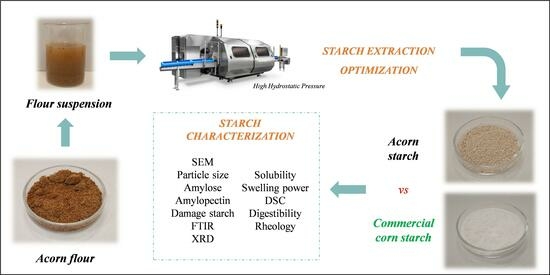

Modification of Acorn Starch Structure and Properties by High Hydrostatic Pressure

Abstract

:1. Introduction

2. Results and Discussion

2.1. Granular Morphology

2.2. Granular Distribution and Particle Size

2.3. Amylose and Amylopectin

2.4. Damaged Starch

2.5. Fourier Transform Infrared Spectroscopy

2.6. X-ray Diffraction

2.7. Solubility and Swelling Power

2.8. Differential Scanning Calorimetry

2.9. In Vitro Digestibility

2.10. Steady Flow Behavior

2.11. Dynamic Oscillation

3. Conclusions

4. Materials and Methods

4.1. Acorn Sampling and Commercial Corn Starch

4.2. Acorn Starch Extraction

4.3. Structural Characterization

4.3.1. Scanning Electron Microscopy

4.3.2. Particle Size

4.3.3. Damaged Starch, Amylose, and Amylopectin

4.3.4. Fourier Transform Infrared Spectroscopy

4.3.5. X-ray Diffraction

4.4. Property Characterization

4.4.1. Solubility and Swelling Power

4.4.2. Differential Scanning Calorimetry

4.4.3. In Vitro Digestibility

4.4.4. Steady Flow Behavior

4.4.5. Dynamic Oscillation

4.5. Statistical Analysis

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Denk, T.; Grimm, G.W.; Manos, P.S.; Deng, M.; Hipp, A.L. An Updated Infrageneric Classification of the Oaks: Review of Previous Taxonomic Schemes and Synthesis of Evolutionary Patterns. In Oaks Physiological Ecology. Exploring the Functional Diversity of Genus Quercus L.; Gil-Pelegrín, E., Peguero-Pina, J.J., Sancho-Knapik, D., Eds.; Tree Physiology; Springer: Cham, Switzerland, 2017; Volume 7, pp. 261–302. ISBN 978-3-319-69098-8. [Google Scholar]

- Silveira, T. Bolota: 55% da produção é desperdiçada. Agro-Vida Vida Económica 2017, 1715, 7. [Google Scholar]

- Castro, L.M.G.; Ribeiro, T.B.; Machado, M.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M. Unraveling the Effect of Dehulling Methods on the Nutritional Composition of Acorn Quercus spp. J. Food Compos. Anal. 2022, 106, 104354. [Google Scholar] [CrossRef]

- Schirmer, M.; Jekle, M.; Becker, T. Starch gelatinization and its complexity for analysis. Starch-Stärke 2015, 67, 30–41. [Google Scholar] [CrossRef]

- Adewale, P.; Yancheshmeh, M.S.; Lam, E. Starch modification for non-food, industrial applications: Market intelligence and critical review. Carbohydr. Polym. 2022, 291, 119590. [Google Scholar] [CrossRef]

- Mortensen, A.; Aguilar, F.; Crebelli, R.; Di Domenico, A.; Dusemund, B.; Frutos, M.J.; Galtier, P.; Gott, D.; Gundert-Remy, U.; Lambré, C.; et al. Re-evaluation of oxidised starch (E 1404), monostarch phosphate (E 1410), distarch phosphate (E 1412), phosphated distarch phosphate (E 1413), acetylated distarch phosphate (E 1414), acetylated starch (E 1420), acetylated distarch adipate (E 1422), hydroxypropyl starch (E 1440), hydroxypropyl distarch phosphate (E 1442), starch sodium octenyl succinate (E 1450), acetylated oxidised starch (E 1451) and starch aluminium octenyl succinate (E 1452) as food additives. EFSA J. 2017, 15, 4911. [Google Scholar]

- European Commission Regulation (EC) No 1333/2008. Available online: http://data.europa.eu/eli/reg/2008/1333/2022-10-31 (accessed on 31 October 2022).

- Park, S.; Kim, Y.R. Clean label starch: Production, physicochemical characteristics, and industrial applications. Food Sci. Biotechnol. 2020, 30, 1–17. [Google Scholar] [CrossRef]

- Castro, L.M.G.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M. Impact of high pressure on starch properties: A review. Food Hydrocoll. 2020, 106, 105877. [Google Scholar] [CrossRef]

- Zhang, J.; Zhang, M.; Zhang, Y.; Bai, X.; Wang, C. Effects of high hydrostatic pressure on the structure and retrogradation inhibition of oat starch. Int. J. Food Sci. Technol. 2022, 57, 2113–2125. [Google Scholar] [CrossRef]

- Larrea-Wachtendorff, D.; Tabilo-Munizaga, G.; Ferrari, G. Potato starch hydrogels produced by high hydrostatic pressure (HHP): A first approach. Polymers 2019, 11, 1673. [Google Scholar] [CrossRef]

- Liu, M.; Wu, N.N.; Yu, G.P.; Zhai, X.T.; Chen, X.; Zhang, M.; Tian, X.H.; Liu, Y.X.; Wang, L.P.; Tan, B. Physicochemical properties, structural properties, and in vitro digestibility of pea starch treated with high hydrostatic pressure. Starch-Stärke 2018, 70, 1700082. [Google Scholar] [CrossRef]

- Heydari, A.; Razavi, S.M.A.; Hesarinejad, M.A.; Farahnaky, A. New Insights into Physical, Morphological, Thermal, and Pasting Properties of HHP-Treated Starches: Effect of Starch Type and Industry-Scale Concentration. Starch-Stärke 2021, 73, 2000179. [Google Scholar] [CrossRef]

- Soni, P.L.; Sharma, H.; Dun, D.; Gharia, M.M. Physicochemical Properties of Quercus leucotrichophora (Oak) Starch. Starch-Stärke 1993, 45, 127–130. [Google Scholar] [CrossRef]

- Yoo, S.H.; Lee, C.S.; Kim, B.S.; Shin, M. The properties and molecular structures of gusiljatbam starch compared to those of acorn and chestnut starches. Starch-Stärke 2012, 64, 339–347. [Google Scholar] [CrossRef]

- He, M.; Ding, T.; Wu, Y.; Ouyang, J. Effects of Endogenous Non-Starch Nutrients in Acorn (Quercus wutaishanica Blume) Kernels on the Physicochemical Properties and In Vitro Digestibility of Starch. Foods 2022, 11, 825. [Google Scholar] [CrossRef]

- Liu, M.; Yang, Q.; Wu, Y.; Ouyang, J. Effects of Endogenous Polyphenols in Acorn (Quercus variabilis Blume) Kernels on the Physicochemical Properties of Starch. Starch-Stärke 2022, 74, 2200005. [Google Scholar] [CrossRef]

- Stevenson, D.G.; Jane, J.; Inglett, G.E. Physicochemical Properties of Pin Oak (Quercus palustris Muenchh.) Acorn Starch. Starch-Stärke 2006, 58, 553–560. [Google Scholar] [CrossRef]

- Deng, M.; Reddy, C.K.; Xu, B. Morphological, physico-chemical and functional properties of underutilized starches in China. Int. J. Biol. Macromol. 2020, 158, 648–655. [Google Scholar] [CrossRef]

- Molavi, H.; Razavi, S.M.A.; Farhoosh, R. Impact of hydrothermal modifications on the physicochemical, morphology, crystallinity, pasting and thermal properties of acorn starch. Food Chem. 2018, 245, 385–393. [Google Scholar] [CrossRef]

- Bayati, A.; Javanmard, M.; Eikani, M.H.; Sharifi, A. The Effect of Starch Isolation Method on Morphological and Physicochemical Properties of Zagros Oak (Quercus brantii var. Persica) Starch. Starch-Stärke 2022, 74, 2200016. [Google Scholar] [CrossRef]

- Zhang, Z.; Saleh, A.S.M.; Wu, H.; Gou, M.; Liu, Y.; Jing, L.; Zhao, K.; Su, C.; Zhang, B.; Li, W. Effect of Starch Isolation Method on Structural and Physicochemical Properties of Acorn Kernel Starch. Starch-Stärke 2020, 72, 1900122. [Google Scholar] [CrossRef]

- Zhang, D.; Xu, H.; Jiang, B.; Wang, X.; Yang, L.; Shan, Y.; Ding, S. Effects of ultra-high pressure on the morphological and physicochemical properties of lily starch. Food Sci. Nutr. 2021, 9, 952–962. [Google Scholar] [CrossRef] [PubMed]

- Błaszczak, W.; Valverde, S.; Fornal, J. Effect of high pressure on the structure of potato starch. Carbohydr. Polym. 2005, 59, 377–383. [Google Scholar] [CrossRef]

- Ahmed, J.; Al-Attar, H. Structural properties of high-pressure-treated chestnut flour dispersions. Int. J. Food Prop. 2017, 20, S766–S778. [Google Scholar] [CrossRef]

- Lindeboom, N.; Chang, P.R.; Tyler, R.T. Analytical, biochemical and physicochemical aspects of starch granule size, with emphasis on small granule starches: A review. Starch-Stärke 2004, 56, 89–99. [Google Scholar]

- Li, G.; Zhu, F. Effect of high pressure on rheological and thermal properties of quinoa and maize starches. Food Chem. 2018, 241, 380–386. [Google Scholar] [CrossRef]

- Leite, T.S.; Jesus, A.L.T.; Schmiele, M.; Tribst, A.A.L.; Cristianini, M. High pressure processing (HPP) of pea starch: Effect on the gelatinization properties. LWT Food Sci. Technol. 2017, 76, 361–369. [Google Scholar] [CrossRef]

- Filippa, L.; Trento, A.; Álvarez, A.M. Sauter mean diameter determination for the fine fraction of suspended sediments using a LISST-25X diffractometer. Meas. J. Int. Meas. Confed. 2012, 45, 364–368. [Google Scholar] [CrossRef]

- Zhang, D.; Mu, T.; Sun, H.; He, J. Effects of different high hydrostatic pressure-treated potato starch on the processing performance of dough-like model systems. Food Res. Int. 2019, 120, 456–463. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L. Changes in structural, functional and antioxidant properties induced by high pressure on quinoa flour. J. Food Meas. Charact. 2020, 14, 401–410. [Google Scholar] [CrossRef]

- Kaur, M.; Punia, S.; Sandhu, K.S.; Ahmed, J. Impact of high pressure processing on the rheological, thermal and morphological characteristics of mango kernel starch. Int. J. Biol. Macromol. 2019, 140, 149–155. [Google Scholar] [CrossRef]

- Rahman, M.H.; Mu, T.H.; Zhang, M.; Ma, M.M.; Sun, H.N. Comparative study of the effects of high hydrostatic pressure on physicochemical, thermal, and structural properties of maize, potato, and sweet potato starches. J. Food Process. Preserv. 2020, 44, e14294. [Google Scholar] [CrossRef]

- Sandhu, K.S.; Kaur, M.; Punia, S.; Ahmed, J. Rheological, thermal, and structural properties of high-pressure treated Litchi (Litchi chinensis) kernel starch. Int. J. Biol. Macromol. 2021, 175, 229–234. [Google Scholar] [CrossRef] [PubMed]

- Correia, P.R.; Cristiana, M.; Beirão-da-Costa, M.L. The effect of starch isolation method on physical and functional properties of Portuguese nut starches. II. Q. rotundifolia Lam. and Q. suber Lam. acorns starches. Food Hydrocoll. 2013, 30, 448–455. [Google Scholar]

- Cappai, M.G.; Alesso, G.A.; Nieddu, G.; Sanna, M.; Pinna, W. Electron microscopy and composition of raw acorn starch in relation to in vivo starch digestibility. Food Funct. 2013, 4, 917–922. [Google Scholar] [CrossRef]

- Chung, D.-H.; Yu, T.-J.; Choi, B.-K. Studies on the Utilization of Acorn Starch—Part I. Properties of Acorn Starch. J. Korean Agric. Chem. Soc. 1975, 18, 102–108. [Google Scholar]

- Irinislimane, H.; Belhaneche-Bensemra, N. Extraction and Characterization of Starch from Oak Acorn, Sorghum, and Potato and Adsorption Application for Removal of Maxilon Red GRL from Wastewater. Chem. Eng. Commun. 2017, 204, 897–906. [Google Scholar] [CrossRef]

- Saleh, M.; Ajo, R.; Al-Ismail, K.; Ondier, G. Effects of hydrocolloids on acorn starch physical properties. Starch-Stärke 2016, 68, 1169–1179. [Google Scholar] [CrossRef]

- Lassoued, R.; Abderrabba, M.; Mejri, J. Comparative chemical composition of two Quercus species seeds growing in Tunisia. S. Afr. J. Bot. 2022, 146, 71–76. [Google Scholar] [CrossRef]

- Boukhelkhal, M.; Moulai-Mostefa, N. Physicochemical characterization of starch isolated from soft acorns of holm oak (Quercus ilex subsp. ballota (Desf.) Samp.) grown in Algeria. J. Food Meas. Charact. 2017, 11, 1995–2005. [Google Scholar] [CrossRef]

- Correia, P.R.; Beirão-da-Costa, M.L. Effect of Drying Temperatures on Starch-Related Functional and Thermal Properties of Acorn Flours. J. Food Sci. 2011, 76, E196–E202. [Google Scholar] [CrossRef]

- Pei-Ling, L.; Qing, Z.; Qun, S.; Xiao-Song, H.; Ji-Hong, W. Effect of high hydrostatic pressure on modified noncrystalline granular starch of starches with different granular type and amylase content. LWT Food Sci. Technol. 2012, 47, 450–458. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Taher, A.; Joseph, A. Impact of high pressure treatment on functional, rheological, pasting, and structural properties of lentil starch dispersions. Carbohydr. Polym. 2016, 152, 639–647. [Google Scholar] [CrossRef]

- Ahmed, J.; Thomas, L.; Arfat, Y.A.; Joseph, A. Rheological, structural and functional properties of high-pressure treated quinoa starch in dispersions. Carbohydr. Polym. 2018, 197, 649–657. [Google Scholar] [CrossRef] [PubMed]

- Jin, J.; Lin, H.; Yagoub, A.E.G.A.; Xiong, S.; Xu, L.; Udenigwe, C.C. Effects of high power ultrasound on the enzymolysis and structures of sweet potato starch. J. Sci. Food Agric. 2020, 100, 3498–3506. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Chaib, S.; Gu, Q.; Hemar, Y. Impact of pressure on physicochemical properties of starch dispersions. Food Hydrocoll. 2017, 68, 164–177. [Google Scholar] [CrossRef]

- Correia, P.M.R.; Cruz-Lopes, L.; Beirão-Da-Costa, L. Morphology and structure of acorn starches isolated by enzymatic and alkaline methods. Open Agric. 2021, 6, 37–46. [Google Scholar] [CrossRef]

- Zarroug, Y.; Boulares, M.; Mejri, J.; Slimi, B.; Hamdaoui, G.; Djebi, S.; Saidi, F.; Nasri, H.; Sfayhi, D.T.; Kharrat, M. Extraction and Characterization of Tunisian Quercus ilex Starch and Its Effect on Fermented Dairy Product Quality. Int. J. Anal. Chem. 2020, 2020, 8868673. [Google Scholar] [CrossRef]

- Li, S.; Zhou, Y.; Liu, M.; Zhang, Y.; Cao, S. Nutrient composition and starch characteristics of Quercus glandulifera Bl. seeds from China. Food Chem. 2015, 185, 371–376. [Google Scholar]

- Zarroug, Y.; Boulares, M.; Sfayhi, D.; Slimi, B.; Stiti, B.; Zaieni, K.; Nefissi, S.; Kharrat, M. Structural and Physicochemical Properties of Tunisian Quercus suber L. Starches for Custard Formulation: A Comparative Study. Polymers 2022, 14, 556. [Google Scholar] [CrossRef]

- Li, W.; Tian, X.; Liu, L.; Wang, P.; Wu, G.; Zheng, J.; Ouyang, S.; Luo, Q.; Zhang, G. High pressure induced gelatinization of red adzuki bean starch and its effects on starch physicochemical and structural properties. Food Hydrocoll. 2015, 45, 132–139. [Google Scholar] [CrossRef]

- Bajaj, R.; Singh, N.; Ghumman, A.; Kaur, A.; Mishra, H.N. Effect of High Pressure Treatment on Structural, Functional, and In-Vitro Digestibility of Starches from Tubers, Cereals, and Beans. Starch-Stärke 2022, 74, 2100096. [Google Scholar] [CrossRef]

- Wang, H.; Hu, F.; Wang, C.; Ramaswamy, H.S.; Yu, Y.; Zhu, S.; Wu, J. Effect of germination and high pressure treatments on brown rice flour rheological, pasting, textural, and structural properties. J. Food Process. Preserv. 2020, 44, e14604. [Google Scholar] [CrossRef]

- Okur, I.; Ozel, B.; Oztop, M.H.; Alpas, H. Effect of high hydrostatic pressure in physicochemical properties and in vitro digestibility of cornstarch by nuclear magnetic resonance relaxometry. J. Food Process. Eng. 2019, 42, e13168. [Google Scholar] [CrossRef]

- Kaur, M.; Oberoi, D.P.S.; Sogi, D.S.; Gill, B.S. Physicochemical, morphological and pasting properties of acid treated starches from different botanical sources. J. Food Sci. Technol. 2011, 48, 460–465. [Google Scholar] [CrossRef] [PubMed]

- Hu, X.P.; Zhang, B.; Jin, Z.Y.; Xu, X.M.; Chen, H.Q. Effect of high hydrostatic pressure and retrogradation treatments on structural and physicochemical properties of waxy wheat starch. Food Chem. 2017, 232, 560–565. [Google Scholar] [CrossRef] [PubMed]

- Zeng, F.; Li, T.; Gao, Q.; Liu, B.; Yu, S. Physicochemical properties and in vitro digestibility of high hydrostatic pressure treated waxy rice starch. Int. J. Biol. Macromol. 2018, 120, 1030–1038. [Google Scholar] [CrossRef]

- Zhi-guang, C.; Jun-rong, H.; Hua-yin, P.; Qi, Y.; Chen-lu, F. The effects of HHP (high hydrostatic pressure) on the interchain interaction and the conformation of amylopectin and double-amylose molecules. Int. J. Biol. Macromol. 2020, 155, 91–102. [Google Scholar] [CrossRef]

- Molavi, H.; Razavi, S.M.A. Steady Shear Rheological Properties of Native and Hydrothermally Modified Persian Acorn (Quercus brantii Lindle.) Starches. Starch-Stärke 2018, 70, 1700156. [Google Scholar] [CrossRef]

- Mezger, T.G. Oscillatory tests. In The Rheology Handbook; Vincentz Network: Hannover, Germany, 2020; pp. 153–247. [Google Scholar]

- Molavi, H.; Razavi, S.M.A. Dynamic Rheological and Textural Properties of Acorn (Quercus brantii Lindle.) Starch: Effect of Single and Dual Hydrothermal Modifications. Starch-Stärke 2018, 70, 1800086. [Google Scholar] [CrossRef]

- Brown, G.H.; Louderback, L.A. Identification of starch granules from oak and grass species in the central coast of California. J. Archaeol. Sci. Rep. 2020, 33, 102549. [Google Scholar] [CrossRef]

| Parameter | Commercial | P0.1/t20 | P460/t20 | R0.1/t17.4 | R333/t17.4 |

|---|---|---|---|---|---|

| <5 μm (%) | 6.4 ± 0.0 b | 9.3 ± 0.0 e | 6.2 ± 0.0 a | 8.2 ± 0.0 c | 9.0 ± 0.0 d |

| 5–10 μm (%) | 12.4 ± 0.0 a | 24.5 ± 0.1 d | 17.1 ± 0.1 b | 23.8 ± 0.0 c | 26.1 ± 0.1 e |

| 10–25 μm (%) | 79.1 ± 0.0 e | 44.0 ± 0.1 d | 37.1 ± 0.2 a | 37.9 ± 0.0 b | 39.0 ± 0.1 c |

| >25 μm (%) | 2.1 ± 0.0 a | 22.2 ± 0.2 b | 39.6 ± 0.3 e | 30.1 ± 0.1 d | 25.9 ± 0.3 c |

| Span (μm) | 0.9 ± 0.0 a | 3.7 ± 0.1 b | 13.0 ± 0.4 e | 7.2 ± 0.1 d | 6.3 ± 0.2 c |

| UD (unitless) | 0.3 ± 0.0 a | 1.4 ± 0.1 b | 3.4 ± 0.1 e | 2.4 ± 0.1 d | 2.0 ± 0.0 c |

| D3,2 (μm) | 8.7 ± 0.0 c | 8.2 ± 0.0 a | 11.3 ± 0.1 e | 9.1 ± 0.0 d | 8.6 ± 0.0 b |

| D4,3 (μm) | 14.0 ± 0.0 a | 26.8 ± 0.8 b | 73.3 ± 2.6 e | 42.3 ± 1.2 d | 34.6 ± 0.7 c |

| D10 (μm) | 8.1 ± 0.0 e | 5.2 ± 0.0 a | 6.4 ± 0.0 d | 5.5 ± 0.0 c | 5.3 ± 0.0 b |

| D50 (μm) | 14.0 ± 0.1 b | 13.3 ± 0.1 a | 18.5 ± 0.1 d | 14.2 ± 0.0 c | 13.2 ± 0.1 a |

| D90 (μm) | 20.9 ± 0.0 a | 53.8 ± 1.1 b | 246.8 ± 9.0 e | 107.3 ± 1.3 d | 87.9 ± 3.1 c |

| SSA (m2/kg) | 687.2 ± 0.2 c | 731.4 ± 1.6 e | 533.3 ± 2.2 a | 661.2 ± 0.6 b | 695.7 ± 2.4 d |

| Parameter | Commercial | P0.1/t20 | P460/t20 | R0.1/t17.4 | R333/t17.4 |

|---|---|---|---|---|---|

| Moisture (%) | 9.6 ± 0.0 a | 13.1 ± 0.3 c | 11.5 ± 0.2 b | 13.9 ± 0.1 d | 16.5 ± 0.2 e |

| Total solids (%) | 90.4 ± 0.0 e | 86.9 ± 0.3 c | 88.5 ± 0.2 d | 86.1 ± 0.1 b | 83.5 ± 0.2 a |

| Damaged starch (%) | 1.01 ± 0.03 b | 0.56 ± 0.01 a | 3.83 ± 0.07 c | 0.57 ± 0.01 a | 1.09 ± 0.08 b |

| Amylose (%) | 51.1 ± 0.1 a | 53.2 ± 0.5 b | 67.7 ± 0.0 e | 58.2 ± 0.1 c | 66.0 ± 0.0 d |

| Amylopectin (%) | 45.0 ± 0.1 e | 27.6 ± 0.5 d | 19.8 ± 0.0 b | 26.1 ± 0.1 c | 15.0 ± 0.0 a |

| Amylose/Amylopectin (unitless) | 1.14 ± 0.00 a | 1.93 ± 0.05 b | 3.41 ± 0.00 d | 2.23 ± 0.01 c | 4.40 ± 0.00 e |

| Parameter | T (°C) | Commercial | P0.1/t20 | P460/t20 | R0.1/t17.4 | R333/t17.4 |

|---|---|---|---|---|---|---|

| Solubility (%) | 50 | n.d. | n.d. | n.d. | n.d. | n.d. |

| 60 | 0.83 ± 0.07 aA | 2.36 ± 0.18 aC | 1.60 ± 0.10 aB | 1.46 ± 0.19 aB | 1.82 ± 0.18 aBC | |

| 70 | 4.71 ± 0.33 bA | 8.97 ± 0.62 bC | 6.22 ± 0.35 bB | 4.52 ± 0.13 bA | 5.07 ± 0.16 bAB | |

| 80 | 7.58 ± 0.51 cA | 11.79 ± 0.06 cD | 10.33 ± 0.24 cC | 8.79 ± 0.12 cB | 7.71 ± 0.02 cA | |

| 90 | 19.09 ± 0.08 dC | 16.16 ± 0.21 dA | 16.18 ± 0.26 dA | 17.74 ± 0.36 dB | 16.53 ± 0.40 dA | |

| 100 | 22.88 ± 0.12 eE | 17.82 ± 0.16 eB | 16.66 ± 0.09 eA | 19.71 ± 0.14 eD | 18.74 ± 0.36 eC | |

| Swelling power (g/g) | 50 | n.d. | n.d. | n.d. | n.d. | n.d. |

| 60 | 2.73 ± 0.11 aA | 6.40 ± 0.10 aB | 6.15 ± 0.02 aB | 6.53 ± 0.09 aB | 6.52 ± 0.37 aB | |

| 70 | 8.73 ± 0.04 bA | 10.10 ± 0.02 bB | 9.05 ± 0.02 bA | 8.64 ± 0.21 bA | 8.82 ± 0.11 bA | |

| 80 | 8.82 ± 0.05 bA | 12.20 ± 0.09 cC | 10.20 ± 0.34 cB | 9.99 ± 0.31 bB | 10.19 ± 0.37 cB | |

| 90 | 15.68 ± 0.07 cB | 15.71 ± 0.17 dB | 13.31 ± 0.04 dA | 15.39 ± 0.49 cB | 15.79 ± 0.23 dB | |

| 100 | 19.03 ± 0.42 cC | 16.83 ± 0.03 eB | 14.28 ± 0.26 eA | 16.75 ± 0.60 cB | 14.07 ± 0.17 eA |

| Starch Content | Commercial | P0.1/t20 | P460/t20 | R0.1/t17.4 | R333/t17.4 |

|---|---|---|---|---|---|

| RDS (g/100g SM) | 16.6 ± 0.4 c | 7.9 ± 0.5 a | 21.8 ± 0.5 d | 12.3 ± 0.8 b | 13.0 ± 1.0 b |

| SDS (g/100g SM) | 46.3 ± 1.9 d | 18.2 ± 0.4 a | 27.7 ± 1.6 b | 38.1 ± 1.9 c | 20.4 ± 1.9 a |

| TDS (g/100g SM) | 86.9 ± 0.4 d | 40.3 ± 2.9 a | 65.9 ± 3.5 c | 50.4 ± 1.2 b | 49.4 ± 2.4 ab |

| RS (g/100g SM) | 9.2 ± 0.3 a | 40.5 ± 1.4 d | 21.6 ± 0.2 b | 33.9 ± 0.1 c | 31.6 ± 1.2 c |

| TS (g/100g SM) | 96.1 ± 0.6 b | 80.8 ± 4.3 a | 87.5 ± 3.7 ab | 84.3 ± 1.1 a | 81.0 ± 1.2 a |

| Parameter | Commercial | P0.1/t20 | P460/t20 | R0.1/t17.4 | R333/t17.4 |

|---|---|---|---|---|---|

| σ | |||||

| K (Pa.sn) | 0.020 ± 0.000 a | 0.035 ± 0.001 b | 0.020 ± 0.000 a | 0.036 ± 0.004 b | 0.031 ± 0.001 b |

| n (unitless) | 0.859 ± 0.001 b | 0.782 ± 0.003 a | 0.859 ± 0.001 b | 0.780 ± 0.023 a | 0.778 ± 0.027 a |

| η* | |||||

| H (unitless) | −0.957 ± 0.004 a | −0.927 ± 0.005 b | −0.906 ± 0.007 c | −0.909 ± 0.008 c | −0.895 ± 0.004 c |

| G* (Pa) | 53.5 ± 2.6 a | 53.9 ± 5.6 a | 60.5 ± 2.3 a | 58.2 ± 5.7 a | 63.0 ± 11.8 a |

| G* | |||||

| n* (unitless) | 0.033 ± 0.002 a | 0.071 ± 0.001 b | 0.087 ± 0.001 c | 0.091 ± 0.000 c | 0.098 ± 0.001 d |

| K* (Pa.sn) | 328.5 ± 9.7 a | 360.7 ± 4.6 ab | 373.7 ± 1.9 b | 411.3 ± 9.6 c | 467.2 ± 11.3 d |

| G′ | |||||

| n′ (unitless) | 0.033 ± 0.001 a | 0.071 ± 0.001 b | 0.086 ± 0.001 c | 0.091 ± 0.000 d | 0.098 ± 0.001 e |

| K′ (Pa.sn) | 327.4 ± 9.7 a | 358.0 ± 4.7 ab | 390.7 ± 6.3 bc | 407.7 ± 9.2 c | 462.0 ± 12.0 d |

| G″ | |||||

| n″ (unitless) | 0.096 ± 0.002 a | 0.086 ± 0.008 a | 0.126 ± 0.005 b | 0.097 ± 0.003 a | 0.114 ± 0.001 b |

| K″ (Pa.sn) | 23.0 ± 1.5 a | 42.2 ± 1.3 b | 52.5 ± 2.1 c | 47.3 ± 4.4 ab | 61.1 ± 3.1 d |

| Quercus spp. | Pressure (MPa) | Time (min) | Nomenclature |

|---|---|---|---|

| Q. pyrenaica | 460 | 20.0 | P460/t20 |

| Q. robur | 333 | 17.4 | R333/t17.4 |

| Q. pyrenaica | 0.1 | 20.0 | P0.1/t20 |

| Q. robur | 0.1 | 17.4 | R0.1/t17.4 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Castro, L.M.G.; Caço, A.I.; Pereira, C.F.; Sousa, S.C.; Brassesco, M.E.; Machado, M.; Ramos, Ó.L.; Alexandre, E.M.C.; Saraiva, J.A.; Pintado, M. Modification of Acorn Starch Structure and Properties by High Hydrostatic Pressure. Gels 2023, 9, 757. https://doi.org/10.3390/gels9090757

Castro LMG, Caço AI, Pereira CF, Sousa SC, Brassesco ME, Machado M, Ramos ÓL, Alexandre EMC, Saraiva JA, Pintado M. Modification of Acorn Starch Structure and Properties by High Hydrostatic Pressure. Gels. 2023; 9(9):757. https://doi.org/10.3390/gels9090757

Chicago/Turabian StyleCastro, Luís M. G., Ana I. Caço, Carla F. Pereira, Sérgio C. Sousa, María E. Brassesco, Manuela Machado, Óscar L. Ramos, Elisabete M. C. Alexandre, Jorge A. Saraiva, and Manuela Pintado. 2023. "Modification of Acorn Starch Structure and Properties by High Hydrostatic Pressure" Gels 9, no. 9: 757. https://doi.org/10.3390/gels9090757