Influence of Cold Pre-Fermentation Maceration on the Volatilomic Pattern and Aroma of White Wines

Abstract

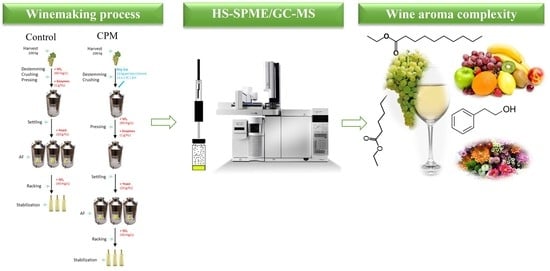

:1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

2.2. White Wines

2.3. Oenological Parameters

2.4. HS-SPME Procedure

2.5. GC-MS Conditions

2.6. Data Treatment and Multivariate Statistical Analysis

3. Results and Discussions

3.1. Physicochemical Parameters

3.2. Volatile Aroma of White Wines Using HS-SPME/GC-MS Methodology

3.3. Multivariate Statistical Analysis

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Moreno-Pérez, A.; Vila-López, R.; Fernández-Fernández, J.I.; Martínez-Cutillas, A.; Gil-Muñoz, R. Influence of cold pre-fermentation treatments on the major volatile compounds of three wine varieties. Food Chem. 2013, 139, 770–776. [Google Scholar] [CrossRef] [PubMed]

- Korenika, A.-M.J.; Maslov, L.; Jakobović, S.; Palčić, I.; Jeromel, A. Comparative study of aromatic and polyphenolic profiles of Croatian white wines produced by cold maceration. Czech J. Food Sci. 2018, 36, 459–469. [Google Scholar] [CrossRef] [Green Version]

- Luan, Y.; Zhang, B.Q.; Duan, C.Q.; Yan, G.L. Effects of Different Pre-Fermentation Cold Maceration Time on Aroma Com-pounds of Saccharomyces cerevisiae Co-Fermentation with Hanseniaspora opuntiae or Pichia kudriavzevii. LWT 2018, 92, 177–186. [Google Scholar] [CrossRef]

- Cai, J.; Zhu, B.-Q.; Wang, Y.-H.; Lu, L.; Lan, Y.-B.; Reeves, M.J.; Duan, C.-Q. Influence of pre-fermentation cold maceration treatment on aroma compounds of Cabernet Sauvignon wines fermented in different industrial scale fermenters. Food Chem. 2014, 154, 217–229. [Google Scholar] [CrossRef] [PubMed]

- Peng, C.-T.; Wen, Y.; Tao, Y.-S.; Lan, Y.-Y. Modulating the Formation of Meili Wine Aroma by Prefermentative Freezing Process. J. Agric. Food Chem. 2013, 61, 1542–1553. [Google Scholar] [CrossRef]

- Petrozziello, M.; Guaita, M.; Motta, S.; Panero, L.; Bosso, A. Analytical and Sensory Characterization of the Aroma of “Langhe D.O.C. Nebbiolo” Wines: Influence of the Prefermentative Cold Maceration with Dry Ice. J. Food Sci. 2011, 76, C525–C534. [Google Scholar] [CrossRef]

- Lukić, I.; Budić-Leto, I.; Bubola, M.; Damijanić, K.; Staver, M. Pre-fermentative cold maceration, saignée, and various thermal treatments as options for modulating volatile aroma and phenol profiles of red wine. Food Chem. 2017, 224, 251–261. [Google Scholar] [CrossRef]

- Aleixandre-Tudo, J.L.; du Toit, W. Cold Maceration Application in Red Wine Production and Its Effects on Phenolic Com-pounds: A Review. LWT 2018, 95, 200–208. [Google Scholar] [CrossRef]

- Alencar, N.M.M.; Cazarin, C.B.B.; Corrêa, L.C.; Junior, M.R.M.; Biasoto, A.C.T.; Behrens, J.H. Influence of Maceration Time on Phenolic Compounds and Antioxidant Activity of the Syrah Must and Wine. J. Food Biochem. 2018, 42, e12471. [Google Scholar] [CrossRef]

- Carbonell-Bejerano, P.; Royo, C.; Torres-Pérez, R.; Grimplet, J.; Fernandez, L.; Franco-Zorrilla, J.M.; Lijavetzky, D.; Baroja, E.; Martínez, J.; García-Escudero, E.; et al. Catastrophic Unbalanced Genome Rearrangements Cause Somatic Loss of Berry Color in Grapevine. Plant Physiol. 2017, 175, 786–801. [Google Scholar] [CrossRef] [Green Version]

- Regulatory Council of the Rioja Qualified Designation of Origin. Grape Varieties. Available online: https://www.riojawine.com/en/home-en (accessed on 19 October 2022).

- OIV Compendium of International Methods of Analysis of Wine and Musts. Organization Internationale de La Vigne et Du Vin, Paris. Available online: https://www.oiv.int/en/technical-standards-and-documents/methods-of-analysis/compendium-of-international-methods-of-analysis-of-wines-and-musts (accessed on 14 October 2022).

- Ribéreau-Gayon, P.; Glories, Y.; Maujean, A.; Dubourdieu, D. Handbook of Enology, The Chemistry of Wine: Stabilization and Treatments, 2nd ed.; John Wiley & Sons, Ltd: Chichester, UK, 2006; Volume 2, ISBN 9780470010396. [Google Scholar]

- Gabriela, D.M. Phytochemical screening, total hydroxycinnamic acids, total phenolic and antioxidant activity of Lavandula angustifolia Mill. GSC Biol. Pharm. Sci. 2020, 10, 01–08. [Google Scholar] [CrossRef]

- Perestrelo, R.; Barros, A.S.; Câmara, J.S.; Rocha, S.M. In-Depth Dearch Focused on Furans, Lactones, Volatile Phenols, and Acetals as Potentialage Markers of Madeira Wines by Comprehensive Two-Dimensional Gas Chromatography with Time-of-Flight Mass Spectrometry Combined with Solid Phase Microextraction. J. Agric. Food Chem. 2011, 59, 3186–3204. [Google Scholar] [CrossRef] [Green Version]

- Spínola, V.; Perestrelo, R.; Câmara, J.S.; Castilho, P.C. Establishment of Monstera deliciosa fruit volatile metabolomic profile at different ripening stages using solid-phase microextraction combined with gas chromatography–mass spectrometry. Food Res. Int. 2015, 67, 409–417. [Google Scholar] [CrossRef]

- Acree, T.; Arn, H. Flavornet Home Page. Available online: http://www.flavornet.org (accessed on 14 February 2019).

- El-Sayed, A.M. The Pherobase: Database of Insect Pheromones and Semiochemicals. Available online: http://www.pherobase.com (accessed on 19 October 2022).

- Pang, Z.; Chong, J.; Zhou, G.; de Lima Morais, D.A.; Chang, L.; Barrette, M.; Gauthier, C.; Jacques, P.-É.; Li, S.; Xia, J. MetaboAnalyst 5.0: Narrowing the gap between raw spectra and functional insights. Nucleic Acids Res. 2021, 49, W388–W396. [Google Scholar] [CrossRef] [PubMed]

- García, J.M.; Diago, A.G.; Hernández, E.B.; Domínguez, E.G.-E. Características agronómicas y potencial enológico de las variedades de vid blancas autorizadas en la D.O.Ca Rioja. Zubía. 2017; Volume 29, pp. 67–82. Available online: https://dialnet.unirioja.es/servlet/articulo?codigo=6337784&info=resumen&idioma=SPA (accessed on 30 January 2023).

- Campo, E.; Ferreira, V.; Escudero, A.; Marques, J.C.; Cacho, J. Quantitative gas chromatography–olfactometry and chemical quantitative study of the aroma of four Madeira wines. Anal. Chim. Acta 2006, 563, 180–187. [Google Scholar] [CrossRef]

- Jiang, B.; Zhang, Z. Volatile Compounds of Young Wines from Cabernet Sauvignon, Cabernet Gernischet and Chardonnay Varieties Grown in the Loess Plateau Region of China. Molecules 2010, 15, 9184–9196. [Google Scholar] [CrossRef] [Green Version]

- Ferreira, V.; López, R.; Cacho, J. Quantitative Determination of the Odorants of Young Red Wines from Different Grape Varieties. J. Sci. Food Agric. 2000, 80, 1659–1667. [Google Scholar] [CrossRef]

- Moreno, J.A.; Zea, L.; Moyano, L.; Medina, M. Aroma Compounds as Markers of the Changes in Sherry Wines Subjected to Biological Ageing. Food Control. 2005, 16, 333–338. [Google Scholar] [CrossRef]

- Peinado, R.A.; Moreno, J.A.; Muñoz, D.; Medina, M.; Moreno, J. Gas Chromatographic Quantification of Major Volatile Compounds and Polyols in Wine by Direct Injection. J. Agric. Food Chem. 2004, 52, 6389–6393. [Google Scholar] [CrossRef]

- Arn, H.; Acree, T. Flavornet: A database of aroma compounds based on odor potency in natural products. In Developments in Food Science; Elsevier: Amsterdam, The Netherlands, 1998; Volume 40, p. 27. [Google Scholar] [CrossRef]

- Moreno-Arribas, M.V.; Polo, M.C. Winemaking Biochemistry and Microbiology: Current Knowledge and Future Trends. Crit. Rev. Food Sci. Nutr. 2005, 45, 265–286. [Google Scholar] [CrossRef]

- Olejar, K.J.; Fedrizzi, B.; Kilmartin, P.A. Influence of harvesting technique and maceration process on aroma and phenolic attributes of Sauvignon blanc wine. Food Chem. 2015, 183, 181–189. [Google Scholar] [CrossRef] [PubMed]

- Malićanin, M.; Danilović, B.; Stojanović, S.S.; Cvetković, D.; Lazić, M.; Karabegović, I.; Savić, D. Pre-Fermentative Cold Mac-eration and Native Non-Saccharomyces Yeasts as a Tool to Enhance Aroma and Sensory Attributes of Chardonnay Wine. Horticulturae 2022, 8, 212. [Google Scholar] [CrossRef]

- Zhang, S.; Petersen, M.A.; Liu, J.; Toldam-Andersen, T.B. Influence of Pre-Fermentation Treatments on Wine Volatile and Sensory Profile of the New Disease Tolerant Cultivar Solaris. Molecules 2015, 20, 21609–21625. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Viana, F.; Gil, J.V.; Vallés, S.; Manzanares, P. Increasing the levels of 2-phenylethyl acetate in wine through the use of a mixed culture of Hanseniaspora osmophila and Saccharomyces cerevisiae. Int. J. Food Microbiol. 2009, 135, 68–74. [Google Scholar] [CrossRef]

- Naranjo, A.; Martínez-Lapuente, L.; Ayestarán, B.; Guadalupe, Z.; Pérez, I.; Canals, C.; Adell, E. Aromatic and Sensory Char-acterization of Maturana Blanca Wines Made with Different Technologies. Beverages 2021, 7, 10. [Google Scholar] [CrossRef]

- Yilmaztekin, M.; Kocabey, N.; Hayaloglu, A.A. Effect of Maceration Time on Free and Bound Volatiles of Red Wines from cv. Karaoğlan (Vitis vinifera L.) Grapes Grown in Arapgir, Turkey. J. Food Sci. 2015, 80, C556–C563. [Google Scholar] [CrossRef]

- Qin, L.; Wei, Q.P.; Kang, W.H.; Zhang, Q.; Sun, J.; Liu, S.Z. Comparison of Volatile Compounds in “Fuji” Apples in the Different Regions in China. Food Sci. Technol. Res. 2017, 23, 79–89. [Google Scholar] [CrossRef] [Green Version]

- Perestrelo, R.; Barros, A.S.A.S.; Rocha, S.M.; Câmara, J.S. Establishment of the Varietal Profile of Vitis vinifera L. Grape Varieties from Different Geographical Regions Based on HS-SPME/GC-QMS Combined with Chemometric Tools. Microchem. J. 2014, 116, 107–117. [Google Scholar] [CrossRef]

- Koundouras, S. Environmental and Viticultural Effects on Grape Composition and Wine Sensory Properties. Elements 2018, 14, 173–178. [Google Scholar] [CrossRef]

- De Oliveira, J.B.; Egipto, R.; Laureano, O.; de Castro, R.; Pereira, G.E.; Ricardo-Da-Silva, J.M. Climate effects on physicochemical composition of Syrah grapes at low and high altitude sites from tropical grown regions of Brazil. Food Res. Int. 2019, 121, 870–879. [Google Scholar] [CrossRef]

| Harvest | Wine | Enological Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Et. (% v/v) | pH | TA (g/L) | Tar.A (g/L) | MA (g/L) | P (mg/L) | YC | HCAs (CAE, %) | TPC (GAE/L) | ||

| 2019 | TB_C | 13.1 ± 0.05 | 3.13 ± 0.00 | 8.12 ± 0.06 | 4.67 ± 0.07 | 1.89 ± 0.03 | 690 ± 18.9 | 0.09 ± 0.00 | 9.15 ± 0.66 | 10.9 ± 1.31 |

| TB_CPM | 13.0 ± 0.05 | 3.27 ± 0.00 | 6.80 ± 0.27 | 2.94 ± 0.09 | 1.98 ± 0.01 | 604 ± 6.24 | 0.07 ± 0.00 | 12.3 ± 0.38 | 13.9 ± 0.38 | |

| SL | ns | *** | *** | *** | * | ** | ns | ** | * | |

| 2020 | TB_C | 13.4 ± 0.00 | 3.39 ± 0.01 | 6.11 ± 0.04 | 2.16 ± 0.04 | 2.26 ± 0.08 | 674 ± 6.42 | 0.05 ± 0.00 | 6.17 ± 0.05 | 7.15 ± 0.11 |

| TB_CPM | 13.7 ± 0.45 | 3.59 ± 0.00 | 5.62 ± 0.02 | 1.60 ± 0.02 | 2.80 ± 0.04 | 881 ± 13.5 | 0.06 ± 0.00 | 6.77 ± 0.18 | 7.90 ± 0.23 | |

| SL | ns | *** | *** | *** | *** | *** | ** | ** | ** | |

| 2019 | MB_C | 13.1 ± 0.17 | 3.01 ± 0.00 | 7.62 ± 0.07 | 4.91 ± 0.03 | 0.86 ± 0.03 | 569 ± 7.50 | 0.10 ± 0.00 | 3.55 ± 0.18 | 6.16 ± 0.16 |

| MB_CPM | 13.1 ± 0.14 | 3.15 ± 0.00 | 6.74 ± 0.12 | 4.16 ± 0.13 | 0.68 ± 0.01 | 642 ± 10.4 | 0.13 ± 0.00 | 5.44 ± 0.38 | 8.81 ± 0.46 | |

| SL | ns | *** | *** | *** | ** | *** | ** | ** | *** | |

| 2020 | MB_C | 14.4 ± 0.11 | 3.09 ± 0.00 | 6.32 ± 0.04 | 4.21 ±0.06 | 0.88 ± 0.02 | 572 ± 12.7 | 0.08 ± 0.00 | 2.85 ± 0.03 | 5.25 ± 0.02 |

| MB_CPM | 14.1 ± 0.20 | 3.22 ± 0.00 | 5.29 ± 0.02 | 3.14 ± 0.05 | 0.98 ± 0.01 | 591 ± 9.84 | 0.09 ± 0.00 | 3.23 ± 0.16 | 5.74 ± 0.15 | |

| SL | ns | *** | *** | *** | ** | ns | ns | * | ** | |

| 2019 | V_C | 12.5 ± 0.14 | 3.16 ± 0.00 | 6.60 ± 0.05 | 4.02 ± 0.08 | 0.68 ± 0.06 | 616 ± 18.1 | 0.04 ± 0.00 | 3.88 ± 0.55 | 5.85 ± 0.70 |

| V_CPM | 12.1 ± 0.17 | 3.28 ± 0.01 | 6.38 ± 0.14 | 3.25 ± 0.06 | 0.82 ± 0.05 | 685 ± 12.1 | 0.06 ± 0.00 | 5.22 ± 0.45 | 7.38 ± 0.51 | |

| SL1 | * | *** | ns | *** | * | ** | *** | * | * | |

| 2020 | V_C | 12.6 ± 0.41 | 3.21 ± 0.01 | 5.41 ± 0.10 | 3.15 ± 0.06 | 0.72 ± 0.02 | 580 ± 13.6 | 0.04 ± 0.00 | 3.62 ± 0.12 | 5.52 ± 0.16 |

| V_CPM | 12.6 ± 0.20 | 3.33 ± 0.02 | 4.60 ± 0.12 | 2.64 ± 0.09 | 0.70 ± 0.10 | 638 ± 16.0 | 0.06 ± 0.00 | 4.30 ± 0.20 | 6.25 ± 0.20 | |

| SL | ns | ** | *** | ** | ns | ** | * | ** | ** | |

| 2019 | GB_C | 13.0 ± 0.05 | 2.95 ± 0.00 | 8.36 ± 0.14 | 5.14 ± 0.04 | 0.72 ± 0.02 | 534 ± 8.50 | 0.04 ± 0.00 | 6.76 ± 0.83 | 7.24 ± 0.93 |

| GB_CPM | 12.4 ± 0.05 | 3.04 ± 0.00 | 7.62 ± 0.05 | 4.59 ± 0.28 | 0.97 ± 0.03 | 640 ± 2.51 | 0.06 ± 0.00 | 8.57 ± 0.21 | 9.45 ± 0.15 | |

| SL | *** | *** | *** | * | *** | *** | ** | * | * | |

| 2020 | GB_C | 13.0 ± 0.09 | 3.02 ± 0.01 | 7.20 ± 0.19 | 4.05 ± 0.03 | 0.74 ± 0.05 | 531 ± 0.57 | 0.04 ± 0.00 | 5.53 ± 0.10 | 6.05 ± 0.07 |

| GB_CPM | 13.3 ± 0.05 | 3.12 ± 0.00 | 6.50 ± 0.14 | 3.46 ± 0.06 | 0.83 ± 0.05 | 600 ± 6.35 | 0.05 ± 0.00 | 6.24 ± 0.30 | 6.56 ± 0.31 | |

| SL | ** | *** | ** | *** | ns | *** | ** | * | * | |

| Peak n° | RT (min) 1 | RI 2 | LRI 3 | ID 4 | Chemical Families | Odor Sensory Descriptors 5 | OT (µg/L) 5 |

|---|---|---|---|---|---|---|---|

| Alcohols | |||||||

| 5 | 16.86 | 1032 | 1033 | S, MS, RI | 1-Propanol | Alcoholic, fermented, weak fusel, musty | 9000 |

| 7 | 19.78 | 1085 | 1085 | MS, RI | Isobutanol | Ethereal winey cortex | 40,000 |

| 10 | 23.25 | 1151 | 1151 | S, MS, RI | 1-Butanol | Wine-like (vinous) | 150,000 |

| 16 | 26.72 | 1207 | 1207 | S, MS, RI | 3-Methyl-1-butanol | Fusel, alcoholic, pungent, ethereal, cognac, fruity | 30,000 |

| 29 | 35.45 | 1357 | 1357 | S, MS, RI | 1-Hexanol | Pungent, ethereal, fruity, alcoholic | 1100 |

| 30 | 36.22 | 1370 | 1372 | MS, RI | 3-Hexen-1-ol isomer | Fresh, green, grass, leaf | 400 |

| 32 | 37.49 | 1390 | 1373 | MS, RI | 4-Hexen-1-ol isomer | Green herbal, musty tomato, metallic | n.d. |

| 35 | 41.30 | 1458 | 1458 | S, MS, RI | 1-Heptanol | Musty, pungent, leafy green, fruity | 200 |

| 39 | 44.81 | 1556 | 1547 | MS, RI | 2-Nonanol | Waxy, green, creamy, citrus orange | 4800 |

| 42 | 46.67 | 1556 | 1556 | MS, RI | 2,3-Butanediol | Fruit | 668,000 |

| 43 | 46.98 | 1613 | 1605 | S, MS, RI | 1-Octanol | Fresh orange, rose | 900 |

| 44 | 48.31 | 1586 | 1585 | MS, RI | 2-Decanol | Sweet fat, floral, waxy, fruity | 400 |

| 48 | 52.33 | 1634 | 1635 | S, MS, RI | 1-Nonanol | Rose, fruity | 58 |

| 56 | 55.79 | 1732 | 1731 | S, MS, RI | Methionol | Powerful sweet, soup or meat | 500 |

| 61 | 65.24 | 1935 | 1936 | S, MS, RI | Phenylethyl alcohol | Sweet, floral, fresh | 14,000 |

| Esters | |||||||

| 2 | 10.41 | 868 | 870 | S, MS, RI | Ethyl acetate | Caramel, sweet, fruity, buttery, pungent | 7500 |

| 3 | 16.22 | 1019 | 1019 | MS, RI | Isobutyl acetate | Sweet, fruity, ethereal, banana, tropical | 1600 |

| 6 | 17.02 | 1035 | 1035 | S, MS, RI | Ethyl butanoate | Fruity, sweet, bubblegum | 20 |

| 9 | 21.92 | 1128 | 1128 | S, MS, RI | Isoamyl acetate | Fresh, sweet, fruity | 30 |

| 15 | 25.98 | 1193 | 1208 | MS, RI | Pentyl propionate | Apple | n.d. |

| 18 | 28.66 | 1242 | 1242 | S, MS, RI | Ethyl hexanoate | Sweet, fruity, waxy | 5 |

| 21 | 31.01 | 1281 | 1281 | S, MS, RI | Hexyl acetate | Green, fruity, sweet, fatty, fresh | 670 |

| 23 | 31.43 | 1288 | 1272 | MS, RI | Ethyl 5-hexenoate | Fruity | n.d. |

| 25 | 33.14 | 1317 | 1313 | MS, RI | 5-Hexenyl acetate | Mild sweet | n.d. |

| 26 | 33.76 | 1328 | 1328 | MS, RI | 3-Hexen-1-ol acetate | Green fruity | n.d. |

| 28 | 34.66 | 1344 | 1345 | S, MS, RI | Ethyl heptanoate | Fruity, winey, cognac | n.d. |

| 31 | 36.98 | 1382 | 1380 | MS, RI | Heptyl acetate | Green, waxy, fatty, citrus, woody | n.d |

| 34 | 40.51 | 1444 | 1444 | S, MS, RI | Ethyl octanoate | Fruity, floral, green, leafy | 2 |

| 36 | 41.87 | 1467 | 1468 | MS, RI | Isopentyl hexanoate | Citrus, floral, oily, sweet | n.d |

| 37 | 43.52 | 1495 | 1486 | MS, RI | Ethyl 7-octenoate | Must, oil, fruit, pungent | n.d |

| 40 | 46.12 | 1545 | 1542 | S, MS, RI | Ethyl 3-hydroxybutanoate | Citrus, fruit, green, sweet | 20,000 |

| 47 | 51.47 | 1625 | 1625 | S, MS, RI | Ethyl decanoate | Sweet, fatty, nut, winey cognac | 2 |

| 49 | 52.61 | 1637 | 1645 | S, MS, RI | 3-Methylbutyl octanoate | Fruity odor | 125 |

| 52 | 53.52 | 1646 | 1642 | S, MS, RI | Diethyl succinate | Fabric, fruity, flower, sweaty, potato | 200,000 |

| 53 | 54.22 | 1653 | 1664 | MS, RI | Ethyl 9-decenoate | Fruity, fatty | n.d. |

| 59 | 60.84 | 1837 | 1837 | S, MS, RI | 2-Phenylethyl acetate | Rose, floral, fruity, sweet | 250 |

| Acids | |||||||

| 60 | 62.56 | 1875 | 1876 | S, MS, RI | Hexanoic acid | Sweaty, pungent, cheesy, rancid | 420 |

| 62 | 71.33 | 2023 | 2022 | S, MS, RI | Octanoic acid | Fatty, cheesy, fresh, moss | 500 |

| Carbonyl compounds | |||||||

| 1 | 7.37 | 640 | 655 | S, MS, RI | Acetaldehyde | Apple | 80,000 |

| 20 | 30.12 | 1267 | 1266 | S, MS, RI | 3-Octanone | Musty mushroom, green vegetable | n.d. |

| 27 | 33.91 | 1330 | 1329 | S, MS, RI | Octanal | Fatty fruity, sweet, citrus orange | n.d |

| 33 | 38.48 | 1406 | 1406 | S, MS, RI | Nonanal | Fatty floral rose, waxy, citrus | 15 |

| 38 | 44.74 | 1518 | 1518 | S, MS, RI | Benzaldehyde | Burnt sugar, almond, woody | 2000 |

| 51 | 53.21 | 1643 | 1643 | MS, RI | 4-Methyl-benzaldehyde | Fruity cherry, deep, phenolic | n.d. |

| 55 | 55.12 | 1718 | 1718 | S, MS, RI | Dodecanal | Sweet, waxy, fatty citrus, herbaceous | n.d. |

| Terpenoids | |||||||

| 4 | 16.67 | 1028 | 1028 | S, MS, RI | α-Pinene | Woody pine, camphoraceous, fresh herbal | 190 |

| 8 | 21.21 | 1115 | 1115 | MS, RI | β-Pinene | Citrus, floral, fruit, green, pine, sweet, wood | 1500 |

| 11 | 23.66 | 1157 | 1157 | MS, RI | 3-Carene | Citrus fruit, orange peel | n.d. |

| 12 | 24.42 | 1170 | 1170 | S, MS, RI | β-Myrcene | Peppery, spicy, balsamic, plastic | 14 |

| 13 | 24.71 | 1175 | 1175 | MS, RI | α-Phellandrene | Citrus, green, black pepper | n.d. |

| 14 | 25.61 | 1189 | 1189 | MS, RI | α-Terpinene | Refreshing, lemony citrus | n.d. |

| 17 | 27.48 | 1221 | 1220 | MS, RI | β-Phellandrene | Peppery minty and slightly citrusy | n.d |

| 19 | 29.66 | 1259 | 1258 | MS, RI | γ-Terpinene | Sweet, citrus, tropical, lime | 260 |

| 22 | 31.29 | 1286 | 1290 | S, MS, RI | m-Cymene | Solvent, gasoline, citrus | n.d. |

| 24 | 31.99 | 1297 | 1292 | MS, RI | Terpinolene | Sweet-piney, oily, pleasant aroma | 41 |

| 41 | 46.47 | 1552 | 1552 | S, MS, RI | Linalool | Citrus, floral, fruity, green, muscat, sweet | 15 |

| 45 | 48.57 | 1591 | 1606 | MS, RI | Isopulegol | Minty cooling medicinal, woody, green herbal | n.d. |

| 46 | 50.06 | 1610 | 1610 | MS, RI | 4-Terpineol | Warm peppery, mildly earthy, musty woody | 110 |

| 50 | 52.78 | 1638 | 1642 | MS, RI | Dehydro-β-cyclocitral | Saffron | n.d. |

| 54 | 54.77 | 1711 | 1714 | S, MS, RI | Citral | Fresh, juicy, lemon peel | n.d. |

| 57 | 57.15 | 1759 | 1760 | MS, RI | Piperitone | Mint | n.d. |

| 58 | 57.62 | 1768 | 1768 | S, MS, RI | Citronellol | Citrus, clove, floral, fresh, sweet | 100 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alti-Palacios, L.; Martínez, J.; Teixeira, J.A.C.; Câmara, J.S.; Perestrelo, R. Influence of Cold Pre-Fermentation Maceration on the Volatilomic Pattern and Aroma of White Wines. Foods 2023, 12, 1135. https://doi.org/10.3390/foods12061135

Alti-Palacios L, Martínez J, Teixeira JAC, Câmara JS, Perestrelo R. Influence of Cold Pre-Fermentation Maceration on the Volatilomic Pattern and Aroma of White Wines. Foods. 2023; 12(6):1135. https://doi.org/10.3390/foods12061135

Chicago/Turabian StyleAlti-Palacios, Laura, Juana Martínez, José A. C. Teixeira, José S. Câmara, and Rosa Perestrelo. 2023. "Influence of Cold Pre-Fermentation Maceration on the Volatilomic Pattern and Aroma of White Wines" Foods 12, no. 6: 1135. https://doi.org/10.3390/foods12061135