High-Performance Layered Oxides for Sodium-Ion Batteries Achieved through Combined Aluminum Substitution and Surface Treatment

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

3.1. Al Substitution of Ni in Layered Na2/3[Ni1/2Mn1/2]O2: Concentration Limits

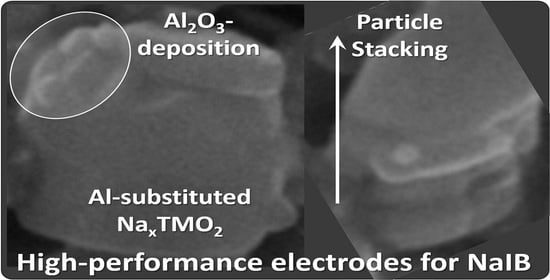

3.2. Treatment of Layered Oxides with Al2O3

3.3. Na Storage Performance of Al-Substituted and Al2O3-Treated Layered Oxides

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, T.; Zhang, Y.; Jiang, Z.; Zeng, X.; Ji, J.; Li, Z.; Gao, X.; Sun, M.; Lin, Z.; Ling, M.; et al. Exploring competitive features of stationary sodium ion batteries for electrochemical energy storage. Energy Environ. Sci. 2019, 12, 1512–1533. [Google Scholar] [CrossRef]

- Hirsh, H.S.; Li, Y.; Tan, D.H.S.; Zhang, M.; Zhao, E.; Meng, Y.S. Sodium-Ion Batteries Paving the Way for Grid Energy Storage. Adv. Energy Mater. 2020, 10, 2001274. [Google Scholar] [CrossRef]

- Su, H.; Jaffer, S.; Yu, H. Transition metal oxides for sodium-ion batteries. Energy Storage Mater. 2016, 5, 116–131. [Google Scholar] [CrossRef]

- Wei, F.; Zhang, Q.; Zhang, P.; Tian, W.; Dai, K.; Zhang, L.; Mao, J.; Shao, G. Review—Research Progress on Layered Transition Metal Oxide Cathode Materials for Sodium Ion Batteries. J. Electrochem. Soc. 2021, 168, 050524. [Google Scholar] [CrossRef]

- Liu, Q.; Hu, Z.; Li, W.; Zou, C.; Jin, H.; Wang, S.; Chou, S.; Dou, S.-X. Sodium transition metal oxides: The preferred cathode choice for future sodium-ion batteries? Energy Environ. Sci. 2021, 14, 158–179. [Google Scholar] [CrossRef]

- Shi, C.; Wang, L.; Chen, X.; Li, J.; Wang, S.; Wang, J.; Jin, H. Challenges of layer-structured cathodes for sodium-ion batteries. Nanoscale Horiz. 2022, 7, 338–351. [Google Scholar] [CrossRef] [PubMed]

- Kalapsazova, M.; Kukeva, R.; Zhecheva, E.; Stoyanova, R. Metal Substitution versus Oxygen-Storage Modifier to Regulate the Oxygen Redox Reactions in Sodium-Deficient Three-Layered Oxides. Batteries 2022, 8, 56. [Google Scholar] [CrossRef]

- Chang, Y.-X.; Yu, L.; Xing, X.; Guo, Y.-J.; Xie, Z.; Xu, S. Ion Substitution Strategy of Manganese-Based Layered Oxide Cathodes for Advanced and Low-Cost Sodium Ion Batteries. Chem. Rec. 2022, 10, e202200122. [Google Scholar] [CrossRef] [PubMed]

- Li, Y.; Chen, M.; Liu, B.; Zhang, Y.; Liang, X.; Xia, X. Heteroatom Doping: An Effective Way to Boost Sodium Ion Storage. Adv. Energy Mater. 2020, 10, 2000927. [Google Scholar] [CrossRef]

- Kaufman, J.L.; Vinckevičiūtė, J.; Kolli, S.K.; Goiri, J.G.; Van der Ven, A. Understanding intercalation compounds for sodium-ion batteries and beyond. Philos. Trans. A Math. Phys. Eng. Sci. 2019, 377, 20190020. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Yu, H.J. Crystalline Domain Battery Material. Acc. Chem. Res. 2020, 53, 368–379. [Google Scholar] [CrossRef] [PubMed]

- Ma, Z.; Zhao, Z.; Xu, H.; Sun, J.; He, X.; Lei, Z.; Liu, Z.-H.; Jiang, R.; Li, Q. A Queue-Ordered Layered Mn-Based Oxides with Al Substitution as High-Rate and High-Stabilized Cathode for Sodium-Ion Batteries. Small 2021, 17, e2006259. [Google Scholar] [CrossRef] [PubMed]

- Abate, I.; Kim, S.Y.; Pemmaraju, C.D.; Toney, M.F.; Yang, W.; Devereaux, T.P.; Chueh, W.C.; Nazar, L.F. The Role of Metal Substitution in Tuning Anion Redox in Sodium Metal Layered Oxides Revealed by X-Ray Spectroscopy and Theory. Angew. Chem. Int. Ed. 2021, 60, 10880–10887. [Google Scholar] [CrossRef] [PubMed]

- Di Lecce, D.; Campanella, D.; Hassoun, J. Insight on the Enhanced Reversibility of a Multi-Metal Layered Oxide for Sodium-Ion Battery. J. Phys. Chem. C 2018, 122, 23925–23933. [Google Scholar] [CrossRef]

- Singh, G.; Tapia-Ruiz, N.; del Amo, J.M.L.; Maitra, U.; Somerville, J.W.; Armstrong, A.R.; de Ilarduya, J.M.; Rojo, T.; Bruce, P.G. High Voltage Mg-Doped Na0.67Ni0.3–xMgxMn0.7O2 (x = 0.05, 0.1) Na-Ion Cathodes with Enhanced Stability and Rate Capability. Chem. Mater. 2016, 28, 5087–5094. [Google Scholar] [CrossRef] [Green Version]

- Kalapsazova, M.; Markov, P.; Kostov, K.; Zhecheva, E.; Nihtianova, D.; Stoyanova, R. Controlling at Elevated Temperature the Sodium Intercalation Capacity and Rate Capability of P3-Na2/3Ni1/2Mn1/2O2 through the Selective Substitution of Nickel with Magnesium. Batter. Supercaps 2020, 3, 1329–1340. [Google Scholar] [CrossRef]

- Wu, X.; Xu, G.-L.; Zhong, G.; Gong, Z.; McDonald, J.; Zheng, S.; Fu, R.; Chen, Z.; Amine, K.; Yang, Y. Insights into the effects of zinc doping on structural phase transition of P2-type sodium nickel manganese oxide cathodes for high-energy sodium ion batteries. ACS Appl. Mater. Interfaces 2016, 8, 22227–22237. [Google Scholar] [CrossRef]

- Bai, X.; Sathiya, M.; Mendoza-Sanchez, B.; Iadecola, A.; Vergnet, J.; Dedryvere, R.; Saubanere, M.; Abakumov, A.M.; Rozier, P.; Tarascon, J.-M. Anionic Redox Activity in a Newly Zn-Doped Sodium Layered Oxide P2-Na2/3Mn1−yZnyO2 (0 < y < 0.23). Adv. Energy Mater. 2018, 8, 1802379. [Google Scholar]

- Wang, H.; Gao, R.; Li, Z.; Sun, L.; Hu, Z.; Liu, X. Different Effects of Al Substitution for Mn or Fe on the Structure and Electrochemical Properties of Na0.67Mn0.5Fe0.5O2 as a Sodium Ion Battery Cathode Material. Inorg. Chem. 2018, 57, 5249–5257. [Google Scholar] [CrossRef]

- Cheng, C.; Ding, M.; Yan, T.; Jiang, J.; Mao, J.; Feng, X.; Chan, T.-S.; Li, N.; Zhang, L. Anionic Redox Activities Boosted by Aluminum Doping in Layered Sodium-Ion Battery Electrode. Small Methods 2022, 6, 2101524. [Google Scholar] [CrossRef]

- Ramasamy, H.V.; Kaliyappan, K.; Thangavel, R.; Seong, W.M.; Kang, K.; Chen, Z.; Lee, Y.-S. Efficient Method of Designing Stable Layered Cathode Material for Sodium Ion Batteries Using Aluminum Doping. J. Phys. Chem. Lett. 2017, 8, 5021–5030. [Google Scholar] [CrossRef] [PubMed]

- Soares, C.; Silvan, B.; Choi, Y.-S.; Celorrio, V.; Seymour, V.R.; Cibin, G.; Griffin, J.M.; Scanlon, D.O.; Tapia-Ruiz, N. Na2.4 Al 0.4 Mn2.6 O7 anionic redox cathode material for sodium-ion batteries—A combined experimental and theoretical approach to elucidate its charge storage mechanism. J. Mater. Chem. A 2022, 10, 7341–7356. [Google Scholar] [CrossRef]

- Li, J.; Hu, H.; Wang, J.; Xiao, Y. Surface chemistry engineering of layered oxide cathodes for sodium-ion batteries. Carbon Neutralization 2022, 1, 96–116. [Google Scholar] [CrossRef]

- Jung, S.C.; Kim, H.-J.; Choi, J.W.; Han, Y.-K. Sodium Ion Diffusion in Al2O3: A Distinct Perspective Compared with Lithium Ion Diffusion. Nano Lett. 2014, 14, 6559–6563. [Google Scholar] [CrossRef] [PubMed]

- Zuo, W.; Qiu, J.; Liu, X.; Zheng, B.; Zhao, Y.; Li, J.; He, H.; Zhou, K.; Xiao, Z.; Li, Q.; et al. Highly-stable P2–Na0.67MnO2 electrode enabled by lattice tailoring and surface engineering. Energy Storage Mater. 2020, 26, 503–512. [Google Scholar] [CrossRef]

- Hwang, J.-Y.; Myung, S.-T.; Choi, J.U.; Yoon, C.S.; Yashirod, H.; Sun, Y.-K. Resolving the degradation pathways of the O3-type layered oxide cathode surface through the nano-scale aluminum oxide coating for high-energy density sodium-ion batteries. J. Mater. Chem. A 2017, 5, 23671–23680. [Google Scholar] [CrossRef]

- Liu, Y.; Fang, X.; Zhang, A.; Shen, C.; Liu, Q.; Enaya, H.A.; Zhou, C. Layered P2-Na2/3[Ni1/3Mn2/3]O2 as high-voltage cathode for sodium-ion batteries: The capacity decay mechanism and Al2O3 surface modification. Nano Energy 2016, 27, 27–34. [Google Scholar] [CrossRef]

- Kalapsazova, M.; Kostov, K.; Kukeva, R.; Zhecheva, E.; Stoyanova, R. Oxygen-Storage Materials to Stabilize the Oxygen Redox Activity of Three-Layered Sodium Transition Metal Oxides. J. Phys. Chem. Lett. 2021, 12, 7804–7811. [Google Scholar] [CrossRef]

- Zhang, Q.; Gu, Q.-F.; Li, Y.; Fan, H.-N.; Luo, W.-B.; Liu, H.-K.; Dou, S.-X. Surface Stabilization of O3-type Layered Oxide Cathode to Protect the Anode of Sodium Ion Batteries for Superior Lifespan. Iscience 2019, 19, 244–254. [Google Scholar] [CrossRef]

- Feng, Y.-H.; Cheng, Z.; Xu, C.-L.; Yu, L.; Si, D.; Yuan, B.; Liu, M.; Zhao, B.; Wang, P.-F.; Han, X. Low-Cost Al-Doped Layered Cathodes with Improved Electrochemical Performance for Rechargeable Sodium-Ion Batteries. ACS Appl. Mater. Interfaces 2022, 14, 23465–23473. [Google Scholar] [CrossRef]

- Nayak, D.; Jha, P.K.; Ghosh, S.; Adyam, V. Aluminium substituted β–type NaMn1-xAlxO2: A stable and enhanced electrochemical kinetic sodium-ion battery cathode. J. Power Sources 2019, 438, 227025. [Google Scholar] [CrossRef]

- Delmas, C.; Fouassier, C.; Hagenmuller, P. Structural Classification and Properties of the Layered Oxides. Phys. B+C 1980, 99, 81–85. [Google Scholar] [CrossRef]

- Kalapsazova, M.; Zhecheva, E.; Tyuliev, G.; Nihtianova, D.; Mihaylov, L.; Stoyanova, R. Effects of the Particle Size Distribution and of the Electrolyte Salt on the Intercalation Properties of P3-Na2/3Ni1/2Mn1/2O2. J. Phys. Chem. C 2017, 121, 5931–5940. [Google Scholar] [CrossRef]

- Pang, W.-L.; Zhang, X.-H.; Guo, J.-Z.; Li, J.-Y.; Yan, X.; Hou, B.-H.; Guan, H.-Y.; Wu, X.-L. P2-type Na2/3Mn1-xAlxO2 cathode material for sodium-ion batteries: Al-doped enhanced electrochemical properties and studies on the electrode kinetics. J. Power Sources 2017, 356, 80–88. [Google Scholar] [CrossRef]

- Kalapsazova, M.; Ortiz, G.F.; Tirado, J.L.; Dolotko, O.; Zhecheva, E.; Nihtianova, D.; Mihaylov, L.; Stoyanova, R. P3-Type Layered Sodium-Deficient Nickel-Manganese Oxides: A Flexible Structural Matrix for Reversible Sodium and Lithium Intercalation. ChemPlusChem 2015, 80, 1642–1656. [Google Scholar] [CrossRef] [PubMed]

- Kalapsazova, M.; Ivanova, S.; Kukeva, R.; Simova, S.; Wegner, S.; Zhecheva, E.; Stoyanova, R. Combined use of EPR and Na-23 MAS NMR spectroscopy for assessing the properties of the mixed cobalt-nickel-manganese layers of P3-NayCo1-2xNixMnxO2. Phys. Chem. Chem. Phys. 2017, 19, 27065–27073. [Google Scholar] [CrossRef]

- Kim, E.J.; Ma, L.A.; Duda, L.C.; Pickup, D.M.; Chadwick, A.V.; Younesi, R.; Irvine, J.T.S.; Armstrong, A.R. Oxygen Redox Activity through a Reductive Coupling Mechanism in the P3-Type Nickel-Doped Sodium Manganese Oxide. ACS Appl. Energy Mater. 2020, 3, 184–191. [Google Scholar] [CrossRef] [Green Version]

- Lee, D.H.; Xu, J.; Meng, Y.S. An advanced cathode for Na-ion batteries with high rate and excellent structural stability. Phys. Chem. Chem. Phys. 2013, 15, 3304–3312. [Google Scholar] [CrossRef]

- Xu, G.-L.; Amine, R.; Xu, Y.-F.; Liu, J.; Gim, J.; Ma, T.; Ren, Y.; Sun, C.-J.; Liu, Y.; Zhang, X.; et al. Insights into the structural effects of layered cathode materials for high voltage sodium-ion batteries. Energy Environ. Sci. 2017, 10, 1677–1693. [Google Scholar] [CrossRef]

- Huang, Q.; Wang, M.; Zhang, L.; Qi, S.; Feng, Y.; He, P.; Ji, X.; Wang, P.; Zhou, L.; Chen, S.; et al. Shear-resistant interface of layered oxide cathodes for sodium ion batteries. Energy Storage Mater. 2022, 45, 389–398. [Google Scholar] [CrossRef]

- Chen, C.; Ding, Z.; Han, Z.; Liang, C.; Lan, H.; Wang, P.; Gao, P.; Wei, W. Unravelling Atomically Irreversible Cation Migration in Sodium Layered Oxide Cathodes. J. Phys. Chem. Lett. 2020, 11, 5464–5470. [Google Scholar] [CrossRef] [PubMed]

- Hall, T.P.P.; Hayes, W.; Stevenson, R.H.W.; Wilkens, J. Investigation of the Bonding of Iron-Group Ions in Fluoride Crystals. I. J. Chem. Phys. 1963, 38, 1977. [Google Scholar] [CrossRef]

- Zhan, C.; Wu, T.; Lu, J.; Amine, K. Dissolution, migration, and deposition of transition metal ions in Li-ion batteries exemplified by Mn-based cathodes—A critical review. Energy Environ. Sci. 2018, 11, 243–257. [Google Scholar] [CrossRef]

- Jung, R.; Linsenmann, F.; Thomas, R.; Wandt, J.; Solchenbach, S.; Maglia, F.; Stinner, C.; Tromp, M.; Gasteiger, H.A. Nickel, Manganese, and Cobalt Dissolution from Ni-Rich NMC and Their Effects on NMC622-Graphite Cells. J. Electrochem. Soc. 2019, 166, A378–A389. [Google Scholar] [CrossRef] [Green Version]

- Pang, P.; Wang, Z.; Tan, X.; Deng, Y.; Nan, J.; Xing, Z.; Li, H. LiCoO2@LiNi0.45Al0.05Mn0.5O2 as high-voltage lithium-ion battery cathode materials with improved cycling performance and thermal stability. Electrochim. Acta 2019, 327, 135018. [Google Scholar] [CrossRef]

| Samples | Structure | a, Å | c, Å | V, Å3 | wt. % |

|---|---|---|---|---|---|

| P3-Na2/3Ni1/2Mn1/2O2 700 °C | P3 | 2.8890 | 16.7230 | 120.88 | |

| x = 0.08, 700 °C | P3 | 2.8890 | 16.7230 | 120.88 | 88 |

| P2 | 2.8905 | 11.1254 | 80.49 | 12 | |

| x = 0.08, 800 °C | P2 | 2.8903 | 11.0865 | 80.21 | |

| x = 0.08, 900 °C | P2 | 2.8888 | 11.0986 | 80.20 | |

| P2-Na2/3Ni1/3Mn2/3O2 900 °C | P2 | 2.8889 | 11.1562 | 80.63 |

| Samples | T = 295 K | T = 100 K | ||

|---|---|---|---|---|

| Pristine Oxide, ΔHpp (mT) | Cycled Oxide, ΔHpp (mT) | Pristine Oxide, ΔHpp (mT) | Cycled Oxide, ΔHpp (mT) | |

| Al-substituted oxide annealed at 700 °C (x = 0.08) | 130 | 137 | 94 | 117 |

| Al-substituted oxide annealed at 800 °C (x = 0.08) | 140 | 146 | 103 | 110 |

| Al-substituted oxide annealed at 900 °C (x = 0.08) | 140 | 158 | 99 | 123 |

| Al2O3-treated oxide, annealed at 700 °C | 130 | 139 | 95 | 105 |

| Al2O3-treated Al-substituted oxide, annealed at 800 °C | 137 | 142 | 98 | 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kalapsazova, M.; Kukeva, R.; Harizanova, S.; Markov, P.; Nihtianova, D.; Zhecheva, E.; Stoyanova, R. High-Performance Layered Oxides for Sodium-Ion Batteries Achieved through Combined Aluminum Substitution and Surface Treatment. Batteries 2023, 9, 144. https://doi.org/10.3390/batteries9020144

Kalapsazova M, Kukeva R, Harizanova S, Markov P, Nihtianova D, Zhecheva E, Stoyanova R. High-Performance Layered Oxides for Sodium-Ion Batteries Achieved through Combined Aluminum Substitution and Surface Treatment. Batteries. 2023; 9(2):144. https://doi.org/10.3390/batteries9020144

Chicago/Turabian StyleKalapsazova, Mariya, Rositsa Kukeva, Sonya Harizanova, Pavel Markov, Diana Nihtianova, Ekaterina Zhecheva, and Radostina Stoyanova. 2023. "High-Performance Layered Oxides for Sodium-Ion Batteries Achieved through Combined Aluminum Substitution and Surface Treatment" Batteries 9, no. 2: 144. https://doi.org/10.3390/batteries9020144