Chemical Modification of Banana Trunk Fibers for the Production of Green Composites

Abstract

:1. Introduction

2. Materials and Methods

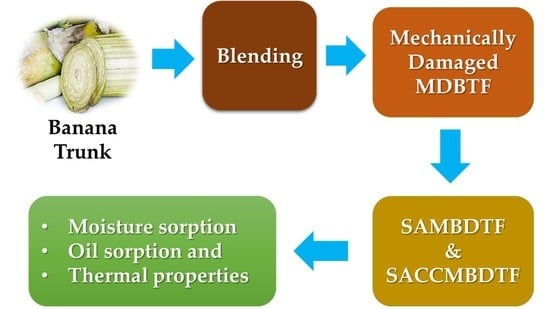

2.1. Preparation of Mechanically Damaged Banana Trunk Fibers

2.2. Treatment of MDBTF with Stearic Acid

2.3. Treatment of MDBTF with Calcium Carbonate Coated with 5% (w/w) Stearic Acid

2.4. Moisture Sorption Study

2.5. Theoretical Approach for Thermal Analysis

2.6. Morphological Analysis

2.7. Roughness Study

2.8. Infrared Analysis

2.9. Oil Uptake Study

2.9.1. Preparation of Weathered Oil Contaminated Seawater (WOCS)

2.9.2. Equilibrium Studies

2.9.3. Study Reusability of Sorbents

3. Results and Discussion

3.1. Moisture Sorption Study

3.2. Thermal Analysis

3.3. Kinetics Study

3.4. Morphological Analysis

3.5. Roughness Analysis

3.6. Infrared Spectra Analysis

3.7. Oil Uptake Study

3.8. Reusability of Sorbents

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Keya, K.N.; Kona, N.A.; Koly, F.A.; Maraz, K.M.; Islam, N.; Khan, R.A. Natural fiber reinforced polymer composites: History, types, advantages, and applications. Mater. Eng. Res. 2019, 1, 69–87. [Google Scholar] [CrossRef] [Green Version]

- Edeerozey, A.M.M.; Akil, H.M.; Azhar, A.B.; Ariffin, M.I.Z. Chemical modification of kenaf fibers. Mater. Lett. 2007, 61, 2023–2025. [Google Scholar] [CrossRef]

- Zini, E.; Scandola, M. Green composites: An overview. Polym. Compos. 2011, 32, 1905–1915. [Google Scholar] [CrossRef]

- Ticoalu, A.; Aravinthan, T.; Cardona, T. A Review of Current Development in Natural Fiber Composites for Structural and Infrastructure Applications. In Proceedings of the Southern Region Engineering Conference (SREC’10), Toowoomba, Australia, 11–12 November 2010; pp. 113–117. [Google Scholar]

- Corrales, F.; Vilaseca, F.; Llop, M.; Gironès, J.; Méndez, J.A.; Mutjè, P. Chemical modification of jute fibers for the production of green-composites. J. Hazard. Mater. 2007, 144, 730–735. [Google Scholar] [CrossRef]

- Akil, H.; Omar, M.F.; Mazuki, A.; Safiee, S.; Ishak, Z.; Abu Bakar, A. Kenaf fiber reinforced composites: A review. Mater. Des. 2011, 32, 4107–4121. [Google Scholar] [CrossRef]

- Shaker, K.; Nawab, Y.; Jabbar, M. Bio-composites: Eco-friendly Substitute of Glass Fiber Composites. In Handbook of Nanomaterials and Nanocomposites for Energy and Environmental Applications; Kharissova, O., Martínez, L., Kharisov, B., Eds.; Springer: Cham, Switzerland, 2020; pp. 1–25. [Google Scholar]

- Gandini, A.; Botaro, V.; Zeno, E.; Bach, S. Activation of solid polymer surfaces with bifunctional reagents. Polym. Int. 2001, 50, 7–9. [Google Scholar] [CrossRef]

- Daria, M.; Krzysztof, L.; Jakub, M. Characteristics of biodegradable textiles used in environmental engineering: A comprehensive review. J. Clean. Prod. 2020, 268, 122129. [Google Scholar] [CrossRef]

- Rao, K.M.M. Extraction and tensile properties of natural fibers: Vakka, date and bamboo. Compos. Struct. 2007, 77, 288–295. [Google Scholar] [CrossRef]

- Muñoz, E.; García-Manrique, J.A. Water Absorption Behaviour and Its Effect on the Mechanical Properties of Flax Fibre Reinforced Bioepoxy Composites. Int. J. Polym. Sci. 2015, 6, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Fortea-Verdejo, M.; Bumbaris, E.; Burgstaller, C.; Bismarck, A.; Lee, K.-Y. Plant fibre-reinforced polymers: Where do we stand in terms of tensile properties? Int. Mater. Rev. 2017, 62, 441–464. [Google Scholar] [CrossRef]

- Al-Maharma, A.Y.; Al-Huniti, N. Critical Review of the Parameters Affecting the Effectiveness of Moisture Absorption Treatments Used for Natural Composites. J. Compos. Sci. 2019, 3, 27. [Google Scholar] [CrossRef] [Green Version]

- Dantas, L.G.; Motta, L.A.D.C.; Pasquini, D.; Vieira, J.G. Surface Esterification of Sisal Fibres for use as Reinforcement in Cementitious Matrix. Mater. Res. 2019, 22, e20180585. [Google Scholar] [CrossRef]

- Yin, C.; Li, J.; Xu, Q.; Peng, Q.; Liu, Y.; Shen, X. Chemical modification of cotton cellulose in supercritical carbon dioxide: Synthesis and characterization of cellulose carbamate. Carbohydr. Polym. 2007, 67, 147–154. [Google Scholar] [CrossRef]

- Oushabi, A.; Sair, S.; Hassani, F.O.; Abboud, Y.; Tanane, O.; El Bouari, A. The effect of alkali treatment on mechanical, morphological and thermal properties of date palm fibers (DPFs): Study of the interface of DPF—Polyurethane composite. S. Afr. J. Chem. Eng. 2017, 23, 116–123. [Google Scholar] [CrossRef]

- Sreekala, M.; Thomas, S. Effect of fibre surface modification on water-sorption characteristics of oil palm fibres. Compos. Sci. Technol. 2003, 63, 861–869. [Google Scholar] [CrossRef]

- Razak, N.I.A.; Ibrahim, N.A.; Zainuddin, N.; Rayung, M.; Saad, W.Z. The Influence of Chemical Surface Modification of Kenaf Fiber using Hydrogen Peroxide on the Mechanical Properties of Biodegradable Kenaf Fiber/Poly(Lactic Acid) Composites. Molecules 2014, 19, 2957–2968. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Malviya, R.; Sharma, P.K.; Dubey, S.K. Modification of polysaccharides: Pharmaceutical and tissue engineering applications with commercial utility (patents). Mater. Sci. Eng. C 2016, 68, 929–938. [Google Scholar] [CrossRef]

- Xie, Y.; Hill, C.A.S.; Xiao, Z.; Militz, H.; Mai, C. Silane coupling agents used for natural fiber/polymer composites: A review. Compos. Part A Appl. Sci. Manuf. 2010, 41, 806–819. [Google Scholar] [CrossRef]

- Tavares, T.D.; Antunes, J.C.; Ferreira, F.; Felgueiras, H.P. Biofunctionalization of Natural Fiber-Reinforced Biocomposites for Biomedical Applications. Biomolecules 2020, 10, 148. [Google Scholar] [CrossRef] [Green Version]

- Huang, X.; Netravali, A. Biodegradable green composites made using bamboo micro/nano-fibrils and chemically modified soy protein resin. Compos. Sci. Technol. 2009, 69, 1009–1015. [Google Scholar] [CrossRef]

- Shih, Y.F.; Huang, C.C.; Chen, P.W. Biodegradable green composites reinforced by the fiber recycling from disposable chopsticks. Mater. Sci. Eng. A 2009, A6, 1516–1521. [Google Scholar] [CrossRef]

- Liu, Z.; Erhan, S.Z. “Green” composites and nanocomposites from soybean oil. Mater. Sci. Eng. A 2008, 483–484, 708–711. [Google Scholar] [CrossRef]

- Gomes, A.; Matsuo, T.; Goda, K.; Ohgi, J. Development and effect of alkali treatment on tensile properties of curaua fiber green composites. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1811–1820. [Google Scholar] [CrossRef]

- Saadoun, I.M. Impact of Oil Spills on Marine Life. In Emerging Pollutants in the Environment—Current and Further Implications; Larramendy, M.L., Soloneski, S., Eds.; IntechOpen: London, UK, 2015. [Google Scholar] [CrossRef] [Green Version]

- Idris, J. Oil Spills and Sustainable Cleanup Approach. Aust. J. Basic Appl. Sci. 2007, 7, 272–280. [Google Scholar]

- Shibi, I.G.; Anirudhan, T.S. Polymer-grafted banana (Musa paradisiaca) stalk as an adsorbent for the removal of lead(II) and cadmium(II) ions from aqueous solutions: Kinetic and equilibrium studies. J. Chem. Technol. Biotechnol. 2006, 81, 433–444. [Google Scholar] [CrossRef]

- Shibi, I.G.; Anirudhan, T.S. Adsorption of Co(II) by a carboxylate-functionalized polyacrylamide grafted lignocellulosics. Chemosphere 2005, 58, 1117–1126. [Google Scholar] [CrossRef] [PubMed]

- Hondroulis, D.G.; Ratowsky, I.P.; Kingham, N.W.; Kingham, K.T.B. Process for Sorbing Liquids Using Tropical Fibers. U.S. Patent No. 6,027,652, 22 February 2000. [Google Scholar]

- Hameed, B.; Mahmoud, D.; Ahmad, A.L. Sorption equilibrium and kinetics of basic dye from aqueous solution using banana stalk waste. J. Hazard Mater. 2008, 158, 499–506. [Google Scholar] [CrossRef]

- Har, M.R.H.M.; Sathasivam, K.; Haris, M.R. The Removal of Methyl Red from Aqueous Solutions Using Banana Pseudostem Fibers. Am. J. Appl. Sci. 2009, 6, 1690–1700. [Google Scholar] [CrossRef]

- Mas Haris, M.R.M.; Sathasivam, K. The removal of methyl red from aqueous solutions using modified banana trunk fibers. Arch. Appl. Sci. Res. 2010, 2, 209–216. [Google Scholar]

- Sathasivam, K.; Haris, M.R.H.M. Banana Trunk Fibers As an Efficient Biosorbent for The Removal of Cd(II), Cu(II), Fe(II) and Zn(II) from Aqueous Solutions. J. Chil. Chem. Soc. 2010, 55, 278–282. [Google Scholar] [CrossRef]

- Sathasivam, K.; Haris, M.R.H.M. Adsorption Kinetics and Capacity of Fatty Acid-Modified Banana Trunk Fibers for Oil in Water. Water Air Soil Pollut. 2010, 213, 413–423. [Google Scholar] [CrossRef]

- Cao, Z.; Daly, M.; Clémence, L.; Geever, L.M.; Major, I.; Higginbotham, C.; Devine, D.M. Chemical surface modification of calcium carbonate particles with stearic acid using different treating methods. Appl. Surf. Sci. 2016, 378, 320–329. [Google Scholar] [CrossRef]

- Xiao, B.; Huang, Q.; Chen, H.; Chen, X.; Long, G. A Fractal Model for Capillary Flow Through A Single Tortuous Capillary with Roughened Surfaces In Fibrous Porous Media. Fractals 2021, 29, 2150017. [Google Scholar] [CrossRef]

- Xiao, B.; Zhang, Y.; Wang, Y.; Jiang, G.; Liang, M.; Chen, X.; Long, G. A fractal model for Kozeny–Carman constant and dimensionless permeability of fibrous porous media with roughened surfaces. Fractals 2019, 27, 1950116. [Google Scholar] [CrossRef]

- Chen, Y.; Cao, X.; Chang, P.R.; Huneault, M.A. Comparative study on the films of poly(vinyl alcohol)/pea starch nanocrystals and poly(vinyl alcohol)/native pea starch. Carbohydr. Polym. 2008, 73, 8–17. [Google Scholar] [CrossRef]

- Kissinger, H.E. Variation of peak temperature with heating rate in differential thermal analysis. J. Res. Natl. Bur. Stand. 1956, 57, 217–221. [Google Scholar] [CrossRef]

- Friedman, H.L. Kinetics of thermal degradation of char-forming plastics from thermogravimetry. Application to a phenolic plastic. J. Polym. Sci. Part C Polym. Symp. 1964, 6, 183–195. [Google Scholar] [CrossRef]

- Flynn, J.H.; Wall, L.A. General treatment of the thermogravimetry of polymers. J. Res. Natl. Bur. Stand. Sect. A Phys. Chem. 1966, 70A, 487–523. [Google Scholar] [CrossRef]

- Ozawa, T. A New Method of Analyzing Thermogravimetric Data. Bull. Chem. Soc. Jpn. 1965, 38, 1881–1886. [Google Scholar] [CrossRef] [Green Version]

- Jian, W.; Kitanaka, A.; Nishijima, W.; Baes, A.U.; Okada, M. Removal of oil pollutants in seawater as pretreatment of reverse osmosis desalination process. Water Res. 1999, 33, 1857–1863. [Google Scholar] [CrossRef]

- Banerjee, S.S.; Joshi, M.V.; Jayaram, R.V. Treatment of oil spill by sorption technique using fatty acid grafted sawdust. Chemosphere 2006, 64, 1026–1031. [Google Scholar] [CrossRef]

- Rowell, R.M. Emerging Technologies for Materials and Chemicals from Biomass, Symposium Series 476; Rowell, R.M., Schultz, T., Narayan, R., Eds.; Oxford University Press: Washington, DC, USA, 1992; p. 469. [Google Scholar]

- Jandura, P.; Riedl, B.; Kokta, B.V. Thermal degradation behavior of cellulose fibers partially esterified with some long chain organic acids. Polym. Degrad. Stab. 2000, 70, 387–394. [Google Scholar] [CrossRef]

- Yao, F.; Wu, Q.; Lei, Y.; Guo, W.; Xu, Y. Thermal decomposition kinetics of natural fibers: Activation energy with dynamic thermogravimetric analysis. Polym. Degrad. Stab. 2008, 93, 90–98. [Google Scholar] [CrossRef]

- Li, X.; Tabil, L.G.; Panigrahi, S. Chemical Treatments of Natural Fiber for Use in Natural Fiber-Reinforced Composites: A Review. J. Polym. Environ. 2007, 15, 25–33. [Google Scholar] [CrossRef]

- Socrates, G. Infrared Characteristic Group Frequencies, 2nd ed.; Wiley: West Sussex, UK, 2001; pp. 115–130. [Google Scholar]

- Zhang, Y.; He, P.; Xu, X.; Li, J. Use of atomic force microscopy for imaging the initial stage of the nucleation of calcium phosphate in Langmuir–blodgett films of stearic acid. Thin Solid Film. 2004, 468, 273–279. [Google Scholar] [CrossRef]

- Changwen, D.; Linker, R.; Shaviv, A. Characterization of Soils Using Photoacoustic Mid-Infrared Spectroscopy. Appl. Spectrosc. 2007, 61, 1063–1067. [Google Scholar] [CrossRef]

- Xie, A.-J.; Zhang, C.-Y.; Shen, Y.-H.; Qiul, L.-G.; Xiao, P.-P.; Hu, Z.-Y. Morphologies of calcium carbonate crystallites grown from aqueous solutions containing polyethylene glycol. Cryst. Res. Technol. 2006, 41, 967–971. [Google Scholar] [CrossRef]

- Martín-Martínez, J.M. Rubber base adhesives. Adhes. Sci. Eng. 2002, 573–675. [Google Scholar] [CrossRef]

- Matolia, J.; Shukla, S.P.; Kumar, S.; Kumar, K.; Singh, A.R. Physical entrapment of chitosan in fixed-down-flow column bed enhances triclosan removal from water. Water Sci. Technol. 2019, 80, 1374–1383. [Google Scholar] [CrossRef] [PubMed]

| Method | Expression | Plots | Reference |

|---|---|---|---|

| Kissinger | [40] | ||

| Friedman | [41] | ||

| Flynn–Wall–Ozawa | [42,43] |

| Fibers | Conversion, α | Friedman Ea (kJ/Mol) | F–W–O Ea (kJ/Mol) |

|---|---|---|---|

| SAMBTF | 0.2 | 104.67 | 112.88 |

| 0.3 | 104.89 | 112.95 | |

| 0.4 | 105.59 | 113.52 | |

| 0.5 | 106.73 | 114.70 | |

| 0.6 | 107.89 | 115.78 | |

| Mean ± SD | 105.95 ± 1.34 | 113.97 ± 1.25 | |

| SACCMBTF | 0.2 | 189.57 | 192.98 |

| 0.3 | 172.11 | 176.56 | |

| 0.4 | 162.96 | 167.49 | |

| 0.5 | 153.88 | 158.39 | |

| 0.6 | 172.94 | 178.15 | |

| Mean ± SD | 170.29 ± 13.27 | 174.77 ± 12.94 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sathasivam, K.V.; Haris, M.R.H.M.; Fuloria, S.; Fuloria, N.K.; Malviya, R.; Subramaniyan, V. Chemical Modification of Banana Trunk Fibers for the Production of Green Composites. Polymers 2021, 13, 1943. https://doi.org/10.3390/polym13121943

Sathasivam KV, Haris MRHM, Fuloria S, Fuloria NK, Malviya R, Subramaniyan V. Chemical Modification of Banana Trunk Fibers for the Production of Green Composites. Polymers. 2021; 13(12):1943. https://doi.org/10.3390/polym13121943

Chicago/Turabian StyleSathasivam, Kathiresan V., Mas Rosemal Hakim Mas Haris, Shivkanya Fuloria, Neeraj Kumar Fuloria, Rishabha Malviya, and Vetriselvan Subramaniyan. 2021. "Chemical Modification of Banana Trunk Fibers for the Production of Green Composites" Polymers 13, no. 12: 1943. https://doi.org/10.3390/polym13121943