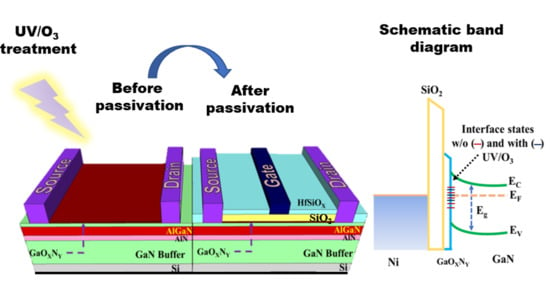

Combined Implications of UV/O3 Interface Modulation with HfSiOX Surface Passivation on AlGaN/AlN/GaN MOS-HEMT

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Borga, M.; Meneghini, M.; Benazzi, D.; Canato, E.; Püsche, R.; Derluyn, J.; Abid, I.; Medjdoub, F.; Meneghessoa, G.; Zanoni, E. Buffer breakdown in GaN-on-Si HEMTs: A comprehensive study based on a sequential growth experiment. Microelectron. Reliab. 2019, 100–101, 1–5. [Google Scholar] [CrossRef]

- Ardaravičius, L.; Matulionis, A.; Liberis, J.; Kiprijanovic, O.; Ramonas, M.; Eastman, L.F.; Shealy, J.R.; Vertiatchikh, A. Electron drift velocity in AlGaN/GaN channel at high electric fields. Appl. Phys. Lett. 2003, 83, 4038–4040. [Google Scholar] [CrossRef]

- Mazumder, S.; Wang, Y.H. Investigation of HfSiOX passivation effect on AlGaN/GaN HEMT. In Proceedings of the 2020 International Symposium on Devices, Circuits and Systems, ISDCS, Howrah, India, 4–6 March 2020; pp. 1–4. [Google Scholar]

- Hori, Y.; Yatabe, Z.; Hashizume, T. Characterization of interface states in Al2O3/AlGaN/GaN structures for improved performance of high-electron-mobility transistors. J. Appl. Phys. 2013, 114, 244503. [Google Scholar] [CrossRef] [Green Version]

- Arulkumaran, S. Surface passivation effects in AlGaN/GaN HEMTs on high-resistivity Si substrate. In Proceedings of the 2007 International Workshop on Physics of Semiconductor Devices, IWPS, Mumbai, India, 16–20 December 2007; pp. 317–322. [Google Scholar]

- Eller, B.S.; Yang, J.; Nemanich, R.J. Electronic surface and dielectric interface states on GaN and AlGaN. J. Vac. Sci. Technol. A 2013, 31, 050807. [Google Scholar] [CrossRef]

- Jussila, H.; Mattila, P.; Oksanen, J.; Perros, A.; Riikonen, J.; Bosund, M.; Varpula, A.; Huhtio, T.; Lipsanen, H.; Sopanen, M. High-k GaAs metal insulator semiconductor capacitors passivated by ex-situ plasma-enhanced atomic layer deposited AlN for fermi-level unpinning. Appl. Phys. Lett. 2012, 100, 071606. [Google Scholar] [CrossRef] [Green Version]

- Passlack, M.; Hong, M.; Mannaerts, J.P. Quasistatic and high frequency capacitance-voltage characterization of Ga2O3-GaAs structures fabricated by in-situ molecular beam epitaxy. Appl. Phys. Lett. 1996, 68, 1099–1101. [Google Scholar] [CrossRef]

- Park, S.; Kim, S.Y.; Choi, Y.; Kim, M.; Shin, H.; Kim, J.; Choi, W. Interface properties of atomic-layer-deposited Al2O3 thin films on ultraviolet/ozone-treated multilayer MoS2 crystals. ACS Appl. Mater. Interfaces 2016, 8, 11189–11193. [Google Scholar] [CrossRef]

- Smith, L.L.; King, S.W.; Nemanich, R.J.; Davis, R.F. Cleaning of GaN surfaces. J. Electron. Mater. 1996, 25, 805–810. [Google Scholar] [CrossRef]

- Bradley, S.T.; Goss, S.H.; Hwang, J.; Schaff, W.J.; Brillson, L.J. Surface cleaning and annealing effects on Ni/AlGaN interface atomic composition and schottky barrier height. Appl. Phys. Lett. 2004, 85, 1368–1370. [Google Scholar] [CrossRef]

- Kim, K.; Ryu, J.H.; Kim, J.; Cho, S.J.; Liu, D.; Park, J.; Lee, I.-K.; Moody, B.; Zhou, W.; Albrecht, J.; et al. Band-bending of Ga-polar GaN interfaced with Al2O3 through ultraviolet/ozone treatment. ACS Appl. Mater. Interfaces 2017, 9, 17576–17585. [Google Scholar] [CrossRef]

- Choi, J.H.; Cho, C.H.; Cha, H.Y. Design consideration of high voltage Ga2O3 vertical Schottky barrier diode with field plate. Results Phys. 2018, 9, 1170–1171. [Google Scholar] [CrossRef]

- Liu, X.; Low, E.K.F.; Pan, J.; Liu, W.; Teo, K.L.; Tan, L.S.; Yeo, Y.C. Impact of in situ vacuum anneal and SiH4 treatment on electrical characteristics of AlGaN/GaN metal-oxide-semiconductor high-electron mobility transistors. Appl. Phys. Lett. 2011, 99, 093504. [Google Scholar] [CrossRef]

- Kim, K.; Liu, D.; Gong, J.; Ma, Z. Reduction of leakage current in GaN Schottky diodes through ultraviolet/ozone plasma treatment. IEEE Electron. Device Lett. 2019, 40, 1796–1799. [Google Scholar] [CrossRef]

- Kim, K.; Kim, T.J.; Zhang, H.; Liu, D.; Jung, Y.H.; Gong, J.; Ma, Z. AlGaN/GaN schottky-gate HEMTs with UV/O3-treated gate interface. IEEE Electron. Device Lett. 2020, 41, 1488–1491. [Google Scholar] [CrossRef]

- Arulkumaran, S.; Egawa, T.; Ishikawa, H.; Jimbo, T.; Sano, Y. Surface passivation effects on AlGaN/GaN high-electron-mobility transistors with SiO2, Si3N4, and silicon oxynitride. Appl. Phys. Lett. 2003, 84, 613–615. [Google Scholar] [CrossRef]

- Javorka, P.; Bernat, J.; Fox, A.; Marso, M.; Lüth, H.; Kordoš, P. Influence of SiO2 and Si3N4 passivation on AlGaN/GaN/Si HEMT performance. Electron. Lett. 2003, 39, 1155–1157. [Google Scholar] [CrossRef]

- Huang, S.; Jiang, Q.; Yang, S.; Zhou, C.; Chen, K.J. Effective passivation of AlGaN/GaN HEMTs by ALD-grown AlN thin film. IEEE Electron. Device Lett. 2012, 33, 516–518. [Google Scholar] [CrossRef]

- Lin, Y.S.; Lin, S.F.; Hsu, W.C. Microwave and power characteristics of AlGaN/GaN/Si high-electron mobility transistors with HfO2 and TiO2 passivation. Semicond. Sci. Technol. 2015, 30, 015016. [Google Scholar] [CrossRef]

- Li, S.; Hu, Q.; Wang, X.; Li, T.; Li, X.; Wu, Y. Improved interface properties and dielectric breakdown in recessed AlGaN/GaN MOS-HEMTs using HfSiOX as gate dielectric. IEEE Electron. Device Lett. 2019, 40, 295–298. [Google Scholar] [CrossRef]

- Chan, S.H.; Tahhan, M.; Liu, X.; Bisi, D.; Gupta, C.; Koksaldi, O.; Li, H.; Mates, T.; Denbaars, S.P.; Keller, S. Metalorganic chemical vapor deposition and characterization of (Al,Si)O dielectrics for GaN-based devices. Jpn. J. Appl. Phys. 2016, 55, 021501. [Google Scholar] [CrossRef]

- Karim, Z.; Boissiere, O.; Lohe, C.; Zhang, Z.; Manke, C.; Lehnen, P.; Baumann, P.K.; Dalton, J.; Park, W.; Ramanathan, S.; et al. Advanced metal gate electrode options compatible with ALD and AVD® HfSiOx based gate dielectrics. ECS Trans. 2006, 3, 363–374. [Google Scholar] [CrossRef]

- Yang, W.; Fronk, M.; Geng, Y.; Chen, L.; Sun, Q.Q.; Gordan, O.D.; Zhou, P.; Zahn, D.R.; Zhang, D.W. Optical properties and bandgap evolution of ALD HfSiOx films. Nanoscale Res. Lett. 2015, 10, 1–5. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hou, B.; Ma, X.; Zhu, J.; Yang, L.; Chen, W.; Mi, M.; Zhu, Q.; Chen, L.; Zhang, R.; Zhang, M.; et al. 0.9-A/mm, 2.6-V flash-like normally-off Al2O3/AlGaN/GaN MIS-HEMTs using charge trapping technique. IEEE Electron. Device Lett. 2018, 39, 397–400. [Google Scholar] [CrossRef]

- Zheng, Y.Y.; Yue, H.; Cheng, Z.J.; Qian, F.; Yu, N.J.; Hua, M.X. A study on Al2O3 passivation in GaN MOS-HEMT by pulsed stress. Chin. Phys. B 2008, 17, 1405. [Google Scholar] [CrossRef]

- Lin, Y.S.; Lin, S.F. Large-signal linearity and high-frequency noise of passivated AlGaN/GaN high-electron mobility transistors. Micromachines 2021, 12, 1–7. [Google Scholar]

- Kikkawa, T.; Nagahara, M.; Okamoto, N.; Tateno, Y.; Yamaaguchi, Y.; Hara, N.; Joshin, K.; Asbeck, P.M. Surface-charge controlled AlGaN/ GaN-power HFET without current collapse and Gm dispersion. IEDM Tech. Dig. 2001, 8, 585. [Google Scholar]

- Cai, Y.; Zhou, Y.; Lau, K.M.; Chen, K.J. Enhancement-mode AlGaN/GaN HEMTs with low on-resistance and low knee voltage. IEEE Trans. Electron. 2006, E89-C7, 1025–1030. [Google Scholar] [CrossRef]

- Yue, Y.; Hao, Y.; Zhang, J.; Ni, J.; Mao, W.; Feng, Q.; Liu, L. AlGaN/GaN MOS-HEMT with HfO2 dielectric and Al2O3 interfacial passivation layer grown by atomic layer deposition. IEEE Electron. Device Lett. 2008, 29, 838–840. [Google Scholar] [CrossRef]

- Tapajna, M.; Kuzmik, J. A comprehensive analytical model for threshold voltage calculation in GaN based metal-oxide-semiconductor high-electronmobility transistors. Appl. Phys. Lett. 2012, 100, 113509. [Google Scholar] [CrossRef]

- Lu, W.; Kumar, V.; Schwindt, R.; Piner, E.; Adesida, I. A comparative study of surface passivation on AlGaN/GaN HEMTs. Solid State Electron. 2002, 46, 1441–1444. [Google Scholar] [CrossRef]

- Liu, L.; Xi, Y.; Ahn, S.; Ren, F.; Gila, B.P.; Pearton, S.J.; Kravchenko, I.I. Characteristics of gate leakage current and breakdown voltage of AlGaN/GaN high electron mobility transistors after postprocess annealing. J. Vac. Sci. Technol. B Microelectron. Nanom. Struct. 2014, 32, 1–5. [Google Scholar] [CrossRef]

- Reddy, M.S.P.; Park, W.S.; Im, K.S.; Lee, J.H. Dual-surface modification of AlGaN/GaN HEMTs using TMAH and piranha solutions for enhancing current and 1/f-Noise Characteristics. IEEE J. Electron. Devices Soc. 2018, 6, 791–796. [Google Scholar] [CrossRef]

- Liu, H.Y.; Ou, W.C.; Hsu, W.C. Investigation of post oxidation annealing effect on H2O2-grown Al2O3/AlGaN/GaN MOSHEMTs. IEEE J. Electron. Devices Soc. 2016, 4, 358–364. [Google Scholar] [CrossRef]

- Mahajan, S.S.; Malik, A.; Laishram, R.; Vinayak, S. Performance enhancement of gate-annealed AlGaN/GaN HEMTs. J. Kor. Phys. Soc. 2017, 70, 533–538. [Google Scholar] [CrossRef]

- Tingting, Y.; Xinyu, L.; Yingkui, Z.; Chengzhan, L.; Ke, W.; Guoguo, L. Impact of UV/ozone surface treatment on AlGaN/GaN HEMTs. J. Semicond. 2009, 30, 124001. [Google Scholar] [CrossRef]

- Kalb, W.L.; Batlogg, B. Calculating the trap density of states in organic field-effect transistors from experiment: A comparison of different methods. Phys. Rev. B 2010, 81, 1–13. [Google Scholar] [CrossRef] [Green Version]

- Anderson, T.J.; Wheeler, V.D.; Shahin, D.I.; Tadjer, M.J.; Koehler, A.D.; Hobart, K.D.; Christou, A.; Kub, F.J.; Eddy, C.R., Jr. Enhancement mode AlGaN/GaN MOS high-electron-mobility transistors with ZrO2 gate dielectric deposited by atomic layer deposition. Appl. Phys. Exp. 2016, 9, 071003. [Google Scholar] [CrossRef]

| Parameters | C-HEMT | C-HEMT with UV/O3 | C-HEMT with UV/O3 and HfSiOX | MOS-HEMT with UV/O3 | MOS-HEMT with UV/O3 and HfSiOX |

|---|---|---|---|---|---|

| IDMAX (mA/mm) | 415 | 504 | 542 | 620 | 655 |

| VTH (V) | −3.1 | −3.05 | −3.05 | −2.65 | −3.0 |

| GMMAX (mS/mm) | 104 | 129 | 138 | 90 | 116 |

| SS (mV/dec) | 160 | 140 | 125 | 95 | 85 |

| ION/IOFF | 4.8 | --- | 1.6 | --- | 3.1 |

| IG (A/mm) (@ VG = −15 V) | --- | 4.3 | --- | ||

| Current collapse (%) | 20 | 13 | 7 | 10 | 0.6 |

| Dit() | |||||

| Hysteresis (∆ V) (V) | 1.04 | 2.12 | 0.804 | 1.95 | 0.11 |

| GVS (V) | 0.87 | 1.15 | 1.55 | 1.60 | 2.53 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mazumder, S.; Li, S.-H.; Wu, Z.-G.; Wang, Y.-H. Combined Implications of UV/O3 Interface Modulation with HfSiOX Surface Passivation on AlGaN/AlN/GaN MOS-HEMT. Crystals 2021, 11, 136. https://doi.org/10.3390/cryst11020136

Mazumder S, Li S-H, Wu Z-G, Wang Y-H. Combined Implications of UV/O3 Interface Modulation with HfSiOX Surface Passivation on AlGaN/AlN/GaN MOS-HEMT. Crystals. 2021; 11(2):136. https://doi.org/10.3390/cryst11020136

Chicago/Turabian StyleMazumder, Soumen, Ssu-Hsien Li, Zhan-Gao Wu, and Yeong-Her Wang. 2021. "Combined Implications of UV/O3 Interface Modulation with HfSiOX Surface Passivation on AlGaN/AlN/GaN MOS-HEMT" Crystals 11, no. 2: 136. https://doi.org/10.3390/cryst11020136