Technical and Economic Viability of Underground Hydrogen Storage

Abstract

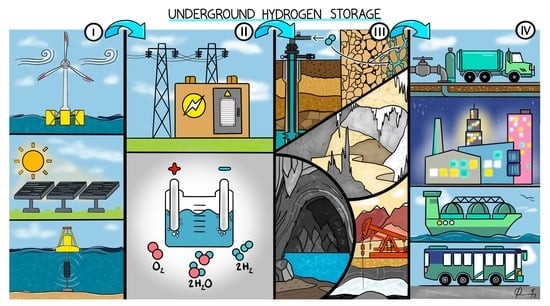

:1. Introduction

2. Geological Structures for Underground Hydrogen Storage and Relevant Parameters

2.1. Depleted Oil and Gas Reservoirs

2.2. Aquifers

2.3. Salt Caverns

2.4. Parameters

2.5. Seasonal Storage

3. Site Selection

- Problem identification: define the decision problem and establish the objectives and criteria relevant to the decision;

- Criteria selection: Select the criteria that will be used to evaluate the alternatives. These criteria should be measurable, relevant to the decision, and reflect the objectives;

- Weighting of criteria: Assign relative weights to each criterion reflecting its significance. Weights indicate the relative importance of each criterion in the decision-making process;

- Alternative generation: generate a set of alternatives that could potentially address the problem;

- Evaluation of alternatives: Assess each alternative. This may involve quantitative analysis, qualitative assessments, expert opinions, or a combination of approaches;

- Scoring and ranking: assign scores or ratings to each alternative based on their performance or suitability with respect to the criteria;

- Decision analysis and decision making: analyze the scores or rankings of the alternatives to identify the best or preferred option.

4. Technical Challenges Ahead

4.1. Site Characterization

4.2. Injection Strategies

4.3. Biological, Geochemical, and Bacterial Effects

4.4. Mechanism and Monitoring

4.5. Withdrawal Strategies

5. Past Experience and Ongoing Projects

6. Market Size

- Purity requirement for hydrogen grids: The viability of business cases related to hydrogen injection into transport pipelines will be impacted by quality specifications, primarily driven by purification costs. It is noteworthy that purification expenses tend to be higher for depleted fields than salt caverns;

- Immature market for hydrogen storage: The demand for large-scale pure hydrogen storage has not yet been established. While this demand will arise in the coming 10–20 years, the forecasts and expected application areas remain unclear. Consequently, there is no clear insight into the future UHS business case and how the returns on investments will evolve. This hinders investors from committing to long-term investment decisions, resulting in delays in the progress of viable cases. The type of market regulation (regulated vs. third-party) on UHS development should be examined;

- Lack of experience in UHS operations: the practical experience with high-purity hydrogen storage has been confined to just a handful of salt cavern storage sites;

- Availability and knowledge of suitable geological structures: The assessment and ranking of viable geological reservoirs is still in the early phases. Selecting and improving potential site identification might need significant financial support for exploration, appraisal, sampling, and testing. Moreover, an uneven distribution of salt deposits, hydrocarbon reservoirs, and aquifers could restrict the prospect of developing economically achievable scenarios.

7. Infrastructure

8. Conclusions

9. Future Outlook

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Country | Project Name | Type | Expected Capacity | Development Status | Expected Start | Description | Source |

|---|---|---|---|---|---|---|---|

| Argentina | Hychico | Depleted gas field | Unknown (testing only) | Testing | n/a | Investigating storage of blended hydrogen (10%) in depleted hydrocarbon reservoirs, including geomethanation. Until 2018, the project focused on producing “green methane”, and it seems to be changing to developing this technology. | [33] |

| Austria | Sun Storage 2030 | Depleted gas field | Unknown | Construction | n/a | Aims to develop safe, seasonal hydrogen storage in depleted natural gas reservoirs. | [34] |

| Sun Storage | Depleted gas field | Unknown (testing only) | Testing completed | 2016 | Experimental trials of injection of 10% hydrogen mixture in a gas field. | [35,36] | |

| Sun Conversion, FlexStore | Depleted gas field | Unknown (testing only) | Testing completed | n/a | Conducting experiments on underground methanation through the injection of hydrogen and carbon dioxide. | [37,38] | |

| HyStorage Bierwang | Depleted gas field | Testing | 2025 | Three operation phases using different natural gas/hydrogen gas blends (5, 10, 25 vol.% H2 in natural gas) to be injected into the natural gas reservoir and withdrawn after a three-month holding period. First hydrogen injection in September 2023. | [39,40] | ||

| Belgium | Loenhout Hydrogen | Aquifer | 2–3 TWh | Pre-feasibility | n/a | Tests with hydrogen–natural gas mixtures. | [41,42,43,44] |

| Denmark | Green Hydrogen Hub | Salt cavern | 200 GWh | Pre-feasibility | 2025 | Aims to be the first viable commercial UHS with large-scale green hydrogen production and compressed-air energy storage. | [45,46] |

| France | Hypster | Salt cavern | 3 tons | Construction | 2023 | E.U.-supported large-scale green UHS. | [47,48,49] |

| Emil’Hy | Salt cavern | Unknown | Proposal | 2023 | Salt cavern in Cerville, Meurthe-et-Moselle department. Starting in 2023 with a production capacity of 5 MW, this project will build a new salt cavern in 2025 to support the increase in the production capacity, which should be in the 50–100 MW range by then. | [49,50] | |

| HyGreen Provence | Salt cavern | Unknown | Proposal | 2028 | H2 will be stored within salt caverns at the Manosque storage site and distributed for different applications. | [49,51] | |

| HyGéo | Salt cavern | 1.5 GWh | Pre-feasibility | 2024 | Constructed on a previous salt cavern site in a municipality within the Nouvelle Aquitaine region, the facility is designed to store 1.5 GWh of energy. | [49,52] | |

| Germany | H2Cast | Salt cavern | Unknown (scalable) | Testing | 2024 | To showcase the viability of extensive UHS and demonstrate the suitability of salt caverns in Etzel. | [53,54] |

| Jemgum Storage | Salt cavern | 48 Mm3 | Pre-feasibility, FEED | 2030 | Evaluating the adequacy for UHS of a salt cavern used to store natural gas in Jemgum. | [55] | |

| HPC Krummhörn | Salt cavern | 0.2 Mm3 | Pre-feasibility | 2024 | Project aiming for 100% hydrogen storage in the former Krummhörn natural gas storage site. The pilot facility is commissioned to store up to 0.25 M m3 of H2. | [56] | |

| Westküste 100 | Salt cavern | Unknown | Pre-feasibility | n/a | A cavern storage system designed for UHS will use surplus wind energy to produce a continuous hydrogen stream for industry. | [57,58] | |

| Bad Lauchstädt | Salt cavern | 150 GWh | Pre-feasibility | n/a | Green hydrogen is produced using an adjacent wind farm and temporarily housed in a salt cavern. Supplied to the hydrogen infrastructure of the chemical sector in central Germany, it is also envisioned for future urban transportation systems. | [59,60] | |

| GET H2 Nukleus Gronau-Epe | Salt cavern | 67 GWh | Planning, permitting | 2027 | Plans include expanding the existing surface infrastructure to incorporate hydrogen injection, storage, and withdrawal systems in caverns. The facility will have 6 M m3 of hydrogen in stock. An additional 28 M m3 will be available for customers to store hydrogen. | [61,62,63] | |

| HyCAVMobil Rüdersdorf | Salt cavern | 500 m3 | Construction | 2023 | Construction of the test cavern began in 2021 and finished in March 2023. It will be filled with hydrogen in 2023, and a “wet” hydrogen-drying system will be tested. Findings should be transferred to caverns with 1000× larger volumes. The main goal is to use caverns with 0.5 M m3 for large-scale UHS. | [64] | |

| Hungary | Aquamarine | Depleted gas field | Unknown | Construction | n/a | The Aquamarine project aims to deploy an electrolysis system with an estimated total capacity of 2.5 MW, as well as the associated hydrogen infrastructure, at the Kardoskut Underground Gas Storage site. The hydrogen produced will be blended with natural gas and employed in the Gas Storage Ltd.’s gas-operated equipment. | [65,66] |

| Ireland | Green hydrogen @Kinsale | Depleted gas field | 3 TWh | Pre-feasibility | n/a | This project (pending license and planning approvals) will have a capacity of up to 3 TWh of green hydrogen and hydrogen carriers. An ample work program is underway, encompassing subsurface research, mineralogical studies, capacity modeling, injection and withdrawal rates, compression mechanisms, drilling assessment, well design, retention assurance, monitoring, electrolysis, and infrastructure integration. | [67] |

| Italy | North Adriatic Hydrogen Valley | Depleted gas field | Unknown | n/a | n/a | Evaluation of potential gas fields and aquifers. | [68] |

| Netherlands | HyStock | Salt cavern | 6000 tons | FEED and permitting | 2027 | Initial borehole tests and demonstration in 2022. The first cavern will be operational in 2027, with a plan to upscale the capacity to four caverns by 2030. | [69,70] |

| Poland | Damasławek | Salt cavern | Unknown | n/a | 2030 | The first UHS facility to be operational in 2030. Placement and geological settings offer an opportunity to establish a storage site crucial to Poland’s energy security and the base of a hydrogen economy. The facility is well suited to integrate hydrogen clusters created around industrial centers and offshore and renewable energy storage facilities. | [71] |

| Portugal | Sines H2 Hub, Carriço | Salt cavern | n/a | Pre-feasibility | 2030 | A significant industrial project is underway for the production of green hydrogen in Sines, which encompasses multiple aspects, including production, processing, storage (at Carriço), transportation (internal and export), and consumption. | [72,73,74] |

| Slovakia | H2I | Depleted gas field | n/a | Pre-feasibility | n/a | The initial stage of H2I S&D has experts searching for a suitable site for storing hydrogen blends (with natural gas). After the identification of the underground structure, lab studies will start. | [75] |

| Spain | Undergy | Depleted gas field | n/a | Pre-feasibility | n/a | Technologies for establishing long-term energy storage considering green hydrogen as a key part of the smart grid. | [76] |

| Sweden | HyBRIT | Lined rock cavern | n/a | Testing | 2024 | Pilot plant with a size of 100 m3. Later, a full-scale hydrogen storage facility of 0.10–0.12 M m3 will be necessary. | [77] |

| U.K. | Teesside | Salt cavern | 25–27 GWh | Operational | 1972 | Pure hydrogen storage for industry feedstock supply. | [78,79] |

| ANGUS+ | Depleted gas field | n/a | Pre-feasibility | n/a | Studying the feasibility of connecting the Saltfleetby facility to the UK National Grid and exploring the potential for storage and methanation. | [80] | |

| HySecure | Salt cavern | Over 1000 tons | Pre-feasibility | n/a | Demonstration project for building a salt cavern for storing hydrogen at Stublach, the U.K.’s largest storage facility for natural gas. | [81,82] | |

| U.S. | Clemens Dome | Salt cavern | 81–92 GWh | Operational | 1983 | Storage of pure hydrogen for industrial purposes. | [78,79] |

| Moss Bluff | Salt cavern | 120–123 GWh | Operational | 2007 | Storage of pure hydrogen for industrial purposes. | [78,79] | |

| Spindle Top | Salt cavern | 274 GWh | Operational | 2016 | Storage of pure hydrogen for industrial purposes. | [78,79] | |

| Advanced Clean Energy Storage | Salt cavern | 300 GWh | FEED | 2025 | Two caverns, each with a capacity of 150 GWh, will store hydrogen produced by a close hydrogen-capable gas turbine combined-cycle power plant of 840 MW. | [83,84] |

| Country | Project Name | Description |

|---|---|---|

| Austria | BIOPore | Studying microbial growth and its implications from the pore to intermediate scales. |

| Europe | HyStories | Investigating UHS technologies for pure hydrogen storage in depleted fields and aquifers. |

| HyUSPRe | Assessing the viability and possibilities of introducing the extensive storage of renewable hydrogen in European porous reservoirs. | |

| HyUnder | Assessing the potential actors and commercial frameworks for large-scale UHS in Europe (2012–2014). | |

| France | Abiotic Reactivity of Minerals at Elevated H2 Concentrations | Examining fluid–rock alteration processes within deep aquifers pressurized with hydrogen. |

| Germany | HyInteger | Investigating the impact of microbial activity on the well structural integrity. |

| H2 React and H2 React Phase 2 | Research on fundamentals of UHS. The project aims to gather empirical data concerning the kinetics of chemical reactions, microbial activities, and hydrogen transport mechanisms within deep geological systems under in situ conditions. | |

| UMAS | The project examines the techno-economic and socio-economic viability and the ecological potential of underground methanation in aquifers. | |

| HyPos-H2UGS | Development of a standardized and transferrable procedure for constructing and converting salt caverns for UHS. | |

| TestUM-II Aquifer | Geophysical and hydrogeological field testing for investigating and monitoring reactive multi-phase transport processes in shallow aquifers induced by subsurface use. It is a continuation project of TestUM Aquifer. | |

| Bio-UGS | Investigating the reaction of green hydrogen with carbon dioxide to produce methane in subsurface storage systems using naturally present microorganisms. | |

| CliMb | Exploring the viability of conversion processes by combining experimental studies with numerical modeling and simulations in a multi-scale approach targeting from the micro- to macroscale. | |

| Netherlands | ADMIRE | Multi-scale numerical–experimental studies of hydro-thermo-mechanics of UHS for the site choice and operation, based on high-PT hydrogen lab. |

| Caves&Waves | Quantification of the probability of induced seismicity associated with large-scale hydrogen storage in Dutch salt formations. | |

| SafeInCave | Mechanics of salt cavern UHS and reservoir-scale simulator for evaluating the time-dependent salt cavern state of stress under cyclic loading. | |

| HyStoreReact | Aims to improve fundamental knowledge of UHS technical viability using salt caverns and porous reservoirs by examining the effects of geo- and biochemical reactions of hydrogen with rocks, fluids, and microorganisms on the subsurface. | |

| New Zealand | PūHiko ukutū | Assessing the technical feasibility, cost effectiveness, and environmental and social impacts of large hydrogen storage (>50 M m3) in sedimentary rock formations in New Zealand, specifically in the Taranaki Basin. |

| Norway | Hydrogeni | Center for supporting the development of a sustainable hydrogen economy in Norway and Europe. |

| HyPE | Research on the physical and microbial processes that regulate the underground gas capacity, deliverability, and hydrogen injection rates in porous media. A numerical simulator will also be established based on lab data from hydrogen storage-related research. | |

| HyValue | Promoting knowledge, methodology, and innovative approaches for hydrogen energy carriers to shape and support a viable hydrogen energy sector. | |

| CSSR | Makes available required studies to address main adversities and create awareness of potential opportunities of reservoir operations in a net-zero future. | |

| Biorisks in Salt Caverns | Gaining critical information about halophilic microbes existing in salt caverns and their potential effects on UHS. | |

| U.K. | GeoEnergy Observatory, Cheshire | An array of wells fit for the comprehension of the flow through porous rocks in an actual operational environment. |

| HyStorPor | Investigating possible U.K. porous reservoir rock sites for hydrogen storage. | |

| IDRIC | Addresses crucial multi-disciplinary and cross-cutting challenges involved in decarbonizing industry, including UHS development. | |

| U.S. | SHASTA | Evaluating the viability, safety, and consistency of the subsurface storage of 100% hydrogen or blends with natural gas. |

References

- Zivar, D.; Kumar, S.; Foroozesh, J. Underground hydrogen storage: A comprehensive review. Int. J. Hydrogen Energy 2020, 46, 23436–23462. [Google Scholar] [CrossRef]

- Caglayan, D.G.; Weber, N.; Heinrichs, H.U.; Linßen, J.; Robinius, M.; Kukla, P.A.; Stolten, D. Technical potential of salt caverns for hydrogen storage in Europe. Int. J. Hydrogen Energy 2020, 45, 6793–6805. [Google Scholar] [CrossRef]

- Miocic, J.; Heinemann, N.; Edlmann, K.; Scafidi, J.; Molaei, F.; Alcalde, J. Underground hydrogen storage: A review. Geol. Soc. Lond. Spec. Publ. 2023, 528, 73–86. [Google Scholar] [CrossRef]

- Kanaani, M.; Sedaee, B.; Asadian-Pakfar, M. Role of Cushion Gas on Underground Hydrogen Storage in Depleted Oil Reservoirs. J. Energy Storage 2022, 45, 103783. [Google Scholar] [CrossRef]

- Höök, M.; Söderbergh, B.; Jakobsson, K.; Aleklett, K. The Evolution of Giant Oil Field Production Behavior. Nat. Resour. Res. 2009, 18, 39–56. [Google Scholar] [CrossRef]

- Sainz-Garcia, A.; Abarca, E.; Rubi, V.; Grandia, F. Assessment of feasible strategies for seasonal underground hydrogen storage in a saline aquifer. Int. J. Hydrogen Energy 2017, 42, 16657–16666. [Google Scholar] [CrossRef]

- Lord, A.S.; Kobos, P.H.; Borns, D.J. Geologic storage of hydrogen: Scaling up to meet city transportation demands. Int. J. Hydrogen Energy 2014, 39, 15570–15582. [Google Scholar] [CrossRef]

- Groenenberg, R.; Koornneef, J.; Sijm, J.; Janssen, G.; Morales-Espana, G.; van Stralen, J.; Hernandez-Serna, R.; Smekens, K.; Juez-Larré, J.; Goncalvez, C.; et al. Large-Scale Energy Storage in Salt Caverns and Depleted Gasfields. TNO (Executive Organization), EBN, Gasunie, Gasterra, NAM and Nouryon, Project Findings 060.36821, Subsidy Reference: TGEO118002, October 2020. Available online: https://publications.tno.nl/publication/34637700/8sBxDu/TNO-20 (accessed on 26 September 2023).

- Jiang, D.; Fan, J.; Chen, J.; Li, L.; Cui, Y. A mechanism of fatigue in salt under discontinuous cycle loading. Int. J. Rock Mech. Min. Sci. 2016, 86, 255–260. [Google Scholar] [CrossRef]

- Michalski, J.; Bünger, U.; Crotogino, F.; Donadei, S.; Schneider, G.-S.; Pregger, T.; Cao, K.-K.; Heide, D. Hydrogen generation by electrolysis and storage in salt caverns: Potentials, economics and systems aspects with regard to the German energy transition. Int. J. Hydrogen Energy 2017, 42, 13427–13443. [Google Scholar] [CrossRef]

- Pan, B.; Yin, X.; Ju, Y.; Iglauer, S. Underground hydrogen storage: Influencing parameters and future outlook. Adv. Colloid Interface Sci. 2021, 294, 102473. [Google Scholar] [CrossRef]

- Heinemann, N.; Booth, M.G.; Haszeldine, R.S.; Wilkinson, M.; Scafidi, J.; Edlmann, K. Hydrogen storage in porous geological formations—Onshore play opportunities in the midland valley (Scotland, UK). Int. J. Hydrogen Energy 2018, 43, 20861–20874. [Google Scholar] [CrossRef]

- Lankof, L.; Tarkowski, R. Assessment of the potential for underground hydrogen storage in bedded salt formation. Int. J. Hydrogen Energy 2020, 45, 19479–19492. [Google Scholar] [CrossRef]

- Tong, D.; Farnham, D.J.; Duan, L.; Zhang, Q.; Lewis, N.S.; Caldeira, K.; Davis, S.J. Geophysical constraints on the reliability of solar and wind power worldwide. Nat. Commun. 2021, 12, 6146. [Google Scholar] [CrossRef] [PubMed]

- Deveci, M. Site selection for hydrogen underground storage using interval type-2 hesitant fuzzy sets. Int. J. Hydrogen Energy 2018, 43, 9353–9368. [Google Scholar] [CrossRef]

- Lewandowska-Śmierzchalska, J.; Tarkowski, R.; Uliasz-Misiak, B. Screening and ranking framework for underground hydrogen storage site selection in Poland. Int. J. Hydrogen Energy 2018, 43, 4401–4414. [Google Scholar] [CrossRef]

- Kumar, K.R.; Honorio, H.; Chandra, D.; Lesueur, M.; Hajibeygi, H. Comprehensive review of geomechanics of underground hydrogen storage in depleted reservoirs and salt caverns. J. Energy Storage 2023, 73, 108912. [Google Scholar] [CrossRef]

- Muhammed, N.S.; Haq, B.; Al Shehri, D.A.; Al-Ahmed, A.; Rahman, M.M.; Zaman, E.; Iglauer, S. Hydrogen storage in depleted gas reservoirs: A comprehensive review. Fuel 2023, 337, 127032. [Google Scholar] [CrossRef]

- Zhang, J.; Li, Y.; Yin, Z.; Linga, P.; He, T.; Zheng, X.Y. Coupling amino acid L-Val with THF for superior hydrogen hydrate kinetics: Implication for hydrate-based hydrogen storage. Chem. Eng. J. 2023, 467, 143459. [Google Scholar] [CrossRef]

- Chabab, S.; Théveneau, P.; Coquelet, C.; Corvisier, J.; Paricaud, P. Measurements and predictive models of high-pressure H2 solubility in brine (H2O + NaCl) for underground hydrogen storage application. Int. J. Hydrogen Energy 2020, 45, 32206–32220. [Google Scholar] [CrossRef]

- Luboń, K.; Tarkowski, R. Numerical simulation of hydrogen injection and withdrawal to and from a deep aquifer in NW Poland. Int. J. Hydrogen Energy 2019, 45, 2068–2083. [Google Scholar] [CrossRef]

- Al-Yaseri, A.; Fatah, A.; Zeng, L.; Al-Ramadhan, A.; Sarmadivaleh, M.; Xie, Q. On hydrogen-cement reaction: Investigation on well integrity during underground hydrogen storage. Int. J. Hydrogen Energy 2023, 48, 35610–35623. [Google Scholar] [CrossRef]

- Hagemann, B.; Rasoulzadeh, M.; Panfilov, M.; Ganzer, L.; Reitenbach, V. Hydrogenization of underground storage of natural gas. Comput. Geosci. 2016, 20, 595–606. [Google Scholar] [CrossRef]

- Panfilov, M.; Gravier, G.; Fillacier, S. Underground Storage of H2 and H2-CO2-CH4 Mixtures. presented at the ECMOR X. In Proceedings of the 10th European Conference on the Mathematics of Oil Recovery, European Association of Geoscientists & Engineers, Amsterdam, The Netherlands, 4–7 September 2006. [Google Scholar] [CrossRef]

- Choudhury, P.K.; Jena, R.; Tomar, S.K.; Puniya, A.K. Reducing Enteric Methanogenesis through Alternate Hydrogen Sinks in the Rumen. Methane 2022, 1, 320–341. [Google Scholar] [CrossRef]

- Lovley, D.R.; Phillips, E.J.P. Competitive Mechanisms for Inhibition of Sulfate Reduction and Methane Production in the Zone of Ferric Iron Reduction in Sediments. Appl. Environ. Microbiol. 1987, 53, 2636–2641. [Google Scholar] [CrossRef] [PubMed]

- Hagemann, B. Numerical and Analytical Modeling of Gas Mixing and Bio-Reactive Transport during Underground Hydrogen Storage; Cuvillier Verlag: Göttingen, Germany, 2017. [Google Scholar]

- 2021 Annual Report: Tasks & Member Updates. IEA Hydrogen Technology Collaboration Program. 2021. Available online: https://www.ieahydrogen.org/annual-reports/ (accessed on 26 September 2023).

- 2022 Annual Report: Tasks & Member Updates. IEA Hydrogen Technology Collaboration Program. 2022. Available online: https://www.ieahydrogen.org/annual-reports/ (accessed on 26 September 2023).

- van Gessel, S.; Hajibeygi, H. Underground Hydrogen Storage: Technology Monitor Report. IEA Hydrogen Technology Collaboration Program Task 42. April 2023. Available online: https://www.ieahydrogen.org/task/task-42-underground-hydrogen-storage// (accessed on 26 September 2023).

- Le Duigou, A.; Bader, A.-G.; Lanoix, J.-C.; Nadau, L. Relevance and costs of large scale underground hydrogen storage in France. Int. J. Hydrogen Energy 2017, 42, 22987–23003. [Google Scholar] [CrossRef]

- International Energy Agency. Global Hydrogen Review 2022. IEA Publications. 2022. Available online: https://www.iea.org/reports/global-hydrogen-review-2022 (accessed on 26 September 2023).

- Hychico. Available online: https://hychico.com.ar/esp/almacenamiento-subterraneo-hidrogeno.php (accessed on 26 September 2023).

- Underground Sun Storage 2030. Available online: https://www.uss-2030.at/en/ (accessed on 26 September 2023).

- Underground Sun Storage. Available online: https://www.underground-sun-storage.at/en/ (accessed on 26 September 2023).

- RAG Austria AG, Axiom Angewandte Prozesstechnik GesmbH, Verbund AG, Montanuniversität Leoben, Universität für Bodenkultur Wien, and Energieinstitut an der Johannes Kepler Universität Linz, Underground Sun Storage Chemical Storage of Renewable Energy in Porous Subsurface Reservoirs with Exemplary Testbed. 840705. October 2017. Available online: https://www.underground-sun-storage.at/fileadmin/bilder/03_NEU_SUNSTORAGE/Downloads/Underground_Sun.Storage_Publizierbarer_Endbericht_English.pdf (accessed on 26 September 2023).

- Konegger, H.; Loibner, A.; Waldmann, N.; Zaduryan, A.; Zeiser, M.; Rüdisüli, M.; Mutschler, R.; Sidler, D.; Boggiano, M.; Kunz, A.; et al. Final Report: Underground Sun Conversion—Flexible Storage. RAG Austria AG, Energie 360° AG, Vienna and Bern. May 2023. Available online: https://www.underground-sun-conversion.at/index.php?eID=dumpFile&t=f&f=17587&token=2fa4de16ca810b3014ea2880ae8aa37828f160ac (accessed on 26 September 2023).

- Underground Sun Conversion. Available online: https://www.underground-sun-conversion.at/en/flexstore.html (accessed on 26 September 2023).

- HyStorage|Uniper. Available online: https://www.uniper.energy/hystorage (accessed on 26 September 2023).

- Escajadillo, E. Uniper Launches Research on German Hydrogen Storage Site. ICIS Explore. Available online: https://www.icis.com/explore/resources/news/2023/08/09/10913772/uniper-launches-research-on-german-hydrogen-storage-site (accessed on 26 September 2023).

- Storage Data. Available online: https://www.fluxys.com/en/natural-gas-and-biomethane/products-services/ztp-storage-storage-data (accessed on 26 September 2023).

- FLUXYS, Service Offer Description Storage Facility of Loenhout. July 2014. Available online: file:///Users/ernestoquintosfuentes/Downloads/Storage%20Programme.pdf (accessed on 26 September 2023).

- Belgium’s Fluxys benefits from Europe’s Rush to Secure Gas Supplies. Available online: https://www.euractiv.com/section/energy/news/belgiums-fluxys-benefits-from-europes-rush-to-secure-gas-supplies/ (accessed on 26 September 2023).

- H. Project|April 2023, Hydrogen Underground Storage in Porous Reservoirs. ArcGIS StoryMaps. Available online: https://storymaps.arcgis.com/stories/2349ba3eb36d4473861b7701a08985e1 (accessed on 26 September 2023).

- JAIC, Green Hydrogen Hub Denmark. Gas Infrastructure Europe. Available online: https://www.gie.eu/green-hydrogen-hub/ (accessed on 26 September 2023).

- About GHH|Green Hydrogen Hub Denmark. Available online: https://greenhydrogenhub.dk/about-ghh/ (accessed on 26 September 2023).

- Hydrogen Pilot Storage for Large Ecosystem Replication|HYPSTER Project|Fact Sheet|H2020′, CORDIS|European Commission. Available online: https://cordis.europa.eu/project/id/101006751 (accessed on 26 September 2023).

- About the Project|HyPSTER. Available online: https://hypster-project.eu/about-the-project/ (accessed on 26 September 2023).

- Netherlands Enterprise Agency (RVO), Embassy of the Kingdom of the Netherlands in France, and Netherlands Business Support Office Lyon & Nantes, Hydrogen in France, Developments and Opportunities for the Netherlands. Netherlands Enterprise Agency. March 2021. Available online: https://www.rvo.nl/sites/default/files/2022/01/Hydrogen-sector-study-France-maart-2021.pdf (accessed on 26 September 2023).

- Storengy, GazelEnergie, Storengy and GazelEnergie Join Forces to Develop the Hydrogen Sector in the Moselle Department. 20 October 2020. Available online: https://www.storengy.com/sites/default/files/mediateque/pdf/2020-10/2020_10_20%20Storengy%20et%20GazelEnergie%20s%27associent%20pour%20d%C3%A9velopper%20la%20fili%C3%A8re%20hydrog%C3%A8ne%20en%20Moselle_EN.pdf (accessed on 26 September 2023).

- JAIC, HyGreen Provence. Gas Infrastructure Europe. Available online: https://www.gie.eu/hygreen-provence/ (accessed on 27 September 2023).

- HDF Energy and Teregéa, Communique de Presse Terega et HDF Energy. 7 July 2020. Available online: https://www.hdf-energy.com/site/assets/files/1209/communique_de_presse_terega_hdf_en_juillet2020.pdf (accessed on 26 September 2023).

- S. E. GmbH, H2CAST Green Hydrogen Dtorage in Etzel. Available online: https://www.storag-etzel.de/en/storage/hydrogen-h2cast (accessed on 27 September 2023).

- Garbe, A. About H2CAST Etzel. Available online: https://h2cast.com/project (accessed on 27 September 2023).

- Future Projects. Available online: https://www.astora.de/en/company/astorah2/future-projects (accessed on 27 September 2023).

- HPC Krummhörn|Uniper. Available online: https://www.uniper.energy/hydrogen-pilot-cavern (accessed on 27 September 2023).

- Bailey, M. German Westküste 100 green hydrogen project secures funding. Fuel Cells Bull. 2020, 2020, 11. [Google Scholar] [CrossRef]

- Project Description|Westkueste100.de. Available online: https://www.westkueste100.de/en/project-description/ (accessed on 27 September 2023).

- JAIC, Bad Lauchstädt Energy Park. Gas Infrastructure Europe. Available online: https://www.gie.eu/bad-lauchstadt-energy-park/ (accessed on 27 September 2023).

- Bad Lauchstädt Energy Park Now in Implementation Phase. Bad Lauchstädt Energy Park Now in Implementation Phase. Available online: https://www.uniper.energy/news/bad-lauchstaedt-energy-park-now-in-implementation-phase (accessed on 27 September 2023).

- RWE, Hydrogen Project GET H2 Nukleus. Available online: https://www.rwe.com/en/research-and-development/hydrogen-projects/hydrogen-project-get-h2/ (accessed on 27 September 2023).

- GET H2 Nukleus. OGE. Available online: https://oge.net/en/hydrogen/our-hydrogen-projects/get-h2-nukleus (accessed on 27 September 2023).

- The German National Hydrogen Council, Statement: Hydrogen Storage Roadmap 2030 for Germany from 4th November 2022. 4 November 2022. Available online: https://www.wasserstoffrat.de/fileadmin/wasserstoffrat/media/Dokumente/EN/2023/2022-11-04_NWR-Position-Paper_Hydrogen-Storage-Roadmap.pdf (accessed on 27 September 2023).

- Blume, L. Hydrogen Cavern for Mobility—Wasserstoff-Niedersachsen.de. Hydrogen-Lower-Saxony.com. Available online: https://www.wasserstoff-niedersachsen.de/en/hydrogen-cavern-for-mobility/ (accessed on 28 September 2023).

- Aquamarine. Available online: https://mfgt.hu/en/Akvamarin (accessed on 28 September 2023).

- Tamás Mérő and Gáspár Geöczeöl, Ongoing Hydrogen Projects in Porous Reservoir in Hungary. Available online: https://www.software.slb.com/-/media/software-media-items/software/documents/external/technical-presentations/digital-forum-2022/et/10-hydrogen-projects-in-porous-reservoir-in-hungary--vision-ambition-and-realisation.pdf?la=en&hash=62D8F9543F2C24B9C8196C86ED0B38E1F971267B (accessed on 28 September 2023).

- ESB and dCarbonX Launch Kinsale Head Hydrogen Storage Project. ESB Corporate. Available online: https://esb.ie/media-centre-news/press-releases/article/2021/08/12/esb-and-dcarbonx-launch-kinsale-head-hydrogen-storage-project (accessed on 28 September 2023).

- Jerneja Sedlar, North Adriatic Cross-Border Hydrogen Valley (NAHV)–Lessons Learned (Till Now)). February 2023. Available online: https://www.clean-hydrogen.europa.eu/system/files/2023-03/2.%20North%20Adriatic%20cross-border%20Hydrogen%20Valley%20%28NAHV%29.pdf (accessed on 28 September 2023).

- The Project. HyStock. Available online: https://www.hystock.nl/en/about-hystock/the-project (accessed on 28 September 2023).

- Demonstration Hydrogen Storage A8, HyStock. Available online: https://www.hystock.nl/en/about-hystock/demonstration-hydrogen-storage-a8 (accessed on 28 September 2023).

- Underground Gas Storage Facility Damasławek. Available online: http://www.gaz-system.pl/en/transmission-system/investment-projects/damaslawek-ugs.html (accessed on 28 September 2023).

- de Saldanha, P.C.L.Q. Sines H2 Hub: A Cost Perspective of the Transmission and Storage Infrastructure of the Sines Green Hydrogen Hub. Master Thesis, Delft University of Technology, Delft, The Netherlands, 2021. Available online: http://resolver.tudelft.nl/uuid:3d395140-7169-4e0f-8e75-ec3b2d8924dc (accessed on 28 September 2023).

- Carneiro, J.F.; Matos, C.R.; Van Gessel, S. Opportunities for large-scale energy storage in geological formations in mainland Portugal. Renew. Sustain. Energy Rev. 2019, 99, 201–211. [Google Scholar] [CrossRef]

- GreenH2Atlantic Project: Creation of Hydrogen Production Hub in Portugal. Available online: https://www.greenh2atlantic.com/project (accessed on 28 September 2023).

- First Important Project of Common European Interest in Hydrogen Technology Approved by the European Commission Comes from NAFTA|Nafta Speicher. Available online: https://nafta-speicher.de/en/news/first-important-project-common-european-interest-hydrogen-technology-approved-european (accessed on 28 September 2023).

- International Trade Administration U.S. Department of Commerce, Spain Renewable Hydrogen Roadmap. Available online: https://www.trade.gov/market-intelligence/spain-renewable-hydrogen-roadmap (accessed on 28 September 2023).

- Hydrogen Storage. Hybrit. Available online: https://www.hybritdevelopment.se/en/a-fossil-free-development/hydrogen-storage/ (accessed on 28 September 2023).

- Williams, J.D.O.; Williamson, J.; Parkes, D.; Evans, D.J.; Kirk, K.L.; Sunny, N.; Hough, E.; Vosper, H.; Akhurst, M.C. Does the United Kingdom have sufficient geological storage capacity to support a hydrogen economy? Estimating the salt cavern storage potential of bedded halite formations. J. Energy Storage 2022, 53, 105109. [Google Scholar] [CrossRef]

- Al-Shafi, M.; Massarweh, O.; Abushaikha, A.S.; Bicer, Y. A review on underground gas storage systems: Natural gas, hydrogen and carbon sequestration. Energy Rep. 2023, 9, 6251–6266. [Google Scholar] [CrossRef]

- ANGUS+—Helmholtz-Centre for Environmental Research. Available online: https://www.ufz.de/index.php?en=37525 (accessed on 28 September 2023).

- Richard Stevenson, Alan Leadbetter, and Louis Day, Project HySecure Phase 1 Summary September 2019, Inovyn Enterprises Limited, Storengy. November 2019. Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/866376/Phase_1_-_Inovyn_-_HySecure.pdf (accessed on 28 September 2023).

- Networks & Storage. Hydrogen UK. Available online: https://hydrogen-uk.org/the-hydrogen-story/storage/ (accessed on 28 September 2023).

- Advanced Clean Energy Storage. Energy.gov. Available online: https://www.energy.gov/lpo/advanced-clean-energy-storage (accessed on 28 September 2023).

- Hubs|ACES Delta. Available online: https://aces-delta.com/hubs/ (accessed on 28 September 2023).

| Properties | H2 | CH4 |

|---|---|---|

| Molecular weight | 2.016 | 16.043 |

| Density (25 °C, 1 atm) | 0.082 kg/m3 | 0.657 kg/m3 |

| Viscosity (25 °C, 1 atm) | 0.89 × 10−5 Pa s | 1.1 × 10−5 Pa s |

| Solubility in pure water (20 °C, 1 atm) | 0.0016 gH2/kgH2O | 0.023 gCH4/kgH2O |

| Boiling point | −253 °C | −165 °C |

| Critical pressure | 12.8 atm | 45.8 atm |

| Critical temperature | −240 °C | −82.3 °C |

| Heating value | 120–142 kJ/g | 205–55.5 kJ/g |

| Diffusion in pure water (25 °C) | 5.13 × 10−9 m2/s | 1.85 × 10−9 m2/s |

| Main Criteria | Sub-Criteria |

|---|---|

| Technique characteristics | Type of storage |

| Reservoir depth | |

| Storage capacity | |

| Gas pressure | |

| Reservoir porosity and permeability | |

| Geology | |

| Reservoir thickness | |

| Costs | Storage cost |

| Investment cost | |

| Socio-economic characteristics | Environmental and public |

| Proximity to suppliers and resources | |

| Risks | Ground features |

| Life expectancy | |

| Regional location and risks |

| Member | Report on UHS |

|---|---|

| Austria | Work for the underground storage of pure hydrogen has started. |

| Canada | Proposals were submitted in 2022 to allocate another USD 2.6 million per year until 2026 on the hydrogen embrittlement of pipelines and well integrity concerns for in situ hydrogen production and UHS in geological formations. |

| France | Objectives include ensuring access to natural gas transmission and distribution infrastructure, establishing prerequisites for UHS, and creating a system for assuring and monitoring the hydrogen source traceability. |

| Germany | Three living laboratory initiatives have started, focusing on producing green hydrogen, subsurface storage, and industrial use (H2-Wyhlen, Energiepark BL, H2-Stahl). |

| HyChico (Argentina) | Hychico has undertaken multiple high-performance projects, including over 85,000 operational hours of a Genset powered by natural gas–hydrogen blends, UHS in depleted gas reservoirs, and bio-methanation processes. Given the proximity of the hydrogen plant to depleted oil and gas reservoirs, a UHS pilot project in one of them is under consideration. |

| The Netherlands | The Hyway27 study reported that repurposing existing gas pipelines is safe and cost effective (4 times less expensive than building a new infrastructure), enabling the creation of a hydrogen infrastructure backbone. A total of 1200 km of hydrogen pipelines for UHS are projected by 2027. |

| Clemens Dome (U.S.) | Moss Bluff (U.S.) | Spindletop (U.S.) | Teesside (U.K.) | |

|---|---|---|---|---|

| Operator | Conoco Phillips | Linde | Air Liquide | Sabic |

| Start of operations | 1986 | 2007 | 2014 | 1972 |

| Geometrical volume (m3) | 580,000 | 566,000 | >580,000 | 3 caverns, 70,000 each |

| Pressure range (bar) | 70–135 | 55–152 | 68–202 | 45 |

| Mean cavern depth (m) | 1000 | 1200 | 1340 | 365 |

| Net energy stored (GWh) | 92 | 120 | 270 | 25 |

| Working gas (ton H2) | 2400 | 3700 | 8200 | 800 |

| Net volume (std m3) | 27.3 | 41.5 | 92.6 | 9.12 |

| Working gas (MM scf) | 960 | 1450 | 3250 | 320 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Quintos Fuentes, J.E.; Santos, D.M.F. Technical and Economic Viability of Underground Hydrogen Storage. Hydrogen 2023, 4, 975-1000. https://doi.org/10.3390/hydrogen4040057

Quintos Fuentes JE, Santos DMF. Technical and Economic Viability of Underground Hydrogen Storage. Hydrogen. 2023; 4(4):975-1000. https://doi.org/10.3390/hydrogen4040057

Chicago/Turabian StyleQuintos Fuentes, José Ernesto, and Diogo M. F. Santos. 2023. "Technical and Economic Viability of Underground Hydrogen Storage" Hydrogen 4, no. 4: 975-1000. https://doi.org/10.3390/hydrogen4040057