3.1. Comparison of Analytical Methodologies through the Greenness Assessment

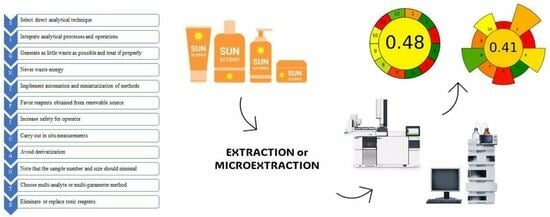

Due to the complexity of the matrix of cosmetics, analytical procedures are time-consuming, energy-intensive, and often require the use of large amounts of solvents. Some analytical methodologies require the use of derivatization of analytes, which is harmful to the environment and, potentially, also to the health of the analyst. Because chromatography is the most widely used analytical method, procedures using this analytical technique were selected to assess their environmental impact. Ten methods were selected, including two methods (4 and 6) previously described by the authors [

19]. Five methodologies based on gas chromatography and five using liquid chromatography were considered in the assessment of greenness. The HPLC methods make it possible to perform analysis without the use of the analyte extraction step; these procedures require the ultrasonically assisted dissolution of cosmetics in solvents and filtration of the solutions. In addition, the content of UV filters in cosmetics is high (max. 25%), so the sample preparation procedures do not require a preconcentration of analytes. Therefore, liquid chromatography is the most commonly used analytical technique for the qualitative and quantitative determination of cosmetic ingredients. Two European standard methods [

6,

7] for the determination of UV filters in cosmetic samples use this analytical technique. One of them, with a higher “greenness” score (Method 1) is presented in the work. This procedure (EN 17156:2018) makes it possible to determine 22 UV filters. However, separate analyses should be performed for water-soluble UV filters (6 analytes), fat-soluble analytes (15 analytes), and one polymeric UV filter (Polysilicone-15). The procedure for determining the fat-soluble UV filters was selected for the “greenness” assessment due to the largest number of analytes. This method (Method 1), among the methods presented in

Table 2, obtained a high AGREEprep score of 0.33. Sample preparation is simple and quick (30 min), which affects positively criterion 6 (

sample throughput), moreover uses a small amount of energy (20 min ultrasonication, criterion 8). In this procedure, 32 mL of ethanol (EtOH) was used to dissolve the cosmetic sample. This large amount of reagent used for sample preparation results in a score of 0 in criterion 2 (

safer solvents and reagents; red color), it is also associated with the generation of large amounts of waste (criterion 4, red color). Whereas, the EtOH, used for sample preparation, has only two pictograms, which is positively assessed in criterion 10 (

safe for operator, yellow color). Compared to Method 1, Method 2 obtained a lower AGREEprep score 0.26. This is mainly due to the use of 10 mL of methanol (MeOH) (criterion 2), which has three pictograms, which have impact on reduce criterion 10 (orange color). In addition, the time of ultrasonication (90 min, criterion 6, red color) influenced the lowering of the score. Methods 1 and 2 use liquid chromatography for analysis, which is associated with the use of even greater amounts of solvents and generated waste. The AGREE scores for methods 1 and 2 were 0.48 and 0.43, respectively. These two highest scores (in

Table 2) were obtained thanks to four criteria: the amount of the sample (0.1 g, criterion 2), the number of procedures steps (2 steps, criterion 4), no derivatization steps (criterion 6) and safety for the analyst (criterion 12). Compared to other presented procedures, Methods 1 and 2 use EtOH and MeOH to dissolve the samples, which has a positive effect on the assessment and improves the “greenness” of criterion 10 (

can be from bio-based sources). As in the AGREEprep assessment, these methods are disadvantaged by the large amount of waste generated. The waste includes solvents, a filter, and a mobile phase used for HPLC analyses. The time needed to analyse one sample using Method 1 is long and takes to 70 min (

sample throughput, criterion 8). This is due to the long-time of HPLC analysis (40 min). During this time, as many as 15 UV filters can be determined (light green color, criterion 8). However, Method 2, despite the short-term HPLC analysis (6 min, criterium 8), obtained a lower score due to the longer sample preparation time (ultrasonication—90 min) and low number of determined analytes (5 UV filters). The final low assessment of Method 2 is also affected by the high energy consumption associated with the long duration of ultrasonication but, above all, with the use of the MS/MS detector for the analysis (red color, criterion 9).

In Method 3, nail products were extracted with acetone, followed by vortexing, sonication, centrifugation, and filtering. During the extraction procedure, the UV filter was derivatized using

N,

O-Bis(trimethylsilyl)trifluoroacetamide, and GC–MS/MS was used for analysis. This sample preparation procedure was evaluated by AGREEprep with a score of 0.41, the highest score among the methods presented in

Table 2. Only 0.8 mL of acetone was used to extract analytes from a 0.1 g sample (green color, criterion 5), which favorably influenced the evaluation of criterion 2 (

use safer solvent and

reagent) and, thus, criterion 4 (

minimize waste). The reagents used (acetone and derivatizing reagent) have only two pictograms, which has a positive effect on criterion 10 (yellow color). On the other hand, Method 3 received a low AGREE score of 0.39. Despite the high scores of criteria 7 and 11 (

waste amount and

volume of toxic reagents), criteria 6, 8, and 9 significantly lowered the final result of the procedure. The procedure presented by the authors of the paper focused on the determination of only one UV filter, and the time needed to perform one analysis was about 1 h, which resulted in a low evaluation of criterion 8 (

analyte throughput). In addition, the low scores for parameters 6 and 9 were affected by the use of a derivatization agent and the use of the MS/MS (

energy consumption) detector, respectively.

In Method 4, the authors used solid phase extraction (SPE), which is a classic, commonly used method of extraction, purification, and concentration of analytes. It achieved the same AGREEprep score as Method 2, 0.26. Only in a detailed report (see

Supplementary Materials) can you notice slight differences in criteria 4, 6, 7, and 8. In this assessment, only two criteria were green: the amount of sample used (0.1 g, criterion 5) and the energy consumption needed to operate the vacuum pump and stirrer (criterion 8). However, this procedure is time-consuming (criterion 6) and consists of three steps: dissolving the cosmetic in water (15 min), extraction lasting approx. 25 min, evaporation of the solvent, and dissolution of the residue (20 min). This method uses large amounts of solvent (15.5 mL, criterion 2). Preparation of one sample generates 14.6 g of waste (criterion 4) consisting of solvents and cartridge SPE. Whereas, water (a cosmetic with water) is not added to the waste, because it is not mixed with toxic and harmful reagents. In addition, 5 mL of solvent is evaporated. On the other hand, the SPE-GC/MS method was assessed more critically by AGREE. The score was 0.38. The lowering of the score (red color) is due to the lack of miniaturization and automation (criterion 5), and high energy consumption—mainly through the use of GC/MS (criterion 9) and not the use of bio-based reagents (criterion 10).

The pressurized liquid extraction (PLE) followed by GC-MS/MS—Method 5—was applied for the simultaneous extraction and analysis of 16 UV filters from cosmetic and personal care products. Extraction was performed on an accelerated solvent extractor (ASE 150). The method was qualified as semi-automatic, which resulted in a higher score in criterion 7. However, the other criteria adversely affected the final score of AGREEprep, which is why this method received the lowest score of 0.19. Method 5 also resulted in the lowest AGREE score, 0.38. Derivatization conducted for 60 min causes three criteria to be lowered simultaneously: use of derivatization agent, analyte throughput, and energy consumption. Also, conducting the analysis using GC-MS/MS significantly increases energy consumption, which further lowers the assessment of criterion 9 in AGREE metric.

Microextraction in packed sorbent (MEPS)—Method 6—is a greener alternative to the conventional SPE, which uses the same syringe for sample extraction and extract injection into the analytical instrument. In this method, smaller volumes of solvents and samples are used, and, as well, sample preparation takes less time than in classical SPE. MEPS can be performed online in a fully automated manner, but, due to high costs, equipment is most often purchased and the process conducted manually. The assessed MEPS procedure is a miniaturized version of the previously presented Method 3 (SPE), developed by the authors in this paper. The miniaturization of the procedure resulted in a significant improvement in the greenness score, which was achieved by AGREEprep with the highest score of 0.41. A satisfactory result is mainly influenced by four criteria—miniaturization (criterion 5), lower consumption of toxic solvents (criterion 2), smaller amount of generated waste (criterion 4), and significantly shortened sample preparation time (criterion 6). Criterion 3—sustainability and renewability of materials—was rated higher than the other assessed methods only in this method because the sorption bed is reusable. The evaluation of the entire procedure performed by AGREE was 0.48. It gained an advantage over other evaluated methods mainly in the criteria concerning the number of toxic reagents used (criterion 11) and the amount of generated waste (criterion 7). On the other hand, it is disadvantageous due to the use of an energy-intensive MS detector for the analysis (decrease in criterion 9). In addition, no bio-based reagents were used in the tests, which results in a negative assessment of criterion 10.

Method 7—micro-matrix solid-phase dispersion (µ-MSPD)—was performed by preparing the sample-sorbent column in a glass Pasteur pipette. µ-MSPD allows extraction and purification to be performed in one step and is easy and cheap to perform. This extraction method (14 UV filters) evaluated by AGREEprep received a high score of 0.36. However, this is not the highest result obtained for microextraction methods. This is due to the use of the largest volume of solvents (10 mL of acetonitrile), which lowers the score of criterion 2. Criterion 10 (safe procedures for the operator) was assessed more favorably than the other evaluated procedures. Only with this method, no energy is used for sample preparation. Therefore, criterion 8 scores 1 point and is green. However, the AGREE rating of this procedure in criterion 9 regarding energy consumption is red. This is related to the use of an energy-intensive MS/MS detector for the analysis. In addition, lowering the total score results in not using bio-based reagents (criterion 10). However, the overall AGREE score of Method 7 is high, at 0.48.

In the case of Method 8—magnetic nanoparticle-based dispersive solid-phase microextraction (MNP-DSPME)—magnetic nanoparticles are used for the separation of the sorbent from the sample solution and eluting the analyte. Due to this, energy consumption decreases and the time of sample preparation is shortened by replacing the centrifugation step with a magnetic field [

17]. This results in the method achieving a high greenness score of 0.33 for AGREEprep and the highest score of 0.52 for AGREE. The AGREEprep score was lowered mainly because the authors of the paper tested only 3 UV filters. In addition, criterion 4 (red color) significantly lowers the assessment of this method, mainly due to the waste of 500 mL of water used to dilute the sample, which is contaminated with acetonitrile. On the other hand, two criteria have a green character, low sample consumption (0.02 g, criterion 5), and low energy consumption (criterion 8). The high rating of AGREE (0.52) was influenced by four criteria that received a green color: 2—sample size, 4—number of steps, 6—no derivatization agents, and 12—operator’s safety. The miniaturization of the method (criterion 5), low energy consumption (criterion 9), and the use of MeOH as an eluent in HPLC (criterion 10) also contributed to the high overall AGREE scoring.

Ultrasound–vortex-assisted dispersive liquid–liquid microextraction (US–VA–DLLME)—Method 9—is a simple and cheap sample preparation procedure. The mass transfer rate of the extraction process was increased by a combination of vortexing (4 min) and ultrasonication (3 min). US-VA-DLLME uses small amounts of extraction solvents (1.57 mL) and a small sample volume (12.5 mg). In addition, bio-derived solvents (anisole) and MeOH were used as extractants and dispersants, respectively. Despite the advantages presented above, this method received a relatively low AGREEprep rating of 0.29. This assessment was mainly influenced by criterion 4 (minimize waste; red color), in which the water used to dissolve the sample was classified as waste (51.6 mL) because it was in contact with the solvent (acetone). In addition, the red character was given to criterion 10 (use safe reagent), because the reagents used had four different pictograms. The AGREE score of 0.47 was influenced by the same factors described above. In addition, due to the use of eluents in HPLC analysis (7.5 mL of acetonitrile), the number of reagents used (criterion 11) and waste generated (criterion 7) increased.

Compared to the other procedures evaluated (

Table 3), method 10—dynamic hollow fiber liquid-phase microextraction (HF-LPME) with HPLC-UV was well evaluated with scores of 0.36 and 0.51 for AGREEprep and AGREE, respectively. This method owes such good results to the use of a UV detector (low energy consumption) for analysis and the generation of a small amount of waste. HF-LPME was adopted as a semi-automated system, which contributed well to criterion 7 in the AGREEprep evaluation. However, the assessment is negatively affected by the use of 3.01 mL of solvents (hexane, acetone, and toluene) for sample preparation, which in total have 5 different pictograms, which means that criterion 10 in AGREEprep has a low scoring (red color). Also in the AGREE assessment, this has a negative impact on criterion 12, because the use poses a risk to the operator and the environment (mainly due to the use of hexane). In addition, 16 mL of methanol is used to perform the HPLC analysis, which increases the volume of solvents used and the low score of criterion 11 (amount of toxic reagents).

3.2. Greenness Assessment Summary

As expected, the microextraction methods (

Table 3) showed a more environmentally friendly effect. When scored with AGREEprep, they achieved higher greenness scores, ranging from 0.29 to 0.41 for US-VA-DLLME and MEPS, respectively. On the other hand, for classical extraction methods, the evaluation results were 0.19–0.33 (

Table 2). Similar results were obtained when assessing the greenness of entire procedures by AGREE metric. For procedures using microextraction methods, their score is high and amounts to 0.47–0.52 for US-VA-DLLME-HPLC/DAD and DSPME-HPLC/DAD, respectively. Lower results (0.38–0.48) were obtained by procedures using classical extraction methods. The AGREE score is largely affected by the type of chromatographic analysis performed. Due to the solvents used in liquid chromatography, this method of analysis adversely affects the assessment of the greenness of the entire procedure. In addition, in many cases, the use of MS and MS/MS detectors (more energy-intensive) significantly lowered the overall assessment of greenness (equally for GC and HPLC).

It should also be noted that both AGREEprep and AGREE assessment methods are not always compatible in assessing the greenness of procedures. This is most evident in the case of the DSPME-HPLC/DAD method, where the sample preparation score is low at 0.33, while AGREE rated this procedure at most at 0.52. Similarly for the UV-DLLME-HPLC/DAD method, for which the AGREEprep score was 0.29, and for AGREE, it was 0.47. This proves that it is justified to evaluate procedures by analysts using two assessment tools. If it is necessary to choose an analytical method, only such an assessment will show the positive and negative sides of each procedure and the possibility of improving its greenness.

Selected procedures presented in the literature were not prepared by their authors in terms of greenness assessment. The aim of this work was mainly to obtain positive validation parameters. Therefore, in each of these procedures, criteria can be indicated, the greenness of which can be easily improved. The AGREE assessment is influenced by the number of analytes determined (sample throughput): in this criterion, the assessed methods showed a large discrepancy (from 1 to 17 analytes). This is a criterion that can be corrected for each chromatography system. Another example of improving the greenness of the SPE method can be obtained by extracting multiple samples simultaneously. Similarly, in Method 5—PLE—in the case of using a multi-station ASE extractor, it is possible to improve such criteria as sample throughput, and energy consumption. In the case of the MEPS method, it can be performed in an automatic system, which will improve criterion automatization. In other methods, the amounts of solvents used (amount of toxic reagents) and execution times (sample throughput, energy consumption) in such steps as dissolving cosmetics (mixing and ultrasonication) can be shortened. Moreover, the great impact on the assessment of the method has the type of detector used, if it is possible less energy-intensive detectors, such as FID, ECD, UV-Vis, and DAD, can be used for routine tests.