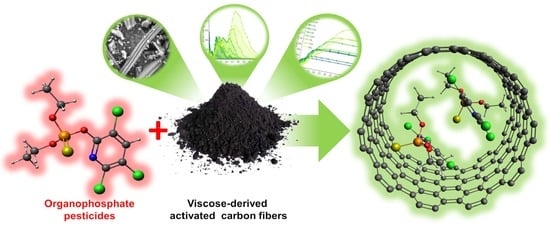

Investigating the Adsorption Kinetics of Dimethoate, Malathion and Chlorpyrifos on Cellulose-Derived Activated Carbons: Understanding the Influence of Physicochemical Properties

Abstract

:1. Introduction

2. Materials and Methods

2.1. Activated Carbon Fiber Preparation

2.2. Characterization of Materials

2.3. Pesticide Adsorption Measurements

2.4. Principal Component Analysis

2.5. Semi-Empirical Quantum Chemical Calculations

3. Results

3.1. Materials Properties

3.2. Performance of the Materials

3.2.1. Chlorpyrifos Removal

3.2.2. Dimethoate and Malathion Removal

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Model | A1 | A2 | A3 | A4 | A5 | A6 | A7 | A8 | R2 |

|---|---|---|---|---|---|---|---|---|---|

| CPF-1 | 16.4 | 0.5 | 27.4 | −140.5 | 112.4 | −0.6 | −1.9 | 3 | 0.97 |

| CPF-2 | −1.9 | −0.8 | −2.0 | 4.2 | −2.0 | 1.5 | 0.2 | −0.3 | 0.73 |

| DMT-1 | 26.6 | 48.7 | −146.1 | 404.0 | −307.1 | −1.3 | −1.7 | 18.5 | 0.93 |

| DMT-2 | −99.6 | 40.4 | −137.3 | 422.0 | −329.6 | 37.4 | 8.6 | 1.8 | 0.9999 |

| MLT-1 | 431.9 | −62.0 | −485.7 | 2202.0 | −1726.5 | −47.4 | −6.6 | 30.6 | 0.68 |

| MLT-2 | −82.6 | 57.7 | −234.0 | 765.7 | −563.9 | 25.1 | 0.3 | −7.5 | 0.99 |

References

- Kwong, T.C. Organophosphate pesticides: Biochemistry and clinical toxicology. Ther. Drug Monit. 2002, 24, 144–149. [Google Scholar] [CrossRef]

- Lazarević-Pašti, T. Organophosphates: Detection, Exposure and Occurrence; Impact on Health and the Natural Environment; Nova Science Publishers: New York, NY, USA, 2022; Volume 1. [Google Scholar]

- Miodovnik, A. Prenatal Exposure to Industrial Chemicals and Pesticides and Effects on Neurodevelopment. In Encyclopedia of Environmental Health; Nriagu, J., Ed.; Elsevier: Oxford, UK, 2019; pp. 342–352. [Google Scholar]

- Lazarević-Pašti, T.; Anićijević, V.; Baljozović, M.; Anićijević, D.V.; Gutić, S.; Vasić, V.; Skorodumova, N.V.; Pašti, I.A. The impact of the structure of graphene-based materials on the removal of organophosphorus pesticides from water. Environ. Sci. Nano 2018, 5, 1482–1494. [Google Scholar] [CrossRef]

- Lazarević-Pašti, T.D.; Pašti, I.A.; Jokić, B.; Babić, B.M.; Vasić, V.M. Heteroatom-doped mesoporous carbons as efficient adsorbents for removal of dimethoate and omethoate from water. RSC Adv. 2016, 6, 62128–62139. [Google Scholar] [CrossRef]

- Anicijevic, V.; Lazarević-Pašti, T.; Vasic Anicijevic, D.; Karkalic, R. Esters of Organophosphorus Acids—Toxicity, Application and Removal from the Environment. Sci. Tech. Rev. 2019, 69, 15–29. [Google Scholar] [CrossRef]

- Hamad, H.N.; Idrus, S. Recent Developments in the Application of Bio-Waste-Derived Adsorbents for the Removal of Methylene Blue from Wastewater: A Review. Polymers 2022, 14, 783. [Google Scholar] [CrossRef] [PubMed]

- Osman, A.I.; El-Monaem, E.M.A.; Elgarahy, A.M.; Aniagor, C.O.; Hosny, M.; Farghali, M.; Rashad, E.; Ejimofor, M.I.; López-Maldonado, E.A.; Ihara, I.; et al. Methods to prepare biosorbents and magnetic sorbents for water treatment: A review. Environ. Chem. Lett. 2023, 21, 2337–2398. [Google Scholar] [CrossRef]

- Fridman, L.I.; Lysenko, A.A. Carbon-Fiber Adsorbents. Fibre Chem. 2018, 50, 230–232. [Google Scholar] [CrossRef]

- Anićijević, V.; Tasić, T.; Milanković, V.; Breitenbach, S.; Unterweger, C.; Fürst, C.; Bajuk-Bogdanović, D.; Pašti, I.A.; Lazarević-Pašti, T. How Well Do Our Adsorbents Actually Perform?—The Case of Dimethoate Removal Using Viscose Fiber-Derived Carbons. Int. J. Environ. Res. Public Health 2023, 20, 4553. [Google Scholar] [CrossRef]

- Soffian, M.S.; Abdul Halim, F.Z.; Aziz, F.; Rahman, M.A.; Mohamed Amin, M.A.; Awang Chee, D.N. Carbon-based material derived from biomass waste for wastewater treatment. Environ. Adv. 2022, 9, 100259. [Google Scholar] [CrossRef]

- Haghseresht, F.; Nouri, S.; Finnerty, J.J.; Lu, G.Q. Effects of Surface Chemistry on Aromatic Compound Adsorption from Dilute Aqueous Solutions by Activated Carbon. J. Phys. Chem. B 2002, 106, 10935–10943. [Google Scholar] [CrossRef]

- Moreno-Castilla, C. Adsorption of organic molecules from aqueous solutions on carbon materials. Carbon 2004, 42, 83–94. [Google Scholar] [CrossRef]

- Sabzehmeidani, M.M.; Mahnaee, S.; Ghaedi, M.; Heidari, H.; Roy, V.A.L. Carbon based materials: A review of adsorbents for inorganic and organic compounds. Mater. Adv. 2021, 2, 598–627. [Google Scholar] [CrossRef]

- Al-Degs, Y.S.; El-Barghouthi, M.I.; El-Sheikh, A.H.; Walker, G.M. Effect of solution pH, ionic strength, and temperature on adsorption behavior of reactive dyes on activated carbon. Dye. Pigment. 2008, 77, 16–23. [Google Scholar] [CrossRef]

- Newcombe, G.; Drikas, M.; Hayes, R. Influence of characterised natural organic material on activated carbon adsorption: II. Effect on pore volume distribution and adsorption of 2-methylisoborneol. Water Res. 1997, 31, 1065–1073. [Google Scholar] [CrossRef]

- Dubinin, M.M. The Potential Theory of Adsorption of Gases and Vapors for Adsorbents with Energetically Nonuniform Surfaces. Chem. Rev. 1960, 60, 235–241. [Google Scholar] [CrossRef]

- Sing, K.S.W. Physisorption of nitrogen by porous materials. J. Porous Mater. 1995, 2, 5–8. [Google Scholar] [CrossRef]

- Li, L.; Quinlivan, P.A.; Knappe, D.R.U. Effects of activated carbon surface chemistry and pore structure on the adsorption of organic contaminants from aqueous solution. Carbon 2002, 40, 2085–2100. [Google Scholar] [CrossRef]

- Bandosz, T.J. Activated Carbon Surfaces in Environmental Remediation; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Wang, S.; Zhu, Z.H.; Coomes, A.; Haghseresht, F.; Lu, G.Q. The physical and surface chemical characteristics of activated carbons and the adsorption of methylene blue from wastewater. J. Colloid Interface Sci. 2005, 284, 440–446. [Google Scholar] [CrossRef]

- Yang, K.; Wu, W.; Jing, Q.; Zhu, L. Aqueous Adsorption of Aniline, Phenol, and their Substitutes by Multi-Walled Carbon Nanotubes. Environ. Sci. Technol. 2008, 42, 7931–7936. [Google Scholar] [CrossRef]

- Yang, K.; Xing, B. Adsorption of Organic Compounds by Carbon Nanomaterials in Aqueous Phase: Polanyi Theory and Its Application. Chem. Rev. 2010, 110, 5989–6008. [Google Scholar] [CrossRef]

- Jocić, A.; Breitenbach, S.; Bajuk-Bogdanović, D.; Pašti, I.A.; Unterweger, C.; Fürst, C.; Lazarević-Pašti, T. Viscose-Derived Activated Carbons Fibers as Highly Efficient Adsorbents for Dimethoate Removal from Water. Molecules 2022, 27, 1477. [Google Scholar] [CrossRef]

- Caturla, F.; Molina-Sabio, M.; Rodríguez-Reinoso, F. Preparation of activated carbon by chemical activation with ZnCl2. Carbon 1991, 29, 999–1007. [Google Scholar] [CrossRef]

- Habila, M.A.; Alothman, Z.A.; Al-Tamrah, S.A.; Ghafar, A.A.; Soylak, M. Activated carbon from waste as an efficient adsorbent for malathion for detection and removal purposes. J. Ind. Eng. Chem. 2015, 32, 336–344. [Google Scholar] [CrossRef]

- Wang, J.; Kaskel, S. KOH activation of carbon-based materials for energy storage. J. Mater. Chem. 2012, 22, 23710–23725. [Google Scholar] [CrossRef]

- Bardestani, R.; Patience, G.S.; Kaliaguine, S. Experimental methods in chemical engineering: Specific surface area and pore size distribution measurements—BET, BJH, and DFT. Can. J. Chem. Eng. 2019, 97, 2781–2791. [Google Scholar] [CrossRef]

- Jocić, A.; Breitenbach, S.; Pašti, I.A.; Unterweger, C.; Fürst, C.; Lazarević-Pašti, T. Viscose-derived activated carbons as adsorbents for malathion, dimethoate, and chlorpyrifos—Screening, trends, and analysis. Environ. Sci. Pollut. Res. 2022, 29, 35138–35149. [Google Scholar] [CrossRef] [PubMed]

- Kupgan, G.; Liyana-Arachchi, T.P.; Colina, C.M. NLDFT Pore Size Distribution in Amorphous Microporous Materials. Langmuir 2017, 33, 11138–11145. [Google Scholar] [CrossRef]

- Stewart, J.J. Mopac2016; Stewart Computational Chemistry: Colorado Springs, CO, USA, 2016. [Google Scholar]

- Stewart, J.J.P. Optimization of parameters for semiempirical methods VI: More modifications to the NDDO approximations and re-optimization of parameters. J. Mol. Model. 2013, 19, 1–32. [Google Scholar] [CrossRef]

- Kostoglou, M.; Karapantsios, T.D. Why Is the Linearized Form of Pseudo-Second Order Adsorption Kinetic Model So Successful in Fitting Batch Adsorption Experimental Data? Colloids Interfaces 2022, 6, 55. [Google Scholar] [CrossRef]

- Derylo-Marczewska, A.; Blachnio, M.; Marczewski, A.W.; Seczkowska, M.; Tarasiuk, B. Phenoxyacid pesticide adsorption on activated carbon—Equilibrium and kinetics. Chemosphere 2019, 214, 349–360. [Google Scholar] [CrossRef]

- Magdalena, B.; Anna, D.-M.; Malgorzata, S. Influence of Pesticide Properties on Adsorption Capacity and Rate on Activated Carbon from Aqueous Solution. In Sorption in 2020s; George, K., Nikolaos, L., Eds.; IntechOpen: Rijeka, Croatia, 2019; Chapter 1. [Google Scholar]

- Marczewski, A.W.; Seczkowska, M.; Deryło-Marczewska, A.; Blachnio, M. Adsorption equilibrium and kinetics of selected phenoxyacid pesticides on activated carbon: Effect of temperature. Adsorption 2016, 22, 777–790. [Google Scholar] [CrossRef]

- Tasić, T.; Milanković, V.; Batalović, K.; Breitenbach, S.; Unterweger, C.; Fürst, C.; Pašti, I.A.; Lazarević-Pašti, T. Application of Viscose-Based Porous Carbon Fibers in Food Processing—Malathion and Chlorpyrifos Removal. Foods 2023, 12, 2362. [Google Scholar] [CrossRef]

- Yahia, M.S.; Elzaref, A.S.; Awad, M.B.; Tony, A.M.; Elfeky, A.S. Efficient adsorption of chlorpyrifos onto modified activated carbon by gamma irradiation; a plausible adsorption mechanism. Z. Für Phys. Chem. 2022, 236, 1–25. [Google Scholar] [CrossRef]

- Vigneshwaran, S.; Preethi, J.; Meenakshi, S. Removal of chlorpyrifos, an insecticide using metal free heterogeneous graphitic carbon nitride (g-C3N4) incorporated chitosan as catalyst: Photocatalytic and adsorption studies. Int. J. Biol. Macromol. 2019, 132, 289–299. [Google Scholar] [CrossRef]

- Bondžić, A.M.; Lazarević Pašti, T.D.; Pašti, I.A.; Bondžić, B.P.; Momčilović, M.D.; Loosen, A.; Parac-Vogt, T.N. Synergistic Effect of Sorption and Hydrolysis by NU-1000 Nanostructures for Removal and Detoxification of Chlorpyrifos. ACS Appl. Nano Mater. 2022, 5, 3312–3324. [Google Scholar] [CrossRef]

- Ndifreke, W.E.; Pasaoglulari Aydinlik, N. KOH modified Thevetia peruviana shell activated carbon for sorption of dimethoate from aqueous solution. J. Environ. Sci. Health Part B 2019, 54, 1–13. [Google Scholar] [CrossRef]

- Deshlahra, P.; Conway, J.; Wolf, E.E.; Schneider, W.F. Influence of Dipole–Dipole Interactions on Coverage-Dependent Adsorption: CO and NO on Pt(111). Langmuir 2012, 28, 8408–8417. [Google Scholar] [CrossRef]

- Lim, S.; Kim, J.; Park, H.; Kwak, C.; Yang, J.; Kim, J.; Ryu, S.; Lee, J. Role of electrostatic interactions in the adsorption of dye molecules by Ti3C2-MXenes. RSC Adv. 2021, 11, 6201–6211. [Google Scholar] [CrossRef]

- Katnić, Đ.B.; Porobić, S.J.; Vujčić, I.; Kojić, M.M.; Lazarević-Pašti, T.; Milanković, V.; Marinović-Cincović, M.; Živojinović, D.Z. Irradiated fig pomace pyrochar as a promising and sustainable sterilized sorbent for water pollutant removal. Radiat. Phys. Chem. 2024, 214, 111277. [Google Scholar] [CrossRef]

- Breitenbach, S.; Lumetzberger, A.; Hobisch, M.A.; Unterweger, C.; Spirk, S.; Stifter, D.; Fürst, C.; Hassel, A.W. Supercapacitor Electrodes from Viscose-Based Activated Carbon Fibers: Significant Yield and Performance Improvement Using Diammonium Hydrogen Phosphate as Impregnating Agent. C 2020, 6, 17. [Google Scholar] [CrossRef]

| X = | 0.00% | 0.25% | 0.50% | 1.00% | 1.50% | 2.00% | 2.50% | 5.00% | 7.50% | 10% | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Pores up to (volume/cm3 g−1) | 1 nm | 0.348 | 0.335 | 0.339 | 0.343 | 0.297 | 0.271 | 0.274 | 0.198 | 0.137 | 0.160 |

| 2 nm | 0.702 | 0.375 | 0.454 | 0.738 | 0.723 | 0.857 | 0.696 | 0.754 | 0.580 | 0.559 | |

| 3 nm | 0.725 | 0.377 | 0.459 | 0.759 | 0.756 | 1.086 | 0.813 | 1.200 | 1.180 | 1.021 | |

| 4 nm | 0.734 | 0.378 | 0.462 | 0.763 | 0.760 | 1.091 | 0.819 | 1.267 | 1.568 | 1.254 | |

| Vtot */cm3 g−1 | 0.757 | 0.383 | 0.472 | 0.774 | 0.770 | 1.094 | 0.833 | 1.291 | 1.681 | 1.322 | |

| Stot **/m2 g−1 | 1932 | 1016 | 1250 | 2037 | 2002 | 2556 | 2018 | 2718 | 2763 | 2718 | |

| Elemental Content ** | C/at.% | 92.4 ± 2.1 | 91.6 ± 3.5 | 93.6 ± 2.3 | 87.9 ± 1.3 | 93.9 ± 1.9 | 91.3 ± 2.0 | 87.9 ± 2.0 | 85.6 ± 2.5 | 82.2 ± 2.2 | 77.8 ± 5.0 |

| O/at.% | 7.6 ± 2.0 | 8.4 ± 3.5 | 6.2 ± 2.2 | 12 ± 1.3 | 5.9 ± 1.9 | 7.7 ± 2.3 | 11.4 ± 2.2 | 13.1 ± 2.7 | 16.1 ± 2.3 | 19.7 ± 5.3 | |

| P/at.% | 0 | 0.02 ± 0.02 | 0.18 ± 0.10 | 0.11 ± 0.04 | 0.28 ± 0.07 | 0.91 ± 0.29 | 0.65 ± 0.30 | 1.32 ± 0.34 | 1.78 ± 0.13 | 1.9 ± 0.64 | |

| X = | 0.00% | 0.25% | 0.50% | 1.00% | 1.50% | 2.00% | 2.50% | 5.00% | 7.50% | 10% |

|---|---|---|---|---|---|---|---|---|---|---|

| Pseudo-first order | ||||||||||

| k1/min−1 | 0.054 | 0.034 | 0.0596 | 0.049 | 0.048 | 0.048 | 0.053 | 0.047 | 0.055 | 0.045 |

| Δk1/min−1 | 0.022 | 0.012 | 0.0048 | 0.015 | 0.014 | 0.018 | 0.019 | 0.015 | 0.025 | 0.023 |

| R2 | 0.7206 | 0.75 | 0.98728 | 0.81 | 0.84 | 0.75 | 0.78 | 0.82 | 0.66 | 0.58 |

| Pseudo-second order | ||||||||||

| k2/g mg−1 min−1 | 0.0053 | 0.0086 | 0.0032 | 0.0028 | 0.0030 | 0.0052 | 0.0067 | 0.0045 | 0.0134 | 0.0085 |

| Δk2/g mg−1 min−1 | 7 × 10−4 | 8 × 10−4 | 2 × 10−4 | 8 × 10−4 | 7 × 10−4 | 1 × 10−4 | 1 × 10−4 | 1 × 10−4 | 2 × 10−4 | 3 × 10−4 |

| R2 | 0.9995 | 0.98 | 0.99996 | 0.998 | 0.998 | 0.9991 | 0.9995 | 0.998 | 0.9996 | 0.998 |

| X = | 0.00% | 0.25% | 0.50% | 1.00% | 1.50% | 2.00% | 2.50% | 5.00% | 7.50% | 10% |

|---|---|---|---|---|---|---|---|---|---|---|

| Pseudo-first order | ||||||||||

| k1/min−1 | 0.204 | 0.044 | 0.074 | 0.039 | 0.070 | 0.088 | 0.053 | 0.0368 | 0.055 | 0.142 |

| Δk1/min−1 | 0.072 | 0.021 | 0.025 | 0.016 | 0.018 | 0.012 | 0.013 | 0.0026 | 0.011 | 0.020 |

| R2 | 0.64 | 0.53 | 0.65 | 0.72 | 0.78 | 0.95 | 0.85 | 0.98 | 0.88 | 0.94 |

| Pseudo-second order | ||||||||||

| k2/g mg−1 min−1 | 0.281 | 0.048 | 0.016 | 0.017 | 0.0343 | 0.0064 | 0.040 | 0.0069 | 0.030 | 0.092 |

| Δk2/g mg−1 min−1 | 6 × 10−3 | 2 × 10−3 | 1 × 10−3 | 2 × 10−3 | 6 × 10−4 | 5 × 10−4 | 3 × 10−3 | 6 × 10−4 | 3 × 10−3 | 2 × 10−3 |

| R2 | 0.99997 | 0.98 | 0.998 | 0.98 | 0.998 | 0.992 | 0.997 | 0.94 | 0.998 | 0.9998 |

| X = | 0.00% | 0.25% | 0.50% | 1.00% | 1.50% | 2.00% | 2.50% | 5.00% | 7.50% | 10% |

|---|---|---|---|---|---|---|---|---|---|---|

| Pseudo-first order | ||||||||||

| k1/min−1 | 0.055 | 0.49 | 0.70 | 0.402 | 0.234 | 0.214 | 0.149 | 0.143 | 0.064 | 0.223 |

| Δk1/min−1 | 0.012 | 0.20 | 0.27 | 0.087 | 0.025 | 0.073 | 0.016 | 0.033 | 0.026 | 0.013 |

| R2 | 0.86 | 0.61 | 0.66 | 0.87 | 0.97 | 0.72 | 0.98 | 0.85 | 0.64 | 0.99 |

| Pseudo-second order | ||||||||||

| k2/g mg−1 min−1 | 0.0075 | 0.0214 | 0.0085 | 0.0608 | 0.1002 | 0.0754 | 0.0166 | 0.0070 | 0.0634 | 0.0097 |

| Δk2/g mg−1 min−1 | 2 × 10−4 | 6 × 10−4 | 5 × 10−4 | 3 × 10−4 | 7 × 10−4 | 7 × 10−4 | 3 × 10−4 | 7 × 10−4 | 4 × 10−4 | 2 × 10−4 |

| R2 | 0.998 | 0.996 | 0.98 | 0.9998 | 0.99999 | 0.99998 | 0.9997 | 0.9996 | 0.9998 | 0.998 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lazarević-Pašti, T.; Jocić, A.; Milanković, V.; Tasić, T.; Batalović, K.; Breitenbach, S.; Unterweger, C.; Fürst, C.; Pašti, I.A. Investigating the Adsorption Kinetics of Dimethoate, Malathion and Chlorpyrifos on Cellulose-Derived Activated Carbons: Understanding the Influence of Physicochemical Properties. C 2023, 9, 103. https://doi.org/10.3390/c9040103

Lazarević-Pašti T, Jocić A, Milanković V, Tasić T, Batalović K, Breitenbach S, Unterweger C, Fürst C, Pašti IA. Investigating the Adsorption Kinetics of Dimethoate, Malathion and Chlorpyrifos on Cellulose-Derived Activated Carbons: Understanding the Influence of Physicochemical Properties. C. 2023; 9(4):103. https://doi.org/10.3390/c9040103

Chicago/Turabian StyleLazarević-Pašti, Tamara, Ana Jocić, Vedran Milanković, Tamara Tasić, Katarina Batalović, Stefan Breitenbach, Christoph Unterweger, Christian Fürst, and Igor A. Pašti. 2023. "Investigating the Adsorption Kinetics of Dimethoate, Malathion and Chlorpyrifos on Cellulose-Derived Activated Carbons: Understanding the Influence of Physicochemical Properties" C 9, no. 4: 103. https://doi.org/10.3390/c9040103