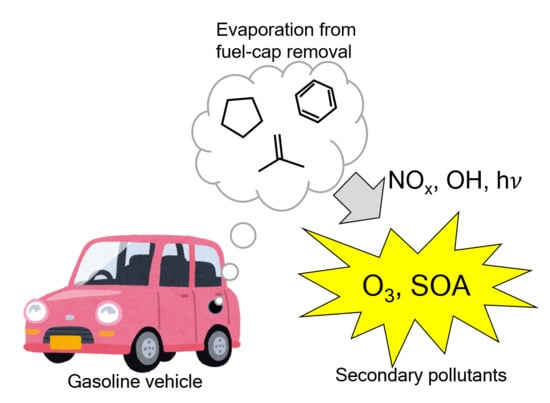

Evaluation of Gasoline Evaporative Emissions from Fuel-Cap Removal after a Real-World Driving Event

Abstract

:1. Introduction

2. Methodology

2.1. Measurement of Puff Loss Emissions

2.2. Composition of VOCs

2.3. Puff Loss Estimation Model

2.3.1. Estimation of VOC Composition in Puff Loss Emissions

2.3.2. Estimation of the Quantity of Puff Loss Emissions

3. Results and Discussion

3.1. Puff Loss Emissions from Real-World Driving

3.2. Temporal Profiles of Fuel Tank Temperature

3.3. VOC Compositions of Liquid Fuel and Puff Loss Emissions

4. Puff Loss Estimation Model

4.1. Accuracy of the Puff Loss Estimation Model

4.2. Sensitivity Analysis of the Puff Loss Estimation Model

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Manufacturer | Toyota |

|---|---|

| Vehicle type | Cargo |

| Engine | Regular gasoline port injection with in-line four-cylinder |

| Vehicle weight (kg) | 1760 |

| Displacement (L) | 1.998 |

| Fuel tank volume (L) | 70 |

| Carbon Number | n-Alkane | iso-Alkane | Alkenes | Naphthene | Aromatics | Total |

|---|---|---|---|---|---|---|

| C3 | 0.02 | - | 0.00 | - | - | 0.02 |

| C4 | 1.87 | 0.81 | 0.83 | - | - | 3.51 |

| C5 | 5.82 | 9.80 | 4.73 | 0.37 | - | 20.72 |

| C6 | 4.56 | 9.73 | 3.45 | 2.32 | 0.50 | 20.56 |

| C7 | 1.61 | 6.96 | 2.67 | 2.23 | 6.53 | 20.00 |

| C8 | 0.47 | 3.15 | 1.63 | 1.42 | 5.19 | 11.86 |

| C9 | 0.19 | 1.88 | 0.49 | 0.77 | 5.93 | 9.26 |

| C10 | 0.13 | 1.24 | 0.38 | 0.17 | 2.92 | 4.84 |

| C11 | 0.10 | 0.62 | 0.14 | 0.07 | 1.03 | 1.96 |

| C12 | 0.04 | 0.31 | 0.05 | 0.00 | 0.16 | 0.56 |

| C13 | 0.02 | 0.02 | 0.00 | 0.00 | 0.00 | 0.04 |

| Total | 14.83 | 34.52 | 14.37 | 7.35 | 22.26 | 93.33 |

| Carbon Number | n-Alkane | iso-Alkane | Alkenes | Naphthene | Aromatics | Total |

|---|---|---|---|---|---|---|

| C3 | 0.02 | - | 0.00 | - | - | 0.02 |

| C4 | 2.05 | 0.92 | 0.99 | - | - | 3.96 |

| C5 | 4.50 | 8.55 | 4.38 | 0.28 | - | 17.71 |

| C6 | 4.67 | 11.97 | 3.39 | 2.21 | 0.45 | 22.69 |

| C7 | 2.06 | 8.98 | 2.26 | 2.04 | 7.87 | 23.21 |

| C8 | 0.46 | 2.74 | 2.77 | 1.33 | 5.48 | 12.78 |

| C9 | 0.16 | 1.55 | 0.59 | 0.73 | 5.59 | 8.62 |

| C10 | 0.10 | 1.05 | 0.33 | 0.13 | 2.02 | 3.63 |

| C11 | 0.06 | 0.53 | 0.11 | 0.05 | 0.54 | 1.29 |

| C12 | 0.02 | 0.12 | 0.05 | 0.00 | 0.05 | 0.24 |

| C13 | 0.01 | 0.00 | 0.00 | 0.00 | 0.00 | 0.01 |

| Total | 14.11 | 36.41 | 14.87 | 6.77 | 22.00 | 94.16 |

| Carbon Number | n-Alkane | iso-Alkane | Alkenes | Naphthene | Aromatics | Total |

|---|---|---|---|---|---|---|

| C3 | 0.07 | - | 0.01 | - | - | 0.08 |

| C4 | 4.05 | 3.33 | 2.62 | - | - | 10.00 |

| C5 | 4.97 | 9.17 | 4.71 | 0.66 | - | 19.51 |

| C6 | 4.16 | 10.84 | 3.24 | 2.35 | 0.50 | 21.09 |

| C7 | 1.55 | 7.16 | 2.13 | 1.99 | 6.45 | 19.28 |

| C8 | 0.42 | 2.66 | 2.32 | 1.27 | 3.84 | 10.51 |

| C9 | 0.16 | 1.66 | 0.50 | 0.64 | 5.04 | 8.00 |

| C10 | 0.10 | 1.05 | 0.28 | 0.12 | 2.00 | 3.55 |

| C11 | 0.06 | 0.55 | 0.10 | 0.05 | 0.48 | 1.24 |

| C12 | 0.02 | 0.12 | 0.12 | 0.00 | 0.05 | 0.31 |

| C13 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 | 0.00 |

| Total | 15.56 | 36.54 | 16.03 | 7.08 | 18.36 | 93.57 |

| Organic Compound | Experimental Month | |||

|---|---|---|---|---|

| July 2019 (SGG) 1 | December 2019 (SGG) 1 | December 2019 (WGG) 2 | April 2020 (WGG) 2 | |

| ethane | 0.40 | 0.13 | 0.09 | 0.26 |

| ethylene | 0.64 | 0.00 | 0.00 | 0.15 |

| propane | 0.23 | 1.22 | 1.50 | 1.16 |

| propylene | 0.00 | 0.08 | 0.22 | 0.24 |

| acetylene | 0.00 | 0.00 | 0.00 | 0.12 |

| isobutane | 4.80 | 13.03 | 26.18 | 22.07 |

| n-butane | 8.15 | 17.04 | 19.65 | 16.63 |

| trans-2-butene | 2.13 | 5.66 | 11.52 | 7.97 |

| 1-butene | 0.46 | 1.32 | 1.24 | 1.50 |

| isobutene | 0.58 | 1.42 | 0.63 | 1.51 |

| cis-2-butene | 1.46 | 3.79 | 5.75 | 4.09 |

| isopentane | 24.16 | 26.07 | 18.52 | 15.42 |

| n-pentane | 10.76 | 7.25 | 4.25 | 6.91 |

| trans-2-pentene | 1.21 | 0.80 | 0.46 | 0.72 |

| 1,3-butadiene | 0.68 | 0.00 | 0.00 | 0.00 |

| 3-methyl-1-butene | 0.54 | 0.57 | 0.37 | 0.27 |

| 1-pentene | 1.66 | 0.75 | 0.42 | 0.56 |

| 2-methyl-1-butene | 0.72 | 1.56 | 0.89 | 1.17 |

| cis-2-pentene? | 1.82 | 1.39 | 0.79 | 1.37 |

| 2-methyl-2-butene | 2.56 | 1.93 | 1.22 | 2.09 |

| isoprene | 0.00 | 0.00 | 0.00 | 0.00 |

| cis-1,3-pentadiene | 0.00 | 0.00 | 0.00 | 0.05 |

| t-1,3-pentadiene | 0.00 | 0.00 | 0.00 | 0.01 |

| 2,2-dimethylbutane | 0.79 | 0.64 | 0.31 | 0.33 |

| cyclopentane | 0.84 | 0.43 | 0.42 | 0.93 |

| 2,3-dimethylbutane | 0.80 | 0.93 | 0.48 | 0.82 |

| 2-methylpentane | 4.76 | 3.09 | 1.38 | 2.60 |

| 3-methylpentane | 3.56 | 2.19 | 0.89 | 1.82 |

| 2-methyl-1-pentene | 0.10 | 0.11 | 0.05 | 0.11 |

| 1-hexene | 0.00 | 0.12 | 0.05 | 0.10 |

| hexane | 3.85 | 1.69 | 0.67 | 1.63 |

| cis-3-hexene | 0.07 | 0.10 | 0.04 | 0.04 |

| cis-2-hexene | 0.73 | 0.25 | 0.11 | 0.15 |

| cis-3-methyl-2-pentene | 0.26 | 0.14 | 0.07 | 0.10 |

| t-2-hexene | 0.40 | 0.17 | 0.07 | 0.21 |

| ethyl-tert-butylether | 6.22 | 1.74 | 0.34 | 2.13 |

| t-3-methyl-2-pentene | 0.29 | 0.18 | 0.08 | 0.16 |

| methylcyclopentane | 1.83 | 0.82 | 0.38 | 1.08 |

| 2,4-dimethylpentane | 0.56 | 0.14 | 0.04 | 0.16 |

| benzene | 0.69 | 0.18 | 0.09 | 0.30 |

| cyclohexane | 0.38 | 0.13 | 0.07 | 0.19 |

| 2-methylhexane | 1.73 | 0.63 | 0.17 | 0.68 |

| 2,3-dimethylpentane | 0.55 | 0.18 | 0.05 | 0.16 |

| 3-methylhexane | 1.23 | 0.57 | 0.16 | 0.54 |

| 1-heptene | 0.34 | 0.11 | 0.04 | 0.12 |

| 2,2,4-trimethylpentane | 0.01 | 0.00 | 0.00 | 0.02 |

| heptane | 0.82 | 0.25 | 0.05 | 0.20 |

| methylcyclohexane | 0.40 | 0.07 | 0.02 | 0.08 |

| 2,3,4-trimethylpentane | 0.15 | 0.00 | 0.00 | 0.00 |

| toluene | 3.48 | 0.84 | 0.23 | 0.81 |

| 2-methylheptane | 0.11 | 0.04 | 0.01 | 0.03 |

| 3-methylheptane | 0.19 | 0.04 | 0.01 | 0.03 |

| octane | 0.03 | 0.01 | 0.00 | 0.01 |

| ethylbenzene | 0.34 | 0.04 | 0.01 | 0.03 |

| m-xylene | 0.60 | 0.07 | 0.01 | 0.05 |

| p-xylene | 0.16 | 0.02 | 0.00 | 0.02 |

| styrene | 0.00 | 0.00 | 0.00 | 0.00 |

| o-xylene | 0.22 | 0.03 | 0.00 | 0.02 |

| nonane | 0.03 | 0.00 | 0.00 | 0.00 |

| isopropylbenzene | 0.02 | 0.00 | 0.00 | 0.00 |

| alpha-pinene | 0.00 | 0.00 | 0.00 | 0.00 |

| propylbenzene | 0.02 | 0.01 | 0.00 | 0.00 |

| m-ethyltoluene | 0.13 | 0.01 | 0.00 | 0.01 |

| p-ethyltoluene | 0.00 | 0.01 | 0.00 | 0.00 |

| 1,3,5-trimethylbenzene | 0.02 | 0.01 | 0.00 | 0.00 |

| o-ethyltoluene | 0.03 | 0.00 | 0.00 | 0.00 |

| beta-pinene | 0.00 | 0.00 | 0.00 | 0.00 |

| 1,2,4-trimethylbenzene | 0.11 | 0.02 | 0.00 | 0.01 |

| decane | 0.03 | 0.00 | 0.00 | 0.00 |

| 1,2,3-trimethylbenzene | 0.00 | 0.00 | 0.00 | 0.00 |

| m-diethylbenzene | 0.00 | 0.00 | 0.00 | 0.00 |

| p-diethylbenzene | 0.00 | 0.00 | 0.00 | 0.00 |

| 2-ethyl-p-xylene | 0.05 | 0.00 | 0.00 | 0.00 |

| 4-ethyl-m-xylene | 0.04 | 0.00 | 0.00 | 0.00 |

| undecane | 0.07 | 0.01 | 0.00 | 0.01 |

| 1,2,3,5-tetramethylbenzene | 0.02 | 0.00 | 0.00 | 0.00 |

References

- Lelieveld, J.; Evans, J.S.; Fnais, M.; Giannadaki, D.; Pozzer, A. The contribution of outdoor air pollution sources to premature mortality on a global scale. Nature 2015, 525, 367–371. [Google Scholar] [CrossRef] [PubMed]

- Ghude, S.D.; Chate, D.M.; Jena, C.; Beig, G.; Kumar, R.; Barth, M.C.; Pfister, G.G.; Fadnavis, S.; Pithani, P. Premature mortality in India due to PM2.5 and ozone exposure. Geophys. Res. Lett. 2016, 43, 4650–4658. [Google Scholar] [CrossRef] [Green Version]

- Punger, E.M.; West, J.J. The effect of grid resolution on estimates of the burden of ozone and fine particulate matter on premature mortality in the USA. Air Qual. Atmos. Health 2013, 6, 563–573. [Google Scholar] [CrossRef] [PubMed]

- Nawahda, A.; Yamashita, K.; Ohara, T.; Kurokawa, J.; Yamaji, K. Evaluation of premature mortality caused by exposure to PM2.5 and ozone in East Asia: 2000, 2005, 2020. Water Air Soil Pollut. 2012, 223, 3445–3459. [Google Scholar] [CrossRef]

- Sun, J.; Fu, J.S.; Huang, K.; Gao, Y. Estimation of future PM2.5- and ozone-related mortality over the continental United States in a changing climate: An application of high-resolution dynamical downscaling technique. J. Air Waste Manag. Assoc. 2015, 65, 611–623. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, R.; Cai, J.; Meng, X.; Kim, H.; Honda, Y.; Guo, Y.L.; Samoli, E.; Yang, X.; Kan, H. Ozone and daily mortality rate in 21 cities of East Asia: How does season modify the association? Am. J. Epidemiol. 2014, 180, 729–736. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ministry of the Environment in Japan. About Air Pollution Situation in 2017. Available online: https://www.env.go.jp/press/106609.html (accessed on 23 June 2020).

- United States Environmental Protection Agency. National Air Quality: Status and Trends of Key Air Pollutants. Available online: https://www.epa.gov/air-trends (accessed on 28 September 2020).

- European Environment Agency. Air Pollution. Available online: https://www.eea.europa.eu/themes/air (accessed on 28 September 2020).

- Zhang, W.; Lu, Z.; Xu, Y.; Wang, C.; Gu, Y.; Xu, H.; Streets, D.G. Black carbon emissions from biomass and coal in rural China. Atmos. Environ. 2018, 176, 158–170. [Google Scholar] [CrossRef]

- Zhang, W.; Cui, Y.; Wang, J.; Wang, C.; Streets, D.G. How does urbanization affect CO2 emissions of central heating systems in China? An assessment of natural gas transition policy based on nighttime light data. J. Clean. Prod. 2020, 276, 123188. [Google Scholar] [CrossRef]

- Hata, H.; Tonokura, K. Impact of next-generation vehicles on tropospheric ozone estimated by chemical transport model in the Kanto region of Japan. Sci. Rep. 2019, 9, 3573. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brandt, E.P.; Wang, Y.; Grizzle, J.W. Dynamic modeling of a three-way catalyst for SI engine exhaust emission control. IEEE Trans. Control Syst. Technol. 2002, 8, 767–776. [Google Scholar] [CrossRef]

- Chen, J.; Chen, Y.; Zhou, M.; Huang, Z.; Gao, J.; Ma, Z.; Chen, J.; Tang, X. Enhanced performance of ceria-based NOx reduction catalysts by optimal support effect. Environ. Sci. Technol. 2017, 51, 472–478. [Google Scholar] [CrossRef] [PubMed]

- Mellios, G.; Samaras, Z.; Martini, G.; Manfredi, U.; McArragher, S.; Rose, K. A vehicle testing program for calibration and validation of an evaporative emissions model. Fuel 2009, 88, 1504–1512. [Google Scholar] [CrossRef]

- Grigoratos, T.; Martini, G.; Carriero, M. An experimental study to investigate typical temperature conditions in fuel tanks of European vehicles. Environ. Sci. Pollut. Res. 2019, 26, 17608–17622. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Yamada, H. Contribution of evaporative emissions from gasoline vehicles toward total VOC emissions in Japan. Sci. Total Environ. 2013, 449, 143–149. [Google Scholar] [CrossRef] [PubMed]

- Liu, H.; Man, H.; Tschantz, M.; Wu, Y.; He, K.; Hao, J. VOC from vehicular evaporation emissions: Status and control strategy. Environ. Sci. Technol. 2015, 49, 14424–14431. [Google Scholar] [CrossRef] [PubMed]

- Hata, H.; Yamada, H.; Kokuryo, K.; Okada, M.; Funakubo, C.; Tonokura, K. Estimation model for evaporative emissions from gasoline vehicles based on thermodynamics. Sci. Total Environ. 2018, 618, 1685–1691. [Google Scholar] [CrossRef] [PubMed]

- Hata, H.; Yamada, H.; Yanai, K.; Kugata, M.; Noumura, G.; Tonokura, K. Modeling evaporative emissions from parked gasoline cars based on vehicle carbon canister experiments. Sci. Total Environ. 2019, 675, 679–685. [Google Scholar] [CrossRef] [PubMed]

- Yamada, H.; Inomata, S.; Tanimoto, H.; Hata, H.; Tonokura, K. Estimation of refueling emissions based on theoretical model and effects of E10 fuel on refueling and evaporative emissions from gasoline cars. Sci. Total Environ. 2018, 622–623, 467–473. [Google Scholar] [CrossRef] [PubMed]

- Manufacturers of Emission Controls Association. Comments of the Manufacturers of Emission Controls Association on the U.S. Environmental Protection Agency’s Reconsideration of the Final Determination of the Mid-Term Evaluation of Greenhouse Gas Standards for Model Year 2022–2025 Light-Duty Vehicles; Model Year 2021 Greenhouse Gas Emissions Standards; Manufacturers of Emission Controls Association: Arlington, VA, USA, 2017; Available online: http://www.meca.org/attachments/3034/MECA_Comments_on_EPA_Final_Determination_Reconsideration___appendix_10052017.pdf (accessed on 23 June 2020).

- Japanese Industrial Standards Committee. Japan’s Standardization Policy 2017. Available online: https://www.jisc.go.jp/eng/index.html (accessed on 21 July 2020).

- Japan Meteorological Agency. Previous meteorological data. Available online: https://www.data.jma.go.jp/obd/stats/etrn/index.php (accessed on 23 June 2020).

- Hata, H.; Okada, M.; Funakubo, C.; Hoshi, J. Tailpipe VOC emissions from late model gasoline passenger vehicles in the Japanese market. Atmosphere 2019, 10, 621. [Google Scholar] [CrossRef] [Green Version]

- NIST Chemistry WebBook. Available online: https://webbook.nist.gov/chemistry/ (accessed on 23 June 2020).

- Honkawa Data Tribune. Available online: https://honkawa2.sakura.ne.jp/7231.html (accessed on 2 July 2019). (In Japanese).

- Morikawa, T.; Chatani, S.; Nakatsuka, S. Technological Report of Japan Auto-Oil Program. Requisition material for Japan Petroleum Energy Center. Available online: https://www.pecj.or.jp/en/ (accessed on 16 October 2020).

- Ministry of Land, Infrastructure, Transport and Tourism in Japan. Statistical Data of Vehicle Usage. Available online: https://www.mlit.go.jp/jidosha/iinkai/seibi/5th/5-2.pdf (accessed on 12 October 2020).

- Automobile Inspection & Registration Information Association. Statistics. Available online: https://www.airia.or.jp/publish/statistics/index.html (accessed on 12 October 2020).

- Ministry of the Environment in Japan. Report of the Evaluation of VOC Emission Inventory in 2019. Available online: https://www.env.go.jp/air/air/osen/voc/inventory/R1/R1-Mat03.pdf (accessed on 12 October 2020).

| Parameter | Experimental Date | |||

|---|---|---|---|---|

| 30 July 2019 | 17 December 2019 | 24 December 2019 | 16 April 2020 | |

| Gasoline type | SGG 1 | SGG 1 | WGG 2 | WGG 2 |

| Tank-filling (L) | 20, 40, 60 | 20, 30, 40, 50 | 10, 20, 30, 40, 50 | 10, 20, 30, 40, 50 |

| Ambient temperature at 12 PM (°C) | 33.0 | 8.3 | 12.2 | 14.8 |

| Ambient pressure at 12 PM (kPa) | 100.8 | 101.5 | 101.8 | 101.4 |

| Weather | Sunny | Cloudy | Sunny | Sunny |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hata, H.; Tanaka, S.-y.; Noumura, G.; Yamada, H.; Tonokura, K. Evaluation of Gasoline Evaporative Emissions from Fuel-Cap Removal after a Real-World Driving Event. Atmosphere 2020, 11, 1110. https://doi.org/10.3390/atmos11101110

Hata H, Tanaka S-y, Noumura G, Yamada H, Tonokura K. Evaluation of Gasoline Evaporative Emissions from Fuel-Cap Removal after a Real-World Driving Event. Atmosphere. 2020; 11(10):1110. https://doi.org/10.3390/atmos11101110

Chicago/Turabian StyleHata, Hiroo, Syun-ya Tanaka, Genta Noumura, Hiroyuki Yamada, and Kenichi Tonokura. 2020. "Evaluation of Gasoline Evaporative Emissions from Fuel-Cap Removal after a Real-World Driving Event" Atmosphere 11, no. 10: 1110. https://doi.org/10.3390/atmos11101110