1. Introduction

Synthetic dyes are widely used in various industries, including the production of textiles, food, plastic, cosmetics and paper. According to current data, more than 100,000 dyes are known, and their annual production has reached 700,000 tons [

1]. The consumption of dyes in the textile industry around the world exceeds 10,000 tons per year, of which about 1% is discharged into the aquatic environment [

2].

Dyes are characterized by intense color, even when their concentrations are small [

3,

4,

5]. They can affect the photosynthetic activity of aquatic plants due to the reduced penetration of light. Dyes also show toxicity for some aquatic organisms, and their carcinogenic, mutagenic or teratogenic effects have been proved in relation to some microorganisms and fish species [

6,

7]. It was estimated that LD50 (lethal dose, 50%) values greater than 2 × 10

3 mg/kg were exhibited by 90% of the 4000 dyes tested. The highest toxicity was found for basic and diazo direct dyes [

8]. Dyes may adversely affect human health, causing dysfunction of the kidneys, reproductive system, liver, brain and central nervous system [

9]. Particularly dangerous is the introduction of azo dyes into the environment, which are broken down to toxic amines [

8]. A number of chemical (including photochemical and electrochemical), biological and physical methods are used to remove dyes from polluted waters [

10,

11,

12,

13,

14,

15,

16,

17,

18].

The biological methods used to remove dyes include bioremediation using bacteria, algae, fungi and systems of cooperating plants and microbes, phytoremediation and the use of plant parts and enzymes. Biological methods are cheap and environmentally friendly, while their main limitation is the insufficient efficiency of removal in relation to many dyes.

Physical treatment includes membrane filtration, electrokinetic coagulation and sorption methods. The main advantage of the first two methods is the high efficiency of decolorization, while the disadvantage is the formation of large amounts of concentrated sludge production [

16].

Adsorption is one of the most effective wastewater treatment processes [

17]. Many textile companies use commercial activated carbon to remove dyes from wastewater. Currently, research is focused on the use of alternative materials for commercial activated carbon, which is a very effective sorbent, but its use is associated with high costs [

10,

18].

One of the directions of research is the search for low-cost adsorbents of natural origin or obtained from industrial or agricultural solid waste [

19,

20,

21]. Various unconventional adsorbents, including clay, wheat bran fly ash, walnut husk, microalga

Spirulina platensis,

Cucumis sativus, rice straw, crop residues, maize cob, barley hull, nanomaterials and

Salxi babylonic leaf powder, have been used to remove dyes from aqueous solutions [

19,

20,

21]. The disadvantages of this type of adsorption material are its very low capacity for dyes and low mechanical and chemical strength, as well as physicochemical properties that depend, e.g., on the region of occurrence of a given material, which make it difficult to compare their effectiveness.

An alternative to this type of material may be ion exchange resins. They are characterized primarily by a very high sorption capacity towards dyes and excellent chemical stability and mechanical strength. The wide range of materials of this type available on the market allows them to be used to remove dyes of anionic and cationic nature. In addition, high resistance to pressure changes enables their use in the column system. The disadvantage of their use is the cost of building an industrial-scale plant. Not only cation exchangers but also anion exchangers with polystyrene, polyacrylic and phenol-formaldehyde matrices as well as different basicities of functional groups (i.e., weakly, intermediate and strongly basic) such as Lewatit MonoPlus MP62, Lewatit MonoPlus MP64, Purolite A847, Amberlite IRA67, Amberlite IRA 478, Amberlite IRA 458, Amberlite IRA958, Amberlyst A21, Amberlyst A23 or Amberlyst A24 have been used to remove acid (e.g., C.I. Acid Orange 7, C.I. Acid Red 18, C.I. Acid Blue 249, C.I. Acid Green 16, C.I. Acid Violet 1), direct (e.g., C.I. Direct Blue 71, C.I. Direct Red 75, C.I. Direct Yellow 50) and reactive (e.g., C.I. Reactive Black 5, C.I. Reactive Blue 21) dyes from model solutions and wastewater [

22,

23,

24,

25,

26,

27,

28,

29,

30,

31].

Chemical methods used for dyes in wastewater treatment mainly include advanced oxidation processes, most often using ozone, hydrogen peroxide and hydrogen peroxide in combination with Fe

2+ salts (Fenton’s reagent) [

32,

33,

34]. Oxidation processes are usually highly effective in decolorizing solutions containing both azo dyes and dyes with different structures, also in the form of mixtures [

35,

36,

37,

38]. The main characteristics of AOPs are the in-situ production of highly reactive radicals capable of the degradation of organic chemicals. The most frequently produced radical is

˙OH, which has a high standard oxidizing potential and reacts non-selectively with compounds present in its environment. Oxidation can take place in a homogeneous or heterogeneous system. In the latter, the oxidation activator is a solid substance—most often TiO

2 and other transition metal oxides. In photochemical methods, ultraviolet or visible light is used as an oxidation-promoting agent. Light activation is combined with oxidation with ozone, H

2O

2 and the Fenton reaction and used in photocatalysis processes [

39]. To increase the efficiency of oxidation processes, other physical factors such as electric current (electro-Fenton reaction), ultrasounds, microwaves, heat and ionizing radiation are also used [

40].

Relatively recently, inorganic peracids in the form of salts—i.e., peroxymonosulfates (PMS) and persulfates (PS)—as well as organic peracids, mainly peracetic acid (PAA), have been used as oxidants in AOPs processes [

41,

42,

43]. Oxidation in these processes takes place through the action of radicals formed in the solution, which besides

˙OH are SO

4˙− or CH

3COO

˙ [

41]. Oxidation processes under the influence of PAA, which, as a non-toxic and environmentally friendly compound, is widely used in practice to disinfect surfaces intended for contact with food, are particularly little studied [

42]. Similar factors are used to activate PAA as in the case of H

2O

2. The most commonly used are Fe

2+ ions (pseudo-Fenton system) and UV light [

41]. Due to the method of synthesis, commercial preparations of this compound exist in the form of an equilibrium mixture of PAA and H

2O

2.

The main advantage of AOPs is that the removed contaminants are degraded into simpler compounds. In most cases, organic compounds are completely mineralized and converted to carbon dioxide, water and inorganic salts [

44].

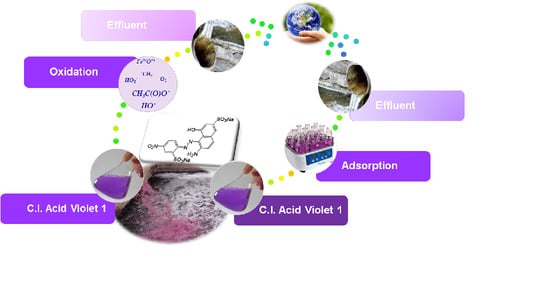

The aim of this study was to compare the efficiency of AV1 (C.I. Acid Violet 1) dye removal by the adsorption technique using anion exchange resins and by an advanced oxidation process using hydrogen peroxide and peracetic acid. Parameters influencing the adsorption of AV1 on the anion exchangers such as initial dye concentration, phase contact time and presence of additives (Na2SO4, CH3COOH, anionic and non-ionic surfactants) were investigated by determining kinetic and equilibrium parameters. Regeneration efficiency was also evaluated. The course of AV1 oxidation in seven different oxidation systems based on the use of hydrogen peroxide (H2O2 alone, H2O2/solar light, H2O2/Fe2+) and peracetic acid (PAA alone, PAA/solar light, PAA/Fe2+, PAA/Fe2+/solar light) was determined. The influence of the oxidant concentration on the course of the processes was investigated and kinetic studies were performed. The efficiency of the oxidation processes was determined both on the basis of changes in absorbance in the maximum of absorption (decolorization), as well as on the basis of changes in chemical oxygen demand (COD), which allowed for the evaluation of mineralization.

4. Conclusions

This paper describes the results of C.I. Acid Violet 1 (azo class dye) removal from aqueous solutions and dyeing baths using two techniques—adsorption and advanced oxidation—taking into consideration different experimental conditions. In adsorption tests, the selectivity of the macroporous strongly basic anion exchangers (Purolite A520E and Lewatit S5428) with quaternary ammonium functional groups differing in the chemical composition of the matrix was evaluated. Large values of the sorption capacities of both resins described by the Langmuire and Freundlich isotherm model allowed their use in the removal of AV1 dye, also in the presence of salts and surfactants. The dye removal efficiency reached more than 99% after 240 min in 100–500 mg/L solutions using A520E and S5428. The effective regeneration of the adsorbents has also been proposed, which enables their practical application.

The results of oxidation experiments indicate that AOPs based on H2O2 and PAA can effectively remove AV1 from its water solutions. Both sunlight and iron ions used as oxidation activators accelerate the degradation of the tested dye. The Fenton reaction, PAA/Fe2+ and PAA/Fe2+/sunlight systems are most effective in both the decolorization and mineralization of AV1 solutions. It was found that PAA, which is an oxidant that is rarely used and relatively little studied, works more efficiently and faster than H2O2. In addition, oxidation with PAA requires lower concentrations of the oxidant than in the case of H2O2, which reduces the cost of the process and the impact on the environment.

In conclusion, the proposed techniques can be considered as highly effective for the removal of AV1, and the performed studies are of significant importance not only from a scientific but also from a practical point of view, especially in the treatment of wastewaters containing acid-type dyes.