Ameliorated Performance of Sulfonated Poly(Arylene Ether Sulfone) Block Copolymers with Increased Hydrophilic Oligomer Ratio in Proton-Exchange Membrane Fuel Cells Operating at 80% Relative Humidity

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Synthesis of A

2.3. Synthesis of B

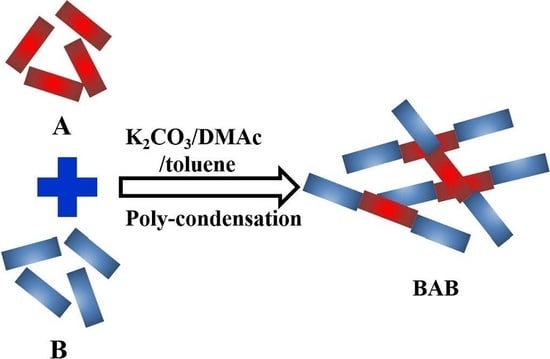

2.4. Synthesis of AB, ABA and BAB

2.5. Membrane Preparation

3. Characterizations

4. Results and Discussion

4.1. Synthesis and Structural Properties

4.2. Morphologic Behaviors

4.3. Thermal and Mechanical Behaviors

4.4. Oxidative Stability

4.5. Water Uptake, Swelling Ratio, IEC and Water Sorption

4.6. Proton Conductivity and Arrhenius Plots

4.7. Single Cell Performance

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Conflicts of Interest

References

- Gahlot, S.; Sharma, P.P.; Kulshrestha, V.; Jha, P.K. SGO/SPES-based highly conducting polymer electrolyte membranes for fuel cell application. ACS Appl. Mater. Interfaces 2014, 6, 5595–5601. [Google Scholar] [CrossRef] [PubMed]

- Gnana kumar, G.; Balanay, M.P.; Nirmala, R.; Kim, D.H.; Kumar, T.R.; Senthilkumar, N.; Kim, A.R.; Yoo, D.J. The photovoltaic performances of PVdF-HFP electrospun membranes employed quasi-solid-state dye sensitized solar cells. J. Nanosci. Nanotechnol. 2016, 16, 581–587. [Google Scholar] [CrossRef] [PubMed]

- Hossian, S.I.; Aziz, M.A.; Shanmugam, S. Ultrahigh ion-selective and durable Nafion-NdZr composite layer membranes for all-vanadium redox flow batteries. ACS Sustain. Chem. Eng. 2020, 8, 1998–2007. [Google Scholar] [CrossRef]

- Zhong, S.L.; Liu, C.G.; Dou, Z.Y.; Li, X.F.; Zhao, C.J.; Fu, T.Z.; Na, H. Synthesis and properties of sulfonated poly(ether ether ketone ketone) containing tert-butyl groups as proton exchange membrane material. J. Membr. Sci. 2006, 285, 404–411. [Google Scholar] [CrossRef]

- Kim, R.; Gabunada, J.C.; Yoo, D.J. Amelioration in physicochemical properties and single cell performance of sulfonated poly(ether ether ketone) block copolymer composite membrane using sulfonated carbon nanotubes for intermediate humidity fuel cells. Int. J. Energy Res. 2019, 43, 2974–2989. [Google Scholar] [CrossRef]

- Vinothkannan, M.; Kim, A.R.; Gnana kumar, G.; Yoon, J.M.; Yoo, D.J. Toward improved mechanical strength, oxidative stability and proton conductivity of an aligned quadratic hybrid (SPEEK/FPAPB/Fe3O4-FGO) membrane for application in high temperature and low humidity fuel cells. RSC Adv. 2017, 7, 39034–39048. [Google Scholar] [CrossRef] [Green Version]

- Kim, A.R.; Vinothkannan, M.; Yoo, D.J. Artificially designed, low humidifying organic–inorganic (SFBC-50/FSiO2) composite membrane for electrolyte applications of fuel cells. Compos. B Eng. 2017, 130, 103–118. [Google Scholar] [CrossRef]

- Zarrin, H.; Higgins, D.; Jun, Y.; Chen, Z.; Fowler, M. Functionalized graphene oxide nanocomposite membrane for low humidity and high temperature proton exchange membrane fuel cells. J. Phys. Chem. C. 2011, 115, 20774–20781. [Google Scholar] [CrossRef]

- Velayutham, P.; Sahu, A.K. Graphitic carbon nitride nanosheets-Nafion as a methanol barrier hybrid membrane for direct methanol fuel cells. J. Phys. Chem. C. 2018, 122, 21735–21744. [Google Scholar] [CrossRef]

- Sahu, A.K.; Ketpang, K.; Shanmugam, S.; Kwon, O.; Lee, S.; Kim, H. Sulfonated graphene−Nafion composite membranes for polymer electrolyte fuel cells operating under reduced relative humidity. J. Phys. Chem. C. 2016, 120, 15855–15866. [Google Scholar] [CrossRef]

- Ghassemi, H.; Ndip, G.; McGrath, J.E. New multiblock copolymers of sulfonated poly(4′-phenyl-2,5-benzophenone) and poly(arylene ether sulfone) for proton exchange membranes. Polymer 2004, 45, 5855–5862. [Google Scholar] [CrossRef]

- Kumar, G.; Kim, A.R.; Nahm, K.S.; Yoo, D.J. High proton conductivity and low fuel crossover of polyvinylidene fluoride–hexafluoro propylene–silica sulfuric acid composite membranes for direct methanol fuel cells. Curr. Appl. Phys. 2011, 11, 896–902. [Google Scholar] [CrossRef]

- Bae, B.; Miyatake, K.; Watanabe, M. Effect of the hydrophobic component on the properties of sulfonated poly(arylene ether sulfone)s. Macromolecules. 2009, 42, 1873–1880. [Google Scholar] [CrossRef]

- Yoo, D.J.; Hyun, S.H.; Kim, A.R.; Kumar, G.G.; Nahm, K.S. Novel sulfonated poly(arylene biphenylsulfone ether) copolymers containing bisphenyl sulfonyl biphenyl moiety: Structural, thermal, electrochemical and morphological characteristics. Polym. Int. 2011, 60, 85–92. [Google Scholar] [CrossRef]

- Kim, A.R.; Vinothkannan, M.; Yoo, D.J. Sulfonated-fluorinated copolymer blending membranes containing SPEEK for use as the electrolyte in polymer electrolyte fuel cells (PEFC). Int. J. Hydrogen Energy 2017, 42, 4349–4365. [Google Scholar] [CrossRef]

- Kim, D.S.; Robertson, G.P.; Guiver, M.D. Comb-shaped poly(arylene ether sulfone)s as proton exchange membranes. Macromolecules 2008, 41, 2126–2134. [Google Scholar] [CrossRef] [Green Version]

- Hossain, M.A.; Lim, Y.D.; Lee, S.H.; Jang, H.Y.; Choi, S.Y.; Hong, T.H.; Jin, L.; Kim, W.G. Synthesis and characterization of tetra-imidazolium hydroxides poly(fluorenylene ether sulfone) anion exchange membranes. React. Funct. Polym. 2013, 73, 1299–1305. [Google Scholar] [CrossRef]

- Badami, A.S.; Lane, O.; Lee, H.S.; Roy, A.; McGrath, J.E. Fundamental investigations of the effect of the linkage group on the behavior of hydrophilic–hydrophobic poly(arylene ether sulfone) multiblock copolymers for proton exchange membrane fuel cells. J. Membr. Sci. 2009, 333, 1–11. [Google Scholar] [CrossRef]

- Kopitzke, R.W.; Linkous, C.A.; Anderson, H.R.; Nelson, G.L. Conductivity and water uptake of aromatic-based proton exchange membrane electrolytes. J. Electrochem. Soc. 2000, 147, 1677–1681. [Google Scholar] [CrossRef]

- Devrim, Y.; Erkan, S.; Bac, N.; Eroglu, L. Nafion/titanium silicon oxide nanocomposite membranes for PEM fuel cells. Int. J. Energy Res. 2013, 37, 435–442. [Google Scholar] [CrossRef]

- Kim, A.R.; Yoo, D.J. A Comparative Study on physiochemical, thermomechanical and electrochemical properties of sulfonated poly(ether ether ketone) block copolymer membranes with and without Fe3O4 nanoparticles. Polymers 2019, 11, 536. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Neelakandan, S.; Kanagaraj, P.; Sabarathinam, R.M.; Muthumeenal, A.; Nagendran, A. Effect of sulfonated graphene oxide on the performance enhancement of acid–base composite membranes for direct methanol fuel cells. RSC Adv. 2016, 6, 51599–51608. [Google Scholar] [CrossRef]

- Kim, A.R.; Vinothkannan, M.; Park, C.J.; Yoo, D.J. Alleviating the mechanical and thermal degradations of highly sulfonated poly(ether ether ketone) blocks via copolymerization with hydrophobic unit for intermediate humidity fuel cells. Polymers 2018, 10, 1346. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Huang, H.; Ni, L.; Xu, J.; Xie, X.; Zhang, L.; Yang, C.; Fan, J.; Li, H.; Wang, H.J. An in situ cross-linked vinylphosphonic acid modified aminosilicon oxide gel electrolyte for proton exchange membrane fuel cells. Sustain. Energy Fuels 2020, 4, 2859–2868. [Google Scholar] [CrossRef]

- Miyahara, T.; Hayano, T.; Matsuno, S.; Watanabe, M.; Miyatake, K. Sulfonated polybenzophenone/poly(arylene ether) block copolymer membranes for fuel cell applications. ACS Appl. Mater. Interfaces 2012, 4, 2881–2884. [Google Scholar] [CrossRef]

- Aboki, J.; Jing, B.; Luo, S.; Zhu, Y.; Zhu, L.; Guo, R. Highly proton conducting polyelectrolyte membranes with unusual water swelling behavior based on triptycene-containing poly(arylene ether sulfone) multiblock copolymers. ACS Appl. Mater. Interfaces 2018, 10, 1173–1186. [Google Scholar] [CrossRef]

- Bae, B.; Miyatake, K.; Watanabe, M. Synthesis and properties of sulfonated block copolymers having fluorenyl groups for fuel-cell applications. ACS Appl. Mater. Interfaces 2009, 1, 1279–1286. [Google Scholar] [CrossRef]

- Rambabu, G.; Bhat, S.D. Simultaneous tuning of methanol crossover and ionic conductivity of sPEEK membrane electrolyte by incorporation of PSSA functionalized MWCNTs: A comparative study in DMFCs. Chem. Engin. J. 2014, 43, 517–525. [Google Scholar] [CrossRef]

- Rambabu, G.; Nagaraju, N.; Bhat, S.D. Functionalized fullerene embedded in Nafion matrix: A modified composite membrane electrolyte for direct methanol fuel cells. Chem. Engin. J. 2016, 306, 43–52. [Google Scholar] [CrossRef]

- Jiang, Z.; Zhao, X.; Fu, Y.; Manthiram, A. Composite membranes based on sulfonated poly(ether ether ketone) and SDBS-adsorbed graphene oxide for direct methanol fuel cells. J. Mater. Chem. 2012, 22, 24862–24869. [Google Scholar] [CrossRef]

- Oh, K.; Son, B.; Sanetuntikul, J.; Shanmugam, S. Polyoxometalate decorated graphene oxide/sulfonated poly(arylene ether ketone) block copolymer composite membrane for proton exchange membrane fuel cell operating under low relative humidity. J. Membr. Sci. 2017, 541, 386–392. [Google Scholar] [CrossRef]

- Xue, Y.L.; Lau, C.H.; Cao, B.; Li, P. Elucidating the impact of polymer crosslinking and fixed carrier on enhanced water transport during desalination using pervaporation membranes. J. Membr. Sci. 2019, 575, 135–146. [Google Scholar] [CrossRef]

| Polymer | Molar Ratio a | Mn, g mol−1 | Mw, g mol−1 | Mz, g mol−1 | Mw/ Mn (PDI) |

|---|---|---|---|---|---|

| A | 10:0 | 4300 | 13,900 | 31,200 | 3.2 |

| B | 0:10 | 16,500 | 35,600 | 68,000 | 2.1 |

| Control | – | 4600 | 14,800 | 38,100 | 3.2 |

| AB | 1:1 | 9600 | 45,200 | 212,100 | 4.6 |

| ABA | 2:1 | 8400 | 61,900 | 431,800 | 6.9 |

| BAB | 1:2 | 12,800 | 78,400 | 915,500 | 6.1 |

| Membrane | Tensile Strength (Mpa) | Elongation at Break (%) | Young’s Modulus (Mpa) |

|---|---|---|---|

| AB | 24.68 | 9.60 | 2005.32 |

| ABA | 28.20 | 4.13 | 1451.35 |

| BAB | 24.31 | 32.51 | 1284 |

© 2020 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, A.R.; Vinothkannan, M.; Lee, K.H.; Chu, J.Y.; Ryu, S.K.; Kim, H.G.; Lee, J.-Y.; Lee, H.-K.; Yoo, D.J. Ameliorated Performance of Sulfonated Poly(Arylene Ether Sulfone) Block Copolymers with Increased Hydrophilic Oligomer Ratio in Proton-Exchange Membrane Fuel Cells Operating at 80% Relative Humidity. Polymers 2020, 12, 1871. https://doi.org/10.3390/polym12091871

Kim AR, Vinothkannan M, Lee KH, Chu JY, Ryu SK, Kim HG, Lee J-Y, Lee H-K, Yoo DJ. Ameliorated Performance of Sulfonated Poly(Arylene Ether Sulfone) Block Copolymers with Increased Hydrophilic Oligomer Ratio in Proton-Exchange Membrane Fuel Cells Operating at 80% Relative Humidity. Polymers. 2020; 12(9):1871. https://doi.org/10.3390/polym12091871

Chicago/Turabian StyleKim, Ae Rhan, Mohanraj Vinothkannan, Kyu Ha Lee, Ji Young Chu, Sumg Kwan Ryu, Hwan Gyu Kim, Jae-Young Lee, Hong-Ki Lee, and Dong Jin Yoo. 2020. "Ameliorated Performance of Sulfonated Poly(Arylene Ether Sulfone) Block Copolymers with Increased Hydrophilic Oligomer Ratio in Proton-Exchange Membrane Fuel Cells Operating at 80% Relative Humidity" Polymers 12, no. 9: 1871. https://doi.org/10.3390/polym12091871