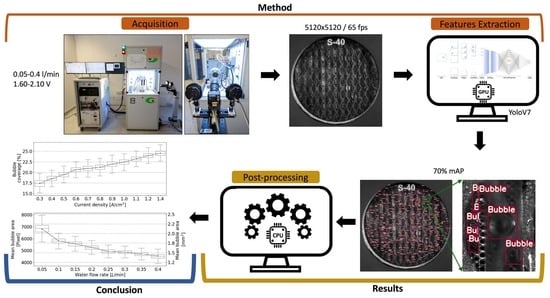

Oxygen Bubble Dynamics in PEM Water Electrolyzers with a Deep-Learning-Based Approach

Abstract

:1. Introduction

- −

- An automated approach is developed to map the bubble regime according to various operating conditions;

- −

- The YOLOV7 is fine-tuned and particularly efficient for fast and accurate anodic bubble recognition;

- −

- The proposed approach is experimentally validated and shows promising results.

2. Experimental Setup

3. Proposed CNN-Based Bubble Detection Method

3.1. Brief Review of CNNs

3.2. Dataset Preparation and Preprocessing

3.3. Training, Inference, and Post-Processing

4. Experimental Results

4.1. Inference Results

4.2. Discussion

5. Conclusions and Prospect

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Dawood, F.; Anda, M.; Shafiullah, G.M. Hydrogen Production for Energy: An Overview. Int. J. Hydrogen Energy 2020, 45, 3847–3869. [Google Scholar] [CrossRef]

- K/bidi, F.; Damour, C.; Grondin, D.; Hilairet, M.; Benne, M. Multistage Power and Energy Management Strategy for Hybrid Microgrid with Photovoltaic Production and Hydrogen Storage. Appl. Energy 2022, 323, 119549. [Google Scholar] [CrossRef]

- Johnson, S.C.; Rhodes, J.D.; Webber, M.E. Understanding the Impact of Non-Synchronous Wind and Solar Generation on Grid Stability and Identifying Mitigation Pathways. Appl. Energy 2020, 262, 114492. [Google Scholar] [CrossRef]

- Al-Shetwi, A.Q.; Hannan, M.A.; Jern, K.P.; Mansur, M.; Mahlia, T.M.I. Grid-Connected Renewable Energy Sources: Review of the Recent Integration Requirements and Control Methods. J. Clean. Prod. 2020, 253, 119831. [Google Scholar] [CrossRef]

- Kovač, A.; Paranos, M.; Marciuš, D. Hydrogen in Energy Transition: A Review. Int. J. Hydrogen Energy 2021, 46, 10016–10035. [Google Scholar] [CrossRef]

- Ishaq, H.; Dincer, I.; Crawford, C. A Review on Hydrogen Production and Utilization: Challenges and Opportunities. Int. J. Hydrogen Energy 2022, 47, 26238–26264. [Google Scholar] [CrossRef]

- Carmo, M.; Fritz, D.L.; Mergel, J.; Stolten, D. A Comprehensive Review on PEM Water Electrolysis. Int. J. Hydrogen Energy 2013, 38, 4901–4934. [Google Scholar] [CrossRef]

- Maier, M.; Smith, K.; Dodwell, J.; Hinds, G.; Shearing, P.R.; Brett, D.J.L. Mass Transport in PEM Water Electrolysers: A Review. Int. J. Hydrogen Energy 2022, 47, 30–56. [Google Scholar] [CrossRef]

- Falcão, D.S.; Pinto, A.M.F.R. A Review on PEM Electrolyzer Modelling: Guidelines for Beginners. J. Clean. Prod. 2020, 261, 121184. [Google Scholar] [CrossRef]

- Dedigama, I.; Angeli, P.; Ayers, K.; Robinson, J.B.; Shearing, P.R.; Tsaoulidis, D.; Brett, D.J.L. In Situ Diagnostic Techniques for Characterisation of Polymer Electrolyte Membrane Water Electrolysers—Flow Visualisation and Electrochemical Impedance Spectroscopy. Int. J. Hydrogen Energy 2014, 39, 4468–4482. [Google Scholar] [CrossRef]

- Ito, H.; Maeda, T.; Nakano, A.; Takenaka, H. Properties of Nafion Membranes under PEM Water Electrolysis Conditions. Int. J. Hydrogen Energy 2011, 36, 10527–10540. [Google Scholar] [CrossRef]

- Nie, J.; Chen, Y.; Cohen, S.; Carter, B.D.; Boehm, R.F. Numerical and Experimental Study of Three-Dimensional Fluid Flow in the Bipolar Plate of a PEM Electrolysis Cell. Int. J. Therm. Sci. 2009, 48, 1914–1922. [Google Scholar] [CrossRef]

- Selamet, O.F.; Pasaogullari, U.; Spernjak, D.; Hussey, D.S.; Jacobson, D.L.; Mat, M.D. Two-Phase Flow in a Proton Exchange Membrane Electrolyzer Visualized in Situ by Simultaneous Neutron Radiography and Optical Imaging. Int. J. Hydrogen Energy 2013, 38, 5823–5835. [Google Scholar] [CrossRef]

- Aubras, F.; Deseure, J.; Kadjo, J.-J.A.; Dedigama, I.; Majasan, J.; Grondin-Perez, B.; Chabriat, J.-P.; Brett, D.J.L. Two-Dimensional Model of Low-Pressure PEM Electrolyser: Two-Phase Flow Regime, Electrochemical Modelling and Experimental Validation. Int. J. Hydrogen Energy 2017, 42, 26203–26216. [Google Scholar] [CrossRef]

- Majasan, J.O.; Cho, J.I.S.; Dedigama, I.; Tsaoulidis, D.; Shearing, P.; Brett, D.J.L. Two-Phase Flow Behaviour and Performance of Polymer Electrolyte Membrane Electrolysers: Electrochemical and Optical Characterisation. Int. J. Hydrogen Energy 2018, 43, 15659–15672. [Google Scholar] [CrossRef]

- Hoeh, M.A.; Arlt, T.; Kardjilov, N.; Manke, I.; Banhart, J.; Fritz, D.L.; Ehlert, J.; Lüke, W.; Lehnert, W. In-Operando Neutron Radiography Studies of Polymer Electrolyte Membrane Water Electrolyzers. ECS Trans. 2015, 69, 1135–1140. [Google Scholar] [CrossRef]

- Ito, H.; Maeda, T.; Nakano, A.; Hasegawa, Y.; Yokoi, N.; Hwang, C.M.; Ishida, M.; Kato, A.; Yoshida, T. Effect of Flow Regime of Circulating Water on a Proton Exchange Membrane Electrolyzer. Int. J. Hydrogen Energy 2010, 35, 9550–9560. [Google Scholar] [CrossRef]

- Sadeghi Lafmejani, S.; Olesen, A.C.; Al Shakhshir, S.; Kær, S.K. Analysing Gas-Liquid Flow in PEM Electrolyser Micro-Channels Using a Micro-Porous Ceramic as Gas Permeable Wall. ECS Trans. 2017, 80, 1107–1115. [Google Scholar] [CrossRef]

- Dedigama, I.; Angeli, P.; van Dijk, N.; Millichamp, J.; Tsaoulidis, D.; Shearing, P.R.; Brett, D.J.L. Current Density Mapping and Optical Flow Visualisation of a Polymer Electrolyte Membrane Water Electrolyser. J. Power Sources 2014, 265, 97–103. [Google Scholar] [CrossRef]

- Maier, M.; Meyer, Q.; Majasan, J.; Tan, C.; Dedigama, I.; Robinson, J.; Dodwell, J.; Wu, Y.; Castanheira, L.; Hinds, G.; et al. Operando Flow Regime Diagnosis Using Acoustic Emission in a Polymer Electrolyte Membrane Water Electrolyser. J. Power Sources 2019, 424, 138–149. [Google Scholar] [CrossRef]

- Maier, M.; Meyer, Q.; Majasan, J.; Owen, R.E.; Robinson, J.B.; Dodwell, J.; Wu, Y.; Castanheira, L.; Hinds, G.; Shearing, P.R.; et al. Diagnosing Stagnant Gas Bubbles in a Polymer Electrolyte Membrane Water Electrolyser Using Acoustic Emission. Front. Energy Res. 2020, 8, 582919. [Google Scholar] [CrossRef]

- Su, X.; Xu, L.; Hu, B. Simulation of Proton Exchange Membrane Electrolyzer: Influence of Bubble Covering. Int. J. Hydrogen Energy 2022, 47, 20027–20039. [Google Scholar] [CrossRef]

- Garcia-Navarro, J.C.; Schulze, M.; Friedrich, K.A. Detecting and Modeling Oxygen Bubble Evolution and Detachment in Proton Exchange Membrane Water Electrolyzers. Int. J. Hydrogen Energy 2019, 44, 27190–27203. [Google Scholar] [CrossRef]

- Li, Y.; Yang, G.; Yu, S.; Mo, J.; Li, K.; Xie, Z.; Ding, L.; Wang, W.; Zhang, F.-Y. High-Speed Characterization of Two-Phase Flow and Bubble Dynamics in Titanium Felt Porous Media for Hydrogen Production. Electrochim. Acta 2021, 370, 137751. [Google Scholar] [CrossRef]

- Ilonen, J.; Juránek, R.; Eerola, T.; Lensu, L.; Dubská, M.; Zemčík, P.; Kälviäinen, H. Comparison of Bubble Detectors and Size Distribution Estimators. Pattern Recognit. Lett. 2018, 101, 60–66. [Google Scholar] [CrossRef]

- Nielsen, F. Detecting Lines in Images: The Hough Transform; Sony Computer Science Laboratories, Inc.: Tokyo, Japan, 2011. [Google Scholar] [CrossRef]

- Ayala-Ramirez, V.; Garcia-Capulin, C.H.; Perez-Garcia, A.; Sanchez-Yanez, R.E. Circle Detection on Images Using Genetic Algorithms. Pattern Recognit. Lett. 2006, 27, 652–657. [Google Scholar] [CrossRef]

- Pan, L.; Chu, W.-S.; Saragih, J.M.; De la Torre, F.; Xie, M. Fast and Robust Circular Object Detection With Probabilistic Pairwise Voting. IEEE Signal Process. Lett. 2011, 18, 639–642. [Google Scholar] [CrossRef]

- Taboada, B.; Vega-Alvarado, L.; Córdova-Aguilar, M.S.; Galindo, E.; Corkidi, G. Semi-Automatic Image Analysis Methodology for the Segmentation of Bubbles and Drops in Complex Dispersions Occurring in Bioreactors. Exp. Fluids 2006, 41, 383–392. [Google Scholar] [CrossRef]

- Viola, P.; Jones, M. Rapid Object Detection Using a Boosted Cascade of Simple Features. In Proceedings of the 2001 IEEE Computer Society Conference on Computer Vision and Pattern Recognition. CVPR 2001, Kauai, HI, USA, 8–14 December 2001; Volume 1, pp. I-511–I-518. [Google Scholar] [CrossRef]

- Dalal, N.; Triggs, B. Histograms of Oriented Gradients for Human Detection. In Proceedings of the 2005 IEEE Computer Society Conference on Computer Vision and Pattern Recognition (CVPR’05), San Diego, CA, USA, 20–25 June 2005; Volume 1, pp. 886–893. [Google Scholar] [CrossRef]

- Poletaev, I. Bubble Patterns Recognition Using Neural Networks: Application to the Analysis of a Two-Phase Bubbly Jet. Int. J. Multiph. Flow 2020, 14, 103194. [Google Scholar] [CrossRef]

- Wang, Q.; Li, X.; Xu, C.; Yan, T.; Li, Y. Bubble Recognizing and Tracking in a Plate Heat Exchanger by Using Image Processing and Convolutional Neural Network. Int. J. Multiph. Flow 2021, 138, 103593. [Google Scholar] [CrossRef]

- Park, H.; Choi, D.; Kim, H. Bubble Velocimetry Using the Conventional and CNN-Based Optical Flow Algorithms. Sci. Rep. 2022, 12, 11879. [Google Scholar] [CrossRef]

- Cui, Y.; Li, C.; Zhang, W.; Ning, X.; Shi, X.; Gao, J.; Lan, X. A Deep Learning-Based Image Processing Method for Bubble Detection, Segmentation, and Shape Reconstruction in High Gas Holdup Sub-Millimeter Bubbly Flows. Chem. Eng. J. 2022, 449, 137859. [Google Scholar] [CrossRef]

- Xiang, Z.; Xie, B.; Fu, R.; Qian, M. Advanced Deep Learning-Based Bubbly Flow Image Generator under Different Superficial Gas Velocities. Ind. Eng. Chem. Res. 2022, 61, 1531–1543. [Google Scholar] [CrossRef]

- Kim, Y.; Park, H. Deep Learning-Based Automated and Universal Bubble Detection and Mask Extraction in Complex Two-Phase Flows. Sci. Rep. 2021, 11, 8940. [Google Scholar] [CrossRef] [PubMed]

- Cerqueira, R.F.L.; Paladino, E.E. Development of a Deep Learning-Based Image Processing Technique for Bubble Pattern Recognition and Shape Reconstruction in Dense Bubbly Flows. Chem. Eng. Sci. 2021, 230, 116163. [Google Scholar] [CrossRef]

- Haas, T.; Schubert, C.; Eickhoff, M.; Pfeifer, H. BubCNN: Bubble Detection Using Faster RCNN and Shape Regression Network. Chem. Eng. Sci. 2020, 216, 115467. [Google Scholar] [CrossRef]

- Gong, C.; Song, Y.; Huang, G.; Chen, W.; Yin, J.; Wang, D. BubDepth: A Neural Network Approach to Three-Dimensional Reconstruction of Bubble Geometry from Single-View Images. Int. J. Multiph. Flow 2022, 152, 104100. [Google Scholar] [CrossRef]

- Chen, L.; Li, S.; Bai, Q.; Yang, J.; Jiang, S.; Miao, Y. Review of Image Classification Algorithms Based on Convolutional Neural Networks. Remote Sens. 2021, 13, 4712. [Google Scholar] [CrossRef]

- Ren, J.; Wang, Y. Overview of Object Detection Algorithms Using Convolutional Neural Networks. J. Comput. Commun. 2022, 10, 115–132. [Google Scholar]

- Wang, C.-Y.; Bochkovskiy, A.; Liao, H.-Y.M. YOLOv7: Trainable Bag-of-Freebies Sets New State-of-the-Art for Real-Time Object Detectors. arXiv 2022, arXiv:2207.02696. [Google Scholar]

- Redmon, J.; Divvala, S.; Girshick, R.; Farhadi, A. You Only Look Once: Unified, Real-Time Object Detection. arXiv 2016, arXiv:1506.02640. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLO9000: Better, Faster, Stronger. arXiv 2016, arXiv:1612.08242. [Google Scholar]

- Redmon, J.; Farhadi, A. YOLOv3: An Incremental Improvement. arXiv 2018, arXiv:1804.02767. [Google Scholar]

- Bochkovskiy, A.; Wang, C.-Y.; Liao, H.-Y.M. YOLOv4: Optimal Speed and Accuracy of Object Detection. arXiv 2020, arXiv:2004.10934. [Google Scholar]

- Pan, S.; Liu, J.; Chen, D. Research on License Plate Detection and Recognition System Based on YOLOv7 and LPRNet. AJST 2023, 4, 62–68. [Google Scholar] [CrossRef]

- Wang, Y.; Wang, H.; Xin, Z. Efficient Detection Model of Steel Strip Surface Defects Based on YOLO-V7. IEEE Access 2022, 10, 133936–133944. [Google Scholar] [CrossRef]

- Li, Y.; Lei, C.; Xue, Z.; Zheng, Z.; Long, Y. A Comparison of YOLO Family for Apple Detection and Counting in Orchards. Int. J. Comput. Syst. Eng. 2021, 15, 334–343. [Google Scholar]

- Gillani, I.S.; Munawar, M.R.; Talha, M.; Azhar, S.; Mashkoor, Y.; Uddin, M.S.; Zafar, U. Yolov5, Yolo-x, Yolo-r, Yolov7 Performance Comparison: A Survey. In Artificial Intelligence and Fuzzy Logic System; Academy and Industry Research Collaboration Center (AIRCC): Chennai, India, 2022; pp. 17–28. [Google Scholar] [CrossRef]

- Wu, D.; Jiang, S.; Zhao, E.; Liu, Y.; Zhu, H.; Wang, W.; Wang, R. Detection of Camellia Oleifera Fruit in Complex Scenes by Using YOLOv7 and Data Augmentation. Appl. Sci. 2022, 12, 11318. [Google Scholar] [CrossRef]

- LabelImg. Available online: https://github.com/heartexlabs/labelImg (accessed on 26 March 2023).

- Yuan, S.; Zhao, C.; Cai, X.; An, L.; Shen, S.; Yan, X.; Zhang, J. Bubble Evolution and Transport in PEM Water Electrolysis: Mechanism, Impact, and Management. Prog. Energy Combust. Sci. 2023, 96, 101075. [Google Scholar] [CrossRef]

| Image Input Size: 512 | Momentum: 0.937 |

| Batch size: 4 | Weight-decay: 0.0005 |

| Learning-rate start (lr0): 0.01 | Conf threshold: 0.25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sinapan, I.; Lin-Kwong-Chon, C.; Damour, C.; Kadjo, J.-J.A.; Benne, M. Oxygen Bubble Dynamics in PEM Water Electrolyzers with a Deep-Learning-Based Approach. Hydrogen 2023, 4, 556-572. https://doi.org/10.3390/hydrogen4030036

Sinapan I, Lin-Kwong-Chon C, Damour C, Kadjo J-JA, Benne M. Oxygen Bubble Dynamics in PEM Water Electrolyzers with a Deep-Learning-Based Approach. Hydrogen. 2023; 4(3):556-572. https://doi.org/10.3390/hydrogen4030036

Chicago/Turabian StyleSinapan, Idriss, Christophe Lin-Kwong-Chon, Cédric Damour, Jean-Jacques Amangoua Kadjo, and Michel Benne. 2023. "Oxygen Bubble Dynamics in PEM Water Electrolyzers with a Deep-Learning-Based Approach" Hydrogen 4, no. 3: 556-572. https://doi.org/10.3390/hydrogen4030036