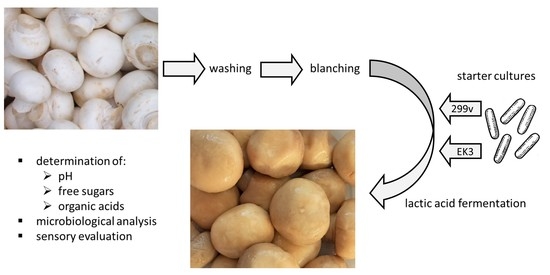

3.3. Changes in the Levels of Free Sugars and Mannitol during Fermentation

The content of carbohydrates used as a carbon source by lactic acid bacteria in raw materials intended for fermentation is an important parameter. Free sugars were represented in the analyzed mushroom fruiting bodies by three monosaccharides (glucose, fructose, and ribose), two disaccharides (sucrose and trehalose), and one polyol (mannitol). Mannitol and ribose are the dominant sugars in fresh mushroom fruiting bodies; their levels were estimated at 738.43 ± 26.58 and 377.08 ± 33.73 mg/100 g of fresh mass, respectively. The content of trehalose, which is a characteristic mushroom disaccharide, was estimated at 116.46 ± 6.85 mg/100 g of fresh mass. The amounts of sucrose, glucose, and fructose were substantially smaller (

Table 3). The available literature data in this field vary. However, studies conducted by other authors have evidenced that mannitol is the main component of the soluble carbohydrate fraction in

Agaricus bisporus [

27,

28]. Together with free 5′-nucleotides and free amino acids, mannitol is the main component responsible for the taste of mushrooms [

29].

The sugar content is influenced by many factors, e.g., the stage of maturity or the morphological part of the mushroom. These values also change during the post-harvest storage of mushrooms [

27,

28,

29,

30]. The mushrooms analyzed in the present study were harvested at an early stage of maturity. Following the five maturity categories proposed by Tsai et al. [

27] (stage 1—pin head stage; 2—veil intact, tight; stage 3—veil intact stretched; stage 4—veil opened; stage 5—gills exposed), the mushrooms used in the present study represented stage 2 and were processed within 4 h after harvesting.

The blanching process reduced the content of the analyzed sugars. No glucose, fructose, or sucrose were detected in the blanched mushroom samples. The content of mannitol and trehalose decreased significantly to the level of 543.4 ± 47.6 and 93.51 ± 5.55 mg/100 g of fresh mass, respectively. The ribose content was reduced as well, but the decline was not statistically significant (

Table 3). Probably, the losses of the analyzed compounds were associated with soluble sugar leaching into water. This was confirmed by Li et al. [

31] in their study on the influence of water blanching and microwave blanching on the soluble sugar and polyol content in

Lentinula edodes. As suggested by the authors, Maillard reactions occurring during high-temperature blanching may be another possible cause of sugar loss. Despite the negative impact of blanching on the sugar content, this procedure cannot be ignored. Its main aim is to remove air from mushroom tissues, which creates anaerobic conditions. This is essential for the proper course of the lactic fermentation process. Moreover, the blanching procedure inactivates enzymes and reduces microflora abundance [

6].

The dynamics of changes in the sugar content induced by the fermentation process was investigated both in the mushroom fruiting bodies and in the brine. Samples for analyses were collected on experimental days 2, 4, 7, 14, and 42. The content of sugars underwent dynamic changes, which were correlated significantly with the starting culture used for the fermentation process.

The content of ribose in the mushrooms on day 2 of the fermentation process significantly decreased in comparison with its level in the blanched mushrooms (

Table 3). It seems that the decline can mainly be explained by the process of leaching, as large amounts of this monosaccharide were present in the brine (

Table 4). Throughout the fermentation period, the content of ribose in the

L. plantarum 299v-fermented samples was similar both in the fruiting bodies and in the brine. The content of this compound in the

L. plantarum EK3-fermented samples exhibited certain fluctuations. The content of ribose both in the fruiting bodies and in the brine increased on day 4 and then decreased again.

As shown by Westby et al. [

32],

L. plantarum strains differ in the utilization of ribose as a carbon source. Some strains do not grow on substrates supplemented with ribose as the only carbon source, whereas others are able to metabolize the compound. Most

L. plantarum strains, however, require the presence of glucose and amino acids to induce the enzyme system for ribose metabolism. Ribose used in fermentation is metabolized into lactic and acetic acids. Our previous investigations have shown that the

L. plantarum EK3 isolate can grow on a substrate with ribose as the only carbon source [

18].

Fructose, glucose, and sucrose, which were not detected in the blanched mushrooms, were present in the fermented mushrooms and the brine (

Table 3 and

Table 4) due to the addition of 1% of sucrose as an ingredient in the recipe. Sugar is used as an easily available source of carbon for lactic bacteria. Most authors of available studies on fermented mushrooms recommend the addition of sucrose, most often in the amount of 1% [

6]. Instead of pure sucrose, table sugar, which may contain some glucose and fructose, was used in the study [

33,

34]. The small amounts of these simple sugars in the fermented mushroom samples and the brine may therefore originate from the added table sugar or from sucrose hydrolysis [

34]. The presence of glucose and fructose in the fruiting bodies and the brine was detected only in the isolate-fermented samples (

Table 3 and

Table 4). The amounts of these sugars declined substantially along the fermentation process. As demonstrated by Yang et al. [

35], LAB prefer reducing sugars, mainly glucose and fructose, as a carbon source. However, due to their low content in mushroom fruiting bodies, these sugars cannot play a key role in the lactic fermentation process, unlike in the fermentation of cabbage. As reported by Xiong et al. [

34], even if glucose is present in the raw material, the addition of sucrose significantly reduces the utilization thereof. The authors revealed an even lower degree of utilization of fructose, whose amount in the finished fermented product (sauerkraut) was significantly higher than the initial content, i.e., greater amounts of this sugar were generated by, e.g., sucrose transformation than the amount consumed by LAB. Milanovic et al. [

36] used an addition of sucrose, glucose, or fructose as a medium for lactic bacteria. The authors observed the fastest decrease in the pH value in samples of fermented fungi supplemented with glucose. Nevertheless, after 10 days of fermentation, the lactic acid content was similar in all samples, regardless of the type of sugar added.

In the initial period of fermentation, sucrose was mainly present in the brine. The concentration of this compound immediately after the start of the fermentation process was over 3.3 g/100 mL in the brine and slightly over 200 mg/100 g in the mushroom fruiting bodies (see

Figure S1 in the Supplementary Materials), as the sugar had not yet saturated the raw material tissues. On day 2 of the experiment, the greatest decrease in the sucrose content in the brine and an increase in the mushroom tissues were observed. Throughout the fermentation period, water-soluble components, such as sugars and acids, migrate between the brine and the raw material, and the sugars are gradually utilized by LAB to produce organic acids (mainly lactic acid). The sucrose concentration in the raw material and the brine on day 14 was identical due to the saturation of mushroom tissue with this sugar on the one hand and the utilization thereof from the brine by LAB on the other hand (

Table 3 and

Table 4). In a study on fermented cabbage conducted by Xiong et al. [

34], equal concentrations of sucrose in brine and shredded cabbage were noted after 72 h of fermentation. However, the cabbage was finely shredded, whereas whole mushrooms were used in the present study. The degree of fragmentation of the raw material had a significant effect on the rate of concentration equalization.

The largest decrease in sugar content in the first fermentation period is closely associated with the intensive growth of LAB in an anaerobic environment (

Table 2) and production of high amounts of lactic acid (

Table 5 and

Table 6), which is discussed in greater detail in

Section 3.4.

It was observed that sucrose was not completely utilized by LAB in the fermentation process. Significantly lower amounts of this sugar were left in the

L. plantarum EK3 isolate fermentation variant (132.42 ± 1.4 mg/100 g of mushrooms and 134.27 ± 1.78 mg/100 mL of brine) than in the probiotic strain variant (271.45 ± 2.25 mg/100 g of mushrooms and 261.05 ± 3.94 mg/100 mL of brine). This may indicate that the isolate exhibited a higher sucrose utilization rate and produced greater amounts of lactic acid. Possibly, the 1% addition of sucrose suggested by most authors to be used in the mushroom fermentation process [

6] is too high. However, even greater amounts of sucrose (2–3%) were used in some studies [

19,

36,

37,

38].

The content of trehalose in the fermented mushrooms was significantly lower than in the blanched material. Very similar trehalose contents were detected in the brine. The mushrooms and the brine exhibited equal levels of this compound (

Table 3 and

Table 4). The content of this sugar in the mushroom fruiting bodies and the brine was significantly lower in the samples fermented with the probiotic strain, which may indicate greater efficiency of

L. plantarum 299v in utilization of trehalose in comparison with

L. plantarum EK3. Our previous research demonstrated the ability of the

L. plantarum EK3 isolate to grow on a trehalose-supplemented substrate [

18]. Trehalose is a disaccharide used as a storage compound by some microbes. It is an important source of carbon for lactic acid bacteria supporting their growth and increasing the production of bacteriocins [

39]. Trehalose also plays an important role in enhancement of the tolerance of lactic acid bacteria to acidic environments, thereby influencing their viability at pH 3 or at even lower values [

40].

There were no significant differences in the mannitol content in the fermented versus blanched mushrooms (

Table 3). A significant decline in the content of this compound in the fruiting bodies and the brine was found only in the probiotic strain-fermentation variant on day 42 (

Table 3 and

Table 4). Interestingly, mannitol leached into the brine relatively quickly, and its concentrations in the mushroom fruiting bodies and in the brine were similar already on day 2. Concurrently, there was no significant decrease in the content of this compound, compared to that in the blanched mushrooms. Mannitol is a polyol that can be used as a carbon source. Both

L. plantarum 299v and

L. plantarum EK3 were able to grow on a mannitol-supplemented medium [

18,

41]. On the other hand, this compound can also be produced by lactic acid bacteria in the heterofermentation process. Mannitol can be converted from glucose, fructose, and sucrose mainly by heterofermentative bacteria. Some homofermentative LAB produce some amounts of this compound as well [

42]. The most probable metabolic pathway for mannitol production is the reversion of mannitol catabolism via mannitol-1-phosphate (mannitol-1P) dehydrogenase, an enzyme whose activity has been detected in

L. plantarum [

43]. In contrast to mannitol production, its utilization is more common among homofermentative lactic acid bacteria [

42].

Unfortunately, the present results cannot be compared with any other findings in this field. To our knowledge, no similar research on mushrooms has been carried out to date. There are only two studies assessing the impact of the fermentation process on the total sugar content in fermented mushrooms. As reported by Ogidi and Agbaje [

20], the carbohydrate content in the lactic fermentation process decreased from 77.4% of dry mass of fresh

Pleurotus ostreatus fruiting bodies to 67.3% of dry mass in fermented samples. In turn, as reported by Choi et al. [

21], the content of total free sugars decreased from 9.68 mg% in aqueous extracts of

Lentinula edodes fruiting bodies to 8.19–9.31 mg% in fermented extracts, depending on the strain used. In both studies, 3% sucrose [

20] or 3% lactose and 2% sucrose [

21] were added to the bacterial growth medium. Also, other fungal carbohydrates, e.g., polysaccharides (glucans), glycogen, and chitin, can be used as an energy source for LAB [

20].

3.4. Changes in the Levels of Organic Acids during Fermentation

Six organic acids were identified in the fresh mushroom fruiting bodies (

Table 5), with the greatest amounts of malic acid and succinic acid (476.18 ± 21.42 and 465.6 ± 84.92 mg/100 g, respectively), followed by lactic acid and citric acid (280.59 ± 19.6 and 273.23 ± 26.52 mg/100 g, respectively), and the lowest contents of fumaric and acetic acids (40.02 ± 0.92 and 67.55 ± 1.62 mg/100 g, respectively). The qualitative and quantitative composition of organic acids in

A. bisporus fruiting bodies may vary largely depending mainly on the strain. Gąsecka et al. [

44] analyzed the organic acid profile in fruiting bodies of various strains of cultivated button mushrooms. Succinic acid (2242.2–11478.4 mg/100 g of dry mass) was the dominant acid in five of the six analyzed strains. Similarly, the button mushrooms analyzed by Pei et al. [

45] exhibited the predominance of succinic acid. In turn, Barros et al. [

46] showed the highest amounts of citric and malic acids, i.e., 43.23 and 29.51 mg/g of dry mass, respectively, in button mushroom fruiting bodies. As demonstrated by Aisal et al. [

47], malic acid clearly dominated among the organic acids present in mushroom fruiting bodies.

Organic acids have an impact on the taste and aroma of mushrooms, especially malic [

46] and succinic [

31] acids. These compounds also play an important biological role. They have antioxidant properties, e.g., malic, citric, and succinic acids [

46] prevent the enzymatic darkening process, which is a considerable problem during harvesting, marketing, storage, and processing of button mushrooms [

22,

48]. Organic acids play a particularly important role in products subjected to lactic acid fermentation, as they largely determine the stability of the finished product [

4,

9,

11]. Their antibacterial and antifungal properties contribute to inhibition of the growth of undesirable microflora in fermented products [

44,

49].

The blanching process applied in the present study resulted in a decrease in the content of organic acids (

Table 5), mostly succinic acid, whose content exhibited an almost 10-fold decrease. In a study conducted by Li et al. [

31], the blanching process resulted in a 100% loss of this compound. As explained by the authors, this was caused by the decarboxylation process accompanying the hot water blanching procedure.

Malic acid, which dominated in the fresh mushrooms, was present in the blanched mushrooms by a four-fold lower amount. With the exception of lactic acid, the levels of all the other acids were statistically significantly reduced, probably due to the process of leaching into the water or the high temperature in the case of volatile acids, e.g., acetic acid.

The changes in the content of the analyzed acids induced by the fermentation process varied (

Table 5 and

Table 6). Lactic acid was the main acid produced by both strains during fermentation.

L. plantarum is a homofermentative LAB metabolizing hexoses via the Embden–Meyerhof pathway, with pyruvate as the central branching point of metabolism. Further changes depend on the availability of oxygen and nutrients. Depending on the fermentation conditions, they may be facultatively heterofermentative; however, lactic acid is the predominant end product [

11].

The content of lactic acid systematically increased during the fermentation process, with the greatest increase recorded in the initial period and it was accompanied by the highest decrease in the sucrose content observed during the experiment (

Figure S1). The coefficient of correlation between the content of these compounds in the brine during the fermentation process and their content during the cold storage period was −0.974 and −0.957 in the

L. plantarum 299v strain and EK3 isolate variants, respectively. Finally, its content was significantly higher in the

L. plantarum EK3-fermented samples, i.e., 1531.28 ± 103.9 mg/100 g and 1520.91 ± 28.06 mg/100 mL in the mushrooms and the brine, respectively. In turn, the content of lactic acid in the probiotic strain-fermented samples was 1266.93 ± 35.37 mg/100 g and 1364.02 ± 10.09 mg/100 mL in the mushrooms and the brine, respectively. These results are consistent with the observations of the changes in the pH value in the fermented mushrooms, where the value of this parameter in the final product was significantly lower in the EK3 starter-fermented samples (

Table 1). Sucrose, which was the main source of carbon in the lactic fermentation process, was utilized at a higher rate and in greater amounts by the

L. plantarum EK3 isolate (

Table 3 and

Table 4). This starter was also characterized by a significantly higher LAB count (

Table 2).

The content of malic acid in the fermented mushrooms was significantly lower than in the blanched samples. This can be partially explained by the leaching of this compound from the mushrooms into the brine. However, a further decline in its content was observed in the brine along the fermentation process (

Table 6). A decrease in the malic acid content during lactic fermentation of Pleurotus spp. fruiting bodies was reported by Liu et al. [

19]. It may have been caused mainly by decarboxylation of malic acid to lactic acid by the malolactic enzyme produced by most LAB species [

50]. This process is characteristic of malolactic fermentation, which is widely used for partial deacidification of wines [

51]. Decarboxylation of malic acid yielding lactic acid and CO

2 was also observed by McDonald et al. [

52] in the process of fermentation of cucumbers by naturally occurring

L. plantarum strains. The authors also report that some LAB strains can degrade 100% of malic acid. In turn, Tkacz et al. [

53] indicate the greatest reduction of malic acid within the first 24–72 h of fermentation by

L. plantarum strains, which is fully consistent with our observations.

The content of succinic acid in the initial fermentation stage was almost three-fold higher than that in the blanched mushrooms (

Table 5). Similar amounts of this compound were also detected in the brine (

Table 6). Similarly, Liu et al. [

19] observed an increase in succinic acid content during lactic fermentation of

Pleurotus spp. Succinic acid is produced via conversion of citric acid in the tricarboxylic acid cycle [

50,

54]. Kaneuchi et al. [

55] reported that a number of

Lactiplantibacillus strains produced various amounts of succinic acid in MRS broth. In the absence of oxaloacetate decarboxylase, the utilization of citrate proceeds through the succinic acid pathway. In such a case, lactate, acetate, and succinate are formed from glucose and citrate [

56]. Succinic and malic acids are responsible for the aroma of fermented products [

35]. The content of both of these acids in the final products was significantly higher in the probiotic strain-fermented samples.

During the fermentation process, the content of citric acid was significantly reduced in both the mushroom fruiting bodies and the brine, regardless of the starter culture used (

Table 5 and

Table 6). The amount of this acid on fermentation day 2 was similar (in the case of the mushroom fruiting bodies) or slightly higher (in the brine) to its amount in the blanched mushrooms. It systematically decreased from fermentation day 4. Similar findings (an initial slight increase followed by a decrease in the content of the acid) were reported by Liu et al. [

19], who carried out fermentation of

Pleurotus spp. This can be explained by the gradual degradation of citric acid by lactic acid bacteria. As shown by Mirmohammadi et al. [

57],

L. plantarum are able to metabolize citric acid as a carbon source during fermentation. C4 aromatic compounds may be the end product of these transformations. Tkacz et al. [

53] reported that, probably due to the low pH value,

L. plantarum revealed a higher preference for acids than sugars as a carbon source. On the other hand, as indicated before, citric acid can be converted to succinic [

50] and acetic acids [

54].

The amount of acetic acid systematically increased during the fermentation process. On day 42 of the experiment, its content in the probiotic strain-fermented samples was 90.72 ± 1.5 mg/100 g and 86.86 ± 5.31 mg/100 mL in the fruiting bodies and the brine, respectively. In the EK3 isolate fermentation variant, the fruiting bodies and the brine contained 76.35 ± 6.73 mg/100 g and 109.48 ± 4.49 mg/100 mL of acetic acid, respectively. Similar results were reported by Liu et al. [

19]. As shown by Tkacz et al. [

53],

L. plantarum is one of the facultatively heterofermentative bacteria (heterolactic metabolism), which means that they are capable of producing lactic acid and other compounds, e.g., acetic acid, depending on the fermentation conditions. Acetic acid can also be formed from citric acid [

53,

54,

58]. The presence of acetic acid in products fermented by

Lactiplantibacillus strains may result from lactic acid degradation [

56]. Acetic acid in combination with ethanol (heterofermentative metabolites) forms ethyl acetate, which improves the organoleptic properties of fermented products [

35].

The content of fumaric acid in the initial fermentation period decreased significantly in relation to the amount detected in the blanched mushrooms. From day 4, the level of this acid was very low and remained practically unchanged (

Table 5 and

Table 6). Its content in the final product slightly exceeded 3 mg/100 g of the mushroom fruiting bodies or in 100 mL of the brine, regardless of the starting culture used. The low content of this acid is a positive phenomenon, as its higher concentrations may inhibit the growth of LAB [

59,

60].