 | - | - | - | 0.18 | - | - | - | - | - | - | - |

| Sase I | 1 | 6.3 | 0.09 | 3.6 | <0.01 | 1.3 | 1.2 | 0.27 | <0.01 | 150 | 16 | 0.27 |

| Sase II | 1 | 4.1 | 0.04 | 1.3 | <0.01 | 1.3 | 1.1 | 0.23 | <0.01 | 260 | 6.9 | 0.51 |

| Veovača | 1 | 33 | 0.07 | <1.0 | 0.02 | <0.10 | 3.2 | 0.36 | <0.01 | 240 | 1.0 | 0.46 |

| Badovac | 6 | 15 | 0.57 | 22 | 0.02 | 6.6 | <1.0 | 0.59 | <0.01 | 66 | 31 | 0.32 |

| Kišnica | 5 | 26 | 2.3 | 52 | 0.06 | 6.6 | 8.0 | 0.59 | - | 120 | 16 | 1.4 |

| Leposavić I | 6 | 6.8 | 0.09 | 7.4 | 0.01 | 1.8 | 1.4 | 0.39 | <0.01 | 110 | 8.5 | 0.16 |

| Leposavić II | 6 | - | - | - | - | - | - | - | - | - | - | - |

| Novo Brdo | 5 | 19 | 2.5 | 44 | 0.04 | 3.9 | 8.0 | 0.52 | - | 120 | 10 | 1.1 |

| Gornje polje I | 6 | 5.0 | 0.95 | 24 | 0.05 | 2.4 | <1.0 | 0.21 | <0.01 | 170 | 88 | 0.17 |

| Gornje polje II | 6 | 13 | 0.82 | 64 | 0.02 | 2.6 | 1.4 | 0.60 | <0.01 | 330 | 120 | 0.29 |

| Gornje Polje III | 6 | 86 | 0.06 | 77 | 0.27 | 6.8 | 38 | 5.1 | <0.01 | 1100 | 47 | 8.0 |

| Žarkov potok | 5 | 10 | 0.21 | 60 | 0.05 | 3.3 | 8.0 | 0.37 | - | 100 | 64 | 1.3 |

| Žitkovac | 6 | 23 | 1.9 | 100 | 0.01 | 1.4 | 5.2 | 0.87 | <0.01 | 240 | 200 | 0.10 |

| K. Mitrovica | 6 | 13 | 0.80 | 84 | 0.07 | 1.6 | 1.9 | 0.38 | <0.01 | 97 | 37 | 0.26 |

| Gradac | 3 | 3.2 | 0.08 | 4.2 | 0.03 | 0.22 | <1.0 | 0.19 | <0.01 | 21 | 5.2 | 0.41 |

| Probištip I | 2 | 21 | 0.08 | 6.7 | 0.04 | 13 | 9.5 | 0.68 | <0.01 | 39 | 5.0 | 0.58 |

| Probištip II | 2 | 11 | 0.10 | 4.3 | 0.02 | 6.6 | 7.1 | 0.25 | <0.01 | 22 | 5.0 | 0.13 |

| Probištip III | 2 | 7.7 | 0.04 | 2.4 | 0.02 | 5.4 | 6.1 | 0.30 | <0.01 | 17 | 4.6 | 0.30 |

| Sasa I | 2 | 4.3 | 0.01 | 9.9 | 0.02 | 1.1 | 4.3 | 0.33 | <0.01 | 7.0 | 14 | 0.36 |

| Sasa II | 2 | 5.0 | 0.07 | 16 | 0.02 | 2.0 | 5.7 | 0.33 | <0.01 | 6.0 | 19 | 0.36 |

| Sasa III | 2 | 4.4 | 0.01 | 9.7 | 0.03 | 1.3 | 2.7 | 0.57 | <0.01 | 7.8 | 23 | 0.36 |

| Toranica | 2 | 4.4 | <0.01 | 9.8 | 0.03 | 2.7 | 5.0 | 0.66 | 0.010 | 8.2 | 17 | 0.37 |

| Veles | 3 | 39 | 0.07 | 35 | 0.70 | 67 | 44 | 2.5 | <0.01 | 450 | 23 | 8.3 |

| Lojane | 2 | 0.13 | <0.01 | 0.24 | <0.01 | <0.10 | 100 | <0.10 | 0.01 | 12,000 | 43.6 | <0.10 |

| Bor I | 3 | 2.0 | 0.52 | 1.4 | 0.36 | 0.30 | 46 | <0.10 | <0.01 | 8.5 | 4.8 | <0.10 |

| Bor II | 3 | 1.1 | 0.27 | 1.4 | 0.16 | <0.10 | 7.6 | <0.10 | <0.01 | 2.9 | 5.4 | <0.10 |

| Bor III | 1 | <1.0 | 0.05 | 3.1 | 0.40 | 4.6 | 1100 | 0.12 | 0.11 | 120 | 9.4 | 0.79 |

| Bor IV | - | - | - | - | - | - | - | - | - | - | - | |

| Bor V | - | - | - | - | - | - | - | - | - | - | - | |

| Grot | 1 | 1.0 | 0.03 | <1.0 | <0.01 | 0.13 | 5.1 | 0.37 | <0.01 | 4.9 | 19 | 0.27 |

| Lece | 7 | 5.3 | 1.2 | - | 0.04 | 17 | - | 0.14 | - | - | - | 0.55 |

| Rudnica I | 1 | 1.4 | 0.01 | 15 | 0.19 | 7.0 | 6.8 | <0.10 | <0.01 | 4.7 | 71 | <0.10 |

| Rudnica II | - | - | - | - | - | - | - | - | - | - | - | - |

| Rudnik | 1 | 15 | <0.01 | 48 | 0.08 | 0.37 | <1.0 | 0.50 | <0.01 | 16 | 78 | 0.44 |

| Veliki Majdan I | - | - | - | - | - | - | - | - | - | - | - | - |

| Veliki Majdan II | - | - | - | - | - | - | - | - | - | - | - | - |

| Zajača | 1 | 14 | 0.19 | <1.0 | 0.02 | <0.10 | 5.7 | <0.10 | <0.01 | 11,000 | 0.3 | 0.11 |

| Location | Remark | Ag (t) | Au (t) | Bi (t) | Cu (Kt) | In (t) | Mo (Kt) | Pb (Kt) | Re (t) | Sb (Kt) | W (Kt) | Zn (Kt) |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Fushë Arrëz | 8 | - | 2.4 | - | 5.9 | - | - | - | - | - | - | - |

| Kukës | 4 | - | - | - | 5.1 | - | - | - | - | - | - | - |

| Rehove | 4 | - | - | - | <1.0 | - | - | - | - | - | - | - |

| Reps | 4 | - | - | - | 6.7 | - | - | - | - | - | - | - |

| Rreshen | 4 | - | - | - | <1.0 | - | - | - | - | - | - | - |

| Sase I | 1 | - | - | - | - | - | - | - | - | - | - | - |

| Sase II | 1 | - | - | - | - | - | - | - | - | - | - | 5.1 |

| Veovača | 1 | 65 | - | - | - | - | - | - | - | - | - | - |

| Badovac | 6 | 120 | 4.6 | - | - | - | - | 47 | - | - | - | - |

| Kišnica | 5 | 52 | 4.7 | 100 | - | - | - | 12 | - | - | - | 27 |

| Leposaviæ I | 6 | - | - | - | - | - | - | - | - | - | - | - |

| Leposaviæ II | 6 | - | - | - | - | - | - | - | - | - | - | - |

| Novo Brdo | 5 | 10 | 1.3 | - | - | - | - | 2.6 | - | - | - | 5.3 |

| Gornje polje I | 6 | - | 8.5 | - | - | - | - | - | - | - | - | - |

| Gornje polje II | 6 | 140 | 9.0 | 710 | - | - | - | 66 | - | - | 1.3 | - |

| Gornje Polje III | 6 | 220 | - | 190 | 6.7 | - | - | 130 | - | 2.7 | - | 200 |

| Žarkov potok | 5 | 100 | 2.1 | 600 | - | - | - | - | - | - | - | 130 |

| Žitkovac | 6 | 270 | 23 | 1200 | - | - | - | 100 | - | - | 2.4 | - |

| K. Mitrovica | 6 | 40 | 2.4 | 250 | - | - | - | - | - | - | - | - |

| Gradac | 3 | - | - | - | - | - | - | - | - | - | - | - |

| Probištip I | 2 | 150 | - | - | - | 89 | - | 48 | - | - | - | 41 |

| Probištip II | 2 | 130 | 1.2 | - | - | - | - | - | - | - | - | - |

| Probištip III | 2 | - | - | - | - | - | - | - | - | - | - | - |

| Sasa I | 2 | - | - | - | - | - | - | - | - | - | - | - |

| Sasa II | 2 | - | - | - | - | - | - | - | - | - | - | - |

| Sasa III | 2 | - | - | - | - | - | - | 57 | - | - | - | - |

| Toranica | 2 | - | - | - | - | - | - | 66 | - | - | - | - |

| Veles | 3 | 71 | - | - | 13 | 120 | - | 45 | - | - | - | 150 |

| Lojane | 2 | - | - | - | - | - | - | - | - | 6.0 | - | - |

| Bor I | 3 | - | 4.2 | - | 29 | - | - | - | - | - | - | - |

| Bor II | 3 | - | 6.0 | - | 36 | - | - | - | - | - | - | - |

| Bor III | 1 | - | - | - | 200 | - | 55 | - | 5.3 | - | - | 390 |

| Bor IV | - | - | - | - | - | - | - | - | - | - | - | |

| Bor V | - | - | - | - | - | - | - | - | - | - | - | - |

| Grot | 1 | - | - | - | - | - | - | - | - | - | - | - |

| Lece | 7 | - | 3.3 | - | - | 46 | - | - | - | - | - | 15 |

| Rudnica I | 1 | - | - | - | 5.8 | - | - | - | - | - | - | - |

| Rudnica II | - | - | - | - | - | - | - | - | - | - | - | - |

| Rudnik | 1 | 130 | - | - | - | - | - | 44 | - | - | - | - |

| Veliki Majdan I | - | - | - | - | - | - | - | - | - | - | - | - |

| Veliki Majdan II | - | - | - | - | - | - | - | - | - | - | - | - |

| Zajača | 1 | 8.5 | 0.1 | - | - | - | - | - | - | 6.6 | - | - |

| WB | 1500 | 73 | 3100 | 310 | 260 | 55 | 620 | 5.3 | 15 | 3.7 | 970 |

| Element | Metal (t) | Rate (USD/kg) | Millions USD | ||||

|---|---|---|---|---|---|---|---|

| 2000 | 2020 | 2022 | 2000 | 2020 | 2022 | ||

| Ag 1 | 1500 | 192 | 463 | 884 | 289 | 698 | 1330 |

| Au 1 | 73 | 10,300 | 53,900 | 68,600 | 752 | 3940 | 5010 |

| Bi 2 | 3100 | 6.0 | 7.72 | 7.17 | 18 | 24 | 22 |

| Cu 1 | 310,000 | 1.27 | 4.81 | 10.5 | 394 | 1490 | 3260 |

| In 2 | 260 | 188 | 220 | 299 | 48 | 56 | 76 |

| Mo 1 | 55,000 | 5.90 | 24.8 | 45.8 | 327 | 1370 | 2540 |

| Pb 1 | 620,000 | 0.387 | 1.57 | 2.38 | 240 | 972 | 1470 |

| Re 2 | 5.3 | 1110 | 1030 | 3550 | 6 | 5 | 19 |

| Sb 2 | 15,000 | 1.50 | 5.87 | 12.8 | 23 | 90 | 196 |

| W 2 | 3700 | 8.20 | 30.3 | 49.3 | 30 | 113 | 183 |

| Zn 1 | 970,000 | 1.08 | 1.91 | 4.10 | 1040 | 1840 | 3950 |

| SUM | 3170 | 10,600 | 18,100 | ||||

| Element | Albania | B and H | N. Macedonia | Kosovo * | Serbia |

|---|---|---|---|---|---|

| Ag | - | 58 | 309 | 842 | 124 |

| Au | 168 | 369 | 85 | 3830 | 934 |

| Bi | - | - | - | 22 | - |

| Cu | 201 | - | 132 | 70 | 2850 |

| In | - | - | 62 | - | 14 |

| Mo | - | - | - | - | 2540 |

| Pb | - | - | 514 | 856 | 104 |

| Re | - | - | - | - | 19 |

| Sb | - | - | 77 | 35 | 84 |

| W | - | - | - | 183 | - |

| Zn | - | 21 | 781 | 1480 | 1670 |

| SUM | 369 | 448 | 1960 | 7310 | 8340 |

| Method(s) | Metals | Results | Ref. | |

|---|---|---|---|---|

| 1 | chloride leaching | gold, copper, cobalt, nickel, and zinc | final extraction increased up to Cu (98%), Ni (93%), Zn (83%), Co (76%), and Fe (80%). | [64] |

| 2 | carbothermic reduction method | tailings from the vanadium extraction process | final extraction increased up to V (90%) and Cr (95%) | [65] |

| 3 | varieties of leaching, cementing, reducing agents, peeling, coagulants, adsorbents, agglomeration solvents, ion exchange resins, and biosorbents | gold from secondary sources | gold | [66] |

| 4 | - | copper, zinc and nickel and the sulfating agent used was pyrite, from coal wastes | Cu, Zn, Ni | [67] |

| 5 | pyrometallurgical, electrometallurgical, hydrometallurgical bioleaching (chemical leaching, acid leaching, alkaline leaching, thiosulfate leaching, thiourea leaching, halide leaching, cyanide leaching | industrial sludge | Ni, Cu, Zn, Cr, Mn, Fe | [68] |

| 6 | review methods | industrials wastes | Cu, Cr, V, Zn, Pb, Co, itd. | [69] |

| 7 | biohydrometallurgy biorecovery (bioprecipitation, biosorption, bioreduction, bioaccumulation) | sludges, dusts, residues, slags, red mud, and tailing wastes | [70] | |

| 8 | review methods | coal and coal combustion byproducts | REE 90–99.8% | [71] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Šajn, R.; Ristović, I.; Čeplak, B. Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region. Minerals 2022, 12, 547. https://doi.org/10.3390/min12050547

Šajn R, Ristović I, Čeplak B. Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region. Minerals. 2022; 12(5):547. https://doi.org/10.3390/min12050547

Chicago/Turabian StyleŠajn, Robert, Ivica Ristović, and Barbara Čeplak. 2022. "Mining and Metallurgical Waste as Potential Secondary Sources of Metals—A Case Study for the West Balkan Region" Minerals 12, no. 5: 547. https://doi.org/10.3390/min12050547