High-Density Bio-PE and Pozzolan Based Composites: Formulation and Prototype Design for Control of Low Water Flow

Abstract

:1. Introduction

2. Materials and Methods

2.1. Raw Materials

2.2. Preparation of Composite Pellets and the Filaments for 3D Printing

2.3. Thermal Characterization

2.4. Rheological Measurements

2.5. 3D-Printed Specimens and Drip Watering Close System Prototype Preparation

2.6. Mechanical Characterization

2.7. Characterization of the Prototype System

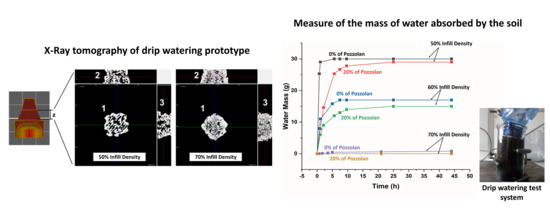

2.7.1. X-ray Tomography

2.7.2. Measurement and Analysis of the Water Flow in Real Conditions

Water Flow Measurement System

Analysis of the Water Flow through the Prototype System

3. Results and Discussion

3.1. Thermal Properties

3.2. Rheological Properties

3.3. Mechanical Properties

3.4. Drip Watering Prototype Characterization

3.4.1. Morphological Analysis

3.4.2. Water Flow Measuring

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Crump, S.S. Apparatus and Method for Creating Three-Dimensional Objects. U.S. Patent No. 5,121,329, 9 June 1992. [Google Scholar]

- Braconnier, D.J.; Jensen, R.E.; Peterson, A.M. Processing Parameter Correlations in Material Extrusion Additive Manufacturing. Addit. Manuf. 2020, 31, 100924. [Google Scholar] [CrossRef]

- Chard, J.; van Iersel, M.; Bugbee, B. Mini-Lysimeters to Monitor Transpiration and Control Drought Stress: System Design and Unique Applications; Merrill-Cazier Library: Logan, UT, USA, 2010. [Google Scholar]

- Hess, L.; De Kroon, H. Effects of Rooting Volume and Nutrient Availability as an Alternative Explanation for Root Self/Non-Self Discrimination. J. Ecol. 2007, 95, 241–251. [Google Scholar] [CrossRef]

- Schrader, J.A.; Kratsch, H.A.; Graves, W.R. Bioplastic Container Cropping Systems: Green Technology for the Green Industry; Sustainable Horticulture Research Consortium: Ames, IA, USA, 2016. [Google Scholar]

- Poorter, H.; Bühler, J.; van Dusschoten, D.; Climent, J.; Postma, J.A. Pot Size Matters: A Meta-Analysis of the Effects of Rooting Volume on Plant Growth. Funct. Plant Biol. 2012, 39, 839–850. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ray, J.D.; Sinclair, T.R. The Effect of Pot Size on Growth and Transpiration of Maize and Soybean during Water Deficit Stress. J. Exp. Bot. 1998, 49, 1381–1386. [Google Scholar] [CrossRef]

- Biran, I.; Eliassaf, A. The Effect of Container Size and Aeration Conditions on Growth of Roots and Canopy of Woody Plants. Sci. Hortic. 1980, 12, 385–394. [Google Scholar] [CrossRef]

- Nikolaou, G.; Neocleous, D.; Katsoulas, N.; Kittas, C. Irrigation of Greenhouse Crops. Horticulturae 2019, 5, 7. [Google Scholar] [CrossRef] [Green Version]

- Massetani, F.; Savini, G.; Neri, D. Effect of Rooting Time, Pot Size and Fertigation Technique on Strawberry Plant Architecture. J. Berry Res. 2014, 4, 217–224. [Google Scholar] [CrossRef] [Green Version]

- Ujeniya, P.S.; Rachchh, N.V. A Review on Manufacturing, Machining, and Recycling of 3D Printed Composite Materials. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2019; Volume 653, p. 012024. [Google Scholar]

- Askanian, H.; Muranaka de Lima, D.; Commereuc, S.; Verney, V. Toward a Better Understanding of the Fused Deposition Modeling Process: Comparison with Injection Molding. 3D Print. Addit. Manuf. 2018, 5, 319–327. [Google Scholar] [CrossRef]

- Vidakis, N.; Petousis, M.; Tzounis, L.; Maniadi, A.; Velidakis, E.; Mountakis, N.; Kechagias, J. Sustainable Additive Manufacturing: Mechanical Response of Polyamide 12 over Multiple Recycling Processes. Materials 2021, 14, 466. [Google Scholar] [CrossRef]

- Vidakis, N.; Vairis, A.; Petousis, M.; Savvakis, K.; Kechagias, J. Fused Deposition Modelling Parts Tensile Strength Characterisation. Acad. J. Manuf. Eng. 2016, 14, 87–94. [Google Scholar]

- Kumar, M.; Ramachandran, R.; Omarbekova, A. 3D Printed Polycarbonate Reinforced Acrylonitrile–Butadiene–Styrene Composites: Composition Effects on Mechanical Properties, Micro-Structure and Void Formation Study. J. Mech. Sci. Technol. 2019, 33. [Google Scholar] [CrossRef]

- Rodzeń, K.; Sharma, P.K.; McIlhagger, A.; Mokhtari, M.; Dave, F.; Tormey, D.; Sherlock, R.; Meenan, B.J.; Boyd, A. The Direct 3D Printing of Functional PEEK/Hydroxyapatite Composites via a Fused Filament Fabrication Approach. Polymers 2021, 13, 545. [Google Scholar] [CrossRef]

- HDPE. Available online: https://polymerdatabase.com/Commercial%20Polymers/HDPE.html (accessed on 26 March 2021).

- Zander, N.E.; Gillan, M.; Burckhard, Z.; Gardea, F. Recycled Polypropylene Blends as Novel 3D Printing Materials. Addit. Manuf. 2019, 25, 122–130. [Google Scholar] [CrossRef]

- Sang, L.; Han, S.; Li, Z.; Yang, X.; Hou, W. Development of Short Basalt Fiber Reinforced Polylactide Composites and Their Feasible Evaluation for 3D Printing Applications. Compos. Part B Eng. 2019, 164, 629–639. [Google Scholar] [CrossRef]

- Lee, J.-Y.; An, J.; Chua, C.K. Fundamentals and Applications of 3D Printing for Novel Materials. Appl. Mater. Today 2017, 7, 120–133. [Google Scholar] [CrossRef]

- Wang, T.-M.; Xi, J.-T.; Jin, Y. A Model Research for Prototype Warp Deformation in the FDM Process. Int. J. Adv. Manuf. Technol. 2007, 33, 1087–1096. [Google Scholar] [CrossRef]

- Plastics Market Size, Share & Trends Report, 2020–2027. Available online: https://www.grandviewresearch.com/industry-analysis/global-plastics-market (accessed on 26 March 2021).

- Schirmeister, C.G.; Hees, T.; Licht, E.H.; Mülhaupt, R. 3D Printing of High Density Polyethylene by Fused Filament Fabrication. Addit. Manuf. 2019, 28, 152–159. [Google Scholar] [CrossRef]

- Tarrés, Q.; Melbø, J.K.; Delgado-Aguilar, M.; Espinach, F.X.; Mutjé, P.; Chinga-Carrasco, G. Bio-Polyethylene Reinforced with Thermomechanical Pulp Fibers: Mechanical and Micromechanical Characterization and Its Application in 3D-Printing by Fused Deposition Modelling. Compos. Part B Eng. 2018, 153, 70–77. [Google Scholar] [CrossRef]

- Balani, S.B.; Chabert, F.; Nassiet, V.; Cantarel, A. Influence of Printing Parameters on the Stability of Deposited Beads in Fused Filament Fabrication of Poly (Lactic) Acid. Addit. Manuf. 2019, 25, 112–121. [Google Scholar] [CrossRef] [Green Version]

- Mazzanti, V.; Malagutti, L.; Mollica, F. FDM 3D Printing of Polymers Containing Natural Fillers: A Review of Their Mechanical Properties. Polymers 2019, 11, 1094. [Google Scholar] [CrossRef] [Green Version]

- Stoof, D.; Pickering, K. Sustainable Composite Fused Deposition Modelling Filament Using Recycled Pre-Consumer Polypropylene. Compos. Part B Eng. 2018, 135, 110–118. [Google Scholar] [CrossRef]

- Chong, S.; Pan, G.-T.; Khalid, M.; Yang, T.C.-K.; Hung, S.-T.; Huang, C.-M. Physical Characterization and Pre-Assessment of Recycled High-Density Polyethylene as 3D Printing Material. J. Polym. Environ. 2017, 25, 136–145. [Google Scholar] [CrossRef]

- Peng, F.; Jiang, H.; Woods, A.; Joo, P.; Amis, E.J.; Zacharia, N.S.; Vogt, B.D. 3D Printing with Core–Shell Filaments Containing High or Low Density Polyethylene Shells. ACS Appl. Polym. Mater. 2019, 1, 275–285. [Google Scholar] [CrossRef]

- Mohan, V.B.; Bhattacharyya, D. Mechanical, Electrical and Thermal Performance of Hybrid Polyethylene-Graphene Nanoplatelets-Polypyrrole Composites: A Comparative Analysis of 3D Printed and Compression Molded Samples. Polym. Plast. Technol. Mater. 2020, 59, 780–796. [Google Scholar] [CrossRef]

- Zhang, F.; Ma, G.; Tan, Y. The Nozzle Structure Design and Analysis for Continuous Carbon Fiber Composite 3D Printing. In Proceedings of the 2017 7th International Conference on Advanced Design and Manufacturing Engineering (ICADME 2017), Shenzhen, China, 10–11 May 2017; Atlantis Press: Moscow, Russia, 2017; pp. 193–199. [Google Scholar]

- Wang, X.; Jiang, M.; Zhou, Z.; Gou, J.; Hui, D. 3D Printing of Polymer Matrix Composites: A Review and Prospective. Compos. Part B Eng. 2017, 110, 442–458. [Google Scholar] [CrossRef]

- Naigaga, E. An Examination of the Sustainability of Pozzolana Mining Processes in Uganda. Int. J. Res. Chem. Metall. Civ. Eng. 2014, 1, 25. [Google Scholar]

- El Youbi, M.S.; Ahmed, E. Development and Study of Physical, Chemical and Mechanical Properties of a New Formulation of Cement of a Varying Percentage of Natural Pozzolan. J. Chem. Technol. Met. 2017, 52, 873–884. [Google Scholar]

- Kim, H.; Choi, S.; Lee, B.; Kim, S.; Kim, H.; Cho, C.; Cho, D. Thermal Properties of Bio Flour-Filled Polypropylene Bio-Composites with Different Pozzolan Contents. J. Therm. Anal. Calorim. 2007, 89, 821–827. [Google Scholar] [CrossRef]

- Sbaffoni, S.; Boni, M.R.; Vaccari, M. Potential of Compost Mixed with Tuff and Pozzolana in Site Restoration. Waste Manag. 2015, 39, 146–157. [Google Scholar] [CrossRef] [PubMed]

- Seco, A.; Ramirez, F.; Miqueleiz, L.; Urmeneta, P.; García, B.; Prieto, E.; Oroz, V. Types of Waste for the Production of Pozzolanic Materials—A Review; Intech: Rabat, Morocco, 2012; p. 29. [Google Scholar]

- Rocher, P. Mémento Roches et Minéraux Industriels; BRGM: Orléans, France, 1992; p. 47. [Google Scholar]

- Les Services de l’État dans le Puy-de-Dôme. Schéma Départemental des Carriers. Available online: http://www.puy-de-dome.gouv.fr/schema-departemental-des-carrieres-r1292.html (accessed on 25 March 2021).

- Pouzzolane. Available online: http://www.ciment.wikibis.com/pouzzolane.php (accessed on 25 March 2021).

- Schiavone, N.; Verney, V.; Askanian, H. Pozzolan Based 3D Printing Composites: From the Formulation Till the Final Application in the Precision Irrigation Field. Materials 2021, 14, 43. [Google Scholar] [CrossRef]

- Esposito Corcione, C.; Palumbo, E.; Masciullo, A.; Montagna, F.; Torricelli, M.C. Fused Deposition Modeling (FDM): An Innovative Technique Aimed at Reusing Lecce Stone Waste for Industrial Design and Building Applications. Constr. Build. Mater. 2018, 158, 276–284. [Google Scholar] [CrossRef]

- Wasti, S.; Adhikari, S. Use of Biomaterials for 3D Printing by Fused Deposition Modeling Technique: A Review. Front. Chem. 2020, 8. [Google Scholar] [CrossRef] [PubMed]

- Available online: https://www.hitachi-hightech.com/file/global/pdf/products/science/appli/ana/thermal/application_TA_026e.pdf (accessed on 25 March 2021).

- Refaa, Z.; Boutaous, M.; Xin, S.; Siginer, D.A. Thermophysical Analysis and Modeling of the Crystallization and Melting Behavior of PLA with Talc. J. Anal. Calorim. 2017, 128, 687–698. [Google Scholar] [CrossRef]

- Marek, A.A.; Verney, V. Rheological Behavior of Polyolefins during UV Irradiation at High Temperature as a Coupled Degradative Process. Eur. Polym. J. 2015, 72, 1–11. [Google Scholar] [CrossRef]

- Schiavone, N.; Verney, V.; Askanian, H. Effect of 3D Printing Temperature Profile on Polymer Materials Behavior. 3D Print. Addit. Manuf. 2020, 7, 311–325. [Google Scholar] [CrossRef]

- Wypych, G. 2-Mechanisms of Adhesion. In Handbook of Adhesion Promoters; Wypych, G., Ed.; ChemTec Publishing: Scarborough, ON, Canada, 2018; pp. 5–44. ISBN 978-1-927885-29-1. [Google Scholar]

- Graziano, A.; Jaffer, S.; Sain, M. Review on Modification Strategies of Polyethylene/Polypropylene Immiscible Thermoplastic Polymer Blends for Enhancing Their Mechanical Behavior. J. Elastomers Plast. 2019, 51, 291–336. [Google Scholar] [CrossRef]

- Perry’s Chemical Engineers’ Handbook, 9th ed.; McGraw-Hill Education—Access Engineering: New York, NY, USA, 2019; Available online: https://www.accessengineeringlibrary.com/content/book/9780071834087 (accessed on 26 May 2021).

- Whitaker, S. Flow in Porous Media I: A Theoretical Derivation of Darcy’s Law. Transp. Porous Med. 1986, 1, 3–25. [Google Scholar] [CrossRef]

- Bird, R.B.; Stewart, W.E.; Lightfoot, E.N. Transport Phenomena; John Wiley & Sons: Hoboken, NJ, USA, 2006; ISBN 978-0-470-11539-8. [Google Scholar]

- Ouedraogo, F.; Cherblanc, F.; Naon, B.; Bénet, J.-C. Water Transfer in Soil at Low Water Content. Is the Local Equilibrium Assumption Still Appropriate? J. Hydrol. 2013, 492, 117–127. [Google Scholar] [CrossRef] [Green Version]

- Fundamental Equations in Colloid and Surface Science. In Introduction to Applied Colloid and Surface Chemistry; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 74–95. ISBN 978-1-118-88119-4.

- Phan, D.D.; Horner, J.S.; Swain, Z.R.; Beris, A.N.; Mackay, M.E. Computational Fluid Dynamics Simulation of the Melting Process in the Fused Filament Fabrication Additive Manufacturing Technique. Addit. Manuf. 2020, 33, 101161. [Google Scholar] [CrossRef]

- Patki, R.P.; Phillips, P.J. Crystallization Kinetics of Linear Polyethylene: The Maximum in Crystal Growth Rate–Temperature Dependence. Eur. Polym. J. 2008, 44, 534–541. [Google Scholar] [CrossRef]

- Valentina, I.; Haroutioun, A.; Fabrice, L.; Vincent, V.; Roberto, P. Poly(Lactic Acid)-Based Nanobiocomposites with Modulated Degradation Rates. Materials 2018, 11, 1943. [Google Scholar] [CrossRef] [Green Version]

- Escócio, V.A.; Pacheco, E.B.A.V.; da Silva, A.L.N.; de Paula Cavalcante, A.; Visconte, L.L.Y. Rheological Behavior of Renewable Polyethylene (HDPE) Composites and Sponge Gourd (Luffa cylindrica) Residue. Int. J. Polym. Sci. 2015, 2015, 714352. Available online: https://www.hindawi.com/journals/ijps/2015/714352/ (accessed on 2 February 2021). [CrossRef] [Green Version]

- Shah, P.; Stansbury, J. Role of Filler and Functional Group Conversion in the Evolution of Properties in Polymeric Dental Restoratives. Dent. Mater. 2014, 30. [Google Scholar] [CrossRef] [Green Version]

- Casavola, C.; Cazzato, A.; Moramarco, V.; Pappalettera, G. Residual Stress Measurement in Fused Deposition Modelling Parts. Polym. Test. 2017, 58, 249–255. [Google Scholar] [CrossRef]

- Askanian, H.; Verney, V.; Commereuc, S.; Guyonnet, R.; Massardier, V. Wood Polypropylene Composites Prepared by Thermally Modified Fibers at Two Extrusion Speeds: Mechanical and Viscoelastic Properties. Holzforschung 2015, 69, 313–319. [Google Scholar] [CrossRef]

- Kiran, M.D.; Govindaraju, H.K.; Jayaraju, T.; Kumar, N. Review-Effect of Fillers on Mechanical Properties of Polymer Matrix Composites. Mater. Today: Proc. 2018, 5, 22421–22424. [Google Scholar] [CrossRef]

- Jancar, J. Chapter 31—Composite materiomics: Multi length scale hierarchical composites for structural and tissue engineering applications. In Multifunctionality of Polymer Composites; Friedrich, K., Breuer, U., Eds.; William Andrew Publishing: Oxford, UK, 2015; pp. 903–944. ISBN 978-0-323-26434-1. [Google Scholar]

- Kariz, M.; Sernek, M.; Obućina, M.; Kuzman, M.K. Effect of Wood Content in FDM Filament on Properties of 3D Printed Parts. Mater. Today Commun. 2018, 14, 135–140. [Google Scholar] [CrossRef]

- Wu, C.-S.; Liao, H.-T.; Cai, Y.-X. Characterisation, Biodegradability and Application of Palm Fibre-Reinforced Polyhydroxyalkanoate Composites. Polym. Degrad. Stab. 2017, 140, 55–63. [Google Scholar] [CrossRef]

- Filgueira, D.; Holmen, S.; Melbø, J.K.; Moldes, D.; Echtermeyer, A.T.; Chinga-Carrasco, G. 3D Printable Filaments Made of Biobased Polyethylene Biocomposites. Polymers 2018, 10, 314. [Google Scholar] [CrossRef] [Green Version]

- Liao, Y.; Liu, C.; Coppola, B.; Barra, G.; Di Maio, L.; Incarnato, L.; Lafdi, K. Effect of Porosity and Crystallinity on 3D Printed PLA Properties. Polymers 2019, 11, 1487. [Google Scholar] [CrossRef] [Green Version]

| Heating Zone | Z1 | Z2 | Z3 | Z4 | Z5 | Z6 | Z7 | Z8 |

|---|---|---|---|---|---|---|---|---|

| Temperature (°C) | 180 | 220 | 220 | 220 | 230 | 240 | 240 | 220 |

| Screw Rate (rpm) | 200 | |||||||

| Total Mass Flow (kg/h) | 0.6 | |||||||

| Parameter | Value |

|---|---|

| Nozzle diameter (mm) | 0.6 |

| Nozzle temperature (°C) | 265 |

| Layer thickness (mm) | 0.15 |

| Bed temperature (°C) | 35 |

| Printing speed for the first layer (mm/s) | 20 |

| Printing speed for the other layers (mm/s) | 20 |

| Parameters | Values |

|---|---|

| ρ (kg/m3) | 1000 |

| µ (Pa s) | 0.0001 |

| r (mm) | 5 |

| L (mm) | 7 |

| Δh (cm) | 18 |

| Vs (cm3) | 30 |

| Pozzolan | ΔHm (J/g) | Tm (°C) | ΔHc (J/g) | Tc (°C) | Xc (%) |

|---|---|---|---|---|---|

| 0% | 112 | 135 | 127 | 114 | 39 |

| 20% | 74 | 133 | 89 | 115 | 33 |

| 40% | 58 | 133 | 64 | 116 | 34 |

| 60% | 36 | 134 | 43 | 116 | 34 |

| Samples | Reynolds Number | k (m2) |

|---|---|---|

| 50%ID–0%PR | 1.2 × 100 | 3.2 × 10−18 |

| 50%ID–20%PR | 2.7 × 10−1 | 5.3 × 10−19 |

| 60%ID–0%PR | 3.7 × 10−1 | 9.9 × 10−20 |

| 60%ID–20%PR | 2.1 × 10−1 | 3.3 × 10−20 |

| 70%ID–0%PR | 2.5 × 10−3 | 2.6 × 10−21 |

| 70%ID–20%PR | 7.1 × 10−4 | 1.2 × 10−21 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Schiavone, N.; Verney, V.; Askanian, H. High-Density Bio-PE and Pozzolan Based Composites: Formulation and Prototype Design for Control of Low Water Flow. Polymers 2021, 13, 1908. https://doi.org/10.3390/polym13121908

Schiavone N, Verney V, Askanian H. High-Density Bio-PE and Pozzolan Based Composites: Formulation and Prototype Design for Control of Low Water Flow. Polymers. 2021; 13(12):1908. https://doi.org/10.3390/polym13121908

Chicago/Turabian StyleSchiavone, Nicola, Vincent Verney, and Haroutioun Askanian. 2021. "High-Density Bio-PE and Pozzolan Based Composites: Formulation and Prototype Design for Control of Low Water Flow" Polymers 13, no. 12: 1908. https://doi.org/10.3390/polym13121908