Catalyst-Free Crosslinking Modification of Nata-de-Coco-Based Bacterial Cellulose Nanofibres Using Citric Acid for Biomedical Applications

Abstract

:1. Introduction

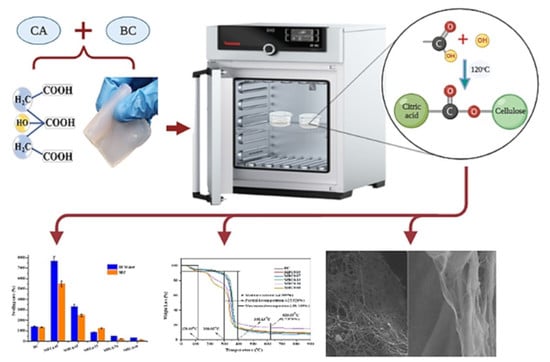

2. Materials and Methods

2.1. Chemicals and Materials

2.2. Purification and Modification of Bacterial Cellulose (BC)

2.3. Characterisation

2.3.1. Scanning Electron Microscopy (SEM)

2.3.2. Fourier Transformed Infrared (FTIR)

2.3.3. X-ray Diffraction (XRD)

2.3.4. Water Contact Angle (WAC)

2.3.5. Swelling Rate (SR)

2.3.6. Thermal Gravimetric Analysis (TGA)

2.3.7. Tensile Properties

3. Results and Discussion

3.1. Scanning Electron Microscopy (SEM)

3.2. Fourier Transformed Infrared (FTIR)

3.3. X-ray Diffraction (XRD)

3.4. Water Contact Angle (WCA)

3.5. Swelling Rate (SR)

3.6. Thermal Gravimetric Analysis (TGA)

3.7. Tensile Testing

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Nugroho, D.A.; Aji, P. Characterization of Nata de Coco Produced by Fermentation of Immobilized Acetobacter xylinum. Agric. Agric. Sci. Procedia 2015, 3, 278–282. [Google Scholar] [CrossRef] [Green Version]

- Phisalaphong, M.; Tran, T.-K.; Taokaew, S.; Budiraharjo, R.; Febriana, G.G.; Nguyen, D.-N.; Chu-Ky, S.; Dourado, F. Nata de coco Industry in Vietnam, Thailand, and Indonesia a Muenduen Phisalaphong, Tien-Khai Tran, Son Chu-Ky, and Fernando Dourado have contributed equally to this work. Bact. Nanocellulose 2016, 231–236. [Google Scholar] [CrossRef]

- Halib, N.; Amin, M.; Ahmad, I. Physicochemical properties and characterization of nata de coco from local food indus-tries as a source of cellulose. Sains Malays. 2012, 41, 205–211. [Google Scholar]

- Brown, R.M., Jr. Cellulose structure and biosynthesis: What is in store for the 21st century? J. Polym. Sci. Part A Polym. Chem. 2004, 42, 487–495. [Google Scholar] [CrossRef]

- Jonas, R.; Farah, L.F. Production and application of microbial cellulose. Polym. Degrad. Stab. 1998, 59, 101–106. [Google Scholar] [CrossRef]

- Shoda, M.; Sugano, Y. Recent advances in bacterial cellulose production. Biotechnol. Bioprocess Eng. 2005, 10, 1–8. [Google Scholar] [CrossRef]

- Pang, M.; Huang, Y.; Meng, F.; Zhuang, Y.; Liu, H.; Du, M.; Ma, Q.; Wang, Q.; Chen, Z.; Chen, L.; et al. Application of bacterial cellulose in skin and bone tissue engineering. Eur. Polym. J. 2020, 122, 109365. [Google Scholar] [CrossRef]

- Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M.; Tayeb, A.H.; Amini, E.; Ghasemi, S.; Tajvidi, M. Cellulose Nanomaterials—Binding Properties and Applications: A Review. Molecules 2018, 23, 2684. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, J.; Gultekinoglu, M.; Edirisinghe, M. Bacterial cellulose micro-nano fibres for wound healing applications. Biotechnol. Adv. 2020, 41, 107549. [Google Scholar] [CrossRef]

- Gregory, D.A.; Tripathi, L.; Fricker, A.T.; Asare, E.; Orlando, I.; Raghavendran, V.; Roy, I. Bacterial cellulose: A smart biomaterial with diverse applications. Mater. Sci. Eng. R Rep. 2021, 145, 100623. [Google Scholar] [CrossRef]

- Naeem, M.A.; Siddiqui, Q.; Mushtaq, M.; Farooq, A.; Pang, Z.; Wei, Q. Insitu Self-Assembly of Bacterial Cellulose on Banana Fibers Extracted from Peels. J. Nat. Fibers 2019, 17, 1317–1328. [Google Scholar] [CrossRef]

- Stumpf, T.R.; Yang, X.; Zhang, J.; Cao, X. In situ and ex situ modifications of bacterial cellulose for applications in tissue engineering. Mater. Sci. Eng. C 2018, 82, 372–383. [Google Scholar] [CrossRef] [PubMed]

- Ul-Islam, M.; Khan, T.; Park, J.K. Water holding and release properties of bacterial cellulose obtained by in situ and ex situ modification. Carbohydr. Polym. 2012, 88, 596–603. [Google Scholar] [CrossRef]

- Salihu, R.; Foong, C.Y.; Abd Razak, S.I.; Kadir, M.R.A.; Yusof, A.H.M.; Nayan, N.H.M. Overview of inexpensive production routes of bacterial cellulose and its applications in biomedical engi-neering. Cell Chem. Technol. 2019, 53, 1–13. [Google Scholar] [CrossRef]

- Oryan, A.; Kamali, A.; Moshiri, A.; Baharvand, H.; Daemi, H. Chemical crosslinking of biopolymeric scaffolds: Current knowledge and future directions of crosslinked engineered bone scaffolds. Int. J. Biol. Macromol. 2018, 107, 678–688. [Google Scholar] [CrossRef]

- Dharmalingam, K.; Anandalakshmi, R. Fabrication, characterization and drug loading efficiency of citric acid crosslinked NaCMC-HPMC hydrogel films for wound healing drug delivery applications. Int. J. Biol. Macromole-Cules 2019, 134, 815–829. [Google Scholar] [CrossRef]

- Cumming, M.H.; Leonard, A.R.; LeCorre-Bordes, D.S.; Hofman, K. Intra-fibrillar citric acid crosslinking of marine collagen electrospun nanofibres. Int. J. Biol. Macromol. 2018, 114, 874–881. [Google Scholar] [CrossRef] [PubMed]

- Ren, L.; Zhang, Y.; Wang, Q.; Zhou, J.; Tong, J.; Chen, D.; Su, X. Convenient Method for Enhancing Hydrophobicity and Dispersibility of Starch Nanocrystals by Crosslinking Modification with Citric Acid. Int. J. Food Eng. 2018, 14, 20170238. [Google Scholar] [CrossRef]

- Sedyakina, N.; Kuskov, A.; Velonia, K.; Feldman, N.; Lutsenko, S.; Avramenko, G. Modulation of Entrapment Efficiency and In Vitro Release Properties of BSA-Loaded Chitosan Micro-particles Cross-Linked with Citric Acid as a Potential Protein–Drug Delivery System. Materials 2020, 13, 1989. [Google Scholar] [CrossRef]

- Uranga, J.; Nguyen, B.T.; Si, T.T.; Guerrero, P.; De La Caba, K. The Effect of Cross-Linking with Citric Acid on the Properties of Agar/Fish Gelatin Films. Polymers 2020, 12, 291. [Google Scholar] [CrossRef] [Green Version]

- Salihu, R.; Razak, S.I.A.; Zawawi, N.A.; Kadir, M.R.A.; Ismail, N.I.; Jusoh, N.; Mohamad, M.R.; Nayan, N.H.M. Citric acid: A green cross-linker of biomaterials for biomedical applications. Eur. Polym. J. 2021, 146, 110271. [Google Scholar] [CrossRef]

- Ma, C.; Tian, X.; Kim, J.P.; Xie, D.; Ao, X.; Shan, D.; Lin, Q.; Hudock, M.R.; Bai, X.; Yang, J. Citrate-based materials fuel human stem cells by metabonegenic regulation. Proc. Natl. Acad. Sci. USA 2018, 115, E11741–E11750. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Shah, A.H.; Bhusari, S.; Djordjevic, I.; Steele, T.W. Twin screw extrusion of conductive citrate-based biomaterials. Eur. Polym. J. 2018, 110, 176–182. [Google Scholar] [CrossRef]

- Sabzi, M.; Afshari, M.J.; Babaahmadi, M.; Shafagh, N. pH-dependent swelling and antibiotic release from citric acid crosslinked poly (vinyl alcohol)(PVA)/nano silver hydrogels. Colloids Surf. B Biointerfaces 2020, 188, 110757. [Google Scholar] [CrossRef]

- Huang, L.; Wang, C.; Xu, H.; Peng, G. Targeting citrate as a novel therapeutic strategy in cancer treatment. Biochim. et Biophys. Acta (BBA) Bioenerg. 2020, 1873, 188332. [Google Scholar] [CrossRef] [PubMed]

- Khouri, J. Chitosan Edible Films Crosslinked by Citric Acid; University of Waterloo: Waterloo, ON, Canada, 2019; p. 188. [Google Scholar]

- Tran, R.T.; Yang, J.; Ameer, G.A. Citrate-Based Biomaterials and Their Applications in Regenerative Engineering. Annu. Rev. Mater. Res. 2015, 45, 277–310. [Google Scholar] [CrossRef] [Green Version]

- Ma, C.; Gerhard, E.; Lu, D.; Yang, J. Citrate chemistry and biology for biomaterials design. Biomaterials 2018, 178, 383–400. [Google Scholar] [CrossRef]

- Ciecholewska-Juśko, D.; Żywicka, A.; Junka, A.; Drozd, R.; Sobolewski, P.; Migdał, P.; Kowalska, U.; Toporkiewicz, M.; Fijałkowski, K. Superabsorbent crosslinked bacterial cellulose biomaterials for chronic wound dressings. Carbohydr. Polym. 2021, 253, 117247. [Google Scholar] [CrossRef] [PubMed]

- Feng, X.; Xiao, Z.; Sui, S.; Wang, Q.; Xie, Y. Esterification of wood with citric acid: The catalytic effects of sodium hypophosphite (SHP). Holzforschung 2014, 68, 427–433. [Google Scholar] [CrossRef]

- Meftahi, A.; Khajavi, R.; Rashidi, A.; Rahimi, M.K.; Bahador, A. Preventing the collapse of 3D bacterial cellulose network via citric acid. J. Nanostruct. Chem. 2018, 8, 311–320. [Google Scholar] [CrossRef] [Green Version]

- Bilgi, E.; Bayir, E.; Urkmez, A.S.; Hames, E.E. Optimization of bacterial cellulose production by Gluconacetobacter xylinus using carob and haricot bean. Int. J. Biol. Macromol. 2016, 90, 2–10. [Google Scholar] [CrossRef]

- Khan, H.; Kadam, A.; Dutt, D. Studies on bacterial cellulose produced by a novel strain of Lactobacillus genus. Carbohydr. Polym. 2020, 229, 115513. [Google Scholar] [CrossRef]

- Wada, M.; Okano, T.; Sugiyama, J. Allomorphs of native crystalline cellulose I evaluated by two equatoriald-spacings. J. Wood Sci. 2001, 47, 124–128. [Google Scholar] [CrossRef]

- Poletto, M.; Ornaghi, J.H.L.; Zattera, A.J. Native Cellulose: Structure, Characterization and Thermal Properties. Materials 2014, 7, 6105–6119. [Google Scholar] [CrossRef] [Green Version]

- Zhao, T.; Jiang, L. Contact angle measurement of natural materials. Colloids Surf. B Biointerfaces 2018, 161, 324–330. [Google Scholar] [CrossRef]

- Shao, W.; Wu, J.; Wang, S.; Huang, M.; Liu, X.; Zhang, R. Construction of silver sulfadiazine loaded chitosan composite sponges as potential wound dressings. Carbohydr. Polym. 2017, 157, 1963–1970. [Google Scholar] [CrossRef]

- Ye, S.; Jiang, L.; Su, C.; Zhu, Z.; Wen, Y.; Shao, W. Development of gelatin/bacterial cellulose composite sponges as potential natural wound dressings. Int. J. Biol. Macromol. 2019, 133, 148–155. [Google Scholar] [CrossRef]

- Abba, M.; Nyakuma, B.B.; Ibrahim, Z.; Ali, J.B.; Razak, S.I.A.; Salihu, R. Physicochemical, Morphological, and Microstructural Characterisation of Bacterial Nanocellulose from Glu-conacetobacter xylinus BCZM. J. Nat. Fibers 2020, 1–12. [Google Scholar] [CrossRef]

- Tang, S.; Chi, K.; Xu, H.; Yong, Q.; Yang, J.; Catchmark, J.M. A covalently cross-linked hyaluronic acid/bacterial cellulose composite hydrogel for potential biological appli-cations. Carbohydr. Polym. 2020, 252, 117123. [Google Scholar] [CrossRef] [PubMed]

- Molina-Romero, J.M.; Arteaga-Ballesteros, B.E.; Guevara-Morales, A.; San Martín-Martínez, E.; Vieyra, H. Reduced tensile properties of bacterial cellulose membranes after an accelerated composite tem-perature/humidity cyclic assay. J. Polym. Environ. 2021, 29, 2349–2358. [Google Scholar] [CrossRef]

- Rathinamoorthy, R.; Aarthi, T.; Shree, C.A.A.; Haridharani, P.; Shruthi, V.; Vaishnikka, R.L. Development and Characterization of Self -assembled Bacterial Cellulose Nonwoven Film. J. Nat. Fibers 2019, 1–14. [Google Scholar] [CrossRef]

- Pandit, A.; Kumar, R. A Review on Production, Characterization and Application of Bacterial Cellulose and Its Biocom-posites. J. Polym. Environ. 2021, 29, 2738–2755. [Google Scholar] [CrossRef]

- Wu, Y.-L.; Xu, S.; Wang, T.; Wang, C.-F. Enhanced Metal Ion Rejection by a Low-Pressure Microfiltration System Using Cellulose Filter Papers Modified with Citric Acid. ACS Appl. Mater. Interfaces 2018, 10, 32736–32746. [Google Scholar] [CrossRef]

- Haji, A.; Bidoki, S.M.; Gholami, F. Isotherm and Kinetic Studies in Dyeing of Citric Acid-Crosslinked Cotton with Cation-ic Natural Dye. Fibers Polym. 2020, 21, 2547–2555. [Google Scholar] [CrossRef]

- Raucci, M.G.; Alvarez-Perez, M.A.; Demitri, C.; Giugliano, D.; De Benedictis, V.; Sannino, A.; Ambrosio, L. Effect of citric acid crosslinking cellulose-based hydrogels on osteogenic differentiation. J. Biomed. Mater. Res. Part A 2015, 103, 2045–2056. [Google Scholar] [CrossRef]

- Trovatti, E.; Serafim, L.; Freire, C.; Silvestre, A.; Neto, C. Gluconacetobacter sacchari: An efficient bacterial cellulose cell-factory. Carbohydr. Polym. 2011, 86, 1417–1420. [Google Scholar] [CrossRef]

- Bagheri, M.; Younesi, H.; Hajati, S.; Borghei, S.M. Application of chitosan-citric acid nanoparticles for removal of chromium (VI). Int. J. Biol. Macromol. 2015, 80, 431–444. [Google Scholar] [CrossRef]

- Ramírez, J.A.Á.; Hoyos, C.G.; Arroyo, S.; Cerrutti, P.; Foresti, M.L. Acetylation of bacterial cellulose catalyzed by citric acid: Use of reaction conditions for tailoring the esterification extent. Carbohydr. Polym. 2016, 153, 686–695. [Google Scholar] [CrossRef] [PubMed]

- Ramírez, J.A.Á.; Fortunati, E.; Kenny, J.M.; Torre, L.; Foresti, M.L. Simple citric acid-catalyzed surface esterification of cellulose nanocrystals. Carbohydr. Polym. 2017, 157, 1358–1364. [Google Scholar] [CrossRef]

- Chen, H.; Yan, X.; Feng, Q.; Zhao, P.; Xu, X.; Ng, D.H.; Bian, L. Citric acid/cysteine-modified cellulose-based materials: Green preparation and their applications in anticoun-terfeiting, chemical sensing, and UV shielding. ACS Sustain. Chem. Eng. 2017, 5, 11387–11394. [Google Scholar] [CrossRef]

- Fontes, M.D.L.; Meneguin, A.B.; Tercjak, A.; Gutierrez, J.; Cury, B.; dos Santos, A.M.; Ribeiro, S.; Barud, H.S. Effect of in situ modification of bacterial cellulose with carboxymethylcellulose on its nano/microstructure and methotrexate release properties. Carbohydr. Polym. 2018, 179, 126–134. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zugenmaier, P. History of Cellulose Research; Springer: Berlin/Heidelberg, Germany, 2008; pp. 7–51. [Google Scholar] [CrossRef]

- Moon, R.J.; Martini, A.; Nairn, J.; Simonsen, J.; Youngblood, J. Cellulose nanomaterials review: Structure, properties and nanocomposites. Chem. Soc. Rev. 2011, 40, 3941–3994. [Google Scholar] [CrossRef] [PubMed]

- French, A.D. Idealized powder diffraction patterns for cellulose polymorphs. Cellulose 2013, 21, 885–896. [Google Scholar] [CrossRef]

- Giridhar, G.; Manepalli, R.; Apparao, G. Contact Angle Measurement Techniques for Nanomaterials. In Thermal and Rheological Measurement Techniques for Nanomaterials Characterization; Elsevier BV: Amsterdam, The Netherlands, 2017; pp. 173–195. [Google Scholar]

- Luo, M.-T.; Li, H.-L.; Huang, C.; Zhang, H.-R.; Xiong, L.; Chen, X.-F.; Chen, X.-D. Cellulose-Based Absorbent Production from Bacterial Cellulose and Acrylic Acid: Synthesis and Performance. Polymers 2018, 10, 702. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Lawal, O.S.; Storz, J.; Storz, H.; Lohmann, D.; Lechner, D.; Kulicke, W.-M. Hydrogels based on carboxymethyl cassava starch cross-linked with di- or polyfunctional carboxylic acids: Synthesis, water absorbent behavior and rheological characterizations. Eur. Polym. J. 2009, 45, 3399–3408. [Google Scholar] [CrossRef]

- Portela, R.; Leal, C.R.; Almeida, P.L.; Sobral, R.G. Bacterial cellulose: A versatile biopolymer for wound dressing applications. Microb. Biotechnol. 2019, 12, 586–610. [Google Scholar] [CrossRef]

- Chen, W.H.; Eng, C.F.; Lin, Y.Y.; Bach, Q.V. Independent parallel pyrolysis kinetics of cellulose, hemicelluloses and lignin at various heating rates an-alyzed by evolutionary computation. Energy Convers. Manag. 2020, 221, 113165. [Google Scholar] [CrossRef]

- Vasconcelos, N.F.; Feitosa, J.P.A.; da Gama, F.M.P.; Morais, J.P.S.; Andrade, F.K.; de Souza, M.D.S.M.; de Freitas Rosa, M. Bacterial cellulose nanocrystals produced under different hydrolysis conditions: Properties and morphological features. Carbohydr. Polym. 2017, 155, 425–431. [Google Scholar] [CrossRef] [PubMed]

- Amin, M.C.I.M.; Abadi, A.G.; Katas, H. Purification, characterization and comparative studies of spray-dried bacterial cellulose microparticles. Carbohydr. Polym. 2014, 99, 180–189. [Google Scholar] [CrossRef]

- Awadhiya, A.; Kumar, D.; Rathore, K.; Fatma, B.; Verma, V. Synthesis and characterization of agarose–bacterial cellulose biodegradable composites. Polym. Bull. 2017, 74, 2887–2903. [Google Scholar] [CrossRef]

| Sample | Crystallinity Index (%) | Crystallite Size (Å) | Allomorph |

|---|---|---|---|

| BC | 80 | 51 | Iα rich (triclinic) |

| MBC0.03 | 80 | 56 | Iα rich (triclinic) |

| MBC0.60 | 81 | 56 | Iα rich (triclinic) |

| MBC0.60 | 84 | 56 | Iα rich (triclinic) |

| MBC0.60 | 91 | 56 | Iα rich (triclinic) |

| MBC0.60 | 93 | 56 | Iα rich (triclinic) |

| Samples | Thickness (mm) | Et (MPa) | σM (MPa) | εB (%) |

|---|---|---|---|---|

| BC | 0.99 ± 0.07 | 56.68 ± 7.81 | 1.25 ± 0.16 | 1.94 ± 0.06 |

| MBC0.03 | 2.16 ± 0.19 | 17.97 ± 1.48 | 0.62 ± 0.16 | 3.97 ± 0.60 |

| MBC0.07 | 0.16 ± 0.01 | 473.59 ± 62.02 | 20.60 ± 3.58 | 4.87 ± 0.25 |

| MBC0.15 | 0.12 ± 0.01 | 778.42 ± 132.47 | 28.43 ± 3.15 | 4.11 ± 0.59 |

| MBC0.30 | 0.08 ± 0.01 | 945.73 ± 199.62 | 26.65 ± 10.13 | 3.27 ± 0.71 |

| MBC0.60 | 0.18 ± 0.09 | 1024 ± 44.66 | 16.37 ± 0.63 | 3.23 ± 0.36 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Salihu, R.; Ansari, M.N.M.; Abd Razak, S.I.; Ahmad Zawawi, N.; Shahir, S.; Sani, M.H.; Ramlee, M.H.; Wsoo, M.A.; Mohd Yusof, A.H.; Nayan, N.H.M.; et al. Catalyst-Free Crosslinking Modification of Nata-de-Coco-Based Bacterial Cellulose Nanofibres Using Citric Acid for Biomedical Applications. Polymers 2021, 13, 2966. https://doi.org/10.3390/polym13172966

Salihu R, Ansari MNM, Abd Razak SI, Ahmad Zawawi N, Shahir S, Sani MH, Ramlee MH, Wsoo MA, Mohd Yusof AH, Nayan NHM, et al. Catalyst-Free Crosslinking Modification of Nata-de-Coco-Based Bacterial Cellulose Nanofibres Using Citric Acid for Biomedical Applications. Polymers. 2021; 13(17):2966. https://doi.org/10.3390/polym13172966

Chicago/Turabian StyleSalihu, Rabiu, Mohamed Nainar Mohamed Ansari, Saiful Izwan Abd Razak, Nurliyana Ahmad Zawawi, Shafinaz Shahir, Mohd Helmi Sani, Muhammad Hanif Ramlee, Mohammed Ahmad Wsoo, Abdul Halim Mohd Yusof, Nadirul Hasraf Mat Nayan, and et al. 2021. "Catalyst-Free Crosslinking Modification of Nata-de-Coco-Based Bacterial Cellulose Nanofibres Using Citric Acid for Biomedical Applications" Polymers 13, no. 17: 2966. https://doi.org/10.3390/polym13172966