Force-Controlled Biomechanical Simulation of Orthodontic Tooth Movement with Torque Archwires Using HOSEA (Hexapod for Orthodontic Simulation, Evaluation and Analysis)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomechanical Simulation System

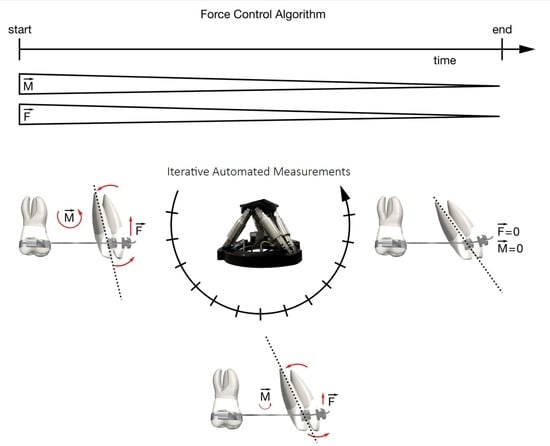

2.2. Measurements and Biomechanical Simulation of Tooth Movement

2.3. Statistical Analysis

3. Results

4. Discussion

- The 0.017″ x 0.025″ archwires in combination with 0.022″ slot brackets produced forces and moments that were too low to achieve adequate palatal incisor root torque, regardless of material group. Therefore, the use of 0.018″ x 0.025″ archwires with 30° torque bends (SS) or 45° torque bends (TSA) are recommended for clinical use.

- Although higher initial moments (My) were measured for the 0.018″ x 0.025″ SS archwires, the 0.018″ x 0.025″ TSA archwires exhibited a lower moment reduction rate, indicating a reduced need for reactivation and appearing to be more suitable for applying more constant rotational moments. Due to collateral effects such as extrusive forces occurring during torque expression, the application of compensatory vertical bends should be considered.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Burstone, C.J.; Pryputniewicz, R.J. Holographic determination of centers of rotation produced by orthodontic forces. Am. J. Orthod. 1980, 77, 396–409. [Google Scholar] [CrossRef] [PubMed]

- Pedersen, E.; Isidor, F.; Gjessing, P.; Andersen, K. Location of centres of resistance for maxillary anterior teeth measured on human autopsy material. Eur. J. Orthod. 1991, 13, 452–458. [Google Scholar] [CrossRef] [PubMed]

- Kojima, Y.; Fukui, H. Numerical simulations of canine retraction with T-loop springs based on the updated moment-to-force ratio. Eur. J. Orthod. 2010, 34, 10–18. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.; Zhou, H.; Liao, X.; Liu, Y. The influence of bracket torque on external apical root resorption in bimaxillary protrusion patients: A retrospective study. BMC Oral. Health 2022, 22, 7. [Google Scholar] [CrossRef]

- Nakano, T.; Hotokezaka, H.; Hashimoto, M.; Sirisoontorn, I.; Arita, K.; Kurohama, T.; Darendeliler, M.A.; Yoshida, N. Effects of different types of tooth movement and force magnitudes on the amount of tooth movement and root resorption in rats. Angle Orthod. 2014, 84, 1079–1085. [Google Scholar] [CrossRef] [PubMed]

- Pandis, N.; Walsh, T.; Polychronopoulou, A.; Katsaros, C.; Eliades, T. Factorial designs: An overview with applications to orthodontic clinical trials. Eur. J. Orthod. 2014, 36, 314–320. [Google Scholar] [CrossRef] [PubMed]

- Wichelhaus, A.; Dulla, M.; Sabbagh, H.; Baumert, U.; Stocker, T. Stainless steel and NiTi torque archwires and apical root resorption. J. Orofac. Orthop. = Fortschritte Kieferorthopadie Organ/Off. J. Dtsch. Ges. Kieferorthopadie 2021, 82, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Cai, Y. Finite element analysis of archwire parameters and activation forces on the M/F ratio of vertical, L- and T-loops. BMC Oral Health 2020, 20, 70. [Google Scholar] [CrossRef] [PubMed]

- Burstone, C.J.; Koenig, H.A. Optimizing anterior and canine retraction. Am. J. Orthod. 1976, 70, 1–19. [Google Scholar] [CrossRef] [PubMed]

- Badawi, H.M.; Toogood, R.W.; Carey, J.P.; Heo, G.; Major, P.W. Three-dimensional orthodontic force measurements. Am. J. Orthod. Dentofac. Orthop. 2009, 136, 518–528. [Google Scholar] [CrossRef] [PubMed]

- Tominaga, J.Y.; Tanaka, M.; Koga, Y.; Gonzales, C.; Kobayashi, M.; Yoshida, N. Optimal loading conditions for controlled movement of anterior teeth in sliding mechanics. Angle Orthod. 2009, 79, 1102–1107. [Google Scholar] [CrossRef] [PubMed]

- Kojima, Y.; Fukui, H. Numeric simulations of en-masse space closure with sliding mechanics. Am. J. Orthod. Dentofac. Orthop. 2010, 138, e701–e706. [Google Scholar] [CrossRef] [PubMed]

- Stokes, I.A.; Chegini, S.; Ferguson, S.J.; Gardner-Morse, M.G.; Iatridis, J.C.; Laible, J.P. Limitation of finite element analysis of poroelastic behavior of biological tissues undergoing rapid loading. Ann. Biomed. Eng. 2010, 38, 1780–1788. [Google Scholar] [CrossRef] [PubMed]

- Singh, J.R.; Kambalyal, P.; Jain, M.; Khandelwal, P. Revolution in Orthodontics: Finite element analysis. J. Int. Soc. Prev. Community Dent. 2016, 6, 110–114. [Google Scholar] [CrossRef] [PubMed]

- Arreghini, A.; Lombardo, L.; Mollica, F.; Siciliani, G. Torque expression capacity of 0.018 and 0.022 bracket slots by changing archwire material and cross section. Prog. Orthod. 2014, 15, 53. [Google Scholar] [CrossRef] [PubMed]

- Hodecker, L.; Bourauel, C.; Braumann, B.; Kruse, T.; Christ, H.; Scharf, S. Sliding behaviour and surface quality after static air polishing of conventional and modern bracket materials: In vitro analysis. J. Orofac. Orthop. 2023, 84, 110–124. [Google Scholar] [CrossRef] [PubMed]

- Stocker, T.; Li, H.; Bamidis, E.P.; Baumert, U.; Hoffmann, L.; Wichelhaus, A.; Sabbagh, H. Influence of normal forces on the frictional behavior in tribological systems made of different bracket types and wire dimensions. Dent. Mater. J. 2022, 41, 402–413. [Google Scholar] [CrossRef]

- Chen, J.; Isikbay, S.C.; Brizendine, E.J. Quantification of three-dimensional orthodontic force systems of T-loop archwires. Angle Orthod. 2010, 80, 566–570. [Google Scholar] [CrossRef]

- McKnight, M.M.; Jones, S.P.; Davies, E.H. A study to compare the effects of simulated torquing forces on pre-adjusted orthodontic brackets. Br. J. Orthod. 1994, 21, 359–365. [Google Scholar] [CrossRef] [PubMed]

- Drescher, D.; Bourauel, C.; Thier, M. Application of the orthodontic measurement and simulation system (OMSS) in orthodontics. Eur. J. Orthod. 1991, 13, 169–178. [Google Scholar] [CrossRef]

- Morina, E.; Eliades, T.; Pandis, N.; Jäger, A.; Bourauel, C. Torque expression of self-ligating brackets compared with conventional metallic, ceramic, and plastic brackets. Eur. J. Orthod. 2008, 30, 233–238. [Google Scholar] [CrossRef] [PubMed]

- Hülsmann, M. Endodontie; Georg Thieme: New York, NY, USA, 2008. [Google Scholar]

- Cignoni, P.; Callieri, M.; Corsini, M.; Dellepiane, M.; Ganovelli, F.; Ranzuglia, G. Meshlab: An open-source mesh processing tool. In Proceedings of the Eurographics Italian Chapter Conference 2008, Salerno, Italy, 2–4 July 2008; pp. 129–136. [Google Scholar]

- Andrews, L.F. The straight-wire appliance. Br. J. Orthod. 1979, 6, 125–143. [Google Scholar] [CrossRef]

- Bantleon, H.P.; Droschl, H. Front torque using a partial arch technic. Fortschr. Kieferorthop. 1988, 49, 203–212. [Google Scholar] [CrossRef]

- Gmyrek, H.; Bourauel, C.; Richter, G.; Harzer, W. Torque capacity of metal and plastic brackets with reference to materials, application, technology and biomechanics. J. Orofac. Orthop./Fortschritte Kieferorthopädie 2002, 63, 113–128. [Google Scholar] [CrossRef] [PubMed]

- Hirai, M.; Nakajima, A.; Kawai, N.; Tanaka, E.; Igarashi, Y.; Sakaguchi, M.; Sameshima, G.T.; Shimizu, N. Measurements of the torque moment in various archwire-bracket-ligation combinations. Eur. J. Orthod. 2012, 34, 374–380. [Google Scholar] [CrossRef] [PubMed]

- Kusy, R.P.; Whitley, J.Q. Influence of archwire and bracket dimensions on sliding mechanics: Derivations and determinations of the critical contact angles for binding. Eur. J. Orthod. 1999, 21, 199–208. [Google Scholar] [CrossRef]

- Cash, A.; Good, S.; Curtis, R.; McDonald, F. An evaluation of slot size in orthodontic brackets—Are standards as expected? Angle Orthod. 2004, 74, 450–453. [Google Scholar]

- Joch, A.; Pichelmayer, M.; Weiland, F. Bracket slot and archwire dimensions: Manufacturing precision and third order clearance. J. Orthod. 2010, 37, 241–249. [Google Scholar] [CrossRef] [PubMed]

- Dalstra, M.; Eriksen, H.; Bergamini, C.; Melsen, B. Actual versus theoretical torsional play in conventional and self-ligating bracket systems. J. Orthod. 2015, 42, 103–113. [Google Scholar] [CrossRef] [PubMed]

- Archambault, A.; Lacoursiere, R.; Badawi, H.; Major, P.W.; Carey, J.; Flores-Mir, C. Torque expression in stainless steel orthodontic brackets. A systematic review. Angle Orthod. 2010, 80, 201–210. [Google Scholar] [CrossRef] [PubMed]

- Garrec, P.; Jordan, L. Stiffness in bending of a superelastic Ni-Ti orthodontic wire as a function of cross-sectional dimension. Angle Orthod. 2004, 74, 691–696. [Google Scholar] [CrossRef] [PubMed]

- Miura, F.; Mogi, M.; Ohura, Y.; Hamanaka, H. The super-elastic property of the Japanese NiTi alloy wire for use in orthodontics. Am. J. Orthod. Dentofac. Orthop. 1986, 90, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Wichelhaus, A.; Sander, F.G. [Biomechanical testing of the new torque-segmented arch (TSA)]. Fortschr. Kieferorthop. 1995, 56, 224–235. [Google Scholar] [CrossRef] [PubMed]

- Schmidt, F.; Geiger, M.E.; Jäger, R.; Lapatki, B.G. Comparison of methods to determine the centre of resistance of teeth. Comput. Methods Biomech. Biomed. Eng. 2016, 19, 1673–1682. [Google Scholar] [CrossRef] [PubMed]

- Reimann, S.; Keilig, L.; Jager, A.; Bourauel, C. Biomechanical finite-element investigation of the position of the centre of resistance of the upper incisors. Eur. J. Orthod. 2007, 29, 219–224. [Google Scholar] [CrossRef] [PubMed]

- Vanden Bulcke, M.M.; Burstone, C.J.; Sachdeva, R.C.; Dermaut, L.R. Location of the centers of resistance for anterior teeth during retraction using the laser reflection technique. Am. J. Orthod. Dentofac. Orthop. 1987, 91, 375–384. [Google Scholar] [CrossRef] [PubMed]

- George, S.S.; Reddy, T.R.J.; Kv, S.K.; Chaudhary, G.; Farooq, U.; Cherukuri, V.; Likitha, C. The Influence of Heights of Power Arm for Controlled Anterior Teeth Movement in Sliding Mechanics: A 3D FEM Study. Cureus 2022, 14, e25976. [Google Scholar] [CrossRef] [PubMed]

- Liu, Y.F.; Zhang, P.Y.; Zhang, Q.F.; Zhang, J.X.; Chen, J. Digital design and fabrication of simulation model for measuring orthodontic force. Biomed. Mater. Eng. 2014, 24, 2265–2271. [Google Scholar] [CrossRef] [PubMed]

| Archwire Material | Material Identification | Applied Torque | Sample Size | Archwire Size |

|---|---|---|---|---|

| Stainless steel | X10CrNi 18-8 | 30° | 10 | 0.017″ x 0.025″ |

| Stainless steel | X10CrNi 18-8 | 30° | 10 | 0.018″ x 0.025″ |

| Torque-segmented archwire | X5CrNi 18-10 Nickel Titanium | 30° | 10 | 0.017″ x 0.025″ |

| Torque-segmented archwire | X5CrNi 18-10 | 45° | 10 | 0.018″ x 0.025″ |

| Nickel Titanium |

| Archwire Category | Torque Bending | My (Nmm) (SD) | My (Nmm) (SD) | My (Nmm) (SD) | My (Nmm) (SD) |

|---|---|---|---|---|---|

| Ry = 1° | Ry = 2.5° | Ry = 5° | Ry = 10° | ||

| 0.018″ x 0.025″ TSA No. of samples | 45° | 8.468 (1.330) 10 | −8.207 (1.372) 10 | −7.297 (1.576) 10 | −3.927 (3.753) 10 |

| 0.018″ x 0.025″ SS No. of samples | 30° | −9.835 (1.701) 10 | −8.604 (1.563) 10 | −6.393 (1.414) 10 | −2.579 (0.916) 4 |

| 0.017″ x 0.025″ SS No. of samples | 30° | −4.914 (1.648) 10 | −4.004 (1.547) 10 | −3.571 (0.664) 5 | - |

| 0.017″ x 0.025″ TSA No. of samples | 30° | −2.284 (0.906) 10 | −1.903 (0.879) 8 | 0.022 (0.022) 3 | - |

| Archwire Category | Torque Bending | My/Ry (Nmm/°) | SD | p |

|---|---|---|---|---|

| 0.018″ x 0.025″ TSA | 45° | −0.405 | 0.045 | <0.001 |

| 0.018″ x 0.025″ SS | 30° | −0.898 | 0.108 | |

| 0.017″ x 0.025″ TSA | 30° | −0.396 | 0.083 | 0.006 |

| 0.017″ x 0.025″ SS | 30° | −0.717 | 0.136 |

| Archwire Category | Torque Bending | Fx (N) (SD) | Fy (N) (SD) | Fz (N) (SD) | Mx (Nmm) (SD) | My (Nmm) (SD) | Mz (Nmm) (SD) | |

|---|---|---|---|---|---|---|---|---|

| a | 0.017″ x 0.025″ SS | 30° | −0.399 (0.133) bc | −0.195 (0.189) cd | −0.083 (0.092) bd | 2.099 (2.037) c | −4.914 (1.648) b | 0.018 (0.086) d |

| b | 0.018″ x 0.025″ SS | 30° | −0.788 (0.159) ac | −0.193 (0.260) | −0.300 (0.089) a | 2.104 (2.723) | −9.835 (1.701) ac | −0.079 (0.173) |

| c | 0.017″ x 0.025″ TSA | 30° | −0.150 (0.055) abd | 0.070 (0.100) ad | −0.113 (0.069) abd | −0.586 (1.189) a | −2.284 (0.906) bd | −0.070 (0.194) |

| d | 0.018″ x 0.025″ TSA | 45° | −0.457 (0.160) c | 0.078 (0.156) ac | −0.325 (0.081) ac | 0.051 (1.664) | −8.468 (1.330) c | −0.886 (0.881) a |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Haas, E.; Schmid, A.; Stocker, T.; Wichelhaus, A.; Sabbagh, H. Force-Controlled Biomechanical Simulation of Orthodontic Tooth Movement with Torque Archwires Using HOSEA (Hexapod for Orthodontic Simulation, Evaluation and Analysis). Bioengineering 2023, 10, 1055. https://doi.org/10.3390/bioengineering10091055

Haas E, Schmid A, Stocker T, Wichelhaus A, Sabbagh H. Force-Controlled Biomechanical Simulation of Orthodontic Tooth Movement with Torque Archwires Using HOSEA (Hexapod for Orthodontic Simulation, Evaluation and Analysis). Bioengineering. 2023; 10(9):1055. https://doi.org/10.3390/bioengineering10091055

Chicago/Turabian StyleHaas, Ellen, Andreas Schmid, Thomas Stocker, Andrea Wichelhaus, and Hisham Sabbagh. 2023. "Force-Controlled Biomechanical Simulation of Orthodontic Tooth Movement with Torque Archwires Using HOSEA (Hexapod for Orthodontic Simulation, Evaluation and Analysis)" Bioengineering 10, no. 9: 1055. https://doi.org/10.3390/bioengineering10091055