Effects of Variations in the Chemical Composition of Individual Rice Grains on the Eating Quality of Hybrid Indica Rice Based on Near-Infrared Spectroscopy

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Determination of Rice Physicochemical Indicators

2.3. NIR Spectral Acquisition System of Individual Rice Grains

2.4. Spectral Acquisition and Modeling Methods

2.5. Analysis of the Variation in Composition of Individual Rice Grains

2.6. Detection Method of Eating Quality

2.7. Data Analysis

3. Results

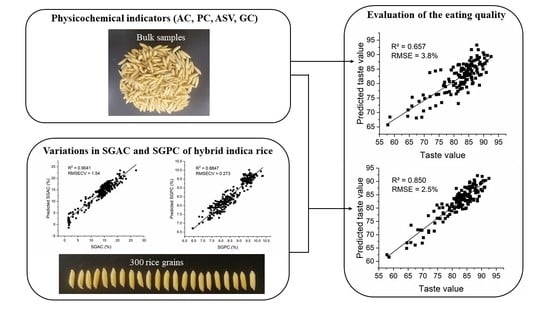

3.1. Chemical Composition Model of Individual Rice Grains

3.2. Correlation Analysis of Single-Grain Chemical Composition Variations and Eating Quality of Hybrid Indica Rice

3.2.1. The Taste Value, Physicochemical Indices, and Variation in the Single-Grain Chemical Composition of Hybrid Indica Rice

3.2.2. Correlations between Taste Value and the Variation in SGAC and SGPC in Hybrid Indica Rice

3.2.3. Effects of Taste Value and the Variation in SGAC and SGPC on Taste Value in Hybrid Indica Rice

3.2.4. The Statistics of Composition-Related Indicators of Indica Hybrid Rice with Different Eating Qualities

4. Discussion

4.1. The Established NIR Models of SGAC and SGPC

4.2. Correlation Analysis of Single-Grain Chemical Composition Variations and Eating Quality of Hybrid Indica Rice

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Custodio, M.C.; Cuevas, R.P.; Ynion, J.; Laborte, A.G.; Velasco, M.L.; Demont, M. Rice quality: How is it defined by consumers, industry, food scientists, and geneticists? Trends Food Sci. Technol. 2019, 92, 122–137. [Google Scholar] [CrossRef] [PubMed]

- Prom-u-thai, C.; Rerkasem, B. Rice quality improvement. A review. Agron. Sustain. Dev. 2020, 40, 28. [Google Scholar] [CrossRef]

- Liao, C.; Yan, W.; Chen, Z.; Xie, G.; Deng, X.W.; Tang, X. Innovation and development of the third-generation hybrid rice technology. Crop J. 2021, 9, 693–701. [Google Scholar] [CrossRef]

- Yang, Y.; Xu, X.; Zhang, M.; Xu, Q.; Feng, Y.; Yuan, X.; Yu, H.; Wang, Y.; Wei, X. Genetic Basis Dissection for Eating and Cooking Qualities of Japonica Rice in Northeast China. Agronomy 2020, 10, 423. [Google Scholar] [CrossRef]

- Zhang, X.C.; Fu, L.B.; Tu, Y.S.; Zhao, H.F.; Kuang, L.H.; Zhang, G.P. The Influence of Nitrogen Application Level on Eating Quality of the Two Indica-Japonica Hybrid Rice Cultivars. Plants 2020, 9, 1663. [Google Scholar] [CrossRef] [PubMed]

- Balindong, J.L.; Ward, R.M.; Liu, L.; Rose, T.J.; Pallas, L.A.; Ovenden, B.W.; Snell, P.J.; Waters, D.L.E. Rice grain protein composition influences instrumental measures of rice cooking and eating quality. J. Cereal Sci. 2018, 79, 35–42. [Google Scholar] [CrossRef]

- Tao, K.Y.; Yu, W.W.; Prakash, S.; Gilbert, R.G. High-amylose rice: Starch molecular structural features controlling cooked rice texture and preference. Carbohydr. Polym. 2019, 219, 251–260. [Google Scholar] [CrossRef]

- Peng, Y.; Mao, B.; Zhang, C.; Shao, Y.; Wu, T.; Hu, L.; Hu, Y.; Tang, L.; Li, Y.; Tang, W.; et al. Influence of physicochemical properties and starch fine structure on the eating quality of hybrid rice with similar apparent amylose content. Food Chem. 2021, 353, 129461. [Google Scholar] [CrossRef]

- Cuevas, R.P.O.; Domingo, C.J.; Sreenivasulu, N. Multivariate-based classification of predicting cooking quality ideotypes in rice (Oryza sativa L.) indica germplasm. Rice 2018, 11, 56. [Google Scholar] [CrossRef]

- Peng, Y.; Mao, B.G.; Zhang, C.Q.; Shao, Y.H.; Wu, T.H.; Hu, L.M.; Hu, Y.Y.; Tang, L.; Li, Y.K.; Zhao, B.R.; et al. Correlations Between Parental Lines and Indica Hybrid Rice in Terms of Eating Quality Traits. Front. Nutr. 2020, 7, 583997. [Google Scholar] [CrossRef]

- Xu, Z.; Fan, S.; Liu, J.; Liu, B.; Tao, L.; Wu, J.; Hu, S.; Zhao, L.; Wang, Q.; Wu, Y. A calibration transfer optimized single kernel near-infrared spectroscopic method. Spectrochim. Acta A Mol. Biomol. Spectrosc. 2019, 220, 117098. [Google Scholar] [CrossRef] [PubMed]

- Xia, Z.; Yang, J.; Wang, J.; Wang, S.; Liu, Y. Optimizing Rice Near-Infrared Models Using Fractional Order Savitzky-Golay Derivation (FOSGD) Combined with Competitive Adaptive Reweighted Sampling (CARS). Appl. Spectrosc. 2020, 74, 417–426. [Google Scholar] [CrossRef]

- Burestan, N.F.; Sayyah, A.H.A.; Taghinezhad, E. Prediction of some quality properties of rice and its flour by near-infrared spectroscopy (NIRS) analysis. Food Sci. Nutr. 2021, 9, 1099–1105. [Google Scholar] [CrossRef] [PubMed]

- Caporaso, N.; Whitworth, M.B.; Fisk, I.D. Protein content prediction in single wheat kernels using hyperspectral imaging. Food Chem. 2018, 240, 32–42. [Google Scholar] [CrossRef] [PubMed]

- Srisawas, W.; Jindal, V.K.; Thanapase, W. Relationship between Sensory Textural Attributes and near Infrared Spectra of Cooked Rice. J. Near Infrared Spectrosc. 2007, 15, 333–340. [Google Scholar] [CrossRef]

- Siriphollakul, P.; Nakano, K.; Kanlayanarat, S.; Ohashi, S.; Sakai, R.; Rittiron, R.; Maniwara, P. Eating quality evaluation of Khao Dawk Mali 105 rice using near-infrared spectroscopy. LWT—Food Sci. Technol. 2017, 79, 70–77. [Google Scholar] [CrossRef]

- Buenafe, R.J.Q.; Kumanduri, V.; Sreenivasulu, N. Deploying viscosity and starch polymer properties to predict cooking and eating quality models: A novel breeding tool to predict texture. Carbohydr. Polym. 2021, 260, 117766. [Google Scholar] [CrossRef]

- Li, X.; Xu, Z.; Cheng, W.; Fan, S.; Wang, H.; Wu, Y.; Zhang, P.; Wang, Q. Research on high-throughput crop authenticity identification method based on near-infrared spectroscopy and InResSpectra model. Infrared Phys. Technol. 2022, 125. [Google Scholar] [CrossRef]

- GB/T 6379.2-2004; Accuracy (Trueness and Precision) of Measurement Methods and Results, Part 2, Basic Method for the Determination of Repeatability and Reproducibility of a Standard Measurement Method. China Standard Press: Beijing, China, 2008.

- Armstrong, P.R.; Tallada, J.G.; Hurburgh, C.; Hildebrand, D.F.; Specht, J.E. Development of single-seed near-infrared spectroscopic. Trans. ASABE 2011, 54, 1529–1535. [Google Scholar]

- Wei, X.; He, J.C.; Zheng, S.H.; Ye, D.P. Modeling for SSC and firmness detection of persimmon based on NIR hyperspectral imaging by sample partitioning and variables selection. Infrared Phys. Technol. 2020, 105, 103099. [Google Scholar] [CrossRef]

- Kim, H.; Kim, O.-W.; Kwak, H.S.; Kim, S.S.; Lee, H.-J. Prediction model of rice eating quality using physicochemical properties and sensory quality evaluation. J. Sens. Stud. 2017, 32, e12273. [Google Scholar] [CrossRef]

- GB/T 15682-2008; Sensory Evaluation Method for Cooking and Eating Quality of Milled Rice. China Standard Press: Beijing, China, 2008.

- McClure, W.F.; Stanfield, D.L. Near-infrared Spectroscopy of Biomaterials. In Handbook of Vibrational Spectroscopy; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2006; pp. 212–227. [Google Scholar] [CrossRef]

- Pasquini, C. Near infrared spectroscopy: A mature analytical technique with new perspectives—A review. Anal. Chim. Acta 2018, 1026, 8–36. [Google Scholar] [CrossRef] [PubMed]

- Workman, J.; Weyer, L. Practical Guide to Interpretive Near-Infrared Spectroscopy; CRC Press: Boca Raton, FL, USA, 2007. [Google Scholar]

- Ma, C.Y.; Ren, Z.H.; Zhang, Z.H.; Du, J.; Jin, C.Q.; Yin, X. Development of simplified models for nondestructive testing of rice (with husk) protein content using hyperspectral imaging technology. Vib. Spectrosc. 2021, 114, 103230. [Google Scholar] [CrossRef]

- Liu, Z.H.; Cheng, F.M.; Cheng, W.D.; Zhang, G.P. Positional variations in phytic acid and protein content within a panicle of japonica rice. J. Cereal Sci. 2005, 41, 297–303. [Google Scholar] [CrossRef]

- Zhou, C.; Huang, Y.; Jia, B.; Wang, Y.; Wang, Y.; Xu, Q.; Li, R.; Wang, S.; Dou, F. Effects of Cultivar, Nitrogen Rate, and Planting Density on Rice-Grain Quality. Agronomy 2018, 8, 246. [Google Scholar] [CrossRef]

- Bryant, R.J.; Anders, M.; McClung, A. Impact of production practices on physicochemical properties of rice grain quality. J. Sci. Food Agric. 2012, 92, 564–569. [Google Scholar] [CrossRef]

- NY/T 593-2021; Cooking Rice Variety Quality. China Standard Press: Beijing, China, 2021.

| n | Mean | Min | Max | Standard Deviation (SD) | Coefficient of Variation (CV, %) | ||

|---|---|---|---|---|---|---|---|

| Calibration Set | Amylose content (%) | 284 | 13.7 | 1.3 | 27.0 | 5.0 | 36.8 |

| Protein content (%) | 269 | 8.6 | 6.4 | 10.3 | 0.8 | 9.3 | |

| Prediction Set | Amylose content (%) | 94 | 14.2 | 1.7 | 23.6 | 4.6 | 32.5 |

| Protein content (%) | 90 | 8.5 | 6.9 | 9.8 | 0.8 | 9.6 | |

| SGAC (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Pretreatment | None | None | COE a | 1 der b | SNV c | MSC d | 1 der + SNV | 1 der + MSC | |

| Factors | 13 | 12 | 12 | 13 | 9 | 10 | 10 | 11 | |

| Calibration set | R2cal | 0.9064 | 0.8528 | 0.8414 | 0.835 | 0.7829 | 0.7915 | 0.7692 | 0.7638 |

| RMSECV | 1.54 | 1.93 | 2 | 2.04 | 2.34 | 2.29 | 2.41 | 2.44 | |

| RPD | 3.27 | 2.61 | 2.51 | 2.46 | 2.15 | 2.19 | 2.08 | 2.06 | |

| bias | −0.00532 | −0.0239 | −0.0209 | −0.0136 | −0.0072 | −0.01 | −0.00853 | 0.00979 | |

| Prediction set | R2p | 0.8628 | 0.8537 | 0.8429 | 0.7762 | 0.8298 | 0.8309 | 0.7549 | 0.7614 |

| RMSEP | 1.7 | 1.75 | 1.82 | 2.17 | 1.89 | 1.88 | 2.27 | 2.24 | |

| RPD | 2.79 | 2.68 | 2.54 | 2.12 | 2.47 | 2.45 | 2.03 | 2.07 | |

| bias | −0.438 | −0.398 | −0.232 | −0.215 | −0.348 | −0.195 | −0.222 | −0.311 | |

| Wavelength ranges (nm) | 2500–1100 | 2452.8–1188 | 2327–2194.8, 2075.3–1188 | 2452.8–1427.1, 1307.6–1175.4 | 2075.3–1685.1, 1559.3–1175.4 | 2327–1188 | 2327–2069, 1949.4–1691.4, 1571.9–1188 | 2327–2194.8, 1949.4–1188 | |

| SGPC (%) | |||||||||

| Pretreatment | None | None | COE a | 1 der b | SNV c | MSC d | 1 der + SNV | 1 der + MSC | |

| Factors | 6 | 12 | 12 | 13 | 8 | 9 | 12 | 10 | |

| Calibration set | R2cal | 0.8321 | 0.8564 | 0.8847 | 0.8409 | 0.8351 | 0.8483 | 0.8308 | 0.8182 |

| RMSECV | 0.329 | 0.304 | 0.273 | 0.32 | 0.326 | 0.313 | 0.33 | 0.342 | |

| RPD | 2.44 | 2.64 | 2.94 | 2.51 | 2.46 | 2.57 | 2.43 | 2.35 | |

| bias | 0.00037 | 0.00196 | 0.00168 | 0.00177 | 0.0021 | 0.00666 | 0.00244 | 0.00227 | |

| Prediction set | R2p | 0.8084 | 0.8496 | 0.8895 | 0.838 | 0.8412 | 0.8383 | 0.8217 | 0.8323 |

| RMSEP | 0.378 | 0.335 | 0.287 | 0.348 | 0.344 | 0.347 | 0.365 | 0.354 | |

| RPD | 2.29 | 2.58 | 3.01 | 2.48 | 2.51 | 2.49 | 2.37 | 2.44 | |

| bias | −0.0146 | 0.0149 | −0.0169 | 0.00433 | 0.00405 | 0.0185 | 0.0125 | −0.00753 | |

| Wavelength ranges (nm) | 2500–1100 | 2201.1–1553, 1301.3–1169.1 | 2327–1936.8, 1559.3–1420.8 | 2201.1–2062.7, 1943.1–1420.8, 1301.3–1169.1 | 2327–2062.7, 1811–1553 | 2452.8–2062.7, 1685.1–1553 | 2452.8–2320.7, 2201.1–2062.7, 1559.3–1420.8 | 2327–2062.7, 1811–1553 | |

| Taste Value | Physicochemical Indicators | SGAC | SGPC | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC | PC | ASV | GC | SD | Variance | Range | QD | CV | SD | Variance | Range | QD | CV | |||

| Taste Value | 1 | −0.670 ** | −0.376 ** | 0.525 ** | 0.562 ** | −0.724 ** | −0.744 ** | −0.658 ** | −0.660 ** | 0.222 ** | −0.050 | −0.045 | 0.034 | −0.205 * | 0.100 | |

| Physicochemical Indicators | AC | 1 | 0.153 | −0.241 ** | −0.448 ** | 0.346 ** | 0.361 ** | 0.303 ** | 0.354 ** | −0.772 ** | −0.022 | −0.030 | −0.026 | −0.004 | −0.082 | |

| PC | 1 | −0.268 ** | −0.283 ** | 0.170 * | 0.188 * | 0.169 * | 0.148 | −0.06 | −0.010 | −0.014 | −0.033 | −0.024 | −0.382 ** | |||

| ASV | 1 | 0.316 ** | −0.335 ** | −0.342 ** | −0.259 ** | −0.385 ** | 0.039 | −0.029 | −0.025 | 0.040 | −0.083 | 0.080 | ||||

| GC | 1 | −0.325 ** | −0.342 ** | −0.255 ** | −0.289 ** | 0.238 ** | −0.069 | −0.068 | −0.003 | −0.172 * | 0.048 | |||||

| SGAC | SD | 1 | 0.998 ** | 0.896 ** | 0.900 ** | 0.273 ** | 0.288 ** | 0.287 ** | 0.147 | 0.372 ** | 0.196 * | |||||

| Variance | 1 | 0.901 ** | 0.898 ** | 0.258 ** | 0.282 ** | 0.281 ** | 0.147 | 0.369 ** | 0.184 * | |||||||

| Range | 1 | 0.760 ** | 0.259 ** | 0.273 ** | 0.273 ** | 0.220 ** | 0.340 ** | 0.185 * | ||||||||

| QD | 1 | 0.204* | 0.261 ** | 0.262 ** | 0.142 | 0.339 ** | 0.181 * | |||||||||

| CV | 1 | 0.182 * | 0.195 * | 0.124 | 0.203 * | 0.191 * | ||||||||||

| SGPC | SD | 1 | 0.997 ** | 0.893 ** | 0.788 ** | 0.926 ** | ||||||||||

| Variance | 1 | 0.893 ** | 0.787 ** | 0.924 ** | ||||||||||||

| Range | 1 | 0.642 ** | 0.833 ** | |||||||||||||

| QD | 1 | 0.737 ** | ||||||||||||||

| CV | 1 | |||||||||||||||

| Physicochemical Indicators | SGAC Dispersion Indicators | SGPC Dispersion Indicators | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| AC | PC | ASV | GC | SD | Variance | Range | QD | CV | SD | Variance | Range | QD | CV | |

| AC of 11–14% (n = 50) | 0.032 | −0.165 | 0.507 ** | 0.136 | −0.646 ** | −0.665 ** | −0.591 ** | −0.585 ** | −0.476 ** | −0.001 | −0.044 | 0.071 | −0.230 | 0.056 |

| AC of 14–17% (n = 67) | −0.059 | −0.465 ** | 0.470 ** | 0.462 ** | −0.490 ** | −0.502 ** | −0.399 ** | −0.335 ** | −0.328 ** | −0.048 | −0.027 | −0.009 | −0.158 | 0.129 |

| PC of 7.6–8.1% (n = 28) | −0.727 ** | 0.292 | 0.608 ** | 0.458 * | −0.282 | −0.283 | −0.198 | −0.262 | 0.439 * | 0.312 | 0.306 | 0.284 | 0.123 | 0.260 |

| PC of 8.1–8.6% (n = 62) | −0.595 ** | −0.045 | 0.366 ** | 0.424 ** | −0.686 ** | −0.706 ** | −0.650 ** | −0.568 ** | 0.142 | 0.024 | −0.006 | 0.093 | −0.078 | 0.024 |

| PC of 8.6–9.1% (n = 35) | −0.777 ** | −0.024 | 0.540 ** | 0.672 ** | −0.821 ** | −0.832 ** | −0.704 ** | −0.793 ** | 0.235 | −0.425 * | −0.436 ** | −0.307 | −0.680 ** | −0.416 * |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, W.; Xu, Z.; Fan, S.; Zhang, P.; Xia, J.; Wang, H.; Ye, Y.; Liu, B.; Wang, Q.; Wu, Y. Effects of Variations in the Chemical Composition of Individual Rice Grains on the Eating Quality of Hybrid Indica Rice Based on Near-Infrared Spectroscopy. Foods 2022, 11, 2634. https://doi.org/10.3390/foods11172634

Cheng W, Xu Z, Fan S, Zhang P, Xia J, Wang H, Ye Y, Liu B, Wang Q, Wu Y. Effects of Variations in the Chemical Composition of Individual Rice Grains on the Eating Quality of Hybrid Indica Rice Based on Near-Infrared Spectroscopy. Foods. 2022; 11(17):2634. https://doi.org/10.3390/foods11172634

Chicago/Turabian StyleCheng, Weimin, Zhuopin Xu, Shuang Fan, Pengfei Zhang, Jiafa Xia, Hui Wang, Yafeng Ye, Binmei Liu, Qi Wang, and Yuejin Wu. 2022. "Effects of Variations in the Chemical Composition of Individual Rice Grains on the Eating Quality of Hybrid Indica Rice Based on Near-Infrared Spectroscopy" Foods 11, no. 17: 2634. https://doi.org/10.3390/foods11172634