Study of Effects of MoS2 Nanofluid MQL Parameters on Cutting Forces and Surface Roughness in Hard Turning Using CBN Insert

Abstract

:1. Introduction

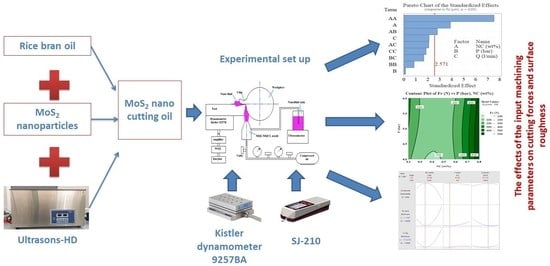

2. Materials and Methods

3. Results and Discussion

3.1. Effects of NF MQL Parameters on Surface Roughness

3.2. Effects of NF MQL Parameters on Resultant Cutting Force

3.3. Determination of Optimal Air Pressure, Air Flow Rate, and Nanoparticle Concentration

4. Conclusions

- –

- The nanoparticle concentration and the interaction effect between NC and P have the greatest influences on the surface roughness. Meanwhile, the air pressure has a great impact on the resultant cutting force.

- –

- From the analysis of the contour plots, it is possible to select a reasonable range of values for the investigated parameters to achieve the smallest Rz or Fz. Values of Q = 200 L/min, NC of about 0.4%, and air pressure of less than 4.5 bar should be used to achieve the smallest Rz (<1.2 µm) and Fr (<100 N).

- –

- For achieving the smallest surface roughness, Rz, the predicted minimum Rz is 1.1354 µm with NC = 0.42%, P = 4.14 bar, and Q = 230 L/min. For achieving the smallest cutting force, Fr, the predicted lowest Fr is 82.17 N at NC = 0.4%, P = 4.0 bar, and Q = 192 L/min.

- –

- Through implementing multi-objective optimization, the optimal set NC = 0.42%, P = 4.14 bar, and Q = 211 L/min should be used to obtain the smallest Rz or Fz values.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Vajjha, R.S.; Das, D.K. A review and analysis on influence of temperature and concentration of nanofluids on thermophysical properties, heat transfer and pumping power. Int. J. Heat Mass Transf. 2012, 55, 4063–4078. [Google Scholar] [CrossRef]

- Chinchanikar, S.; Choudhury, S. Hard turning using HiPIMS-coated carbide tools: Wear behavior under dry and minimum quantity lubrication (MQL). Measurement 2014, 55, 536–548. [Google Scholar] [CrossRef]

- Fernández-Valdivielso, A.; De Lacalle, L.L.; Urbikain, G.; Rodriguez, A. Detecting the key geometrical features and grades of carbide inserts for the turning of nickel-based alloys concerning surface integrity. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 3725–3742. [Google Scholar] [CrossRef]

- Danish, M.; Rubaiee, S.; Gupta, M.K.; Yildirim, M.B.; Ahmed, A. Technological and tribological characteristics improvement of additively manufactured SS 316L components machined under sustainable cooling conditions. Tribol. Int. 2023, 181, 108329. [Google Scholar] [CrossRef]

- Davim, J.P.; Sreejith, P.S.; Silva, J. Turning of Brasses Using Minimum Quantity of Lubricant (MQL) and Flooded Lubricant Conditions. Mater. Manuf. Process. 2007, 22, 45–50. [Google Scholar] [CrossRef]

- Pereira, O.; Martin-Alfonso, J.E.; Rodríguez, A.; Calleja-Ochoa, A.; Fernández-Valdivielso, A.; Lopez de Lacalle, L.N. Sustainability analysis of lubricant oils for minimum quantity lubrication based on their tribo-rheological performance. J. Clean. Prod. 2017, 164, 1419–1429. [Google Scholar] [CrossRef]

- Sharma, A.K.; Tiwari, A.K.; Dixit, A.R. Effects of Minimum Quantity Lubrication (MQL) in machining processes using conventional and nanofluid based cutting fluids: A comprehensive review. J. Clean. Prod. 2016, 127, 1–18. [Google Scholar] [CrossRef]

- Duc, T.M.; Long, T.T.; Tuan, N.M. Performance Investigation of MQL Parameters Using Nano Cutting Fluids in Hard Milling. Fluids 2021, 6, 248. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Nieslony, P.; Tyliszczak, B.; Pusavec, F. Tool wear characterizations in finish turning of AISI 1045 carbon steel for MQCL conditions. Wear 2017, 372, 54–67. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Feldshtein, E.; Pusavec, F.; Szydlowski, M.; Legutko, S.; Sobczak-Kupiec, A. A study on droplets sizes, their distribution and heat exchange for minimum quantity cooling lubrication (MQCL). Int. J. Mach. Tools Manuf. 2016, 100, 81–92. [Google Scholar] [CrossRef]

- Maruda, R.W.; Krolczyk, G.M.; Wojciechowski, S.; Zak, K.; Habrat, W.; Nieslony, P. Effects of extreme pressure and anti-wear additives on surface topography and tool wear during MQCL turning of AISI 1045 steel. J. Mech. Sci. Technol. 2018, 32, 1585–1591. [Google Scholar] [CrossRef]

- Dong, P.Q.; Duc, T.M.; Long, T.T. Performance Evaluation of MQCL Hard Milling of SKD 11 Tool Steel Using MoS2 Nanofluid. Metals 2019, 9, 658. [Google Scholar] [CrossRef]

- Rahman, S.S.; Ashraf, Z.I.; Amin, A.N.; Bashar, M.; Ashik, F.K.; Kamruzzaman, M. Tuning nanofluids for improved lubrication performance in turning biomedical grade titanium alloy. J. Clean. Prod. 2019, 206, 180–196. [Google Scholar] [CrossRef]

- Hegab, H.; Umer, U.; Soliman, M.; Kishawy, H.A. Effects of nano-cutting fluids on tool performance and chip morphology during machining Inconel. Int. J. Adv. Manuf. Technol. 2018, 96, 3449–3458. [Google Scholar] [CrossRef]

- Darshan, C.; Jain, S.; Dogra, M.; Gupta, M.K.; Mia, M. Machinability improvement in Inconel-718 by enhanced tribological and thermal environment using textured tool. J. Therm. Anal. Calorim. 2019, 138, 273–285. [Google Scholar] [CrossRef]

- Gupta, M.K.; Jamil, M.; Wang, X.; Song, Q.; Liu, Z.; Mia, M.; Hegab, H.; Khan, A.M.; Collado, A.G.; Pruncu, C.I.; et al. Performance Evaluation of Vegetable Oil-Based Nano-Cutting Fluids in Environmentally Friendly Machining of Inconel-800 Alloy. Materials 2019, 12, 2792. [Google Scholar] [CrossRef] [Green Version]

- Pontes, F.J.; de Paiva, A.P.; Balestrassi, P.P.; Ferreira, J.R.; da Silva, M.B. Optimization of Radial Basis Function neural network employed for prediction of surface roughness in hard turning process using Taguchi’s orthogonal arrays. Expert Syst. Appl. 2012, 39, 7776–7787. [Google Scholar] [CrossRef]

- Kant, G.; Sangwan, K.S. Predictive Modelling and Optimization of Machining Parameters to Minimize Surface Roughness using Artificial Neural Network Coupled with Genetic Algorithm. Procedia CIRP 2015, 31, 453–458. [Google Scholar] [CrossRef] [Green Version]

- Paturi, U.M.R.; Devarasetti, H.; Narala, S.K.R. Application of Regression and Artificial Neural Network Analysis in Modelling of Surface Roughness In Hard Turning Of AISI 52100 Steel. Mater. Today Proc. 2018, 5, 4766–4777. [Google Scholar] [CrossRef]

- Maran, J.P.; Sivakumar, V.; Thirugnanasambandham, K.; Sridhar, R. Artificial neural network and response surface methodology modeling in mass transfer parameters predictions during osmotic dehydration of Carica papaya L. Alex. Eng. J. 2013, 52, 507–516. [Google Scholar] [CrossRef] [Green Version]

- Sidik, N.A.C.; Samion, S.; Ghaderian, J.; Yazid, M.N.A.W.M. Recent progress on the application of nanofluids in minimum quantity lubrication machining: A review. Int. J. Heat Mass Transf. 2017, 108, 79–89. [Google Scholar] [CrossRef]

- Zhang, Y.; Li, C.; Jia, D.; Zhang, D.; Zhang, X. Experimental evaluation of MoS2 nanoparticles in jet MQL grinding with different types of vegetable oil as base oil. J. Clean. Prod. 2015, 87, 930–940. [Google Scholar] [CrossRef]

- Uysal, A.; Demiren, F.; Altan, E. Applying Minimum Quantity Lubrication (MQL) Method on Milling of Martensitic Stainless Steel by Using Nano Mos2 Reinforced Vegetable Cutting Fluid. Procedia-Soc. Behav. Sci. 2015, 195, 2742. [Google Scholar] [CrossRef] [Green Version]

- Yücel, A.; Yıldırım, V.; Sarıkaya, M.; Şirin, Ş.; Kıvak, T.; Gupta, M.K.; Tomaz, V. Influence of MoS2 based nanofluid-MQL on tribological and machining characteristics in turning of AA 2024 T3 aluminum alloy. J. Mater. Res. Technol. 2021, 15, 1688–1704. [Google Scholar] [CrossRef]

- Rahmati, B.; Sarhan, A.A.; Sayuti, M. Morphology of surface generated by end milling AL6061-T6 using molybdenum disulfide (MoS2) nanolubrication in end milling machining. J. Clean. Prod. 2014, 66, 685–691. [Google Scholar] [CrossRef]

- Park, K.-H.; Olortegui-Yume, A.J.; Joshi, S.; Kwon, P.; Yoon, M.-C.; Lee, G.-B.; Park, S.-B. Measurement of Droplet Size and Distribution for Minimum Quantity Lubrication (MQL). In Proceedings of the International Conference on Smart Manufacturing Application, Goyang-Si, Republic of Korea, 9–11 April 2008; pp. 447–454. [Google Scholar] [CrossRef]

- Hegab, H.; Kishawy, H.A.; Umer, U.; Mohany, A. A model for machining with nano-additives based minimum quantity lubrication. Int. J. Adv. Manuf. Technol. 2019, 102, 2013–2028. [Google Scholar] [CrossRef]

- de Lacalle, L.L.; Angulo, C.; Lamikiz, A.; Sánchez, J. Experimental and numerical investigation of the effect of spray cutting fluids in high speed milling. J. Mater. Process. Technol. 2006, 172, 11–15. [Google Scholar] [CrossRef]

- Ngoc, T.B.; Duc, T.M.; Tuan, N.M.; Hoang, V.L.; Long, T.T. Machinability Assessment of Hybrid Nano Cutting Oil for Minimum Quantity Lubrication (MQL) in Hard Turning of 90CrSi Steel. Lubricants 2023, 11, 54. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Fernández-Abia, A.I.; Barreiro, J.; López de Lacalle, L.N. Cryogenic and minimum quantity lubrication for an eco-efficiency turning of AISI 304. J. Clean. Prod. 2016, 139, 440–449. [Google Scholar] [CrossRef]

- Wang, Y.; Li, C.; Zhang, Y.; Yang, M.; Li, B.; Jia, D.; Hou, Y.; Mao, C. Experimental evaluation of the lubrication properties of the wheel/workpiece interface in minimum quantity lubrication (MQL) grinding using different types of vegetable oils. J. Clean. Prod. 2016, 127, 487–499. [Google Scholar] [CrossRef]

| Element | C | Si | Mn | Ni | S | P | Cr | Mo | W | V | Ti | Cu |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Weight (%) | 0.85–0.95 | 1.20–1.60 | 0.30–0.60 | Max 0.40 | Max 0.03 | Max 0.03 | 0.95–1.25 | Max 0.20 | Max 0.20 | Max 0.15 | Max 0.03 | Max 0.3 |

| No. | Parameter | Symbol | Low Level | High Level | Responses |

|---|---|---|---|---|---|

| 1 | Nanoparticle concentration (%) | NC | 0.2 | 0.8 | Surface roughness, Rz Resultant cutting force, Fr |

| 2 | Air pressure (bar) | p | 4 | 6 | |

| 3 | Air flow rate (L/min) | Q | 150 | 250 |

| Std. Order | Run Order | PtType | Blocks | NC (wt%) | p (bar) | Q (L/min) | Rz (µm) | Fr (N) |

|---|---|---|---|---|---|---|---|---|

| 5 | 1 | 2 | 1 | 0.2 | 5 | 150 | 1.848 | 307.1019 |

| 3 | 2 | 2 | 1 | 0.2 | 6 | 200 | 1.980 | 385.1642 |

| 14 | 3 | 0 | 1 | 0.5 | 5 | 200 | 1.198 | 135.7268 |

| 10 | 4 | 2 | 1 | 0.5 | 6 | 150 | 1.321 | 165.9382 |

| 13 | 5 | 0 | 1 | 0.5 | 5 | 200 | 1.203 | 143.3989 |

| 12 | 6 | 2 | 1 | 0.5 | 6 | 250 | 1.353 | 190.324 |

| 7 | 7 | 2 | 1 | 0.2 | 5 | 250 | 1.955 | 302.4206 |

| 8 | 8 | 2 | 1 | 0.8 | 5 | 250 | 1.898 | 658.5913 |

| 11 | 9 | 2 | 1 | 0.5 | 4 | 250 | 1.291 | 208.8865 |

| 6 | 10 | 2 | 1 | 0.8 | 5 | 150 | 2.518 | 728.2449 |

| 4 | 11 | 2 | 1 | 0.8 | 6 | 200 | 2.143 | 489.8893 |

| 1 | 12 | 2 | 1 | 0.2 | 4 | 200 | 1.295 | 268.6225 |

| 2 | 13 | 2 | 1 | 0.8 | 4 | 200 | 2.436 | 537.0321 |

| 9 | 14 | 2 | 1 | 0.5 | 4 | 150 | 1.846 | 141.9083 |

| 15 | 15 | 0 | 1 | 0.5 | 5 | 200 | 1.213 | 155.6953 |

| Source | DF | Adj. SS | Adj. MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 281.326 | 0.31258 | 10.34 | 0.010 |

| Linear | 3 | 0.59415 | 0.19805 | 6.55 | 0.035 |

| NC (wt%) | 1 | 0.45936 | 0.45936 | 15.19 | 0.011 |

| P (bar) | 1 | 0.00063 | 0.00063 | 0.02 | 0.891 |

| Q (L/min) | 1 | 0.13416 | 0.13416 | 4.44 | 0.089 |

| Square | 3 | 176.171 | 0.58724 | 19.42 | 0.003 |

| NC (wt%)*NC (wt%) | 1 | 170.942 | 170.942 | 56.53 | 0.001 |

| P (bar)*P (bar) | 1 | 0.02270 | 0.02270 | 0.75 | 0.426 |

| Q (L/min)*Q (L/min) | 1 | 0.10629 | 0.10629 | 3.52 | 0.120 |

| 2-Way Interaction | 3 | 0.45740 | 0.15247 | 5.04 | 0.057 |

| NC (wt%)*P (bar) | 1 | 0.23912 | 0.23912 | 7.91 | 0.037 |

| NC (wt%)*Q (L/min) | 1 | 0.13213 | 0.13213 | 4.37 | 0.091 |

| P (bar)*Q (L/min) | 1 | 0.08614 | 0.08614 | 2.85 | 0.152 |

| Error | 5 | 0.15119 | 0.03024 | ||

| Lack-of-Fit | 3 | 0.15108 | 0.05036 | 863.29 | 0.001 |

| Pure Error | 2 | 0.00012 | 0.00006 | ||

| Total | 14 | 296.446 |

| Source | DF | Adj. SS | Adj. MS | F-Value | p-Value |

|---|---|---|---|---|---|

| Model | 9 | 516,799 | 57,422 | 11.69 | 0.007 |

| Linear | 3 | 166,178 | 55,393 | 11.27 | 0.012 |

| NC (wt%) | 1 | 165,441 | 165,441 | 33.67 | 0.002 |

| P (bar) | 1 | 701 | 701 | 0.14 | 0.721 |

| Q (L/min) | 1 | 36 | 36 | 0.01 | 0.935 |

| Square | 3 | 342,414 | 114,138 | 23.23 | 0.002 |

| NC (wt%)*NC (wt%) | 1 | 329,613 | 329,613 | 67.09 | 0.000 |

| P (bar)*P (bar) | 1 | 2047 | 2047 | 0.42 | 0.547 |

| Q (L/min)*Q (L/min) | 1 | 11,319 | 11,319 | 2.30 | 0.190 |

| 2-Way Interaction | 3 | 8207 | 2736 | 0.56 | 0.666 |

| NC (wt%)*P (bar) | 1 | 6698 | 6698 | 1.36 | 0.296 |

| NC (wt%)*Q (L/min) | 1 | 1055 | 1055 | 0.21 | 0.663 |

| P (bar)*Q (L/min) | 1 | 454 | 454 | 0.09 | 0.773 |

| Error | 5 | 24,566 | 4913 | ||

| Lack-of-Fit | 3 | 24,363 | 8121 | 80.04 | 0.012 |

| Pure Error | 2 | 203 | 101 | ||

| Total | 14 | 541,365 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tuan, N.M.; Long, T.T.; Ngoc, T.B. Study of Effects of MoS2 Nanofluid MQL Parameters on Cutting Forces and Surface Roughness in Hard Turning Using CBN Insert. Fluids 2023, 8, 188. https://doi.org/10.3390/fluids8070188

Tuan NM, Long TT, Ngoc TB. Study of Effects of MoS2 Nanofluid MQL Parameters on Cutting Forces and Surface Roughness in Hard Turning Using CBN Insert. Fluids. 2023; 8(7):188. https://doi.org/10.3390/fluids8070188

Chicago/Turabian StyleTuan, Ngo Minh, Tran The Long, and Tran Bao Ngoc. 2023. "Study of Effects of MoS2 Nanofluid MQL Parameters on Cutting Forces and Surface Roughness in Hard Turning Using CBN Insert" Fluids 8, no. 7: 188. https://doi.org/10.3390/fluids8070188