CFD Study of Thermal Stratification in a Scaled-Down, Toroidal Suppression Pool of Fukushima Daiichi Type BWR

Abstract

:1. Introduction

2. Literature Review and Objective

3. Numerical Modelling

3.1. Geometry Description

3.2. Case Set-Up and Mesh Sensitivity Study

3.3. Validation

4. Results and Discussion

4.1. Tunnelling Effect

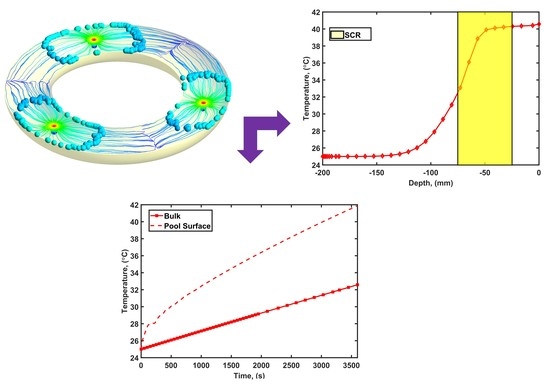

4.2. Thermal Stratification Characteristics for Base Case

4.2.1. Average Temperature Distribution

4.2.2. Volume Fraction Distribution

4.3. Parametric Influence

4.3.1. Effect of Number of Steam Injection Points (Heat Sources)

4.3.2. Effect of Aspect Ratio or Pool Cross-Section

5. Conclusions

- Due to the tunnelling effect, a persistent thermal stratification always develops, resulting in a higher surface average temperature than the bulk average temperature.

- The surface temperature is shown to be significantly impacted significantly by the aspect ratio of the pool and moderately by the number of steam injection points.

- For cases with multiple injections, about 50% of the pool volume is has a <5 °C increase in temperature, compared to 31% of the pool volume in a single-injection case, indicating a steeper thermal stratification in the case of multiple injections, reflected in a higher average surface temperature.

- Observations based on the parametric influence of aspect ratio suggest that the baseline pool temperature rose by a maximum of 10 °C for 81% and 52% of the pool volume for aspect ratios of 2 and 0.5, respectively, demonstrating that a large portion of the pool participates in the heat evacuation process in cases with a larger aspect ratio.

Author Contributions

Funding

Conflicts of Interest

References

- Pellegrini, M.; Dolganov, K.; Herranz, L.E.; Bonneville, H.; Luxat, D.; Sonnenkalb, M.; Ishikawa, J.; Song, J.H.; Gauntt, R.O.; Fernandez Moguel, L.; et al. Benchmark Study of the Accident at the Fukushima Daiichi NPS: Best-Estimate Case Comparison. Nucl. Technol. 2016, 196, 198–210. [Google Scholar] [CrossRef]

- Mizokami, S.; Yamada, D.; Honda, T.; Yamauchi, D.; Yamanaka, Y. Unsolved Issues Related to Thermal-Hydraulics in the Suppression Chamber during Fukushima Daiichi Accident Progressions. J. Nucl. Sci. Technol. 2016, 53, 630–638. [Google Scholar] [CrossRef] [Green Version]

- Pellegrini, M.; Araneo, L.; Ninokata, H.; Ricotti, M.; Naitoh, M.; Achilli, A. Suppression Pool Testing at the SIET Laboratory: Experimental Investigation of Critical Phenomena Expected in the Fukushima Daiichi Suppression Chamber. J. Nucl. Sci. Technol. 2016, 53, 614–629. [Google Scholar] [CrossRef] [Green Version]

- Jo, B.; Erkan, N.; Takahashi, S.; Song, D.; Sagawa, W.; Okamoto, K. Thermal Stratification in a Scaled-down Suppression Pool of the Fukushima Daiichi Nuclear Power Plants. Nucl. Eng. Des. 2016, 305, 39–50. [Google Scholar] [CrossRef]

- Solom, M.; Vierow Kirkland, K. Experimental Investigation of BWR Suppression Pool Stratification during RCIC System Operation. Nucl. Eng. Des. 2016, 310, 564–569. [Google Scholar] [CrossRef]

- Cavaluzzi, J.; Andrs, D.; Vierow Kirkland, K. Two-Zone Stratified Wetwell Model Development and Implementation for RELAP-7. Ann. Nucl. Energy 2021, 164, 108592. [Google Scholar] [CrossRef]

- Li, H.; Villanueva, W.; Kudinov, P. Approach and Development of Effective Models for Simulation of Thermal Stratification and Mixing Induced by Steam Injection into a Large Pool of Water. Sci. Technol. Nucl. Install. 2014, 2014, 108782. [Google Scholar] [CrossRef] [Green Version]

- Gallego-marcos, I.; Villanueva, W.; Kudinov, P. Modelling of Pool Stratification and Mixing Induced by Steam Injection through Blowdown Pipes. Ann. Nucl. Energy 2018, 112, 624–639. [Google Scholar] [CrossRef]

- Villanueva, W.; Li, H.; Puustinen, M.; Kudinov, P. Generalization of Experimental Data on Amplitude and Frequency of Oscillations Induced by Steam Injection into a Subcooled Pool. Nucl. Eng. Des. 2015, 295, 155–161. [Google Scholar] [CrossRef]

- Zhang, Y.; Lu, D.; Wang, Z.; Fu, X.; Cao, Q.; Yang, Y.; Wu, G. Experimental Research on the Thermal Stratification Criteria and Heat Transfer Model for the Multi-Holes Steam Ejection in IRWST of AP1000 Plant. Appl. Therm. Eng. 2016, 107, 1046–1056. [Google Scholar] [CrossRef]

- Qu, X.; Revankar, S.T.; Tian, M. Numerical Investigation on Thermal Status of a Scaled-down Suppression Pool. Nucl. Eng. Des. 2018, 340, 183–192. [Google Scholar] [CrossRef]

- Gamble, R.E.; Nguyen, T.T.; Shiralkar, B.S.; Peterson, P.F.; Greif, R.; Tabata, H. Pressure Suppression Pool Mixing in Passive Advanced BWR Plants. Nucl. Eng. Des. 2001, 204, 321–336. [Google Scholar] [CrossRef]

- Kang, H.S.; Song, C.H. CFD Analysis for Thermal Mixing in a Subcooled Water Tank under a High Steam Mass Flux Discharge Condition. Nucl. Eng. Des. 2008, 238, 492–501. [Google Scholar] [CrossRef]

- Moon, Y.T.; Lee, H.D.; Park, G.C. CFD Simulation of Steam Jet-Induced Thermal Mixing in Subcooled Water Pool. Nucl. Eng. Des. 2009, 239, 2849–2863. [Google Scholar] [CrossRef]

- Song, C.H.; Kim, Y.S. Direct Contact Condensation of Steam Jet in a Pool. In Advances in Heat Transfer; Elsevier Inc.: Amsterdam, The Netherlands, 2011; Volume 43, pp. 227–288. ISBN 9780123815293. [Google Scholar]

- Wang, X.; Grishchenko, D.; Kudinov, P. Pre-Test Analysis for Definition of Steam Injection Tests through Multi-Hole Sparger in PANDA Facility. Nucl. Eng. Des. 2022, 386, 111573. [Google Scholar] [CrossRef]

- Song, D.; Erkan, N.; Jo, B.; Okamoto, K. Dimensional Analysis of Thermal Stratification in a Suppression Pool. Int. J. Multiph. Flow 2014, 66, 92–100. [Google Scholar] [CrossRef]

- Song, D.; Erkan, N.; Jo, B.; Okamoto, K. Relationship between Thermal Stratification and Flow Patterns in Steam-Quenching Suppression Pool. Int. J. Heat Fluid Flow 2015, 56, 209–217. [Google Scholar] [CrossRef]

- Gallego-Marcos, I.; Kudinov, P.; Villanueva, W.; Puustinen, M.; Räsänen, A.; Tielinen, K.; Kotro, E. Effective Momentum Induced by Steam Condensation in the Oscillatory Bubble Regime. Nucl. Eng. Des. 2019, 350, 259–274. [Google Scholar] [CrossRef]

- Liu, X.; Xie, X.; Meng, Z.; Zhang, N.; Sun, Z. Characteristics of Pool Thermal Stratification Induced by Steam Injected through a Vertical Blow down Pipe under Different Vessel Pressures. Appl. Therm. Eng. 2021, 195, 117169. [Google Scholar] [CrossRef]

- Cai, J.; Jo, B.; Erkan, N.; Okamoto, K. Effect of Non-Condensable Gas on Thermal Stratification and Flow Patterns in Suppression Pool. Nucl. Eng. Des. 2016, 300, 117–126. [Google Scholar] [CrossRef]

- Kumar, S.; Grover, R.B.; Vijayan, P.K.; Kannan, U. Numerical Investigation on the Effect of Shrouds around an Immersed Isolation Condenser on the Thermal Stratification in Large Pools. Ann. Nucl. Energy 2017, 110, 109–125. [Google Scholar] [CrossRef]

- De Walsche, C.; de Cachard, F. Experimental Investigation of Condensation and Mixing during Venting of a Steam/Non-Condensable Gas Mixture into a Pressure Suppression Pool. In IAEA Rep: INIS-CH--022; Paul Scherrer Institute Scientific: Villigen, Switzerland, 2000; Volume 4, pp. 53–61. [Google Scholar]

- Li, H.; Kudinov, P.; Villanueva, W. Modeling of Condensation, Stratification, and Mixing Phenomena in a Pool of Water; Technical Report number NKS-225; Nordisk Kernesikkerhedsforskning, Roskilde: Stockholm, Sweden, 2010. [Google Scholar]

- Patel, G.; Tanskanen, V.; Kyrki-Rajamäki, R. Numerical Modelling of Low-Reynolds Number Direct Contact Condensation in a Suppression Pool Test Facility. Ann. Nucl. Energy 2014, 71, 376–387. [Google Scholar] [CrossRef]

- Patel, G. Computational Fluid Dynamics Analysis of Steam Condensation in Nuclear Power. Ph.D. Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 4 April 2017. [Google Scholar]

- Choi, S.W. PUMA-PCCS Separate Effect Tests and RELAP5 Code Evaluation in PUMA. Ph.D. Thesis, Purdue University, West Lafayette, IN, USA, 2009. [Google Scholar]

- Jo, B.; Erkan, N.; Okamoto, K. Richardson Number Criteria for Direct-Contact-Condensation-Induced Thermal Stratification Using Visualization. Prog. Nucl. Energy 2020, 118, 103095. [Google Scholar] [CrossRef]

- Li, H.; Villanueva, W.; Puustinen, M.; Laine, J.; Kudinov, P. Thermal Stratification and Mixing in a Suppression Pool Induced by Direct Steam Injection. Ann. Nucl. Energy 2018, 111, 487–498. [Google Scholar] [CrossRef]

- Youn, D.H.; Ko, K.B.; Lee, Y.Y.; Kim, M.H.; Bae, Y.Y.; Park, J.K. The Direct Contact Condensation of Steam in a Pool at Low Mass Flux. J. Nucl. Sci. Technol. 2003, 40, 881–885. [Google Scholar] [CrossRef]

- Yang, Q.; Qiu, B.; Chen, W.; Zhang, D.; Chong, D.; Liu, J.; Yan, J. Experimental Study on the Influence of Buoyancy on Steam Bubble Condensation at Low Steam Mass Flux. Exp. Therm. Fluid Sci. 2021, 129, 110467. [Google Scholar] [CrossRef]

- Gallego-Marcos, I.; Kudinov, P.; Villanueva, W.; Kapulla, R.; Paranjape, S.; Paladino, D.; Laine, J.; Puustinen, M.; Räsänen, A.; Pyy, L.; et al. Pool Stratification and Mixing Induced by Steam Injection through Spargers: CFD Modelling of the PPOOLEX and PANDA Experiments. Nucl. Eng. Des. 2019, 347, 67–85. [Google Scholar] [CrossRef]

- Li, W.; Wang, J.; Sun, Z.; Zhou, Y.; Liu, J.; Meng, Z. Experimental Investigation on Thermal Stratification Induced by Steam Direct Contact Condensation with Non-Condensable Gas. Appl. Therm. Eng. 2019, 154, 628–636. [Google Scholar] [CrossRef]

- Filich, L. Modeling and Simulation of Thermal Stratification and Mixing Induced by Steam Injection through Spargers into Large Water Pool. Master’s Thesis, Royal Institute of Technology, Stockholm, Sweden, 2015. [Google Scholar]

- ANSYS, Inc. ANSYS Fluent User’s Guide; ANSYS, Inc.: Canonsburg, PA, USA, 2021. [Google Scholar]

- Hoshi, H.; Kawabe, R. Accident Sequence Analysis of Unit 1 to 3 Using MELCOR Code. In Proceedings of the Technical Workshop on the Accident of TEPCO’s Fukushima Dai-ichi NPS Handouts, 23 July 2012. [Google Scholar]

- Krepper, E.; Hicken, E.F.; Jaegers, H. Investigation of Natural Convection in Large Pools. Int. J. Heat Fluid Flow 2002, 23, 359–365. [Google Scholar] [CrossRef]

- Kota, S.B.; Ali, S.M.; Jayanti, S. Thermal Stratification Characteristics in a Reduced Scale Toroidal Suppression Pool. In Proceedings of the 8th International Conference on Advances in Energy Research (ICAER-2022), Mumbai, India, 7–9 July 2022; IIT Bombay: Mumbai, India, 2022; pp. 1–10. [Google Scholar]

| Case | Remarks and Simulation Inputs |

|---|---|

| A | Mesh 1; Penetration length = 25 mm |

| B | Mesh 2; Penetration length = 25 mm |

| C | Mesh 3; Penetration length = 25 mm |

| D | Mesh 3; Time step sensitivity; Penetration length = 25 mm |

| E | Penetration length = 15 mm; Penetration length sensitivity. VHF = X = 16.7 MW/m3; A = 1.0 |

| F | Penetration length = 10 mm; Penetration length sensitivity. Base Case; VHF = X = 42.2 MW/m3; A = 1.0 |

| Parametric Influence (No. of heat sources) | |

| G | 2-heat sources |

| H | 3-heat sources |

| I | 4-heat sources |

| Parametric Influence (Aspect Ratio) | |

| J | |

| K | |

| Property | Value |

|---|---|

| 997.1 | |

| 4182 | |

| 0.6 | |

| 0.001003 | |

| 0.0002594 |

| Point Height, (mm) | [4] | |

|---|---|---|

| 150 | 0.0022 | 0.0026 |

| 100 | 0.0021 | 0.0022 |

| 10 | 5.2 × 10−4 | 5.5 × 10−5 |

| ) | 1 | 0.5 | 2 |

| Volume (mm3) | 1.89 × 108 | 1.89 × 108 | 1.89 × 108 |

| 200.00 | 141.42 | 282.84 | |

| 200.00 | 282.84 | 141.42 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kota, S.B.; Ali, S.M.; Jayanti, S. CFD Study of Thermal Stratification in a Scaled-Down, Toroidal Suppression Pool of Fukushima Daiichi Type BWR. Fluids 2023, 8, 20. https://doi.org/10.3390/fluids8010020

Kota SB, Ali SM, Jayanti S. CFD Study of Thermal Stratification in a Scaled-Down, Toroidal Suppression Pool of Fukushima Daiichi Type BWR. Fluids. 2023; 8(1):20. https://doi.org/10.3390/fluids8010020

Chicago/Turabian StyleKota, Sampath Bharadwaj, Seik Mansoor Ali, and Sreenivas Jayanti. 2023. "CFD Study of Thermal Stratification in a Scaled-Down, Toroidal Suppression Pool of Fukushima Daiichi Type BWR" Fluids 8, no. 1: 20. https://doi.org/10.3390/fluids8010020