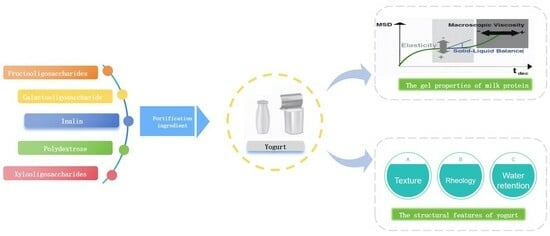

Effects of Different Prebiotics on the Gel Properties of Milk Protein and the Structural Features of Yogurt

Abstract

:1. Introduction

2. Results and Discussion

2.1. Rheological Characteristics

2.1.1. Microrheological Properties

2.1.2. Frequency Sweep

2.1.3. Amplitude Sweep

2.2. Thixotropic and Viscous Properties

2.3. Texture and Water-Retaining Properties

3. Conclusions

4. Materials and Methods

4.1. Preparation of Stirred Yogurt Samples

4.2. Microrheological Properties

4.3. Rheological Properties

4.3.1. Frequency Sweep

4.3.2. Strain Sweep

4.3.3. Apparent Viscosity

4.3.4. Thixotropy

4.4. Textural Properties

4.5. Water-Retaining Properties

4.6. Statistical Analysis

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Free-Manjarrez, S.; Mojica, L.; Espinosa-Andrews, H.; Morales-Hernández, N. Sensory and Biological Potential of Encapsulated Common Bean Protein Hydrolysates Incorporated in a Greek-Style Yogurt Matrix. Polymers 2022, 14, 854. [Google Scholar] [CrossRef]

- Prasad, L.N.; Sherkat, F.; Shah, N.P. Influence of Galactooligosaccharides and Modified Waxy Maize Starch on Some Attributes of Yogurt. J. Food Sci. 2013, 78, 77–83. [Google Scholar] [CrossRef]

- de Paulo Farias, D.; de Araujo, F.F.; Neri-Numa, I.A.; Pastore, G.M. Prebiotics: Trends in food, health and technological applications. Trends Food Sci. Technol. 2019, 93, 23–35. [Google Scholar] [CrossRef]

- Oliveira, R.P.S.; Florence, A.C.R.; Silva, R.C.; Perego, P.; Converti, A.; Gioielli, L.A.; Oliveira, M.N. Effect of different prebiotics on the fermentation kinetics, probiotic survival and fatty acids profiles in nonfat symbiotic fermented milk. Int. J. Food Microbiol. 2009, 128, 467–472. [Google Scholar] [CrossRef]

- Guggisberg, D.; Cuthbert-Steven, J.; Piccinali, P.; Bütikofer, U.; Eberhard, P. Rheological, microstructural and sensory characterization of low-fat and whole milk set yoghurt as influenced by inulin addition. Int. Dairy J. 2009, 19, 107–115. [Google Scholar] [CrossRef]

- Balthazar, C.F.; Silva, H.L.A.; Cavalcanti, R.N.; Esmerino, E.A.; Cappato, L.P.; Abud, Y.K.D.; Moraes, J.; Andrade, M.M.; Freitas, M.Q.; Sant’Anna, C.; et al. Prebiotics addition in sheep milk ice cream: A rheological, microstructural and sensory study. J. Funct. Foods 2017, 35, 564–573. [Google Scholar] [CrossRef]

- Costa, M.F.; Pimentel, T.C.; Guimaraes, J.T.; Balthazar, C.F.; Rocha, R.S.; Cavalcanti, R.N.; Esmerino, E.A.; Freitas, M.Q.; Raices, R.S.L.; Silva, M.C.; et al. Impact of prebiotics on the rheological characteristics and volatile compounds of Greek yogurt. LWT 2019, 105, 371–376. [Google Scholar] [CrossRef]

- Cruz, A.G.; Cavalcanti, R.N.; Guerreiro, L.M.R.; Sant’Ana, A.S.; Nogueira, L.C.; Oliveira, C.A.F.; Deliza, R.; Cunha, R.L.; Faria, J.A.F.; Bolini, H.M.A. Developing a prebiotic yogurt: Rheological, physico-chemical and microbiological aspects and adequacy of survival analysis methodology. J. Food Eng. 2013, 114, 323–330. [Google Scholar] [CrossRef]

- Paseephol, T.; Small, D.M.; Sherkat, F. Rheology and texture of set yogurt as affected by inulin addition. J. Texture Stud. 2008, 39, 617–634. [Google Scholar] [CrossRef]

- Srisuvor, N.; Chinprahast, N.; Prakitchaiwattana, C.; Subhimaros, S. Effects of inulin and polydextrose on physicochemical and sensory properties of low-fat set yoghurt with probiotic-cultured banana puree. LWT 2013, 51, 30–36. [Google Scholar] [CrossRef]

- Debon, J.; Prudencio, E.S.; Petrus, J.C.C. Rheological and physico-chemical characterization of prebiotic microfiltered fermented milk. J. Food Eng. 2010, 99, 128–135. [Google Scholar] [CrossRef]

- Titapiccolo, G.I.; Corredig, M.; Alexander, M. Acid coagulation behavior of homogenized milk: Effect of interacting and non-interacting droplets observed by rheology and diffusing wave spectroscopy. Dairy Sci. Technol. 2011, 91, 185–201. [Google Scholar] [CrossRef]

- He, J.; Han, Y.; Liu, M.; Wang, Y.; Yang, Y.; Yang, X. Effect of 2 types of resistant starches on the quality of yogurt. J. Dairy Sci. 2019, 102, 3956–3964. [Google Scholar] [CrossRef] [PubMed]

- Bai, M.; Huang, T.; Guo, S.; Wang, Y.; Wang, J.; Kwok, L.; Dan, T.; Zhang, H.; Bilige, M. Probiotic Lactobacillus casei Zhang improved the properties of stirred yogurt. Food Biosci. 2020, 37, 100718. [Google Scholar] [CrossRef]

- Surber, G.; Mende, S.; Jaros, D.; Rohm, H. Clustering of Streptococcus thermophilus Strains to Establish a Relation between Exopolysaccharide Characteristics and Gel Properties of Acidified Milk. Foods 2019, 8, 146. [Google Scholar] [CrossRef]

- Zbikowska, A.; Szymanska, I.; Kowalska, M. Impact of Inulin Addition on Properties of Natural Yogurt. Appl. Sci. 2020, 10, 4317. [Google Scholar] [CrossRef]

- Rohart, A.; Michon, C.; Confiac, J.; Bosc, V. Evaluation of ready-to-use SMLS and DWS devices to study acid-induced milk gel changes and syneresis. Dairy Sci. Technol. 2016, 96, 459–475. [Google Scholar] [CrossRef]

- Zhihua, P.; Hilton, D.; Sangeeta, P.; Nidhi, B. Development of rheological and sensory properties of combinations of milk proteins and gelling polysaccharides as potential gelatin replacements in the manufacture of stirred acid milk gels and yogurt. J. Food Eng. 2016, 169, 27–37. [Google Scholar] [CrossRef]

- Heydari, S.; Mortazavian, A.M.; Ehsani, M.R.; Mohammadifar, M.A.; Ezzatpanah, H. Biochemical, microbiological and sensory characteristics of probiotic yogurt containing various prebiotic compounds. Ital. J. Food Sci. 2011, 23, 153–163. [Google Scholar] [CrossRef]

- Gomes, E.R.; Carneiro, L.C.M.; Stephani, R.; de Carvalho, A.F.; Renhe, I.R.T.; Wolfschoon-Pombo, A.F.; Perrone, I.T. Effect of sugar reduction and addition of corn fibre and polydextrose on pore size and syneresis of yoghurt. Int. Dairy J. 2022, 129, 105298. [Google Scholar] [CrossRef]

- Miocinovic, J.; Miloradovic, Z.; Josipovic, M.; Nedeljkovic, A.; Pudja, P. Rheological and textural properties of goat and cow milk set type yoghurts. Int. Dairy J. 2016, 58, 43–45. [Google Scholar] [CrossRef]

- Rosa, M.C.; Carmo, M.R.S.; Balthazar, C.F.; Guimaraes, J.T.; Esmerino, E.A.; Freitas, M.Q.; Silva, M.C.; Pimentel, T.C.; Cruz, A.G. Dairy products with prebiotics: An overview of the health benefits, technological and sensory properties. Int. Dairy J. 2021, 117, 105009. [Google Scholar] [CrossRef]

- Kieserling, K.; Vu, T.M.; Drusch, S.; Schalow, S. Impact of pectin-rich orange fibre on gel characteristics and sensory properties in lactic acid fermented yoghurt. Food Hydrocoll. 2019, 94, 152–163. [Google Scholar] [CrossRef]

- Samakradhamrongthai, R.S.; Jannu, T.; Supawan, T.; Khawsud, A.; Aumpa, P.; Renaldi, G. Inulin application on the optimization of reduced-fat ice cream using response surface methodology. Food Hydrocoll. 2021, 119, 106873. [Google Scholar] [CrossRef]

- Gonzalez-Tomas, L.; Coll-Marques, J.; Costell, E. Viscoelasticity of inulin-starch-based dairy systems. Influence of inulin average chain length. Food Hydrocoll. 2008, 22, 1372–1380. [Google Scholar] [CrossRef]

- Gregersen, S.B.; Glover, Z.J.; Wiking, L.; Simonsen, A.C.; Bertelsen, K.; Pedersen, B.; Poulsen, K.R.; Andersen, U.; Hammershj, M. Microstructure and rheology of acid milk gels and stirred yoghurts –quantification of process-induced changes by auto- and cross correlation image analysis. Food Hydrocoll. 2021, 111, 106269. [Google Scholar] [CrossRef]

- Guénard-Lampron, V.; Bosc, V.; St-Gelais, D.; Villeneuve, S.; Turgeon, S.L. How do smoothing conditions and storage time change syneresis, rheological and microstructural properties of nonfat stirred acid milk gel? Int. Dairy J. 2020, 109, 104780. [Google Scholar] [CrossRef]

- Hahn, C.; Nobel, S.; Maisch, R.; Rosingh, W.; Weiss, J.; Hinrichs, J. Adjusting rheological properties of concentrated microgel suspensions by particle size distribution. Food Hydrocoll. 2015, 49, 183–191. [Google Scholar] [CrossRef]

- Vargas, M.; Chafer, M.; Albors, A.; Chiralt, A.; Gonzalez-Martinez, C. Physicochemical and sensory characteristics of yoghurt produced from mixtures of cows’ and goats’ milk. Int. Dairy J. 2008, 18, 1146–1152. [Google Scholar] [CrossRef]

- Mudgil, P.; Jumah, B.; Ahmad, M.; Hamed, F.; Maqsood, S. Rheological, micro-structural and sensorial properties of camel milk yogurt as influenced by gelatin. LWT 2018, 98, 646–653. [Google Scholar] [CrossRef]

- Huang, T.; Tu, Z.; Shangguan, X.; Wang, H.; Zhang, L.; Bansal, N. Characteristics of fish gelatin-anionic polysaccharide complexes and their applications in yoghurt: Rheology and tribology. Food Chem. 2021, 343, 128413. [Google Scholar] [CrossRef] [PubMed]

- Dias, S.S.; de Souza Vergilio, D.; Pereira, A.M.; Klososki, S.J.; Marcolino, V.A.; Cruz, R.M.S.D.; Costa, G.N.; Barao, C.E.; Pimentel, T.C. Probiotic Greek yogurt: Effect of the addition of prebiotic fat substitutes on the physicochemical characteristics, probiotic survival, and sensory acceptance. J. Dairy Res. 2021, 88, 98–104. [Google Scholar] [CrossRef] [PubMed]

- Niyigaba, T.; Liu, D.; de Dieu Habimana, J. The Extraction, Functionalities and Applications of Plant Polysaccharides in Fermented Foods: A Review. Foods 2021, 10, 3004. [Google Scholar] [CrossRef] [PubMed]

- Gomes, E.R.; Pinto, C.B.D.A.; Stephani, R.; de Carvalho, A.F.; Perrone, I.T. Effect of adding different types of soluble fibre to high-protein yoghurts on water holding capacity, particle size distribution, apparent viscosity, and microstructure. Int. Dairy J. 2023, 141, 105609. [Google Scholar] [CrossRef]

- Bisar, G.H.; El-Saadany, K.; Khattab, A.; El-Kholy, W.M. Implementing Maltodextrin, Polydextrose and Inulin in Making a Synbiotic Fermented Dairy Product. Microbiol. Res. J. Int. 2015, 8, 585–603. [Google Scholar] [CrossRef]

- Alina, K.; Maja, T.; Ehrhard, K.; Mechthild, B.; Jochen, W. Relating Creamy Perception of Whey Protein Enriched Yogurt Systems to Instrumental Data by Means of Multivariate Data Analysis. J. Food Sci. 2013, 78, 314–319. [Google Scholar] [CrossRef]

| Groups | Critical Strain γc (%) | Gc′ (Pa) | Gc″ (Pa) |

|---|---|---|---|

| NT | 7.75 ± 0.53 ab | 18.68 ± 1.55 b | 5.36 ± 0.33 b |

| GOS | 7.40 ± 0.54 b | 23.65 ± 1.60 a | 6.89 ± 0.68 a |

| FOS | 7.31 ± 0.30 b | 24.57 ± 2.03 a | 7.02 ± 0.75 a |

| XOS | 8.22 ± 0.34 a | 23.14 ± 2.88 a | 6.49 ± 0.81 a |

| INU | 8.35 ± 0.34 a | 24.55 ± 2.28 a | 7.04 ± 0.56 a |

| PDX | 8.21 ± 0.10 a | 22.06 ± 0.43 ab | 6.33 ± 0.26 ab |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, D.; Lai, M.; Wang, P.; Ma, H.; Li, H.; Wang, R.; Wu, X. Effects of Different Prebiotics on the Gel Properties of Milk Protein and the Structural Features of Yogurt. Gels 2023, 9, 863. https://doi.org/10.3390/gels9110863

Li D, Lai M, Wang P, Ma H, Li H, Wang R, Wu X. Effects of Different Prebiotics on the Gel Properties of Milk Protein and the Structural Features of Yogurt. Gels. 2023; 9(11):863. https://doi.org/10.3390/gels9110863

Chicago/Turabian StyleLi, Dongdong, Mengxuan Lai, Pengjie Wang, Hairan Ma, Hongliang Li, Ran Wang, and Xiuying Wu. 2023. "Effects of Different Prebiotics on the Gel Properties of Milk Protein and the Structural Features of Yogurt" Gels 9, no. 11: 863. https://doi.org/10.3390/gels9110863