Computational Fluid Dynamics on Solar Dish in a Concentrated Solar Power: A Bibliometric Review

Abstract

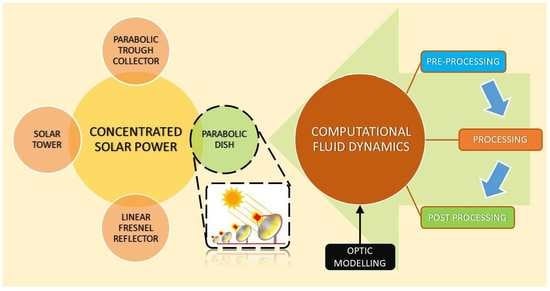

:1. Introduction

1.1. Solar Energy

1.2. Concentrated Solar Power

1.3. Computational Fluid Dynamics

2. Bibliometric Analysis

2.1. Methodology

2.2. The Journal Names

2.3. The Contingency Matrix

2.4. The Inter-Temporal Network Stream

3. The CFD Modeling of Solar Dish System

3.1. The Semantic Network of Keywords and Authors

3.2. Solar Receiver with Helical Absorber Tube

3.3. Volumetric Solar Receiver with Porous Absorber

3.4. Other Types of Solar Receiver Modification

3.5. Design of Solar Dish Technology

4. Current Challenges and Future Perspectives

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Phillips, L. 9—Solar energy. In Managing Global Warming; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 317–332. [Google Scholar]

- Al-Abidi, A.A.; Bin Mat, S.; Sopian, K.; Sulaiman, M.Y.; Mohammed, A.T. CFD applications for latent heat thermal energy storage: A review. Renew. Sustain. Energy Rev. 2013, 20, 353–363. [Google Scholar] [CrossRef]

- Liu, M.; Sun, Y.; Bruno, F. A review of numerical modelling of high-temperature phase change material composites for solar thermal energy storage. J. Energy Storage 2020, 29, 101378. [Google Scholar] [CrossRef]

- Yadav, A.S.; Bhagoria, J.L. Heat transfer and fluid flow analysis of solar air heater: A review of CFD approach. Renew. Sustain. Energy Rev. 2013, 23, 60–79. [Google Scholar] [CrossRef]

- Kasaeian, A.B.; Molana, S.; Rahmani, K.; Wen, D. A review on solar chimney systems. Renew. Sustain. Energy Rev. 2017, 67, 954–987. [Google Scholar] [CrossRef]

- Nadda, R.; Kumar, A.; Maithani, R. Efficiency improvement of solar photovoltaic/solar air collectors by using impingement jets: A review. Renew. Sustain. Energy Rev. 2018, 93, 331–353. [Google Scholar] [CrossRef]

- Chen, Q.; Wang, Y.; Zhang, J.; Wang, Z. The knowledge mapping of concentrating solar power development based on literature analysis technology. Energies 2020, 13, 1988. [Google Scholar] [CrossRef]

- Yılmaz, İ.H.; Mwesigye, A. Modeling, simulation and performance analysis of parabolic trough solar collectors: A comprehensive review. Appl. Energy 2018, 225, 135–174. [Google Scholar] [CrossRef]

- Olia, H.; Torabi, M.; Bahiraei, M.; Ahmadi, M.H.; Goodarzi, M.; Safaei, M.R. Application of nanofluids in thermal performance enhancement of parabolic trough solar collector: State-of-the-art. Appl. Sci. 2019, 9, 463. [Google Scholar] [CrossRef] [Green Version]

- Bellos, E.; Tzivanidis, C.; Tsimpoukis, D. Enhancing the performance of parabolic trough collectors using nanofluids and turbulators. Renew. Sustain. Energy Rev. 2018, 91, 358–375. [Google Scholar] [CrossRef]

- Longeon, M.; Soupart, A.; Fourmigué, J.F.; Bruch, A.; Marty, P. Experimental and numerical study of annular PCM storage in the presence of natural convection. Appl. Energy 2013, 112, 175–184. [Google Scholar] [CrossRef]

- Moriarty, P.; Honnery, D. 6—Global renewable energy resources and use in 2050. In Managing Global Warming; Letcher, T.M., Ed.; Academic Press: Cambridge, MA, USA, 2019; pp. 221–235. [Google Scholar]

- Junginger, M.; Louwen, A. Chapter 1—Introduction. In Technological Learning in the Transition to a Low-Carbon Energy System; Junginger, M., Louwen, A., Eds.; Academic Press: Cambridge, MA, USA, 2020; pp. 3–7. [Google Scholar]

- Rodríguez, I.; Pérez-Segarra, C.D.; Lehmkuhl, O.; Oliva, A. Modular object-oriented methodology for the resolution of molten salt storage tanks for CSP plants. Appl. Energy 2013, 109, 402–414. [Google Scholar] [CrossRef] [Green Version]

- Fornarelli, F.; Camporeale, S.M.; Fortunato, B.; Torresi, M.; Oresta, P.; Magliocchetti, L.; Miliozzi, A.; Santo, G. CFD analysis of melting process in a shell-and-tube latent heat storage for concentrated solar power plants. Appl. Energy 2016, 164, 711–722. [Google Scholar] [CrossRef]

- Hachicha, A.A.; Yousef, B.A.A.; Said, Z.; Rodríguez, I. A review study on the modeling of high-temperature solar thermal collector systems. Renew. Sustain. Energy Rev. 2019, 112, 280–298. [Google Scholar] [CrossRef]

- Ubando, A.T.; San, R.; Cruz, J.D.P. Savonius Wind Turbine Numerical Parametric Analysis Using Space-Filling Design and Gaussian Stochastic Process. Wind 2022, 2, 7. [Google Scholar] [CrossRef]

- Prakash, M.; Kedare, S.B.; Nayak, J.K. Investigations on heat losses from a solar cavity receiver. Sol. Energy 2009, 83, 157–170. [Google Scholar] [CrossRef]

- Taumoefolau, T.; Paitoonsurikarn, S.; Hughes, G.; Lovegrove, K. Experimental investigation of natural convection heat loss from a model solar concentrator cavity receiver. J. Sol. Energy Eng. Trans. ASME 2004, 126, 801–807. [Google Scholar] [CrossRef]

- Li, Z.; Tang, D.; Du, J.; Li, T. Study on the radiation flux and temperature distributions of the concentrator-receiver system in a solar dish/Stirling power facility. Appl. Therm. Eng. 2011, 31, 1780–1789. [Google Scholar] [CrossRef]

- Ubando, A.T.; Africa, A.D.M.; Maniquiz-Redillas, M.C.; Culaba, A.B.; Chen, W.H.; Chang, J.S. Microalgal biosorption of heavy metals: A comprehensive bibliometric review. J. Hazard. Mater. 2021, 402, 123431. [Google Scholar] [CrossRef]

- Marvuglia, A.; Havinga, L.; Heidrich, O.; Fonseca, J.; Gaitani, N.; Reckien, D. Advances and challenges in assessing urban sustainability: An advanced bibliometric review. Renew. Sustain. Energy Rev. 2020, 124, 109788. [Google Scholar] [CrossRef]

- Matsuo, Y.; Ishizuka, M. Key word extraction from a document using word co-occurrence statistical information. Trans. Jpn. Soc. Artif. Intell. 2002, 17, 217–223. [Google Scholar] [CrossRef] [Green Version]

- Craig, K.J.; Slootweg, M.; Le Roux, W.G.; Wolff, T.M.; Meyer, J.P. Using CFD and ray tracing to estimate the heat losses of a tubular cavity dish receiver for different inclination angles. Sol. Energy 2020, 211, 1137–1158. [Google Scholar] [CrossRef]

- Daabo, A.M.; Bellos, E.; Pavlovic, S.; Bashir, M.A.; Mahmoud, S.; Al-Dadah, R.K. Characterization of a micro thermal cavity receiver—Experimental and analytical investigation. Therm. Sci. Eng. Prog. 2020, 18, 100554. [Google Scholar] [CrossRef]

- Barreto, G.; Canhoto, P.; Collares-Pereira, M. Parametric analysis and optimisation of porous volumetric solar receivers made of open-cell SiC ceramic foam. Energy 2020, 200, 117476. [Google Scholar] [CrossRef]

- Herrmann, B.; Behzad, M.; Cardemil, J.M.; Calderón-Muñoz, W.R.; Fernández, R.M. Conjugate heat transfer model for feedback control and state estimation in a volumetric solar receiver. Sol. Energy 2020, 198, 343–354. [Google Scholar] [CrossRef]

- Zhang, Y.; Xiao, H.; Zou, C.; Falcoz, Q.; Neveu, P. Combined optics and heat transfer numerical model of a solar conical receiver with built-in helical pipe. Energy 2020, 193, 116775. [Google Scholar] [CrossRef]

- Barreto, G.; Canhoto, P.; Collares-Pereira, M. Three-dimensional CFD modelling and thermal performance analysis of porous volumetric receivers coupled to solar concentration systems. Appl. Energy 2019, 252, 113433. [Google Scholar] [CrossRef]

- Khalil, I.; Pratt, Q.; Spitler, C.; Codd, D. Modeling a thermoplate conical heat exchanger in a point focus solar thermal collector. Int. J. Heat Mass Transf. 2019, 130, 1–8. [Google Scholar] [CrossRef]

- Soltani, S.; Bonyadi, M.; Madadi Avargani, V. A novel optical-thermal modeling of a parabolic dish collector with a helically baffled cylindrical cavity receiver. Energy 2019, 168, 88–98. [Google Scholar] [CrossRef]

- Zhao, W.; Zhang, Y.; Xu, B.; Li, P.; Wang, Z.; Jiang, S. Multiple-relaxation-time lattice Boltzmann simulation of flow and heat transfer in porous volumetric solar receivers. J. Energy Resour. Technol. Trans. ASME 2018, 140, 082003. [Google Scholar] [CrossRef]

- Yang, S.; Wang, J.; Lund, P.D.; Wang, S.; Jiang, C. Reducing convective heat losses in solar dish cavity receivers through a modified air-curtain system. Sol. Energy 2018, 166, 50–58. [Google Scholar] [CrossRef]

- Aichmayer, L.; Garrido, J.; Laumert, B. Scaling effects of a novel solar receiver for a micro gas-turbine based solar dish system. Sol. Energy 2018, 162, 248–264. [Google Scholar] [CrossRef] [Green Version]

- Giovannelli, A.; Bashir, M.A. Charge and discharge analyses of a PCM storage system integrated in a high-temperature solar receiver. Energies 2017, 10, 1943. [Google Scholar] [CrossRef] [Green Version]

- Uzair, M.; Anderson, T.N.; Nates, R.J. The impact of the parabolic dish concentrator on the wind induced heat loss from its receiver. Sol. Energy 2017, 151, 95–101. [Google Scholar] [CrossRef] [Green Version]

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K.; Ahmad, A. Numerical investigation of pitch value on thermal performance of solar receiver for solar powered Brayton cycle application. Energy 2017, 119, 523–539. [Google Scholar] [CrossRef]

- Daabo, A.M.; Ahmad, A.; Mahmoud, S.; Al-Dadah, R.K. Parametric analysis of small scale cavity receiver with optimum shape for solar powered closed Brayton cycle applications. Appl. Therm. Eng. 2017, 122, 626–641. [Google Scholar] [CrossRef]

- Daabo, A.M.; Mahmoud, S.; Al-Dadah, R.K. The optical efficiency of three different geometries of a small scale cavity receiver for concentrated solar applications. Appl. Energy 2016, 179, 1081–1096. [Google Scholar] [CrossRef] [Green Version]

- Pavlović, S.R.; Vasiljević, D.M.; Stefanović, V.P.; Stamenković, Z.M.; Bellos, E.A. Optical analysis and performance evaluation of a solar parabolic dish concentrator. Therm. Sci. 2016, 20, S1237–S1249. [Google Scholar] [CrossRef]

- Aichmayer, L.; Spelling, J.; Laumert, B. Preliminary design and analysis of a novel solar receiver for a micro gas-turbine based solar dish system. Sol. Energy 2015, 114, 378–396. [Google Scholar] [CrossRef]

- Yuan, J.K.; Ho, C.K.; Christian, J.M. Numerical simulation of natural convection in solar cavity receivers. J. Sol. Energy Eng. Trans. ASME 2015, 137, 031004. [Google Scholar] [CrossRef]

- Christo, F.C. Numerical modelling of wind and dust patterns around a full-scale paraboloidal solar dish. Renew. Energy 2012, 39, 356–366. [Google Scholar] [CrossRef]

- Christo, F.C. Numerical modelling of wind Kumar, N.S.; Reddy, K.S. Investigation of convection and radiation heat losses from modified cavity receiver of solar parabolic dish using asymptotic computational fluid dynamics. Heat Transf. Eng. 2010, 31, 597–607. [Google Scholar] [CrossRef]

- El-Bakry, M.M.; Kassem, M.A.; Hassan, M.A. Passive performance enhancement of parabolic trough solar concentrators using internal radiation heat shields. Renew. Energy 2021, 165, 52–66. [Google Scholar] [CrossRef]

- Lou, W.; Fan, Y.; Luo, L. Single-tank thermal energy storage systems for concentrated solar power: Flow distribution optimization for thermocline evolution management. J. Energy Storage 2020, 32, 101749. [Google Scholar] [CrossRef]

- Coyle, C.; Baglietto, E.; Forsberg, C. Advancing Radiative Heat Transfer Modeling in High-Temperature Liquid Salts. Nucl. Sci. Eng. 2020, 194, 782–792. [Google Scholar] [CrossRef] [Green Version]

- Daabo, A.; Kreshat, Z.; Farhat, R.; Rahawi, K.; Mahmood, A.; Lattimore, T. The suitability of microscale compressed air axial turbine for domestic solar powered Brayton cycle. Int. J. Energy Environ. Eng. 2020, 11, 351–366. [Google Scholar] [CrossRef]

- Wang, G.; Yu, S.; Niu, S.; Chen, Z.; Hu, P. A comprehensive parametric study on integrated thermal and mechanical performances of molten-salt-based thermocline tank. Appl. Therm. Eng. 2020, 170, 115010. [Google Scholar] [CrossRef]

- de la Rocha Camba, E.; Petrakopoulou, F. Earth-cooling air tunnels for thermal power plants: Initial design by CFD modelling. Energies 2020, 13, 797. [Google Scholar] [CrossRef] [Green Version]

- Ali, M.; Rady, M.; Attia, M.A.A.; Ewais, E.M.M. Consistent coupled optical and thermal analysis of volumetric solar receivers with honeycomb absorbers. Renew. Energy 2020, 145, 1849–1861. [Google Scholar] [CrossRef]

- Dehury, P.; Chaudhary, R.K.; Banerjee, T.; Dalal, A. Evaluation of Thermophysical Properties of Menthol-Based Deep Eutectic Solvent as a Thermal Fluid: Forced Convection and Numerical Studies. Ind. Eng. Chem. Res. 2019, 58, 20125–20133. [Google Scholar] [CrossRef]

- Schmitt, A.; Dinter, F.; Reichel, C. Computational fluid dynamics study to reduce heat losses at the receiver of a solar tower plant. Sol. Energy 2019, 190, 286–300. [Google Scholar] [CrossRef]

- Slootweg, M.; Craig, K.J.; Meyer, J.P. A computational approach to simulate the optical and thermal performance of a novel complex geometry solar tower molten salt cavity receiver. Sol. Energy 2019, 187, 13–29. [Google Scholar] [CrossRef]

- Chen, M.; Sun, X.; Christensen, R.N. Thermal-hydraulic performance of printed circuit heat exchangers with zigzag flow channels. Int. J. Heat Mass Transf. 2019, 130, 356–367. [Google Scholar] [CrossRef]

- Mostafavi Tehrani, S.S.; Shoraka, Y.; Diarce, G.; Taylor, R.A. An improved, generalized effective thermal conductivity method for rapid design of high temperature shell-and-tube latent heat thermal energy storage systems. Renew. Energy 2019, 132, 694–708. [Google Scholar] [CrossRef]

- Cuturi, N.; Aronica, S.; Bellini, L.; Salvati, A. Design and CFD analysis of an industrial low-pressure compressor for a concentrating high-temperature solar power plant. Int. J. Thermodyn. 2019, 22, 184–191. [Google Scholar] [CrossRef]

- Sandlin, M.; Abdel-Khalik, S.I. A study of granular flow through horizontal wire mesh screens for concentrated solar power particle heating receiver applications—Part II: Parametric model predictions. Sol. Energy 2018, 174, 1252–1262. [Google Scholar] [CrossRef]

- Sandlin, M.; Abdel-Khalik, S.I. An experimental and numerical study of granular flows through a perforated square lattice for central solar receiver applications. Sol. Energy 2018, 174, 463–473. [Google Scholar] [CrossRef]

- Benoit, H.; Ansart, R.; Neau, H.; Garcia Triñanes, P.; Flamant, G.; Simonin, O. Three-dimensional numerical simulation of upflow bubbling fluidized bed in opaque tube under high flux solar heating. AIChE J. 2018, 64, 3857–3867. [Google Scholar] [CrossRef]

- Moghimi, M.A.; Ahmadi, G. Wind barriers optimization for minimizing collector mirror soiling in a parabolic trough collector plant. Appl. Energy 2018, 225, 413–423. [Google Scholar] [CrossRef] [Green Version]

- Solé, A.; Falcoz, Q.; Cabeza, L.F.; Neveu, P. Geometry optimization of a heat storage system for concentrated solar power plants (CSP). Renew. Energy 2018, 123, 227. [Google Scholar] [CrossRef]

- Iranzo, A.; Suàrez, C.; Guerra, J. Mixing enhancement in thermal energy storage molten salt tanks. Energy Convers. Manag. 2018, 168, 320–328. [Google Scholar] [CrossRef]

- Cagnoli, M.; Mazzei, D.; Procopio, M.; Russo, V.; Savoldi, L.; Zanino, R. Analysis of the performance of linear Fresnel collectors: Encapsulated vs. evacuated tubes. Sol. Energy 2018, 164, 119–138. [Google Scholar] [CrossRef]

- Mahmood, M.; Traverso, A.; Traverso, A.N.; Massardo, A.F.; Marsano, D.; Cravero, C. Thermal energy storage for CSP hybrid gas turbine systems: Dynamic modelling and experimental validation. Appl. Energy 2018, 212, 1240–1251. [Google Scholar] [CrossRef]

- Viereck, S.; Keller, J.; Haselbacher, A.; Jovanovic, Z.R.; Steinfeld, A. Assessment of Heat Exchangers for the Integration of Concentrated Solar Energy into the Catalytic Hydrothermal Gasification of Biomass. Energy Technol. 2017, 5, 2086–2099. [Google Scholar] [CrossRef] [Green Version]

- Dinsenmeyer, R.; Fourmigué, J.F.; Caney, N.; Marty, P. Volume of fluid approach of boiling flows in concentrated solar plants. Int. J. Heat Fluid Flow 2017, 65, 177–191. [Google Scholar] [CrossRef]

- Abagnale, C.; Cameretti, M.C.; De Robbio, R.; Tuccillo, R. Thermal cycle and combustion analysis of a solar-assisted micro gas turbine. Energies 2017, 10, 773. [Google Scholar] [CrossRef] [Green Version]

- Ansart, R.; García-Triñanes, P.; Boissière, B.; Benoit, H.; Seville, J.P.K.; Simonin, O. Dense gas-particle suspension upward flow used as heat transfer fluid in solar receiver: PEPT experiments and 3D numerical simulations. Powder Technol. 2017, 307, 25–36. [Google Scholar] [CrossRef] [Green Version]

- Capuano, R.; Fend, T.; Stadler, H.; Hoffschmidt, B.; Pitz-Paal, R. Optimized volumetric solar receiver: Thermal performance prediction and experimental validation. Renew. Energy 2017, 114, 556–566. [Google Scholar] [CrossRef] [Green Version]

- Fritsch, A.; Uhlig, R.; Marocco, L.; Frantz, C.; Flesch, R.; Hoffschmidt, B. A comparison between transient CFD and FEM simulations of solar central receiver tubes using molten salt and liquid metals. Sol. Energy 2017, 155, 259–266. [Google Scholar] [CrossRef]

- Craig, K.J.; Moghimi, M.A.; Rungasamy, A.E.; Marsberg, J.; Meyer, J.P. Finite-volume ray tracing using Computational Fluid Dynamics in linear focus CSP applications. Appl. Energy 2016, 183, 241–256. [Google Scholar] [CrossRef] [Green Version]

- Ortega, J.; Khivsara, S.; Christian, J.; Ho, C.; Yellowhair, J.; Dutta, P. Coupled modeling of a directly heated tubular solar receiver for supercritical carbon dioxide Brayton cycle: Optical and thermal-fluid evaluation. Appl. Therm. Eng. 2016, 109, 970–978. [Google Scholar] [CrossRef] [Green Version]

- Sarker, M.R.I.; Saha, M.; Rahman, M.S.; Beg, R.A. Recirculating metallic particles for the efficiency enhancement of concentrated solar receivers. Renew. Energy 2016, 96, 850–862. [Google Scholar] [CrossRef]

- Núnez Bootello, J.P.; Mier-Torrecilla, M.; Doblaré, M.; Silva Pérez, M. Aerodynamics of new solar parametric troughs: Two dimensional and three dimensional single module numerical analysis. Sol. Energy 2016, 135, 742–749. [Google Scholar] [CrossRef]

- Cho, H.S.; Van Zee, J.W.; Shimpalee, S.; Tavakoli, B.A.; Weidner, J.W.; Garcia-Diaz, B.L.; Martinez-Rodriguez, M.J.; Olson, L.; Gray, J. Dimensionless analysis for predicting Fe-Ni-Cr alloy corrosion in molten salt systems for concentrated solar power systems. Corrosion 2016, 72, 742–760. [Google Scholar] [CrossRef]

- Mehrabadi, B.A.T.; Weidner, J.W.; Garcia-Diaz, B.; Martinez-Rodriguez, M.; Olson, L.; Shimpalee, S. Multidimensional modeling of nickel alloy corrosion inside high temperature molten salt systems. J. Electrochem. Soc. 2016, 163, C830–C838. [Google Scholar] [CrossRef]

- Şahin, H.M.; Baysal, E.; Dal, A.R.; Şahin, N. Investigation of heat transfer enhancement in a new type heat exchanger using solar parabolic trough systems. Int. J. Hydrogen Energy 2015, 40, 15254–15266. [Google Scholar] [CrossRef]

- Moghimi, M.A.; Craig, K.J.; Meyer, J.P. Optimization of a trapezoidal cavity absorber for the Linear Fresnel Reflector. Sol. Energy 2015, 119, 343–361. [Google Scholar] [CrossRef] [Green Version]

- Moghimi, M.A.; Craig, K.J.; Meyer, J.P. A novel computational approach to combine the optical and thermal modelling of Linear Fresnel Collectors using the finite volume method. Sol. Energy 2015, 116, 407–427. [Google Scholar] [CrossRef] [Green Version]

- Gobereit, B.; Amsbeck, L.; Buck, R.; Pitz-Paal, R.; Röger, M.; Müller-Steinhagen, H. Assessment of a falling solid particle receiver with numerical simulation. Sol. Energy 2015, 115, 505–517. [Google Scholar] [CrossRef] [Green Version]

- Lee, T.; Lim, S.; Shin, S.; Sadowski, D.L.; Abdel-Khalik, S.I.; Jeter, S.M.; Al-Ansary, H. Numerical simulation of particulate flow in interconnected porous media for central particle-heating receiver applications. Sol. Energy 2015, 113, 14–24. [Google Scholar] [CrossRef] [Green Version]

- Pizzolato, A.; Donato, F.; Verda, V.; Santarelli, M. CFD-based reduced model for the simulation of thermocline thermal energy storage systems. Appl. Therm. Eng. 2015, 76, 391–399. [Google Scholar] [CrossRef] [Green Version]

- Craig, K.J.; Gauché, P.; Kretzschmar, H. CFD analysis of solar tower Hybrid Pressurized Air Receiver (HPAR) using a dual-banded radiation model. Sol. Energy 2014, 110, 338–355. [Google Scholar] [CrossRef] [Green Version]

- Andreozzi, A.; Buonomo, B.; Manca, O.; Tamburrino, S. Thermal energy storages analysis for high temperature in air solar systems. Appl. Therm. Eng. 2014, 71, 130–141. [Google Scholar] [CrossRef]

- Veeraragavan, A.; Montgomery, L.; Datas, A. Night time performance of a storage integrated solar thermophotovoltaic (SISTPV) system. Sol. Energy 2014, 108, 377–389. [Google Scholar] [CrossRef] [Green Version]

- Zemler, M.K.; Bohl, G.; Rios, O.; Boetcher, S.K.S. Numerical study of wind forces on parabolic solar collectors. Renew. Energy 2013, 60, 498–505. [Google Scholar] [CrossRef]

- Garbrecht, O.; Al-Sibai, F.; Kneer, R.; Wieghardt, K. CFD-simulation of a new receiver design for a molten salt solar power tower. Sol. Energy 2013, 90, 94–106. [Google Scholar] [CrossRef]

- Al-Ansary, H.; Zeitoun, O. Numerical study of conduction and convection heat losses from a half-insulated air-filled annulus of the receiver of a parabolic trough collector. Sol. Energy 2011, 85, 3036–3045. [Google Scholar] [CrossRef]

- Bashir, M.A.; Daabo, A.M.; Amber, K.P.; Khan, M.S.; Arshad, A.; Elahi, H. Effect of phase change materials on the short-term thermal storage in the solar receiver of dish-micro gas turbine systems: A numerical analysis. Appl. Therm. Eng. 2021, 195, 117179. [Google Scholar] [CrossRef]

- Fend, T.; Hoffschmidt, B.; Pitz-Paal, R.; Reutter, O.; Rietbrock, P. Porous materials as open volumetric solar receivers: Experimental determination of thermophysical and heat transfer properties. Energy 2004, 29, 823–833. [Google Scholar] [CrossRef]

- Ho, C.K.; Iverson, B.D. Review of high-temperature central receiver designs for concentrating solar power. Renew. Sustain. Energy Rev. 2014, 29, 835–846. [Google Scholar] [CrossRef] [Green Version]

| Author(s) | Title | Year | Cited by |

|---|---|---|---|

| Prakash M. et al. [18] | Investigations on heat losses from a solar cavity receiver | 2009 | 160 |

| Longeon M. et al. [11] | Experimental and numerical study of annular PCM storage in the presence of natural convection | 2013 | 124 |

| Taumoefolau T. et al. [19] | Experimental investigation of natural convection heat loss from a model solar concentrator cavity receiver | 2004 | 123 |

| Li Z. et al. [20] | Study on the radiation flux and temperature distributions of the concentrator-receiver system in a solar dish/Stirling power facility | 2011 | 85 |

| Yılmaz İ.H. and Mwesigye A. [8] | Modeling, simulation and performance analysis of parabolic trough solar collectors: A comprehensive review | 2018 | 80 |

| References | Collector Size (mm) | Collector Reflectivity | Solar Irradiance (W/m2) | Receiver Type | Receiver Size (mm) | Tube Size (mm) | Receiver Material |

|---|---|---|---|---|---|---|---|

| [24] | - | 0.8 | 1000 | rectangular with helical pipe | - | - | highly oxidized stainless steel at 1000 K |

| [25] | - | 0.95 | 500–1000 | cylindrical with helical tube | dr = 200, L = 300 | dt = 8 | steel with copper tube |

| [26] | - | 0.95 | 800 | cylindrical porous volumetric receiver | dr = 50, L = 50 | 3 (pore size) | open-cell SiC ceramic foam absorber |

| [27] | - | - | - | square porous absorber module | s = 10 × 10, L = 40 | - | |

| [28] | D = 5060 * f = 3200 | 0.9 | 1000 | conical with built-in helical pipe | dmax = 460 L = 170–630 Loop no. = 4–15 | dt = 42 | 304 stainless steel (pipe and outer cover) |

| [29] | D = 1120 f = 700 | 0.95 | 800 | cylindrical porous volumetric receiver | dr = 50, L = 50 | 3 (pore size) | open-cell SiC ceramic foam absorber |

| [30] | S = 1600 (square) | 0.92 | 826 | conical with helical tube | dmax = 38, L = 50 | - | Inconel sheets coated with Pyromark 2500 paint |

| [31] | D = 2880 f = 1500 | 0.75 | 787 | cylindrical with helically baffled cavity | dr = 200, L = 400 | - | carbon steel |

| [32] | - | - | - | porous volumetric solar receiver | - | - | SiC ceramic foam absorber |

| [33] | - | - | - | cylinder with hollowed cylindrical cavity zoom with U-shaped air channel | dr = 290, L = 320 | w × t = 68 × 4 | |

| [34] | D = 200 | 0.737 | 800 | porous volumetric solar receiver | - | 4 (pore size) porosity = 85% | SiSiC open cell foam absorber |

| [35] | - | - | 500 | cylindrical container with 12 U-tubes | dr = 380, L = 440 | dt = 15 | Silicon Carbide (SiC) |

| [36] | D = 5000 f = 1840 | - | - | conical | dr = 300, L = 710 | - | |

| [37] | D = 1000 | - | - | cylindrical, conical, and spherical with helical tube | dr = 200, L = 250 dr = 200, L = 354.3 dr = 200, L = 218 | dt = 10 | copper tube |

| [38] | D = 1000 to 5000 | - | 500–1000 | cylindrical, conical, and spherical with helical tube | dr = 225, L = 235 dr = 225, L = 240 d r= 225, L = 257 | dt = 19 | copper tube |

| [39] | D = 1000 f = 455–555 | 0.95 | 525 | cylindrical, conical, and spherical with helical tube | dr = 200, L = 250 dr = 200, L = 354.3 dr = 200, L = 218 | dt = 20 | copper tube |

| [40] | D = 3800 f = 2260 | 0.98 | 800 | flat circular disk with spiral coil receiver | dmax = 404 | dt = 9.3 | |

| [41] | - | - | 906 | porous volumetric solar receiver | dr = 145.3 | 4 (cell diameter) 81.1% (porosity) | open-cell SiC ceramic foam absorber |

| [42] | - | - | - | cylindrical dish receiver | - | - | |

| [43] | f = 13,100 A = 425 m2 | - | - | - | - | ||

| [20] | - | 0.95 | 1000 | shallow semi-ellipsoidal receiver, hemispherical, deep semi-ellipsoidal receiver | - | - | |

| [44] | - | - | - | hemispherical with spiral tubes | copper tube | ||

| [18] | - | - | - | cylindrical with helical tube | dr = 330, L = 500 | dt = 9 | copper tube coated with polyurethane |

| References | Heat Transfer Fluid | Flow Rate (kg/s) | Inlet Fluid Temperature (°C) | Outlet Fluid Temperature (°C) | Max. Optical Efficiency (%) | Max. Thermal Efficiency (%) |

|---|---|---|---|---|---|---|

| [24] | air | 0.06 | 657 | 679 | 70 | 50 |

| [25] | air | 0.009–0.02 | 24 | 70 | - | - |

| [26] | air | - | 27 | 334 | - | 80.6 |

| [27] | air | - | 25 | 700 | - | - |

| [28] | air | 0.03 | 350 | - | 87.6 | 72.7 |

| [29] | air | - | 27 | 475 | 93.7 | 85.5 |

| [30] | water | 0.0011 | 18.1 | 206 | - | - |

| [31] | water | 0.007–0.15 | 15–45 | 94.7 | - | 65 |

| [32] | air | - | 20 | 108.5 | - | - |

| [33] | air | - | - | - | - | - |

| [34] | air | 0.07 | 540 | 815 | - | 86.2 (receiver efficiency) |

| [35] | PCM (HTF) air (WF) | 0.1 (air) | 590 | 826 | - | 60 (receiver efficiency) |

| [37] | air | 0.01 | 102 | 132.7 (cylindrical) 136.4 (conical) 128 (spherical) | - | - |

| [38] | air | 0.01 | 102 | 131.2 (cylindrical) 134.8 (conical) 132.8 (spherical) | 93 | 87 |

| [39] | air | 0.01 | 102 | 126.2 (cylindrical) 131 (conical) 124.2 (spherical) | 91 (conical) | 69 (cylindrical) 77.05 (conical) 63 (spherical) |

| [40] | - | - | - | - | 95 | - |

| [41] | air | 0.147 | 568 | 780 | - | 86.7 |

| [42] | air | - | - | - | - | - |

| [20] | - | - | - | - | - | 60.7 |

| [44] | air | - | - | - | - | - |

| [18] | water | 0.02 | 50–75 | - | - | - |

| References | CFD Models | Radiation Models | Software Used for CFD | Software Used for Optics |

|---|---|---|---|---|

| [24] | - | - | Ansys Fluent | Soltrace |

| [25] | - | Surface to surface (S2S) radiation model | ANSYS Fluent | OptisWorks |

| [26] | - | MCRT method (for solar radiation transmission) | OpenFoam | Tonatiuh |

| [27] | - | - | ANSYS CFX | - |

| [28] | Boussniesq model k-ε turbulence model | MCRT S2S model | ANSYS 17.0 | TracePro 7.3.4 |

| [29] | finite volume method SIMPLE-for pressure-velocity coupling | MCRT P1 spherical harmonics method | OpenFoam | Octave 3.6.0 |

| [30] | laminar model | - | ANSYS Fluent | - |

| [31] | k-ε turbulence model | MCRT S2S | ANSYS Fluent | SolTrace |

| [32] | SIMPLE algorithm | - | ANSYS Fluent 17.1 | - |

| [33] | SIMPLE to couple pressure-velocity fields based on FVM k-ε turbulence model | - | Fluent 17.0 and ICEM | - |

| [34] | - | MCRT | COMSOL | MATLAB based ray tracing calculation |

| [35] | solidification and melting model k-ε turbulence model | S2S | ANSYS Fluent 18.0 | - |

| [36] | Shear Stress Transport (SST) turbulence model | - | ANSYS CFX 15.0.7 | - |

| [37] | - | S2S | ANSYS | OptisWorks |

| [38] | - | MCRT | ANSYS Fluent | OptisWorks |

| [39] | k-ε turbulence model | MCRT S2S | ANSYS Fluent | OptisWorks |

| [40] | - | MCRT | - | TracePro |

| [41] | k-ε turbulence model | - | COMSOL Multiphysics | - |

| [42] | k-ε and k-kl-ω turbulence model | Discrete ordinates radiation model | ANSYS Fluent and SolidWorks Flow Simulation | - |

| [43] | SST k-ω turbulence model | - | ANSYS Fluent | - |

| [20] | FVM SIMPLEC (pressure-velocity coupling) | MCRT | FLUENT | TracePro |

| [44] | SIMPLEC (pressure-velocity coupling) | S2S | FLUENT | - |

| [18] | SIMPLEC (pressure-velocity coupling) | - | FLUENT | - |

| Paper No. | Title | CFD Modeling Focus | References |

|---|---|---|---|

| 1 | Passive performance enhancement of parabolic trough solar concentrators using internal radiation heat shields | Parabolic trough | El-Bakry et al. [45] |

| 2 | Single-tank thermal energy storage systems for concentrated solar power: Flow distribution optimization for thermocline evolution management | Storage tank | Lou et al. [46] |

| 3 | Advancing Radiative Heat Transfer Modeling in High-Temperature Liquid Salts | Liquid salts | Coyle et al. [47] |

| 4 | The suitability of microscale compressed air axial turbine for domestic solar powered Brayton cycle | Turbine | Daabo et al. [48] |

| 5 | A comprehensive parametric study on integrated thermal and mechanical performances of molten-salt-based thermocline tank | Molten salt tank | Wang et al. [49] |

| 6 | Earth-cooling air tunnels for thermal power plants: Initial design by CFD modeling | Cooling system | de la Rocha Camba and Petrakopoulou [50] |

| 7 | Consistent coupled optical and thermal analysis of volumetric solar receivers with honeycomb absorbers | Solar tower | Ali et al. [51] |

| 8 | Evaluation of Thermophysical Properties of Menthol-Based Deep Eutectic Solvent as a Thermal Fluid: Forced Convection and Numerical Studies | Heat transfer fluid | Dehury et al. [52] |

| 9 | Computational fluid dynamics study to reduce heat losses at the receiver of a solar tower plant | Solar tower | Schmitt et al. [53] |

| 10 | A computational approach to simulate the optical and thermal performance of a novel complex geometry solar tower molten salt cavity receiver | Solar tower | Slootweg et al. [54] |

| 11 | Thermal-hydraulic performance of printed circuit heat exchangers with zigzag flow channels | Heat exchanger | Chen et al. [55] |

| 12 | An improved, generalized effective thermal conductivity method for rapid design of high temperature shell-and-tube latent heat thermal energy storage systems | Phase changing material (PCM) | Mostafavi Tehrani et al. [56] |

| 13 | Design and CFD analysis of an industrial low-pressure compressor for a concentrating high-temperature solar power plant | Compressor design | Cuturi et al. [57] |

| 14 | A study of granular flow through horizontal wire mesh screens for concentrated solar power particle heating receiver applications–Part II: Parametric model predictions | Solid particles in heat transfer medium | Sandlin and Abdel-Khalik [58] |

| 15 | An experimental and numerical study of granular flows through a perforated square lattice for central solar receiver applications | Solid particles in heat transfer medium | Sandlin and Abdel-Khalik [59] |

| 16 | Three-dimensional numerical simulation of upflow bubbling fluidized bed in opaque tube under high flux solar heating | Solar tower | Benoit et al. [60] |

| 17 | Wind barriers optimization for minimizing collector mirror soiling in a parabolic trough collector plant | Wind barriers | Moghimi and Ahmadi [61] |

| 18 | Geometry optimization of a heat storage system for concentrated solar power plants (CSP) | PCM heat storage system | Solé et al. [62] |

| 19 | Mixing enhancement in thermal energy storage molten salt tanks | Molten salt tank | Iranzo et al. [63] |

| 20 | Analysis of the performance of linear Fresnel collectors: Encapsulated vs. evacuated tubes | Fresnel lens | Cagnoli et al. [64] |

| 21 | Thermal energy storage for CSP hybrid gas turbine systems: Dynamic modeling and experimental validation | Thermal energy storage | Mahmood et al. [65] |

| 22 | Assessment of Heat Exchangers for the Integration of Concentrated Solar Energy into the Catalytic Hydrothermal Gasification of Biomass | Thermal energy storage | Viereck et al. [66] |

| 23 | Volume of fluid approach of boiling flows in concentrated solar plants | Fresnel Lens | Dinsenmeyer et al. [67] |

| 24 | Thermal cycle and combustion analysis of a solar-assisted micro gas turbine | Combustor side | Abagnale et al. [68] |

| 25 | Dense gas-particle suspension upward flow used as heat transfer fluid in solar receiver: PEPT experiments and 3D numerical simulations | Solar tower | Ansart et al. [69] |

| 26 | Optimized volumetric solar receiver: Thermal performance prediction and experimental validation | Volumetric solar receiver | Capuano et al. [70] |

| 27 | A comparison between transient CFD and FEM simulations of solar central receiver tubes using molten salt and liquid metals | Solar tower | Fritsch et al. [71] |

| 28 | Finite-volume ray tracing using Computational Fluid Dynamics in linear focus CSP applications | Fresnel lens | Craig et al. [72] |

| 29 | Coupled modeling of a directly heated tubular solar receiver for supercritical carbon dioxide Brayton cycle: Optical and thermal-fluid evaluation | Solar tower | Ortega et al. [73] |

| 30 | Recirculating metallic particles for the efficiency enhancement of concentrated solar receivers | Solar tower | Sarker et al. [74] |

| 31 | Aerodynamics of new solar parametric troughs: Two dimensional and three dimensional single module numerical analysis | Parabolic trough | Núnez Bootello et al. [75] |

| 32 | Dimensionless analysis for predicting Fe-Ni-Cr alloy corrosion in molten salt systems for concentrated solar power systems | Molten salt | Cho et al. [76] |

| 33 | CFD analysis of melting process in a shell-and-tube latent heat storage for concentrated solar power plants | PCM heat storage system | Fornarelli et al. [15] |

| 34 | Multidimensional modeling of nickel alloy corrosion inside high temperature molten salt systems | Corrosion in molten salt | Mehrabadi et al. [77] |

| 35 | Investigation of heat transfer enhancement in a new type heat exchanger using solar parabolic trough systems | Parabolic trough | Şahin et al. [78] |

| 36 | Optimization of a trapezoidal cavity absorber for the Linear Fresnel Reflector | Fresnel lens | Moghimi et al. [79] |

| 37 | A novel computational approach to combine the optical and thermal modeling of Linear Fresnel Collectors using the finite volume method | Fresnel lens | Moghimi et al. [80] |

| 38 | Assessment of a falling solid particle receiver with numerical simulation | Solar tower | Gobereit et al. [81] |

| 39 | Numerical simulation of particulate flow in interconnected porous media for central particle-heating receiver applications | Porous solar receiver | Lee et al. [82] |

| 40 | CFD-based reduced model for the simulation of thermocline thermal energy storage systems | Thermal energy storage | Pizzolato et al. [83] |

| 41 | CFD analysis of solar tower Hybrid Pressurized Air Receiver (HPAR) using a dual-banded radiation model | Solar tower | Craig et al. [84] |

| 42 | Thermal energy storages analysis for high temperature in air solar systems | Thermal energy storage | Andreozzi et al. [85] |

| 43 | Night time performance of a storage integrated solar thermophotovoltaic (SISTPV) system | Thermal energy storage (PV) | Veeraragavan et al. [86] |

| 44 | Numerical study of wind forces on parabolic solar collectors | Parabolic trough | Zemler et al. [87] |

| 45 | CFD-simulation of a new receiver design for a molten salt solar power tower | Solar tower | Garbrecht et al. [88] |

| 46 | Modular object-oriented methodology for the resolution of molten salt storage tanks for CSP plants | Molten salt tank | Rodríguez et al. [14] |

| 47 | Experimental and numerical study of annular PCM storage in the presence of natural convection | PCM heat storage tank | Longeon et al. [11] |

| 48 | Numerical study of conduction and convection heat losses from a half-insulated air-filled annulus of the receiver of a parabolic trough collector | Parabolic trough | Al-Ansary and Zeitoun [89] |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ubando, A.T.; Conversion, A.; Barroca, R.B.; Enano, N.H., Jr.; Espina, R.U. Computational Fluid Dynamics on Solar Dish in a Concentrated Solar Power: A Bibliometric Review. Solar 2022, 2, 251-273. https://doi.org/10.3390/solar2020014

Ubando AT, Conversion A, Barroca RB, Enano NH Jr., Espina RU. Computational Fluid Dynamics on Solar Dish in a Concentrated Solar Power: A Bibliometric Review. Solar. 2022; 2(2):251-273. https://doi.org/10.3390/solar2020014

Chicago/Turabian StyleUbando, Aristotle T., Ariel Conversion, Renyl B. Barroca, Nelson H. Enano, Jr., and Randell U. Espina. 2022. "Computational Fluid Dynamics on Solar Dish in a Concentrated Solar Power: A Bibliometric Review" Solar 2, no. 2: 251-273. https://doi.org/10.3390/solar2020014